A kind of rfi molding resin film encapsulation and air path setting method

A technology of resin film and gas path, which is applied in the field of liquid molding of resin-based composite materials, can solve problems affecting the quality of the outer surface of the wallboard, and achieve the effect of avoiding the accumulation of resin residues, avoiding dry spots, and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

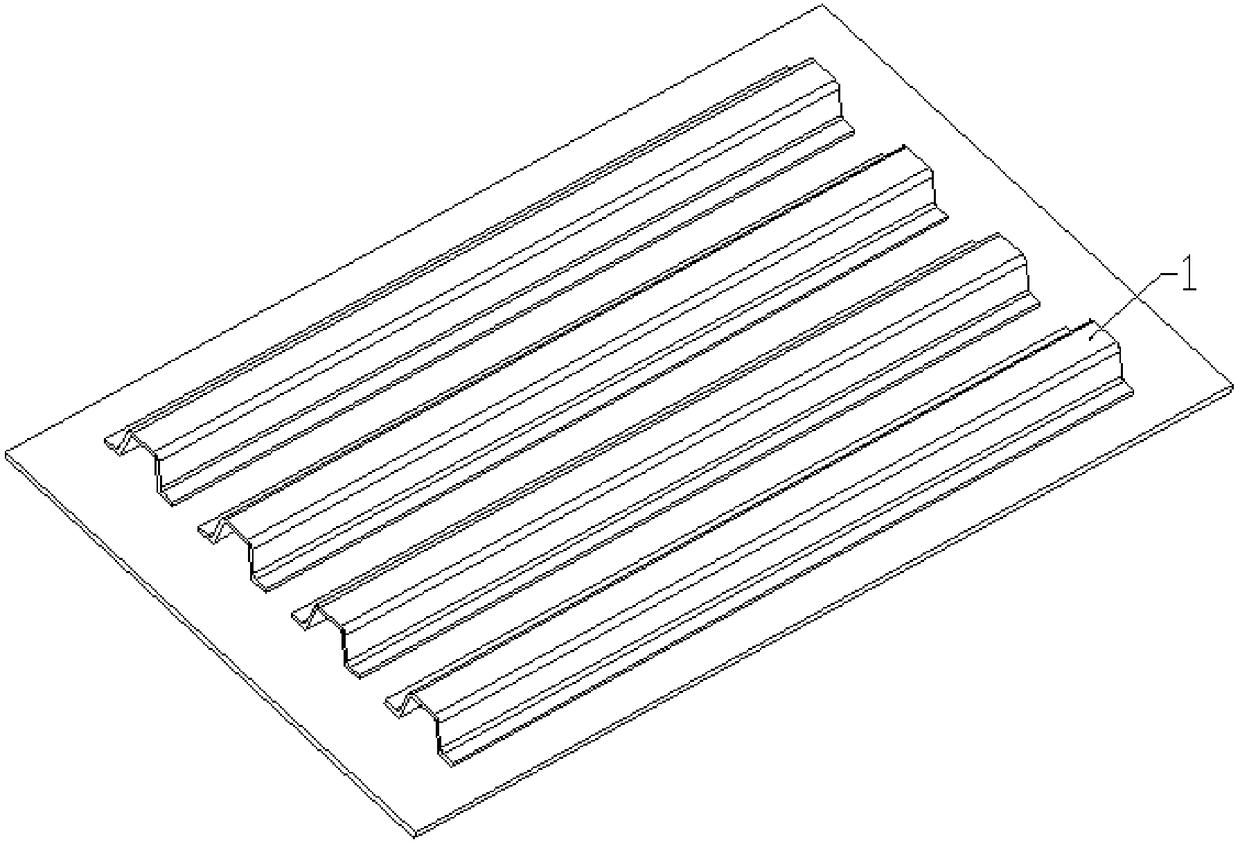

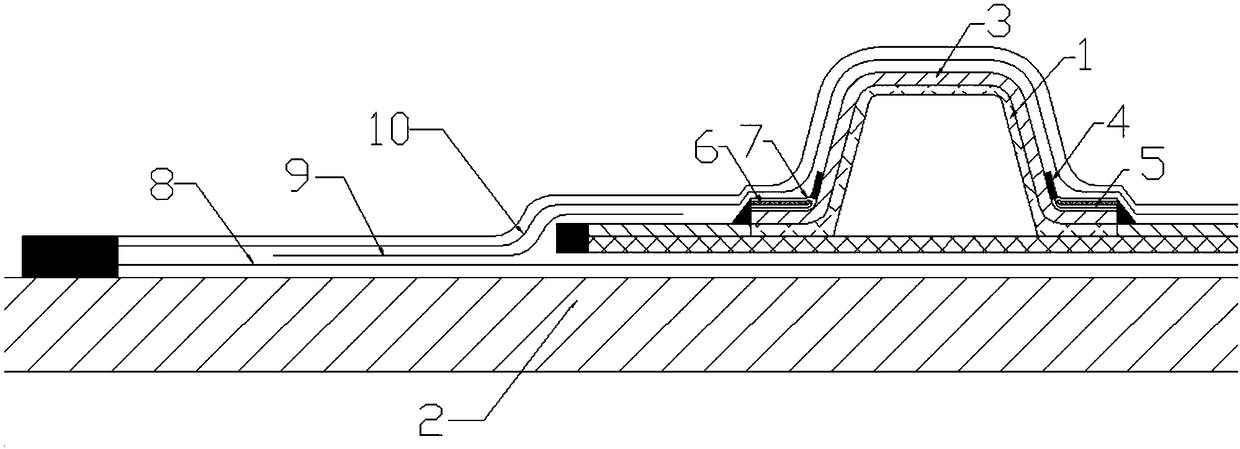

[0047] Example 1: figure 2 Shown is a panel structure with hat ribs, where the hat ribs and skin are integrally formed by the RFI process. For the molding of this structure, resin penetration is required in the flange area of the hat rib. In order to achieve resin penetration and ensure the quality of the outer surface of the wall panel, the resin film packaging method and air path setting method proposed in this plan are adopted, as follows:

[0048] (a) The dry fiber area of the preform 1 that needs to be permeated with resin is the hat rib flange area and the R angle area at the root. The resin film laying area is selected according to the contour edge line of the hat rib flange area, and the distance from the contour edge line The outward offset is 0-30mm, and the inner R-angle area is offset outward by 0-5mm according to the upper tangent of the R-angle.

[0049](b) Punch holes in the hat rib mold corresponding to the resin film laying area of the inner mold 3 of ...

Embodiment 2

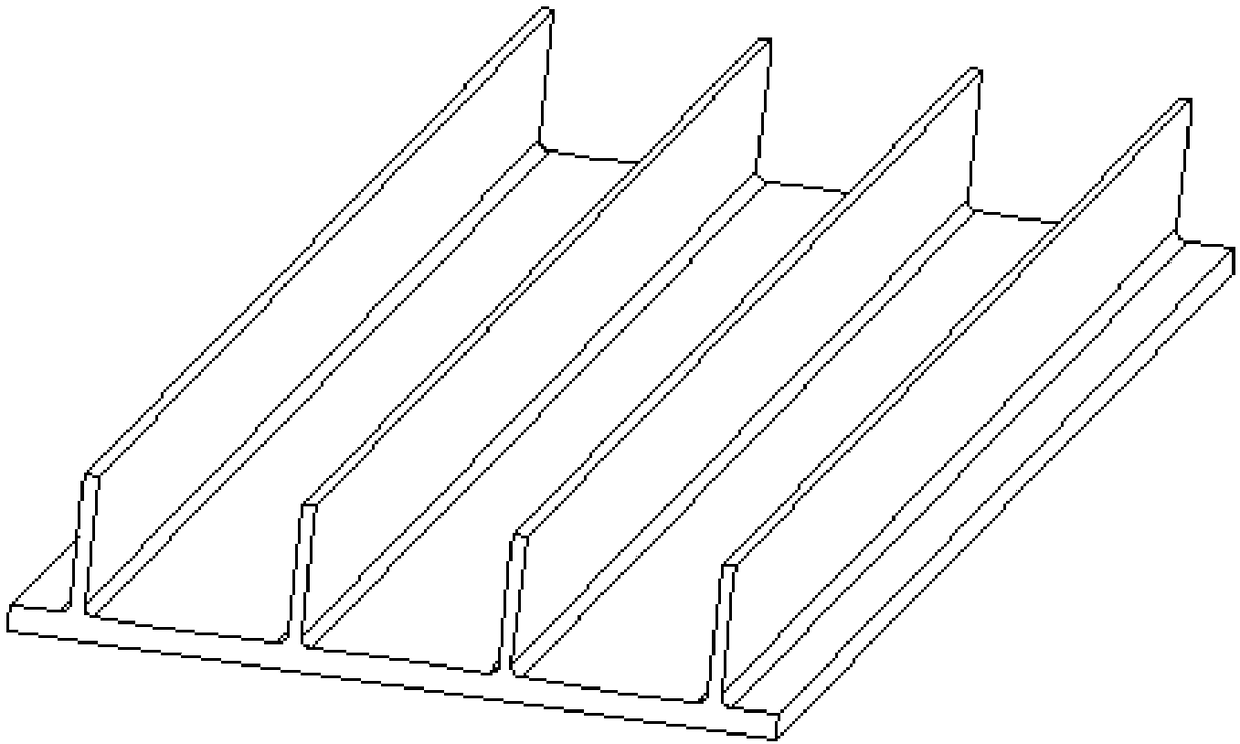

[0059] Example 2: Figure 4 The stiffened siding structure shown, with stiffening and skin integrally formed by the RFI process. For the molding of this structure, resin infiltration is required in the skin area. In order to ensure the quality of the exterior surface of the wall panel, the resin film packaging method and air path setting method of this scheme are adopted, as follows:

[0060] (a) The resin film laying area of the preform 1 is the skin area. In order to avoid package bridging, the edge of the package in the R corner area is selected to be offset inward by 0-5mm from the tangent line on the R corner.

[0061] (b) Drill holes in the skin areas of the molds 3-1 and 3-2 inside the wall panels. The edge of the punched area is offset inwardly from the edge of the resin film laying area by 5 mm to 10 mm, the hole diameter does not exceed φ2 mm, and the hole spacing is 15 mm. After the mold preparation is completed, it is assembled with the preform.

[0062] (c) Ai...

Embodiment 3

[0071] Embodiment 3: The skin of the wall panel with a sunken area on the outer surface is formed by the RFI process. The skin area needs to be permeated with resin. In order to ensure the quality of the external surface of the wall panel, the resin film is laid on the inner side of the wall panel. The resin film packaging method and air path setting method of this plan are adopted, as follows:

[0072] (a) The dry fiber area of the preform that needs to be resin-infiltrated is the wall panel skin area, and the resin film laying area is according to the edge line of the skin contour.

[0073] (b) Holes are drilled on the mold 3 inside the wall panel, and the edge of the punched area is offset inwardly from the edge of the resin film laying area by 5 mm to 10 mm, the hole diameter does not exceed φ2 mm, and the hole spacing is 15 mm. After the mold preparation is completed, it is assembled with the preform.

[0074] (c) Air path is designed between the external surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com