Self-check zero returning method for stepping motor motion system

A stepper motor and motion system technology, applied in control systems, motor generator control, electrical components, etc., can solve the problems affecting the speed and efficiency of zero return, poor zero return accuracy, and poor versatility, and achieve fast and reliable performance. Self-check back to zero, simplify the debugging process and debugging program, reduce the effect of idle travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

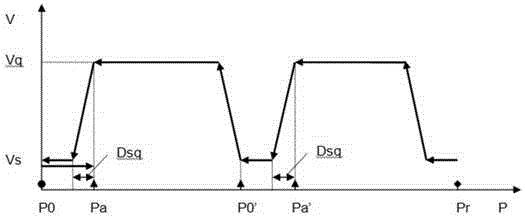

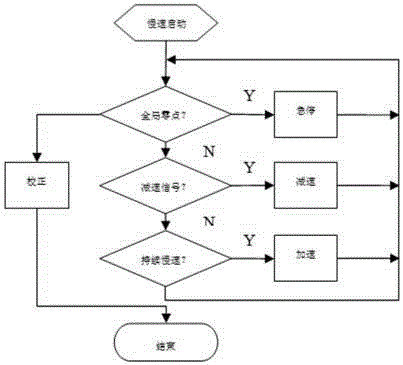

[0055] like Figure 1-2 As shown, this embodiment provides a method for self-checking and returning to zero of the stepping motor motion system, which means that the stepping motor starts from any zero-returning starting position Pr, combines and switches between slow speed and fast speed, and only moves toward one Direction movement finds the global zero point P0, and corrects it to the true zero point Pa, and completes the method of self-checking and returning to zero; the specific steps are as follows:

[0056] (1) The stepper motor moves towards the global zero point P0 starting from any zero-return starting position Pr;

[0057] (2) During the motion process, when moving towards the global zero point P0 at a constant speed at a slower speed Vs, the slow motion distance exceeds the distance from the true zero point Pa to the global zero point P0, and then accelerates;

[0058] During the movement, when moving towards the global zero point P0 at a faster speed Vq at a unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com