Seeking route plan optimizing method of laser cutting machine

A laser cutting machine and path planning technology, applied in laser welding equipment, digital control, manufacturing tools, etc., to achieve the effect of shortening cutting time, improving automation, and shortening idle travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

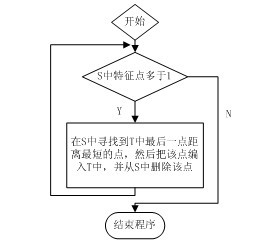

[0029] Such as figure 2 As shown, the greedy program module GREEDY () programming method is as follows:

[0030] The first step is to judge whether the feature points in the array S containing punching point information are more than 1, if not more than 1, the program ends, and if more than 1, the program continues;

[0031] The second step is to find in S the point with the shortest distance to the last point in array T, then program this point into T, and delete this point from S;

[0032] The third step is to return to the first step to judge;

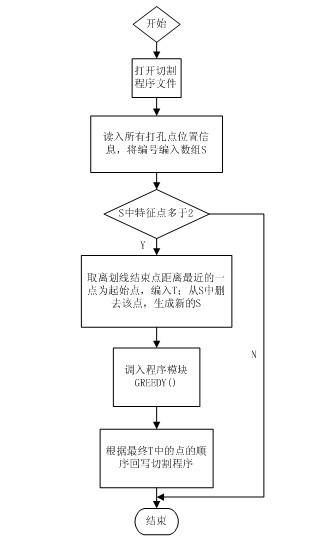

[0033] Such as figure 1 As shown, the steps of using the greedy algorithm to write the tracking path planning optimization method program are as follows:

[0034] The first step is to write a program to compile the information of all "punching points" into the array S in order, and pay attent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com