Novel steel bar rib stripping and rolling thread machine tool and machining method thereof

A technology for stripping ribs and steel bars, which is applied to threaded products, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems that the whole machine structure occupies a large area, is difficult to realize, and is inconvenient to operate, so as to improve processing speed and reduce Effect of additional cost and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

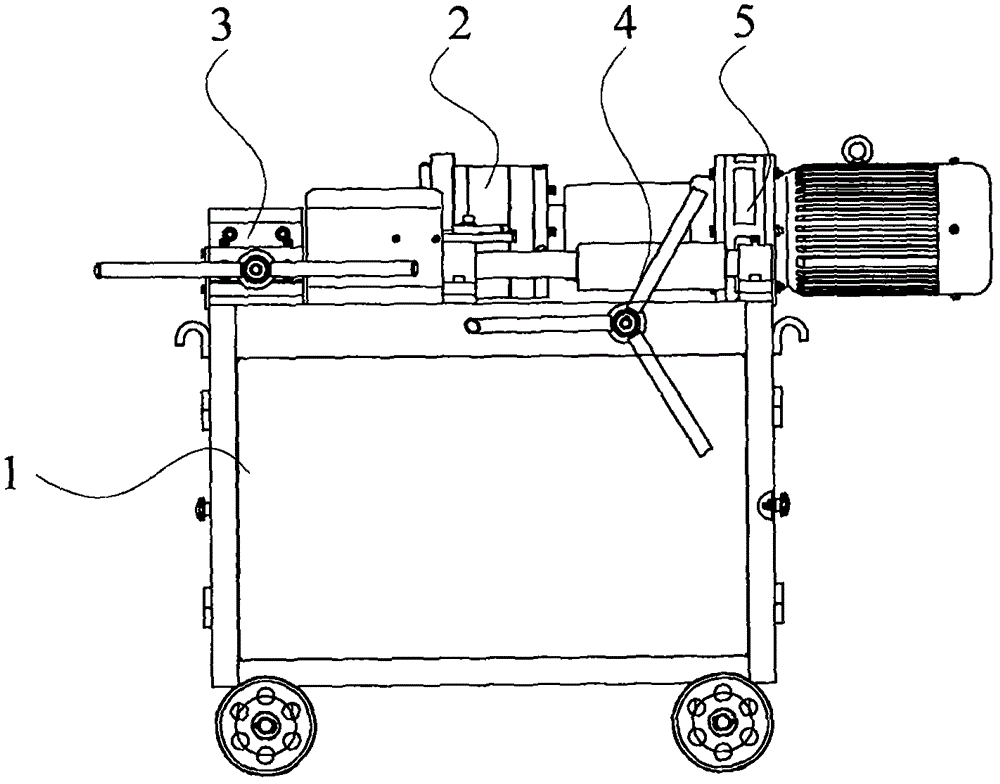

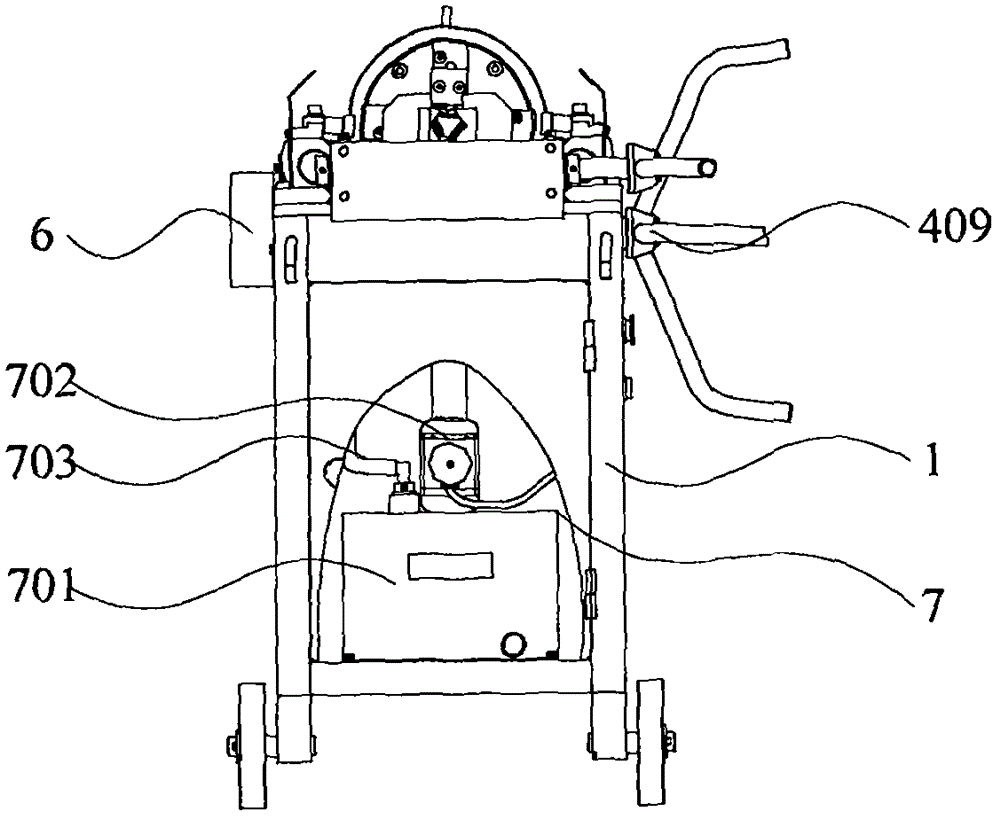

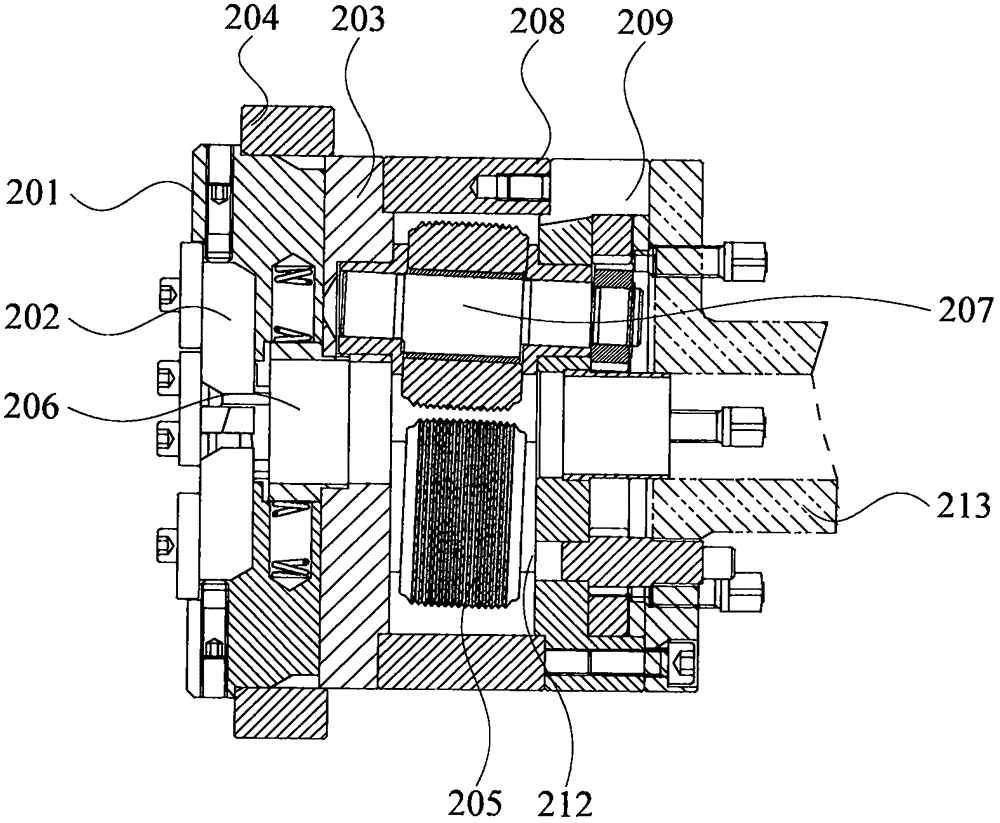

[0034] The present invention provides a novel steel rib stripping and thread rolling machine tool, which includes a frame 1, a rib stripping and thread rolling mechanism 2, a clamp mechanism 3, a feed mechanism 4, a reducer 5, an electrical control system 6 and a cooling system 7, Clamp mechanism 3, rib stripping thread rolling mechanism 2, feed mechanism 4, reducer 5 and electrical control system 6 are sequentially fixed on frame 1, and cooling system 7 is arranged inside frame 1; rib stripping thread rolling mechanism 2 Including a rib stripping assembly and a thread rolling assembly, the rib stripping assembly includes a cutter body 201, a turning tool 202 and a cutting head body 203, the turning tool 202 is equidistantly fixed on the cutter body 201 by an external fixing method, and the cutter body 201 and the cutting head The body 203 is connected, the cutting head body 203 is connected with the thread rolling assembly, and the outside of the cutter body 201 is provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com