Mixed fill path generation method in arc fuse additive manufacturing technology

A technology of additive manufacturing and mixed filling, which is applied in the field of additive manufacturing, can solve the problems of poor outer surface quality and low efficiency, and achieve the effects of improving algorithm execution efficiency, increasing strength, reducing times and empty strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] A method for generating a hybrid filling path in an arc fuse additive manufacturing technology, comprising the steps of:

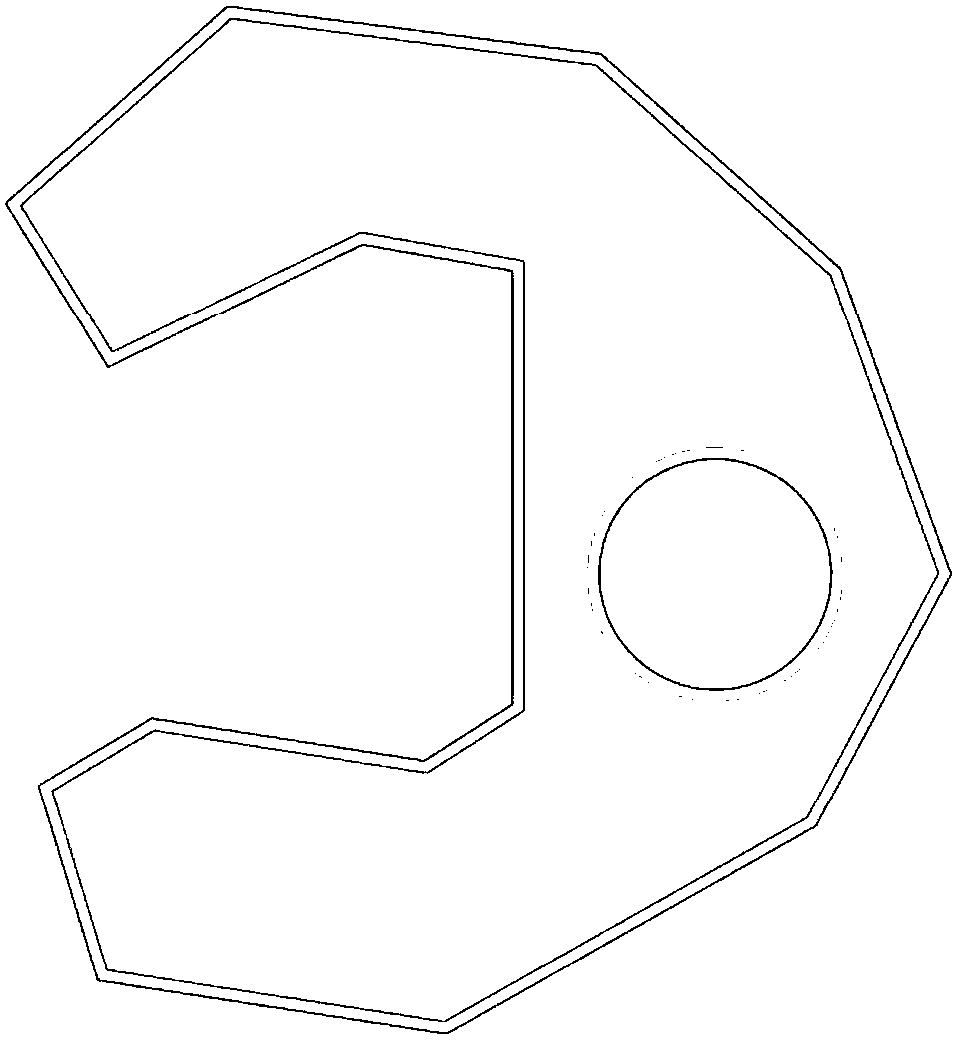

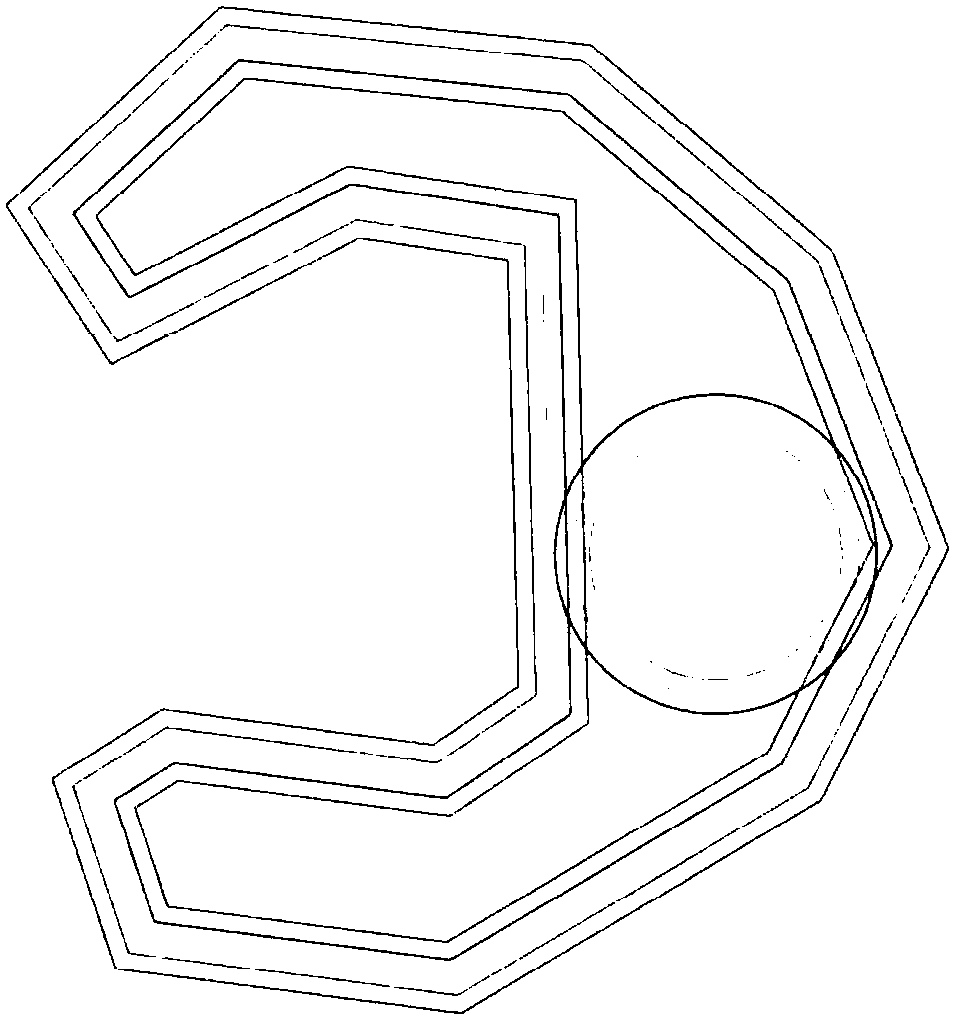

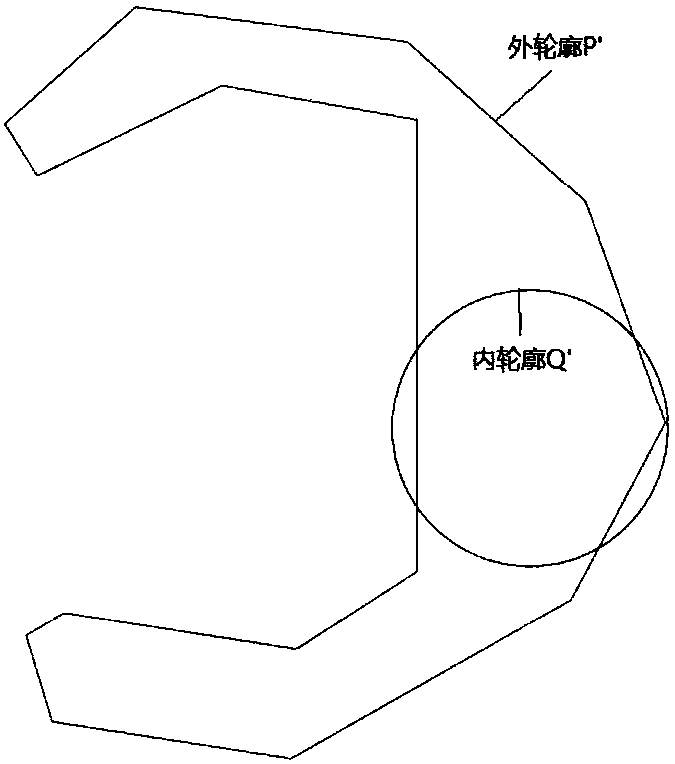

[0036] S1. Traverse the data points of the contour of the section edge and the edge of the hollow area and delete the collinear points on the contour. Specifically, set a vertex in the contour line as P i , looking clockwise along the contour line, the previous point is P i-1 , the latter point is P i+1 , the vector and The included angle is θ, we know If cosθ=0, then P i-1 , P i , P i+1 Three points are collinear, delete P from the contour line i points, and so on, traverse the data points of the contour, delete all collinear points, and only keep the vertices of the contour.

[0037] S2. Sort the data points on the contour clockwise or counterclockwise.

[0038] S3. According to the welding wire material used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com