Patents

Literature

46 results about "Dry spot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of treating sandy soils to reduce water repellency therein

Certain novel formulations of turf additives that act in such a manner as to permit proper amounts of moisture to contact root systems in order to reduce dry spots within highly managed turf areas and / or lawns. It is theorized that the accumulation of humic acid (and other natural byproduct deleterious compounds) at the topsoil surface in most cultivated grassy areas including sandy soils (such as, in particular, golf greens), results in the production of an effective organic waxy coating on the soil components. Such a coating is hydrophobic in nature and thus dries out the soil itself. The inventive formulation thus permits removal of such accumulated humic acid (and other compounds) from the topsoil to the level necessary to provide effective moisture penetration for sustained grass growth therein (hereinafter referred to as "redistributes"). Methods of providing such beneficial removal of humic substances from target sandy soils are also contemplated within this invention, as well as specific test hydrophobic sand formulations.

Owner:MILLIKEN & CO

Method of treating sandy soils with multi-branched regenerating wetting agents

Certain novel formulations of turf additives that act in such a manner as to permit proper amounts of moisture to contact root systems in order to reduce dry spots within highly managed turf areas and / or lawns. The inventive formulation comprising multi-branched surfactant compounds with both hydrophobic and hydrophilic constituents within each branch attached to an oxygen-containing polyfunctional base compound permits effective moisture penetration through such localized dry spots for sustained grass growth therein. Importantly, such multi-branched wetting agents provide sustained moisture penetration over a sustained period of time since the individual branches of such compounds may become dissociated from its base polyfunctional compound. Since such branches include both hydrophobic and hydrophilic constituents themselves, and thus act as wetting agents, even after degradation of the initial surfactant compound, long-term wetting and moisture penetration, at least, are permitted. Methods of treating sandy soils with such compounds and formulations thereof are also contemplated within this invention.

Owner:MILLIKEN & CO

Turf additive formulation for reduction of localized dry spots due to water repellency

Certain novel formulations of turf additives that act in such a manner as to permit proper amounts of moisture to contact root systems in order to reduce dry spots within highly managed turf areas and / or lawns. It is theorized that the accumulation of humic acid (and other natural byproduct deleterious compounds) at the topsoil surface in most cultivated grassy areas including sandy soils (such as, in particular, golf greens, pastures, lawns, and the like), as well as other non-grassy sandy areas in which such humic acid accumulation poses water repellency problems (such as beaches), results in the production of an effective organic waxy coating on the soil and / or sand components. Such a coating is hydrophobic in nature and thus dries out the soil itself. The inventive formulation thus permits removal of such accumulated humic acid (and other compounds) from the topsoil to the level necessary to provide effective moisture penetration for sustained grass growth therein (hereinafter referred to as "redistributes"). Methods of providing such beneficial removal of humic substances from target sandy soils are also contemplated within this invention, as well as specific test hydrophobic sand formulations.

Owner:MILLIKEN & CO

Multi-branched regenerating wetting agents for treating sandy soils for long-term reduction of water repellency

InactiveUS20050028442A1Reduce surface tensionImprove abilitiesHops/wine cultivationSolid waste disposalMoisture penetrationOxygen

Owner:MILLIKEN & CO

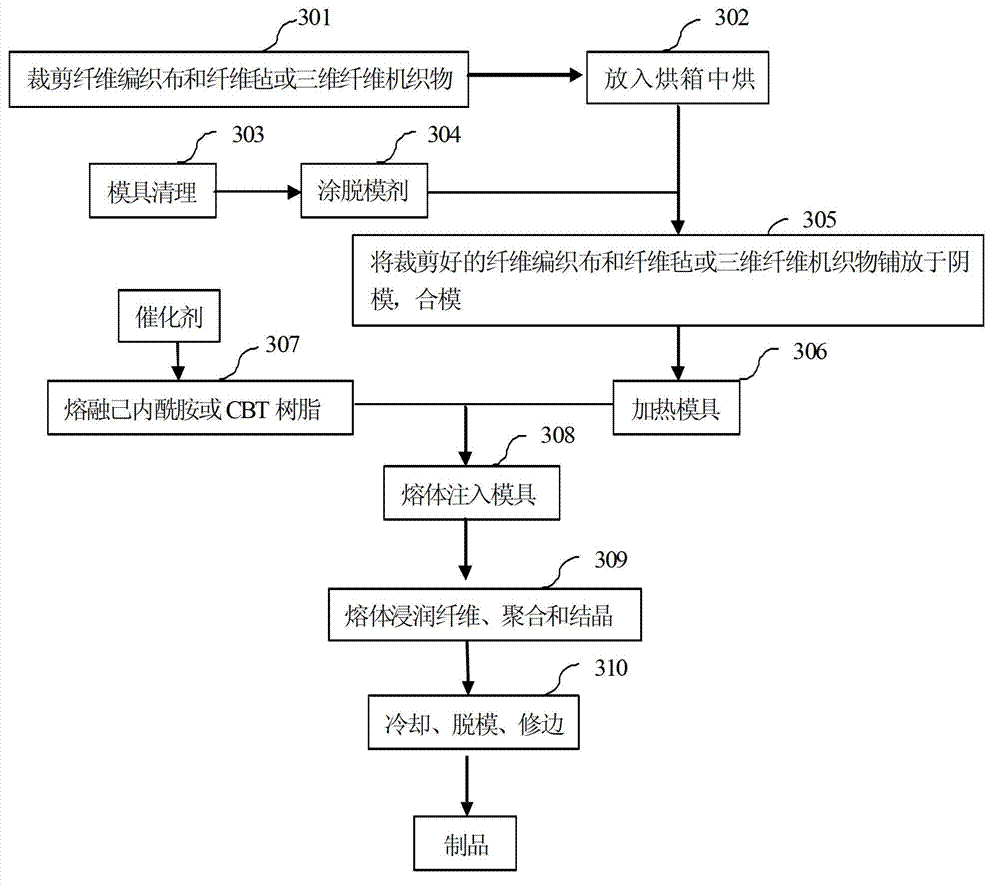

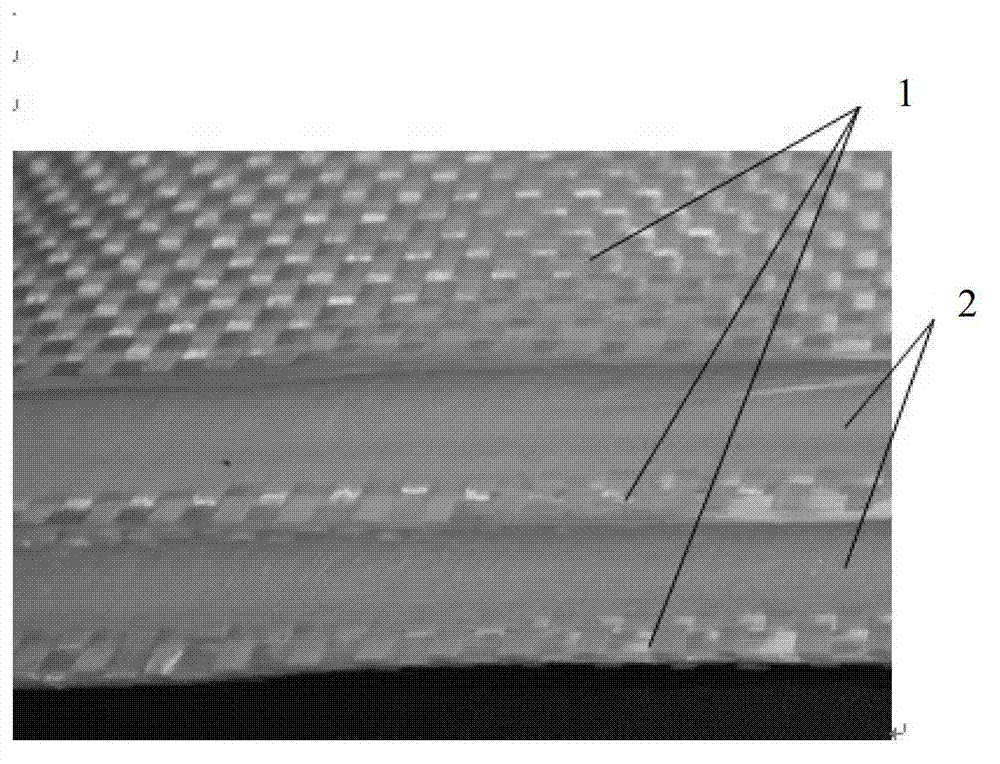

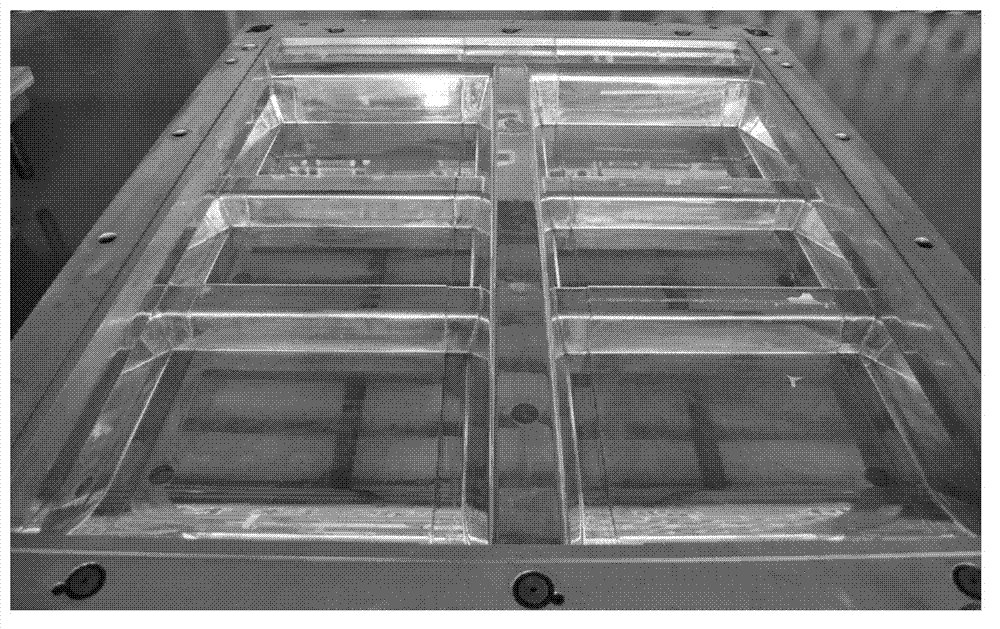

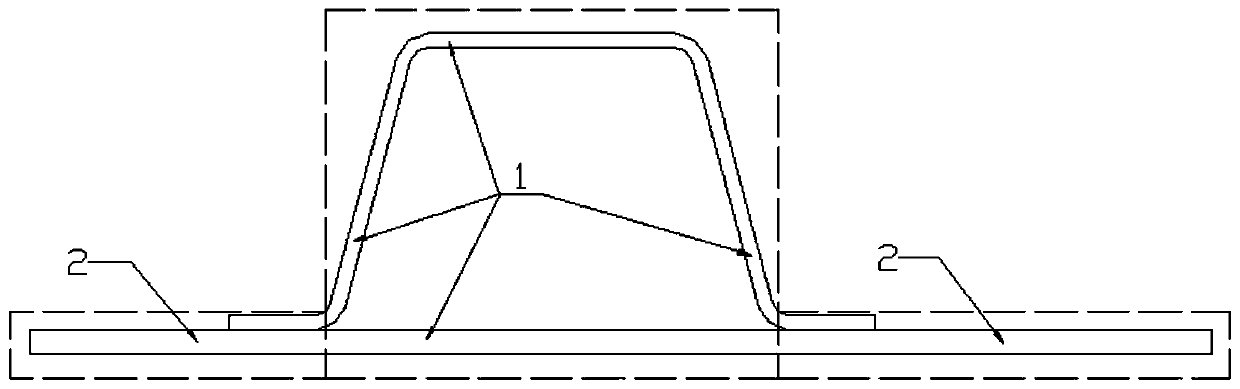

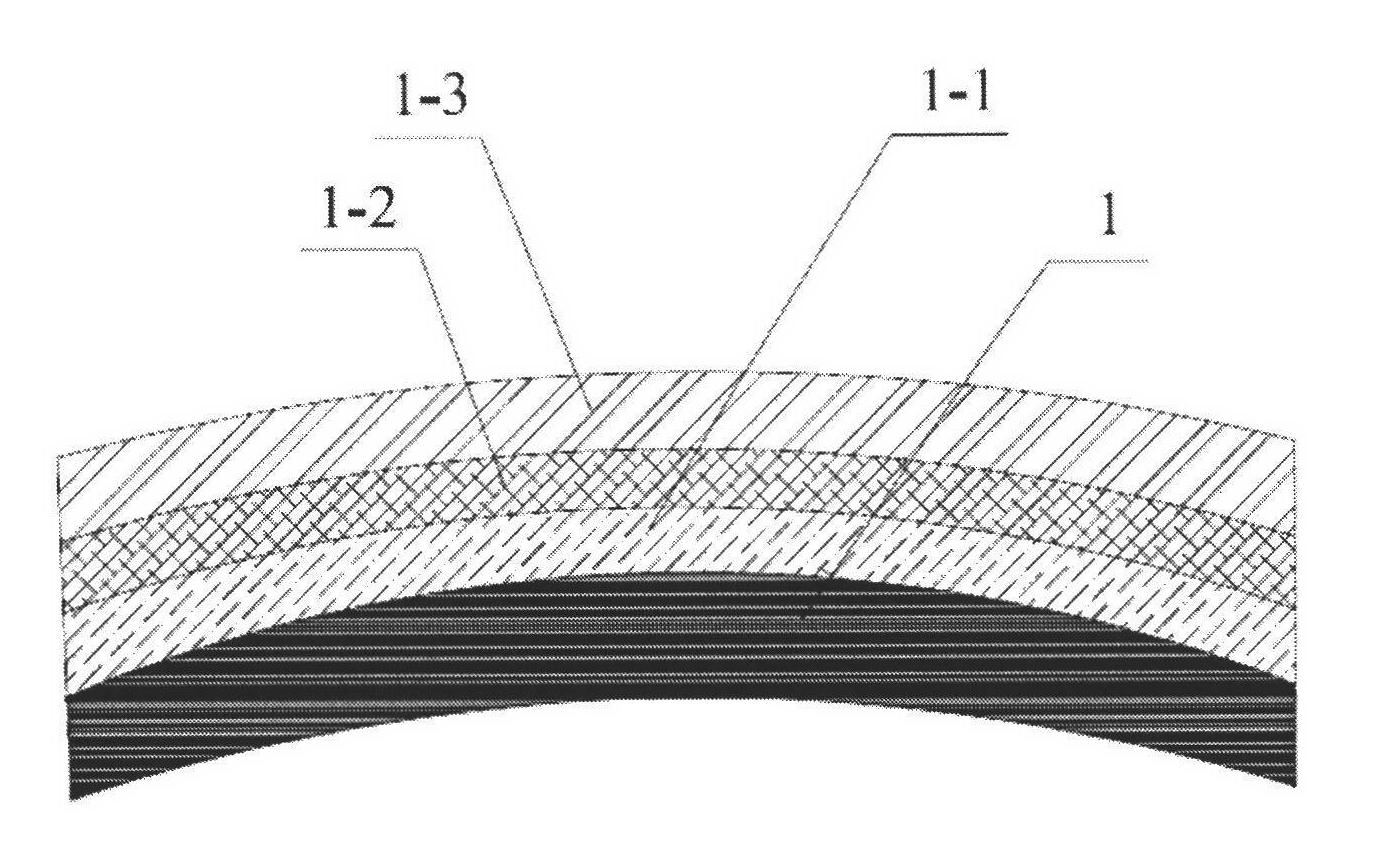

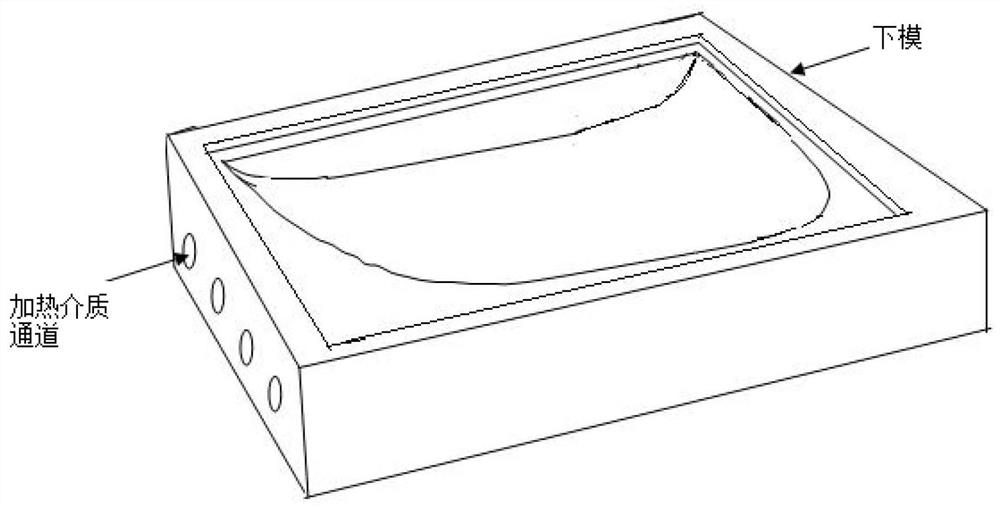

Method capable of reducing the surface defects of fiber reinforced thermoplastic composite products

The invention relates to a method capable of reducing the surface defects of fiber reinforced thermoplastic composite products, a fiber reinforced thermoplastic composite material formed by the method and products made by the composite material. The method comprises the following steps of: (1) providing a mold with a female mold and a male mold which are matched with each other; (b) laying more than one layer of fiber woven fabric and more than one layer of elastic fiber on the mold in a stacked way, or laying a stacked body containing more than one layer of the fiber woven fabric and more than one layer of the elastic fiber on the mold, wherein the elastic fiber products are one or more than two kinds of fabrics selected from fiber felts and three-dimensional fiber woven fabrics; (c) matching the female mold with the male mold and heating the mold; (d) injecting a thermoplastic resin composite into the mold; and (e) demolding the thermoplastic resin composite injected mold to obtain the products after the thermoplastic resin composite is solidified and the mold is cooled. The appearance of the obtained products does not have obvious dry spots or cracks.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

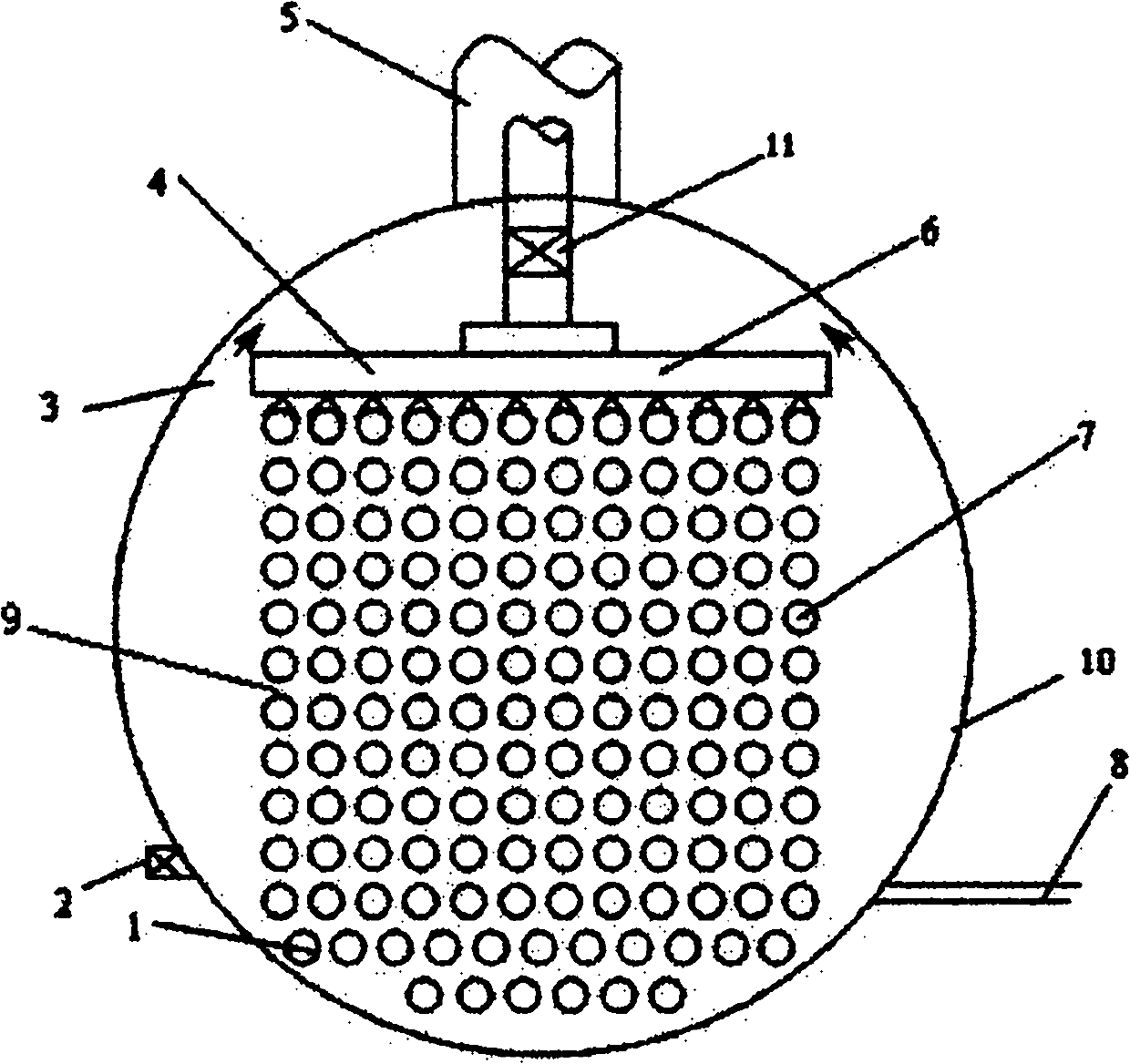

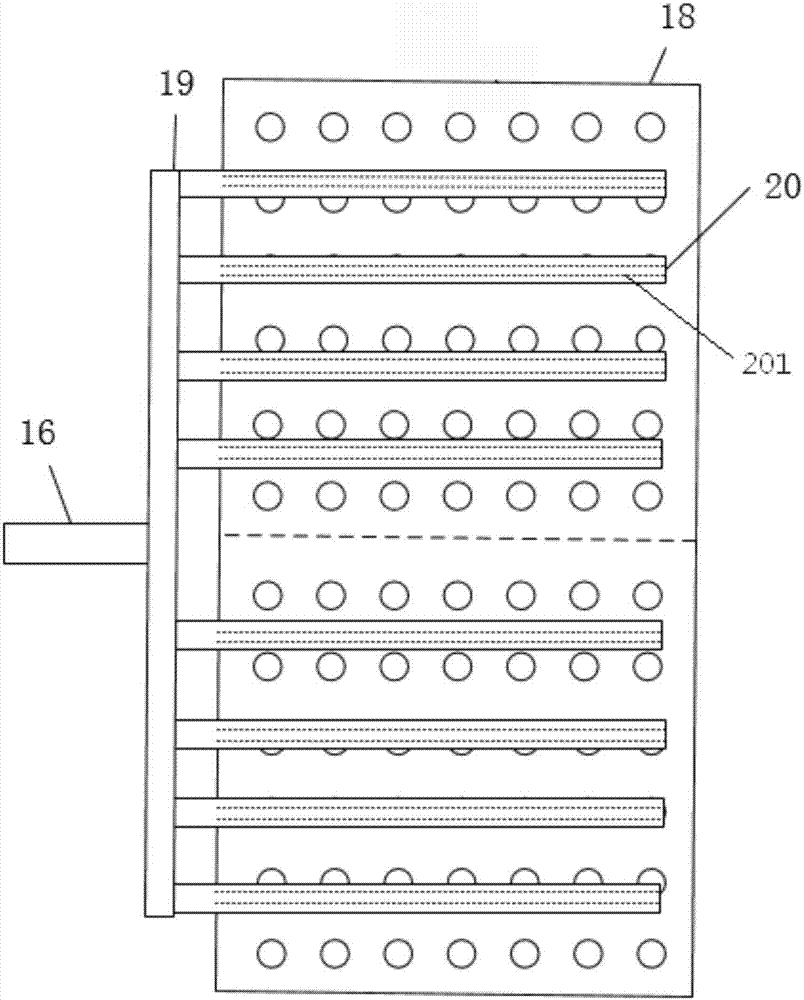

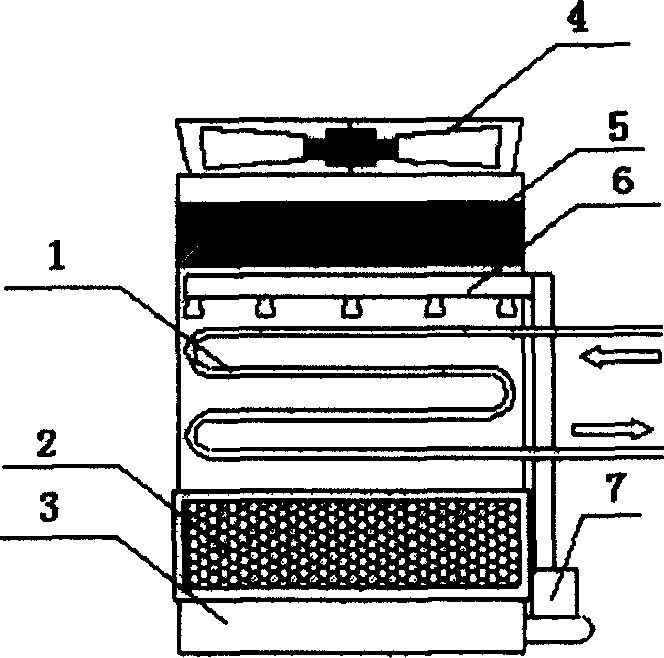

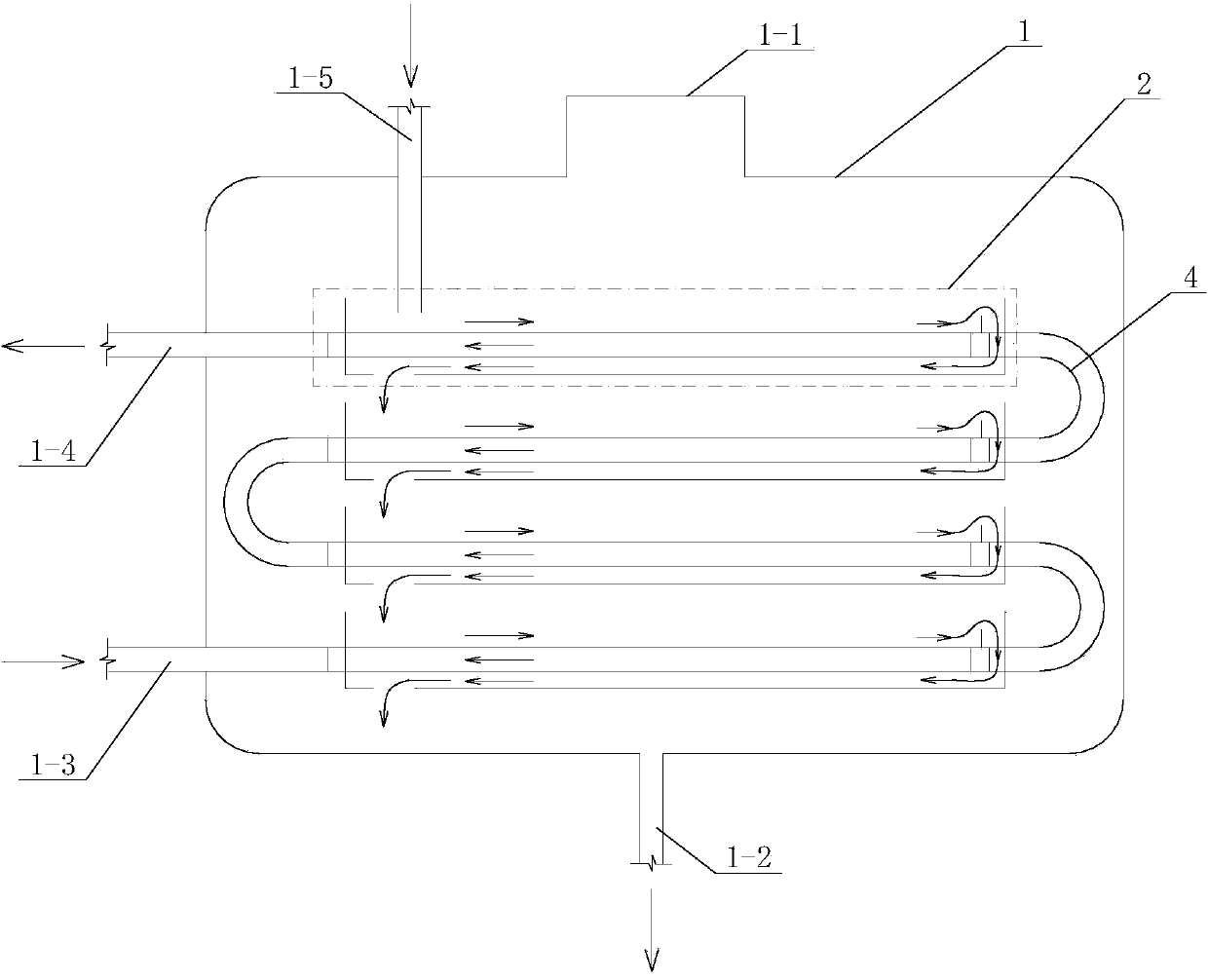

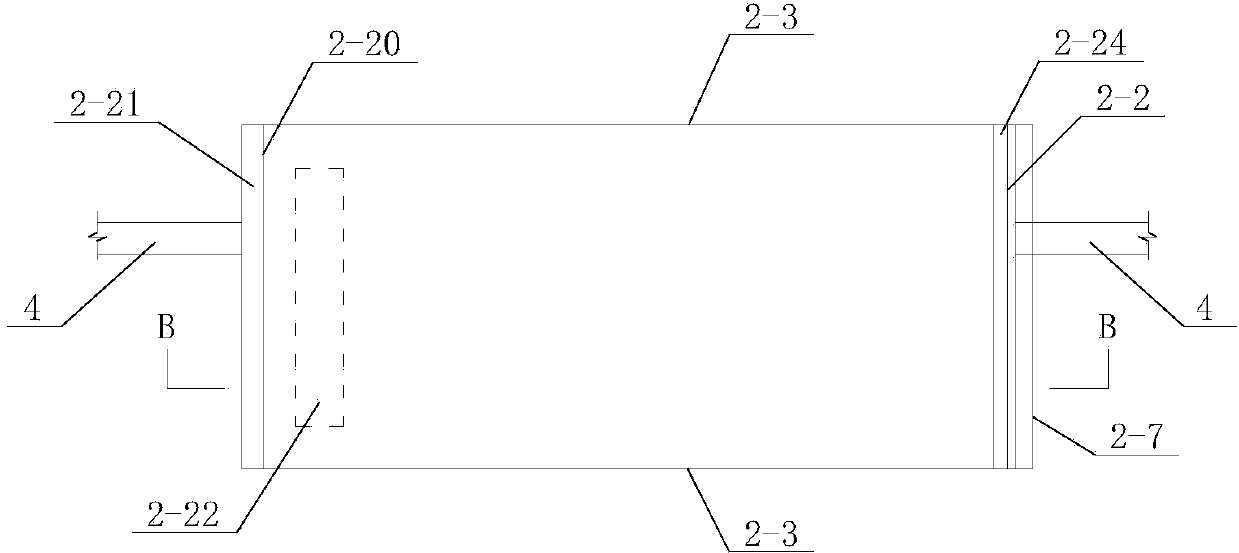

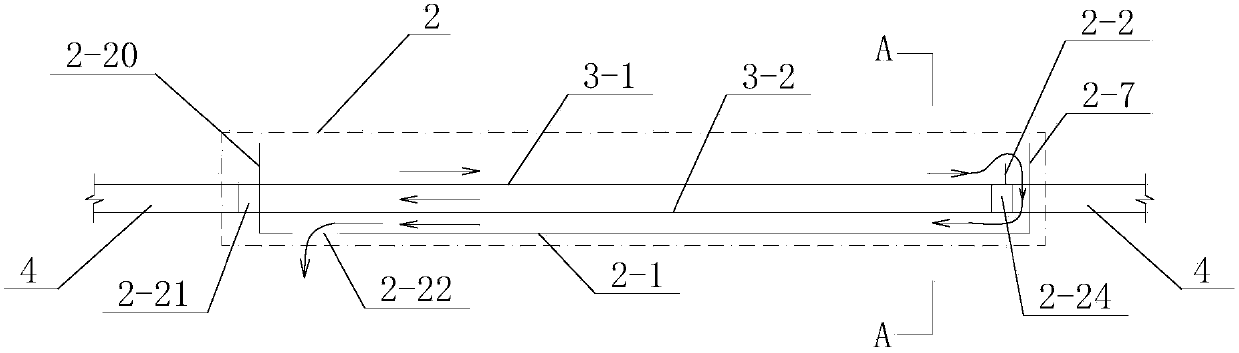

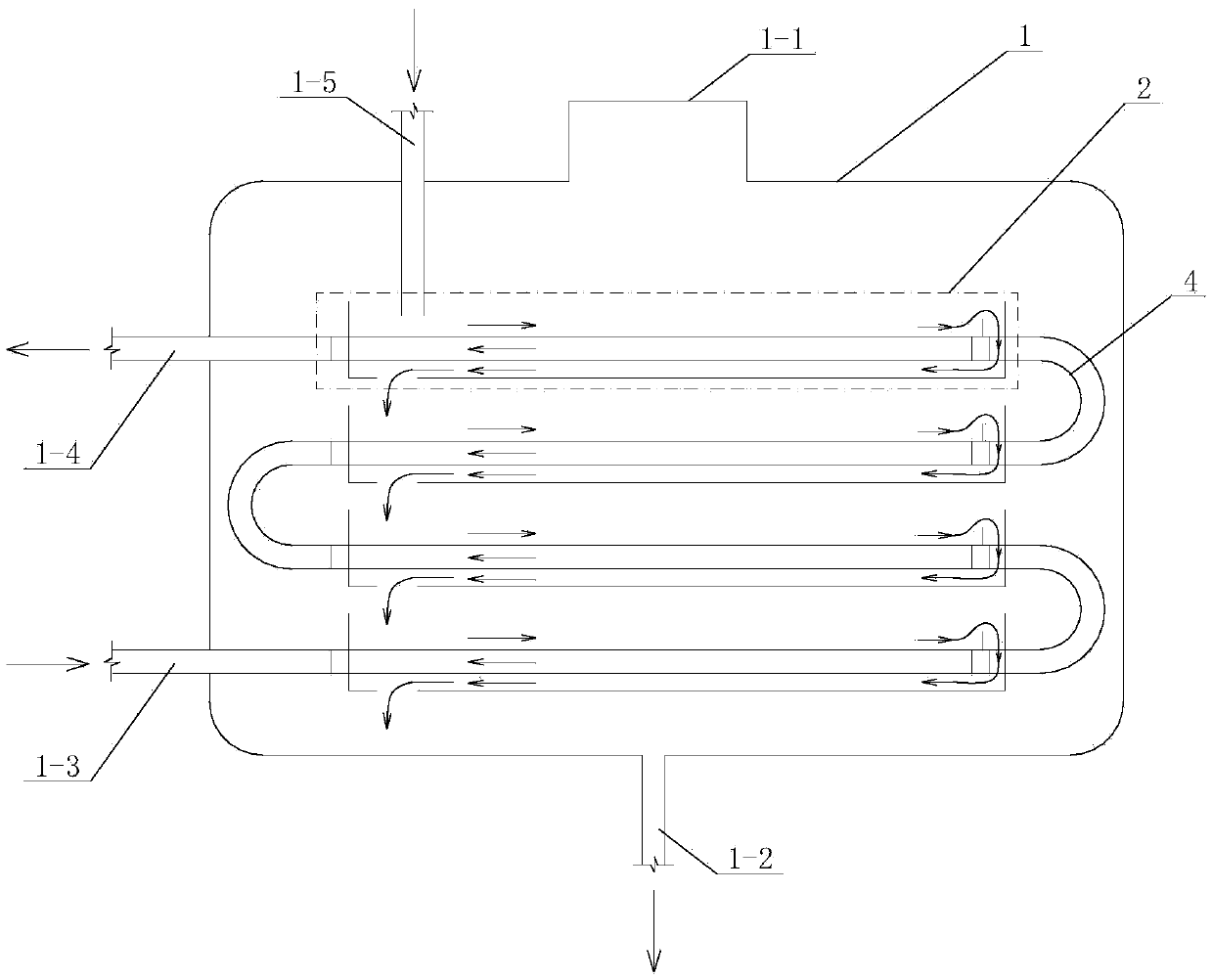

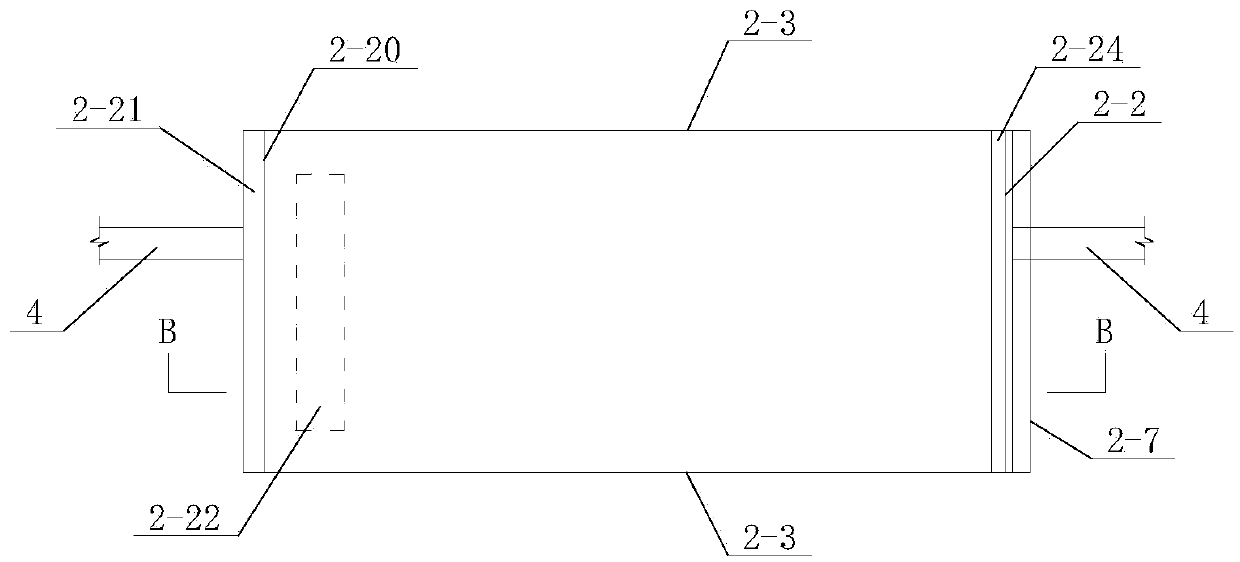

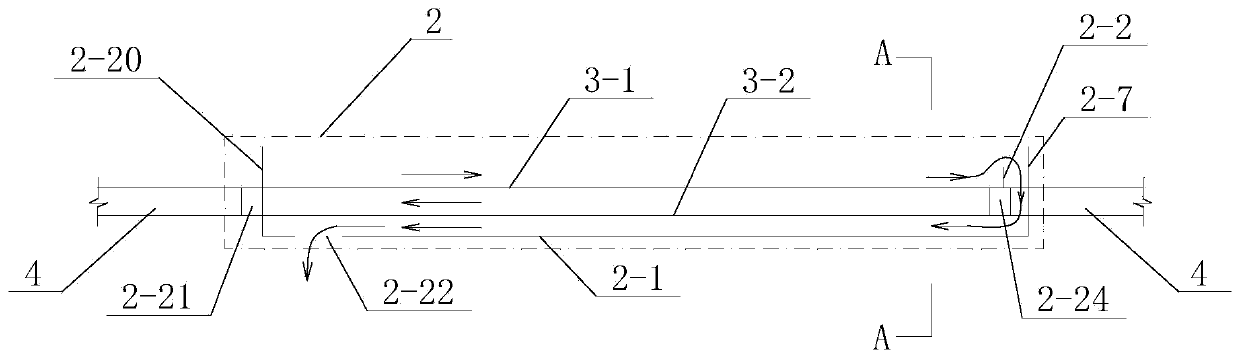

Combined evaporator

InactiveCN102166420AOvercome the defect of "dry spots" prone to appearEnsure safetyEvaporationPlate heat exchangerBoiling point

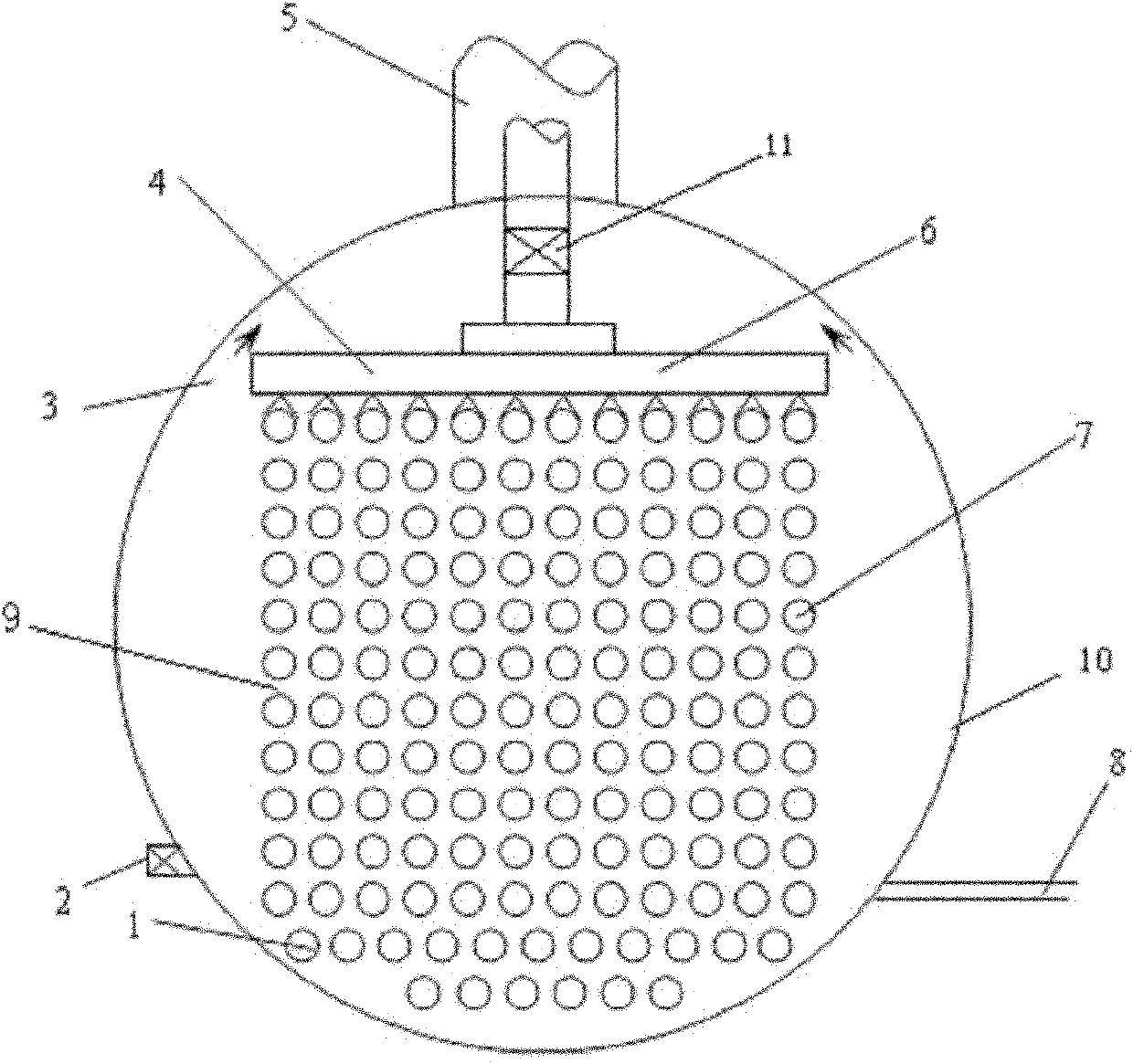

The invention discloses a combined evaporator comprising an evaporator body and a steam outlet communicated with the evaporator, wherein a plurality of heat exchange tubes are horizontally arranged in the evaporator body along the longitudinal direction of the evaporator body; an airflow path is arranged between adjacent heat exchange tubes; the heat exchange tubes comprise a falling film type evaporation heat exchange tube and a flooded heat exchange tube, wherein the falling film type evaporation heat exchange tube is near the top of the evaporator body; the flooded heat exchange tube is near the bottom of the evaporator body; and a film distribution device is arranged above the falling film type evaporation heat exchange tube and is provided with an inlet for a low-boiling-point working medium. Compared with the prior art, the combined evaporator combines the advantages of two evaporators; the problem that the half heat exchange tubes at the lower half always have dry spots because uneven liquid distribution is solved, and the safety of the evaporator is guaranteed; the defect of large evaporated liquor demand in the flooded heat exchange tube is overcome; the evaporation area of the heat exchanger is fully utilized; and evaporation efficiency is still kept in a higher level.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

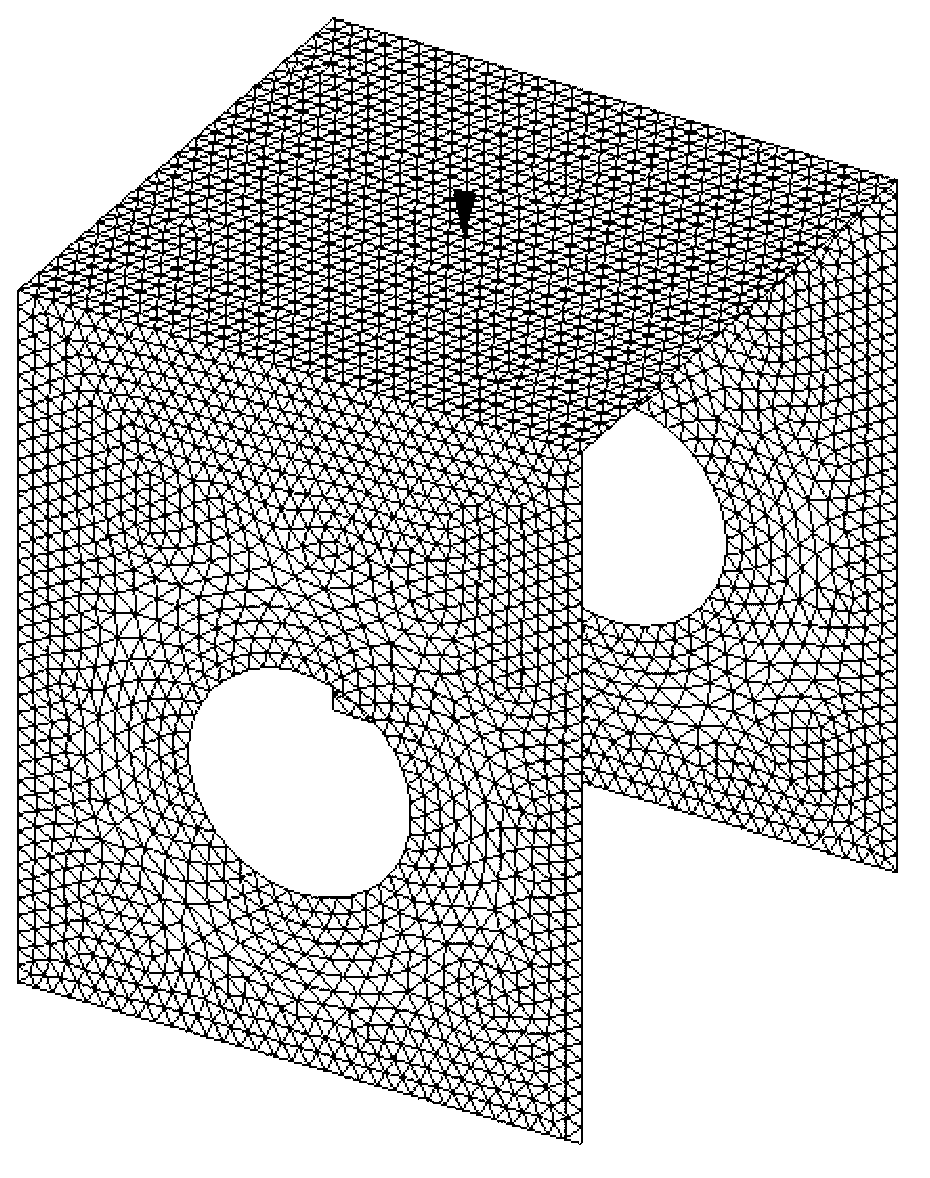

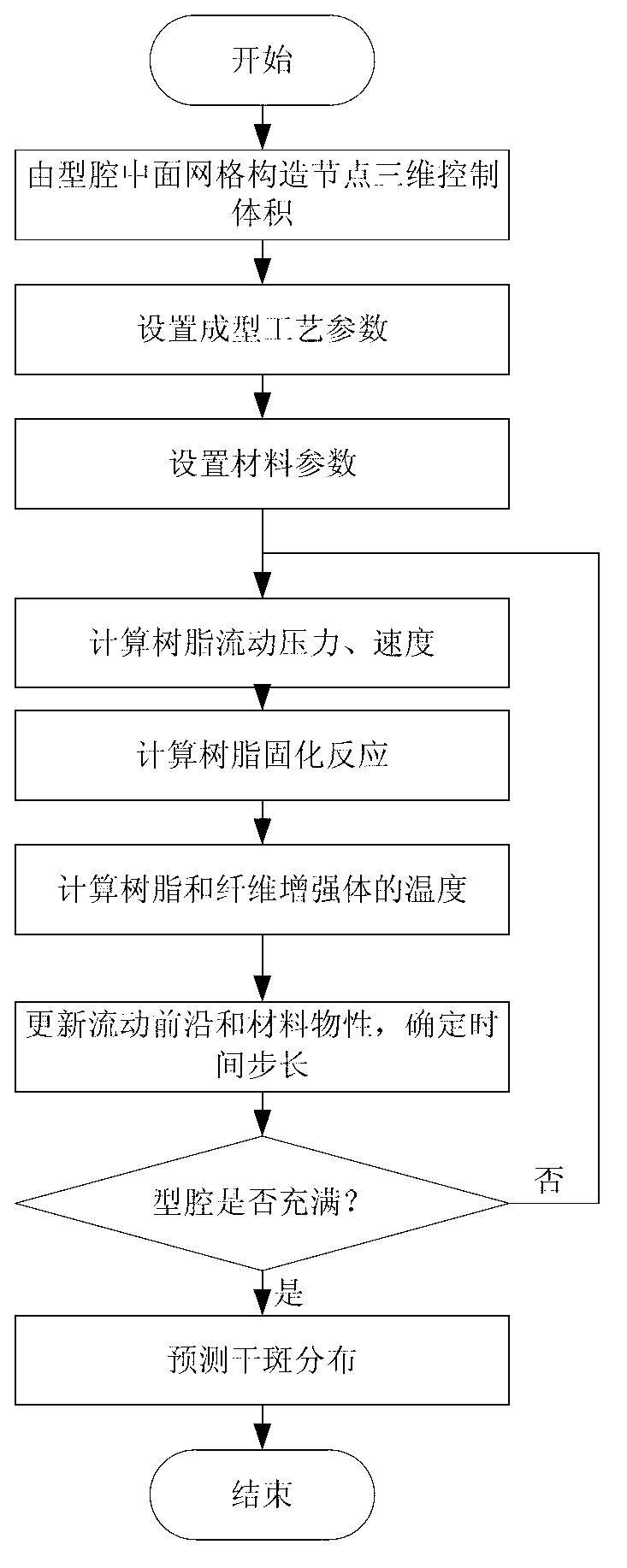

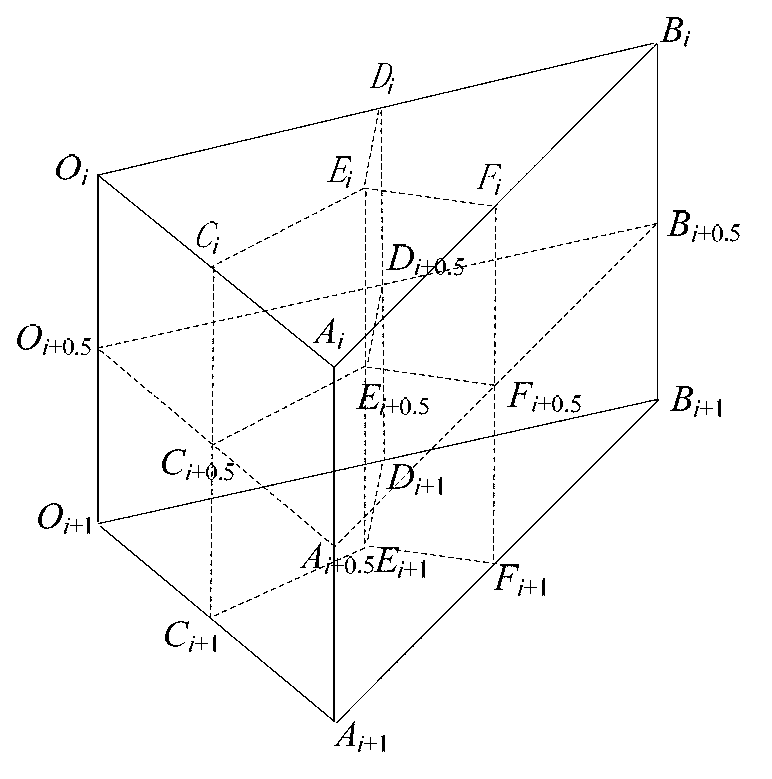

Flow front prediction method of non-isothermal resin transfer molding based on mid-plane model

The invention provides a flow front prediction method of non-isothermal resin transfer molding based on a mid-plane model, comprising the following steps: (1) constructing a node three-dimensional control volume by a die cavity mid-plane grid; (2) setting molding technological parameters; (3) setting material parameters; (4) calculating resin flowing pressure and speed; (5) calculating resin solidifying reaction; (6) calculating the temperatures of resin and fiber reinforcements; (7) updating flow front and material physical properties so as to ensure time step; (8) ensuring whether the die cavity is filled, and entering the step (9) if the die cavity has already been filled, or entering the step (5); and (9) predicting the distribution of dry spots. Based on the mid-plane grid, the three-dimensional control volume is constructed and the finite element method of the control volume is used, the changes of viscidity, speed, temperature, curing degree and the like in the thickness direction and the influence to the calculation of pressure field are considered in the calculation, and the flow front of resin transfer molding and the distribution of various physical quantity fields can be predicted more accurately.

Owner:SHANGHAI JIAO TONG UNIV

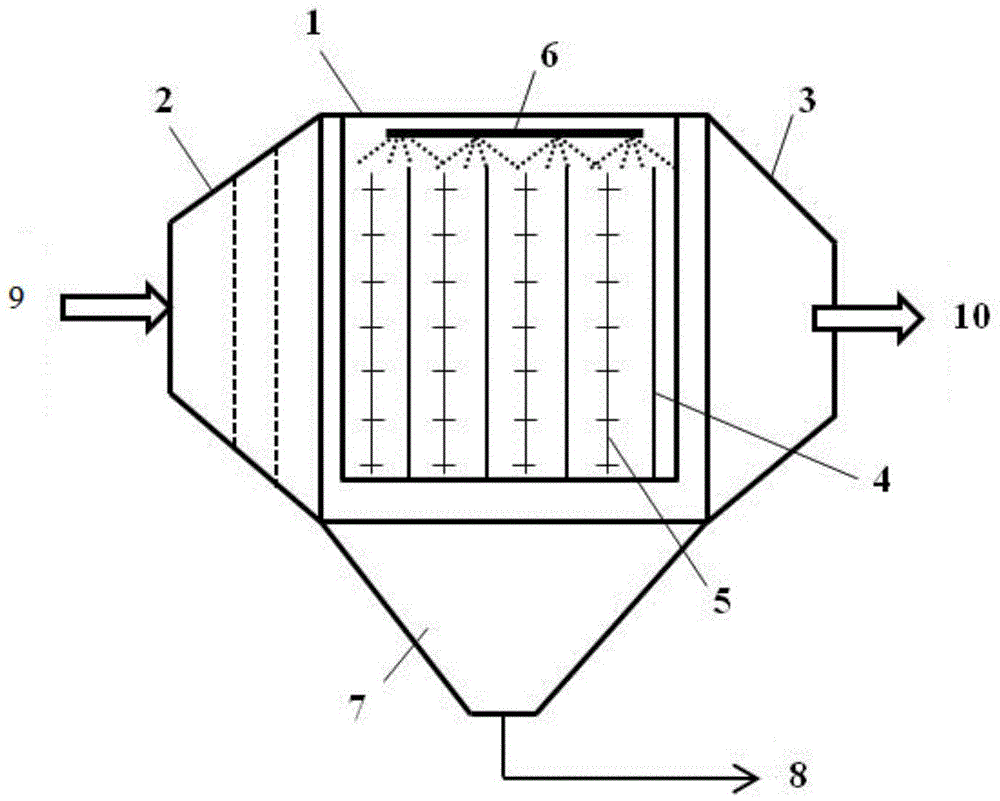

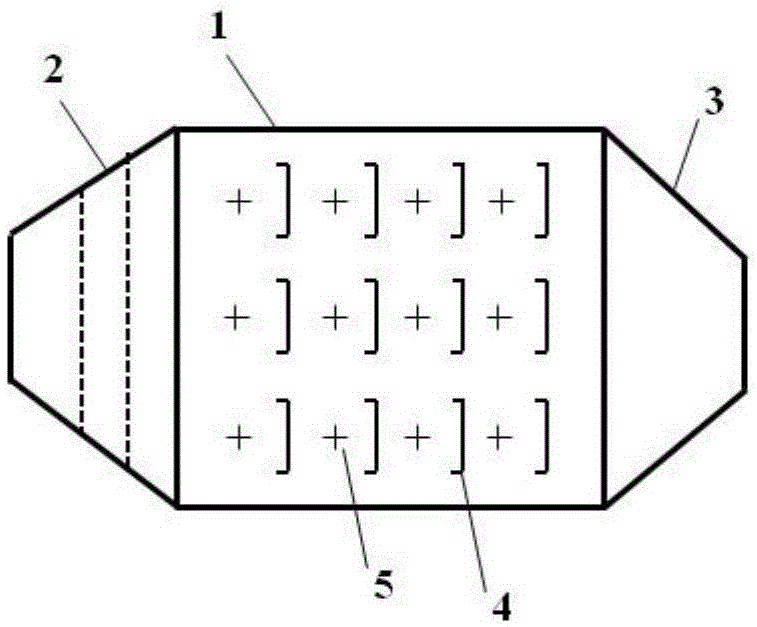

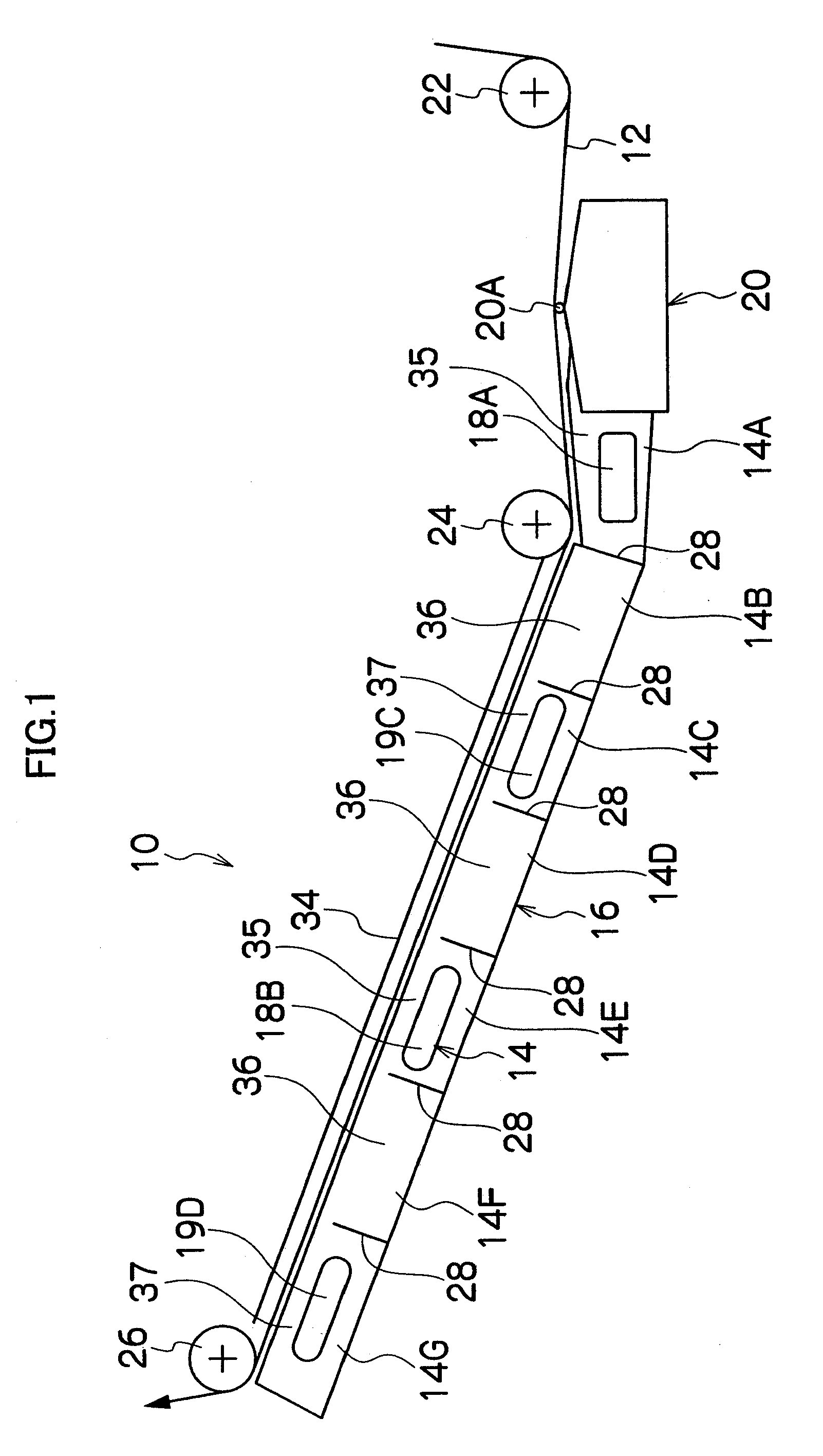

Transverse pole plate circling type wet electrostatic precipitator and wet electrostatic precipitation method

InactiveCN104437868AImprove capture efficiencyLower specific resistanceExternal electric electrostatic seperatorParticulatesEngineering

The invention relates to a transverse pole plate circling type wet electrostatic precipitator and a wet electrostatic precipitation method which are used for trapping and removing multiple pollutants such as particulate matters, SO3, Hg. The transverse pole plate circling type wet electrostatic precipitator comprises a shell; the shell is internally provided with an atomized water spray system and a plurality of dust removing units; the atomized water spray system comprises an atomized water spray pipeline and conical nozzles which are evenly spaced; each dust removing unit comprises a plurality rows of anode plates and a plurality rows of cathode lines, wherein the directions of the anode plates are longitudinal to the flue gas flowing direction. The dust-containing flue gas flows in a circling way after passing through gaps among the anode plates in the same row, so that the scour for water films on the surfaces of the anode plates can be reduced, and the phenomena of local dry spots and back corona can be avoided. The transverse pole plate circling type wet electrostatic precipitator is reliable in operation, and the pollutant trapping efficiency and the system stability of the wet electrostatic precipitator are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

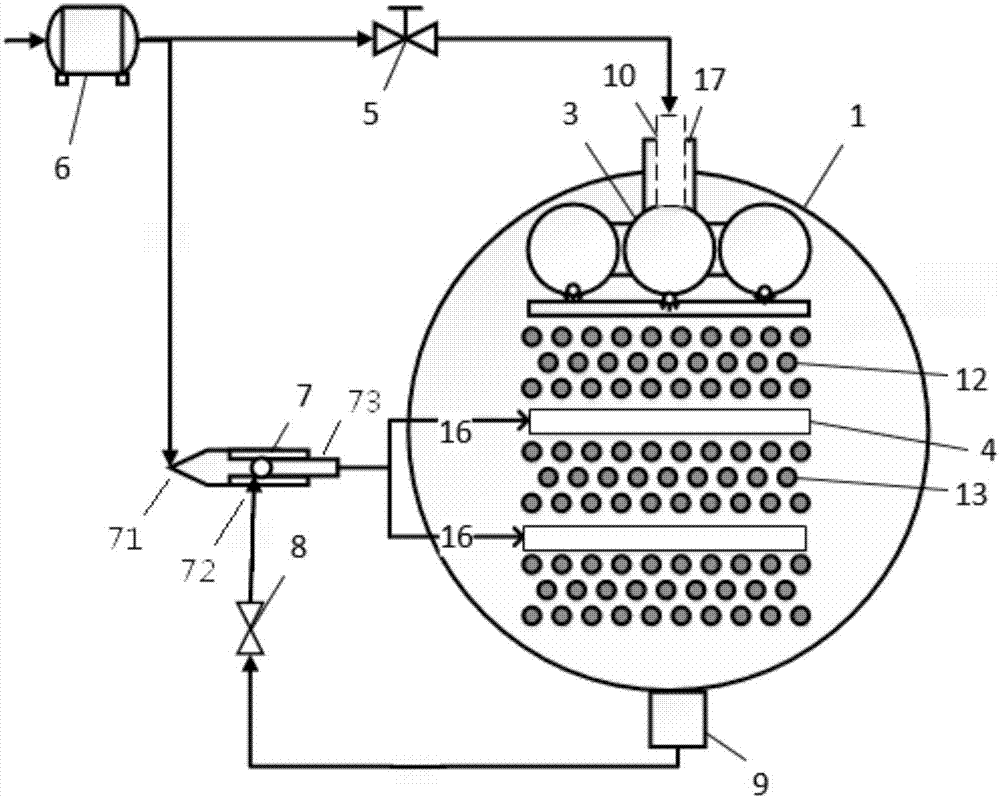

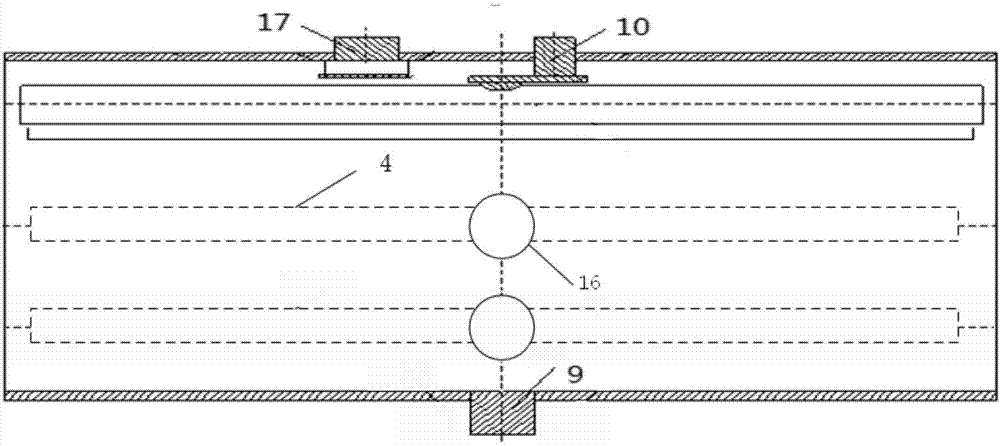

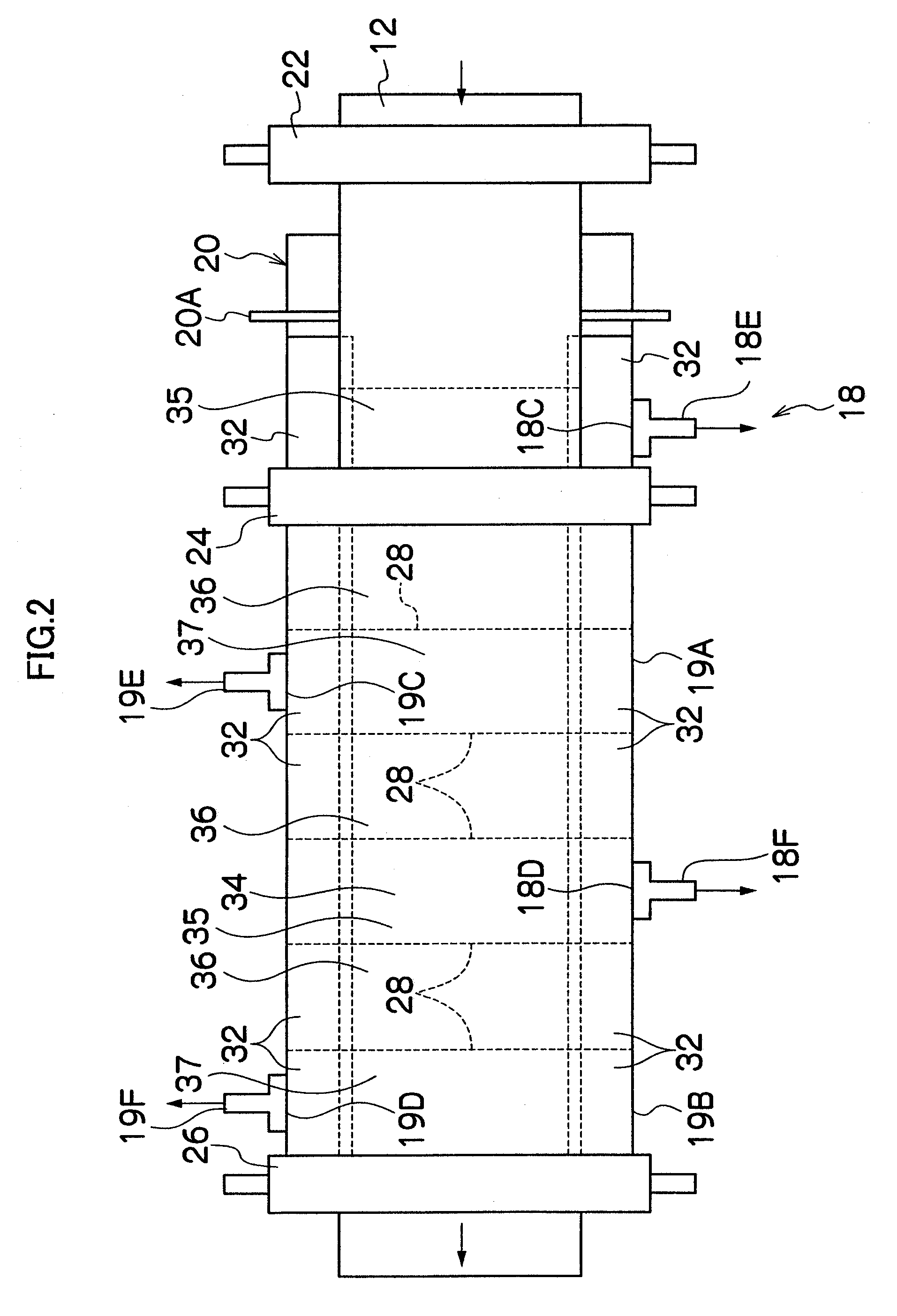

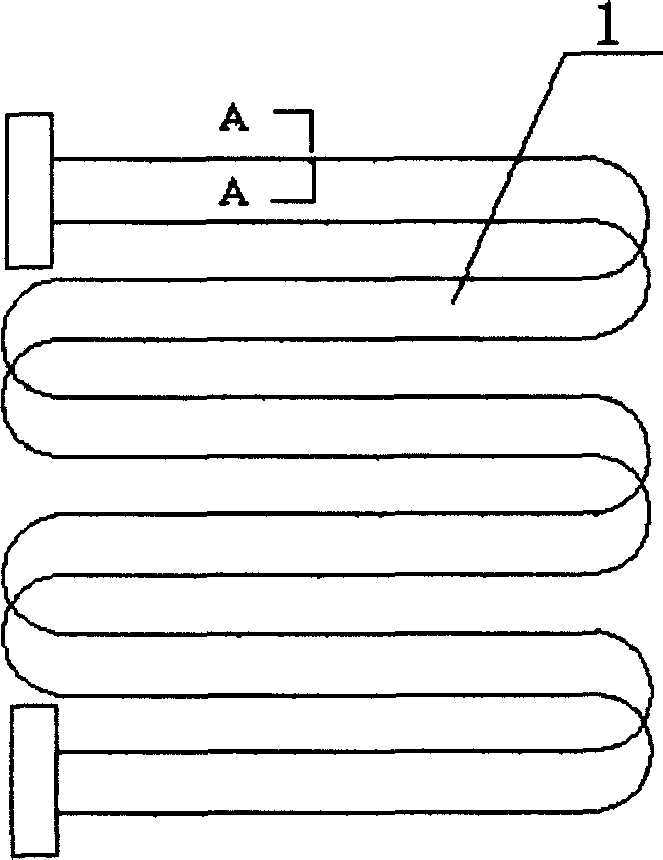

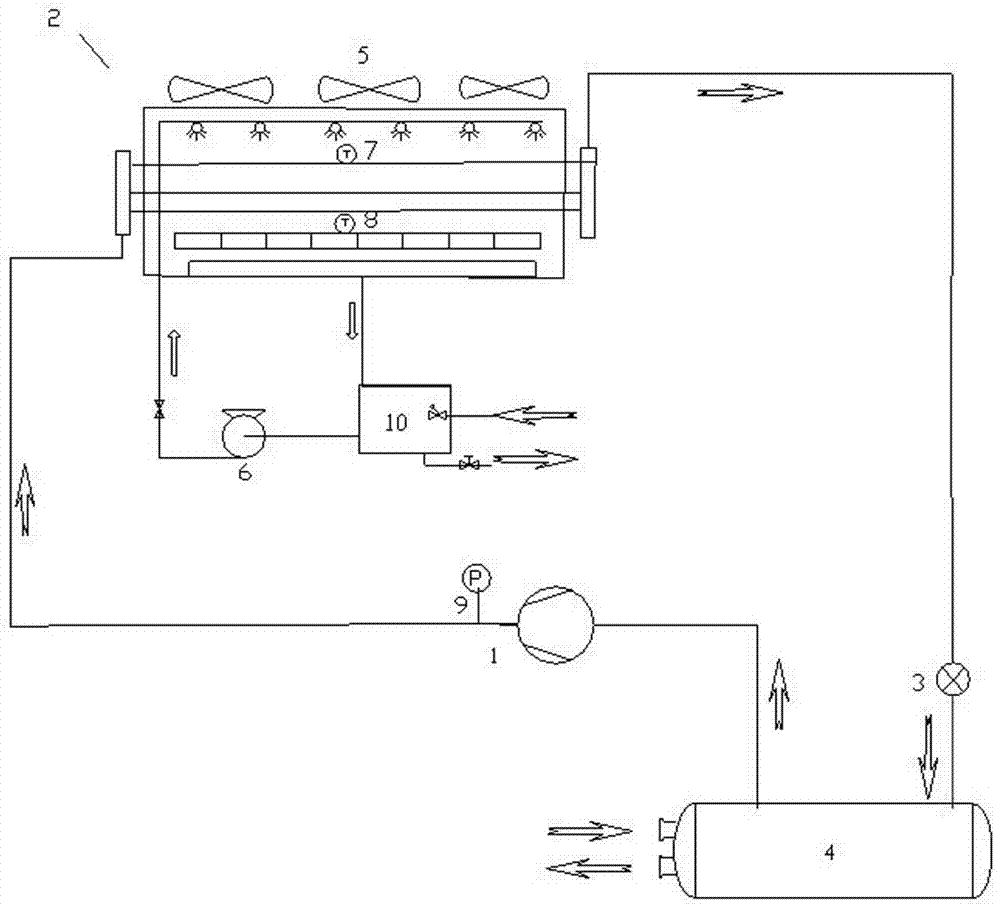

Horizontal tube falling film evaporator

ActiveCN107490212AImprove heat transfer effectIncrease the amount of sprayingEvaporators/condensersAgricultural engineeringHigh pressure

The invention discloses a horizontal tube falling film evaporator. The horizontal tube falling film evaporator comprises a shell; the shell is connected with a high-pressure liquid storage unit; a first-level liquid distributor and a first-level heat exchange tube bank are arranged in the shell; a plurality of second-level liquid distributors are arranged below the first-level heat exchange tube bank, and a second-level heat exchange tube bank is correspondingly arranged below each second-level liquid distributor; and an ejector is connected to the bottom of the shell and comprises a high-pressure inlet, an ejection inlet and a mixing outlet, the high-pressure inlet is connected with the high-pressure liquid storage unit, the ejection inlet is connected with the bottom of the shell, and the mixing outlet is connected with the second-level liquid distributors. According to the horizontal tube falling film evaporator, an ejector circulating device is adopted to suck unevaporated liquid refrigerant at the bottom of the evaporator into the second-level liquid distributors, cycle spraying of the liquid refrigerant is achieved, thus the distribution uniformity of the refrigerant on the outer surfaces of the tube banks on the lower portion of the evaporator is improved, and the purposes of eliminating dry spots outside a tube and enhancing the overall heat exchange performance of the evaporator are achieved.

Owner:NANJING NORMAL UNIVERSITY

Method of treating sandy soils to reduce water repellency therein

Certain novel formulations of turf additives that act in such a manner as to permit proper amounts of moisture to contact root systems in order to reduce dry spots within highly managed turf areas and / or lawns. It is theorized that the accumulation of humic acid (and other natural byproduct deleterious compounds) at the topsoil surface in most cultivated grassy areas including sandy soils (such as, in particular, golf greens), results in the production of an effective organic waxy coating on the soil components. Such a coating is hydrophobic in nature and thus dries out the soil itself. The inventive formulation thus permits removal of such accumulated humic acid (and other compounds) from the topsoil to the level necessary to provide effective moisture penetration for sustained grass growth therein (hereinafter referred to as "redistributes"). Methods of providing such beneficial removal of humic substances from target sandy soils are also contemplated within this invention, as well as specific test hydrophobic sand formulations.

Owner:MILLIKEN & CO

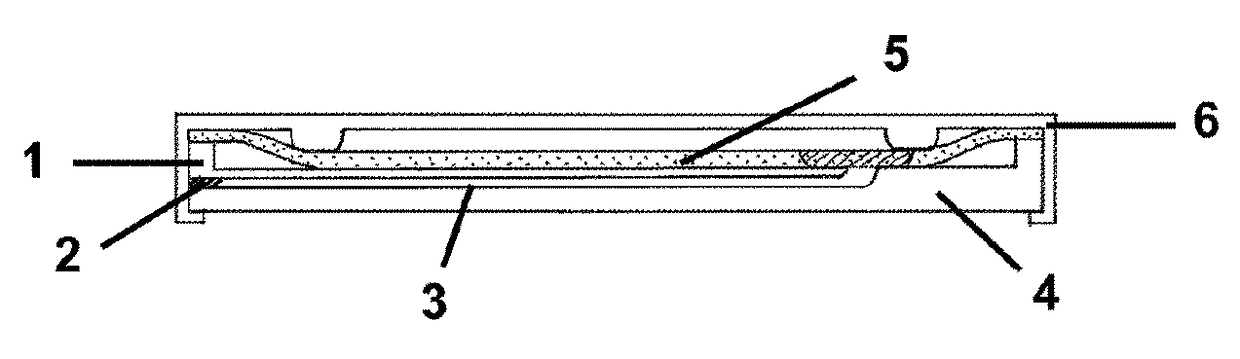

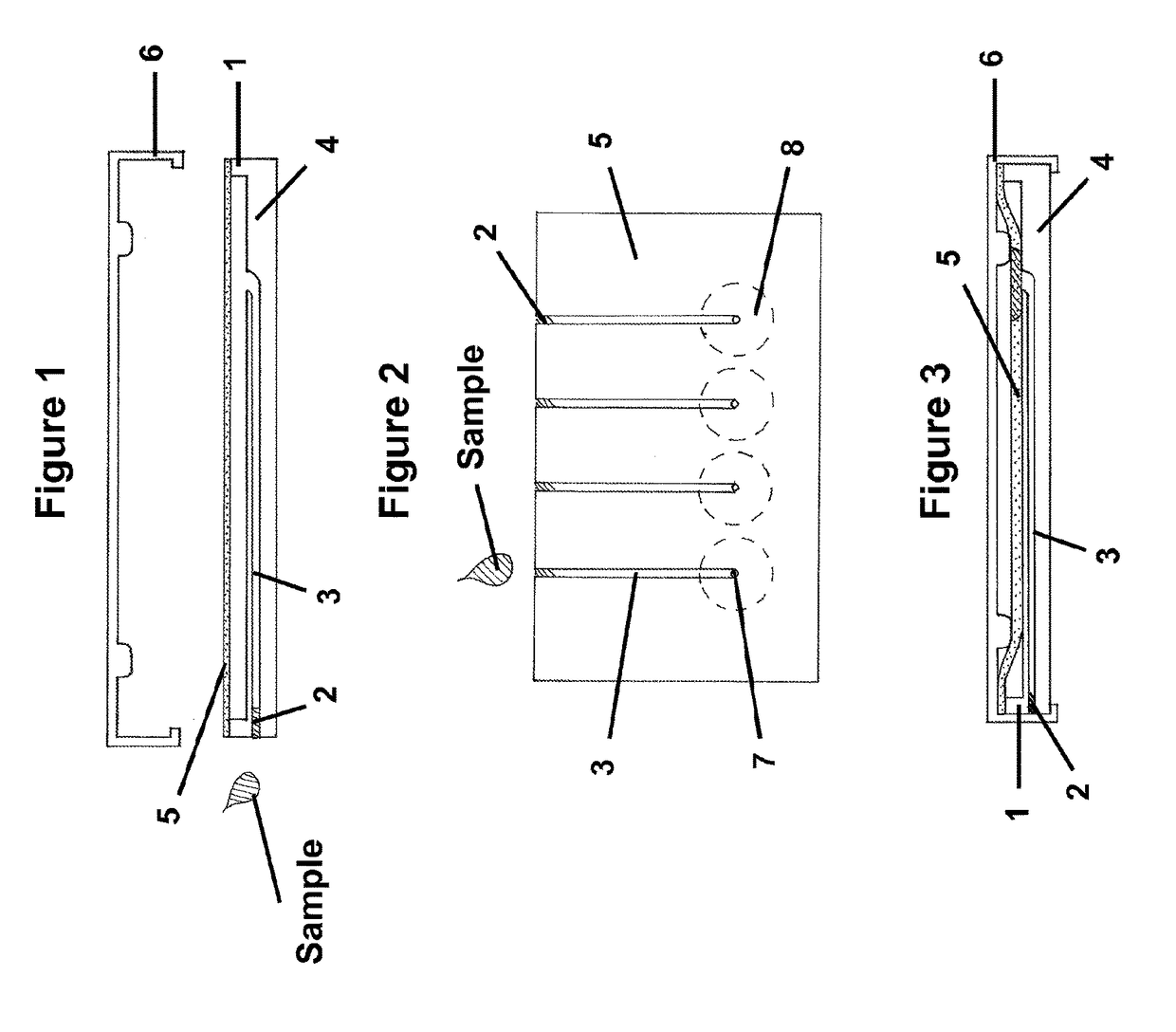

Device and method for dried fluid spot analysis

A lab-on-chip-based system is described for the direct and multiple sampling, control of the volume, fluid filtration, biochemical reactions, sample transfer, and dried spot generation on the conventional and commercial cards for dried fluid spot. Within an all-in-one integrated holder, the invention allows the complete process required to ensure a quantitative analysis of blood, plasma or any other fluids, modification and enrichment of molecule subsets, and formation of a dried fluid spot on the specific spot location of a passive cellulose, non-cellulose, absorbent, or non-absorbent membrane material sampling.

Owner:DBS SYST SA

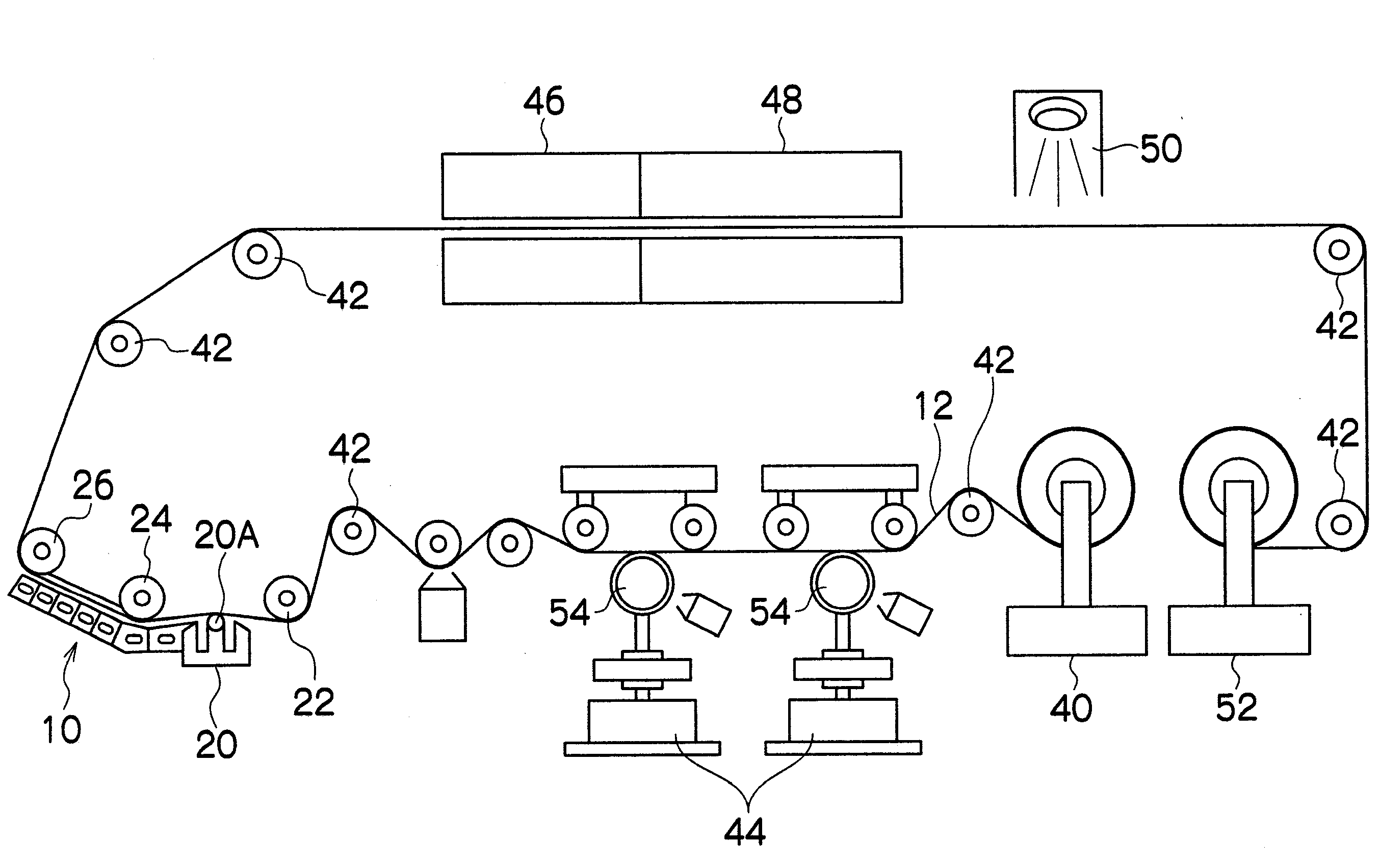

Method for drying coated film, and apparatus therefor

InactiveUS20080172903A1Inhibit productionDry evenlyDrying using combination processesDrying solid materials with heatBiochemical engineeringDry spot

Owner:FUJIFILM CORP

Method for fully stirring water and material of sprayed concrete

InactiveCN101649745AGuaranteed humidityKeep hydratedUnderground chambersTunnel liningShotcreteWorking environment

The invention discloses a method for fully stirring water and material of sprayed concrete, belonging to the technology of mine anchoring spray. A Zeng-type device composed of a bidirectional water ring and a reducing pipe is arranged on the position of a concrete shotcrete machine feed delivery pipe, which is near a spray head; a proper amount of mixing water is added into material in advance; when the mixed material passes through a first water adding port, the mixed material is firstly prewetted and rotates clockwise; the rotary mixed material enters the reducing pipe to generate vortex soas to further stir the mixed material; when the fully stirred mixed material passes through a second water adding port, water force anticlockwise rotates, so that the mixed material changes the rotation direction to form turbulent flow, and then, the mixed material is fully stirred to cause the mixed material to have enough humidity and water content. The invention has the effect that modulus of resilience of dust under the shaft is greatly reduced, air and working environment under the shaft is improved, the phenomenon of uncompacted dry spot on the surface of the spraying layer is stopped, and the strength and working efficiency of the sprayed concrete are improved.

Owner:SHANGHAI DATUN ENERGY

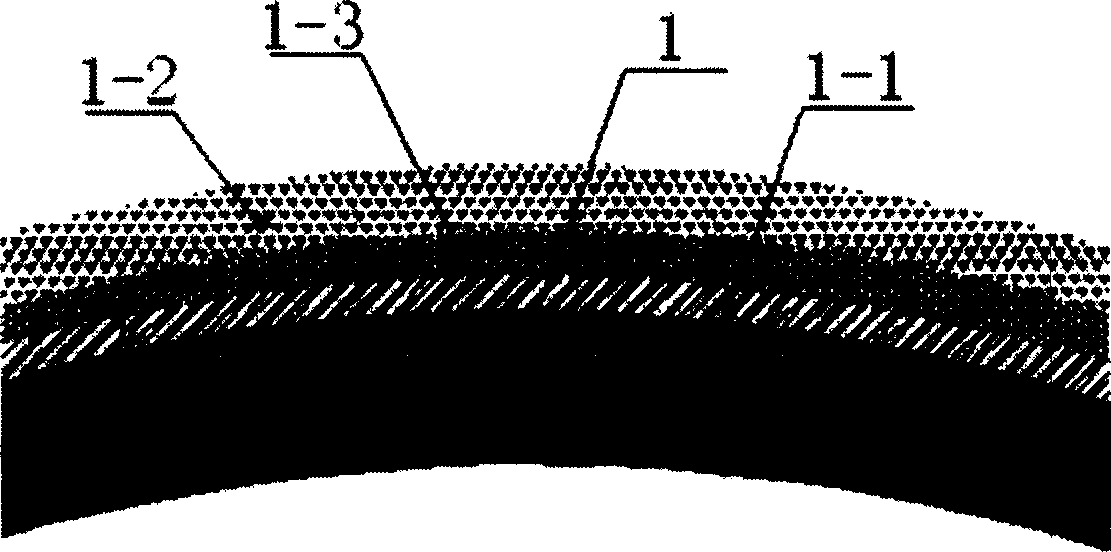

Nanometer coating on coiler surface of heat exchanger

InactiveCN1584483ASufficient heat exchangeEliminates "dry spots"Stationary conduit assembliesHeat transfer modificationNanometreDry spot

Nano coatings on coiled pipelines for heat exchangers consist of a corrosion-proof layer, a hydrophilic film, and a heat transferring film between the formers. An evaporative heat exchanger equipped with such pipelines works with high efficiency and saves water. It modifies surface characteristics of materials to make water film thinner, distributed more uniformly to have largest areas per unit of water so as to eliminate dry spots occurred and to reduce scales formed on surface of the coiled pipelines.

Owner:SOUTH CHINA UNIV OF TECH

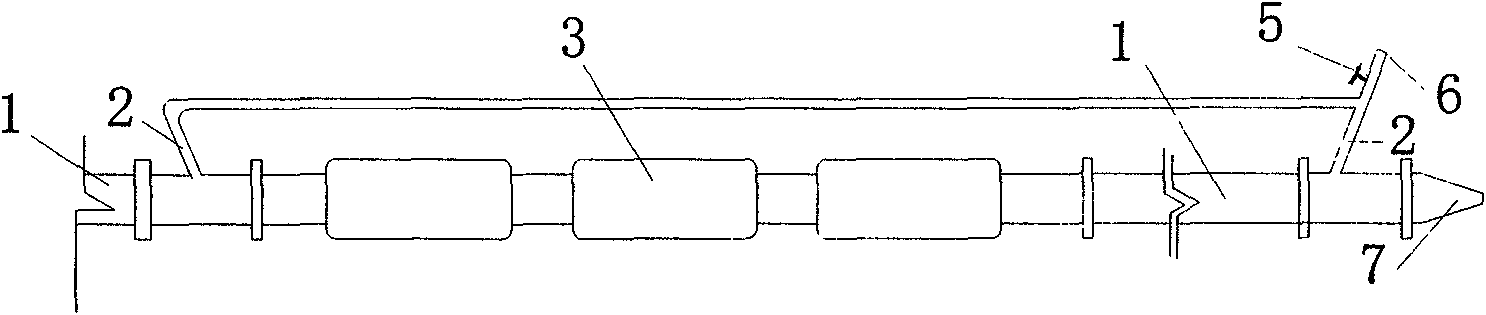

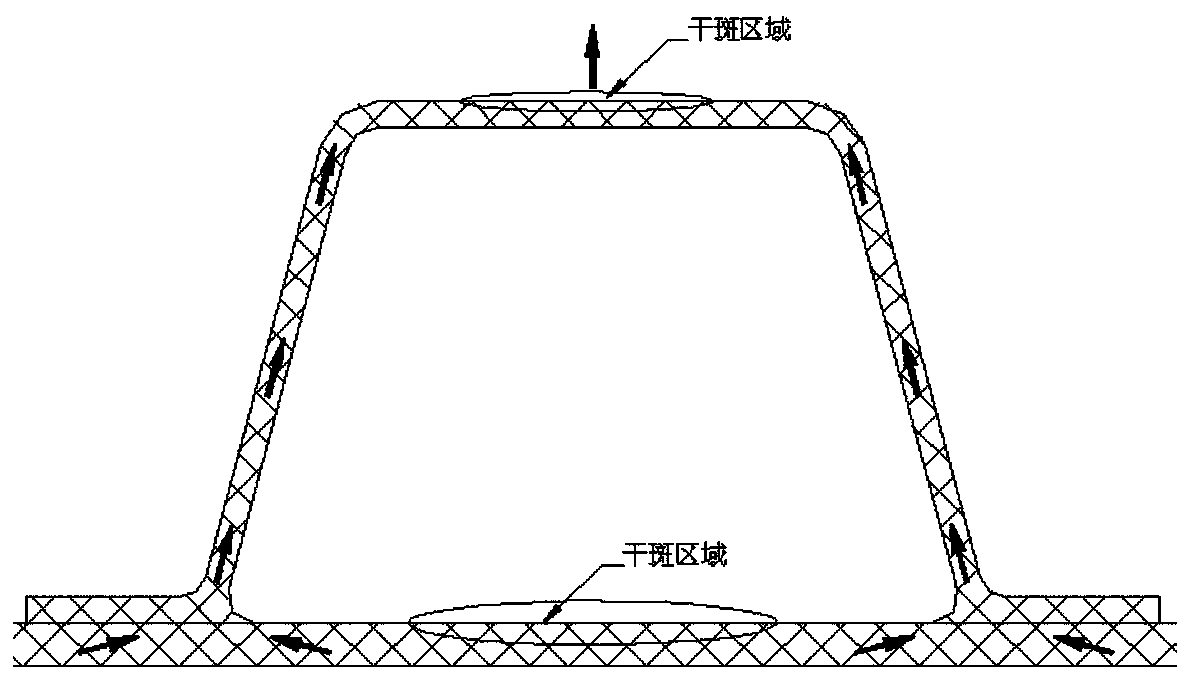

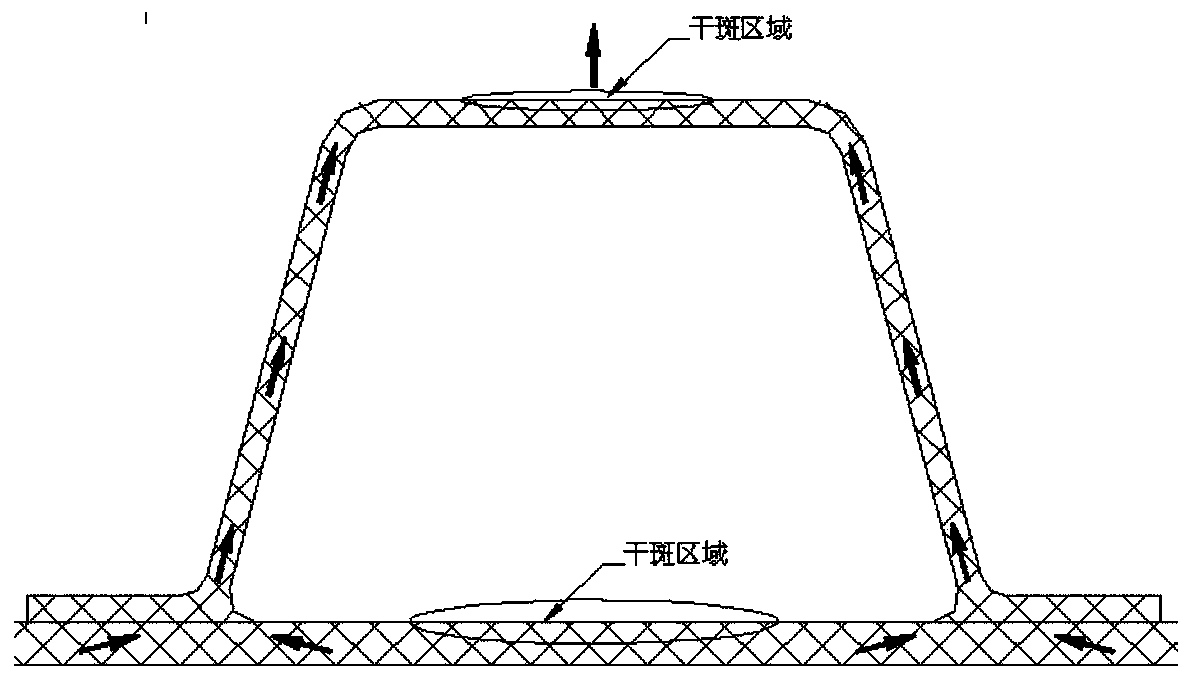

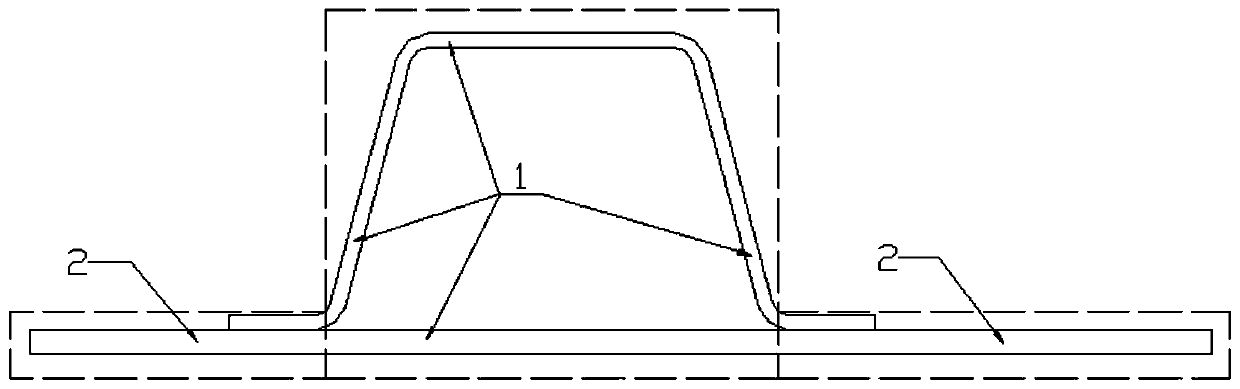

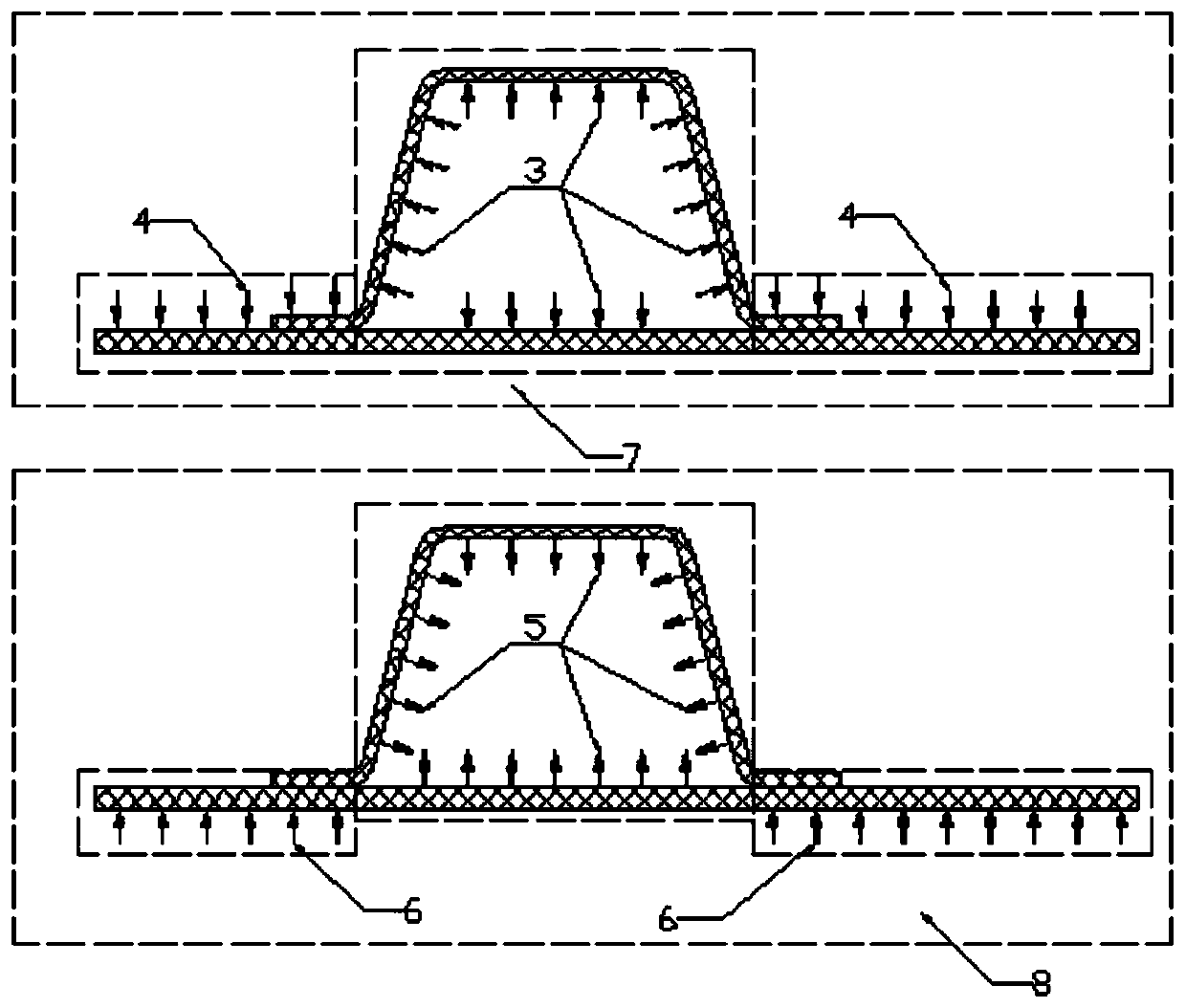

Resin flowing control method for cap-shaped additional rib wall plate RFI overall forming

The invention belongs to the technical field of low-cost manufacturing of high-performance resin matrix composite materials and relates to a resin flowing control method for cap-shaped additional ribwall plate RFI overall forming. In a traditional RFI technology, resin is diverted at the root parts of cap-shaped additional ribs, the resin flows towards cap tops along the interlayer of the two sides of each cap-shaped additional rib, dry spots are likely to be generated at the cap tops and cap bottoms, and part scrapping is caused. By means of the resin flowing control method for cap-shaped additional rib wall plate RFI overall forming, structure characteristics of a cap-shaped additional rib wall plate and RFI technology resin flowing characteristics are taken into consideration, the cap-shaped additional rib wall plate is decomposed into two kinds of structure units including a ring-shaped structure and a plate-shaped structure, a resin flowing module suitable for resin flowing control of the ring-shaped structure and the plate-shaped structure at the same time is established, a cap-shaped additional rib wall plate RFI overall forming resin flowing model is formed, resin laying is conducted according to the established resin flowing model, a gas way is arranged in the RFI technology process for guiding the resin to flow, and complete soaking of a cap-shaped additional rib wall plate pre-formed body in the resin is achieved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

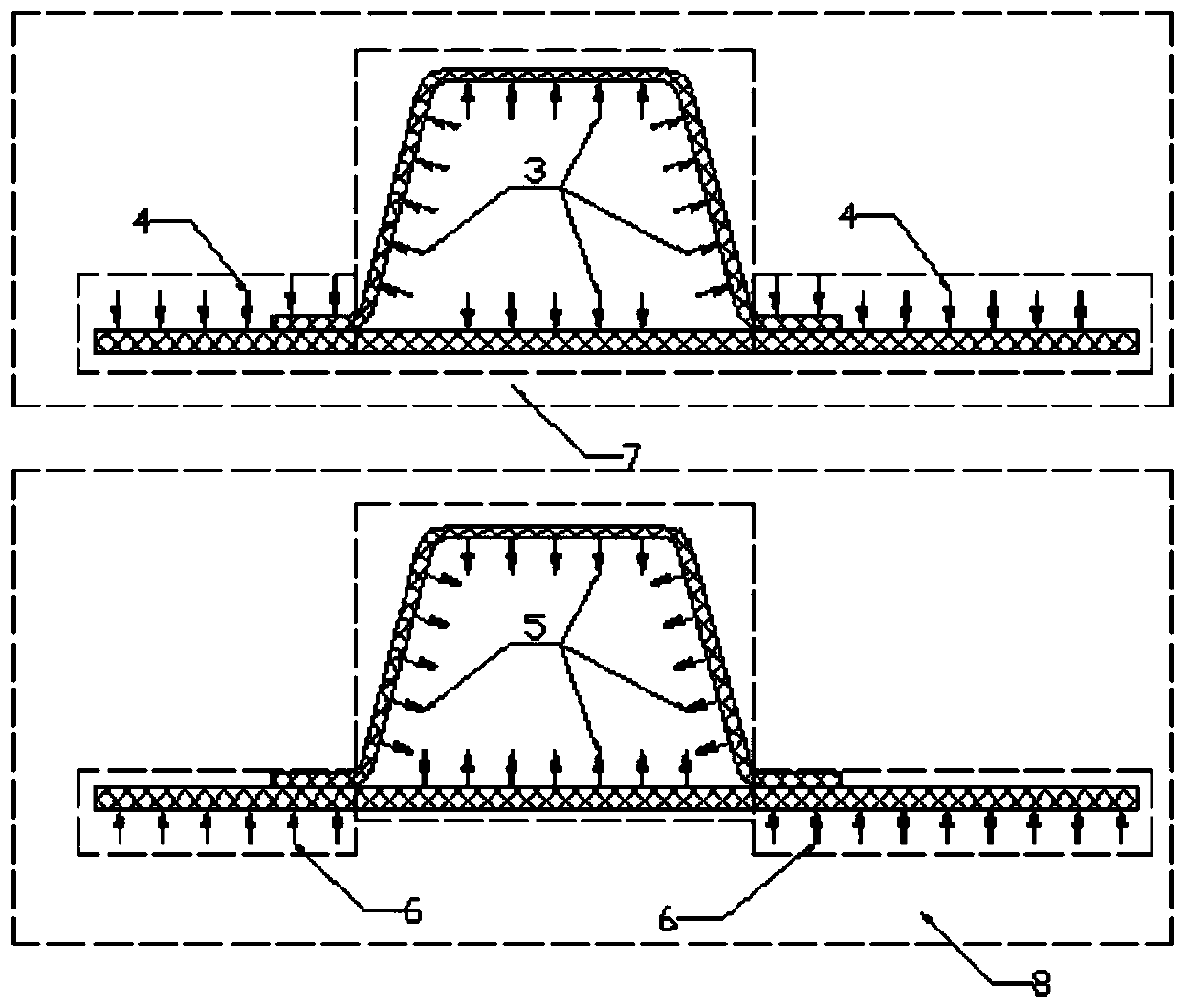

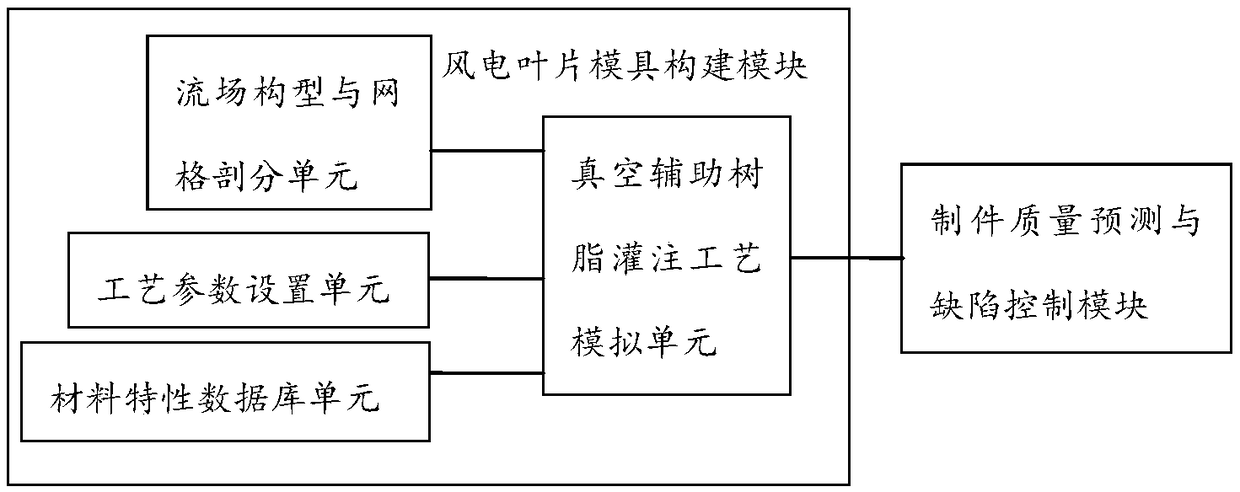

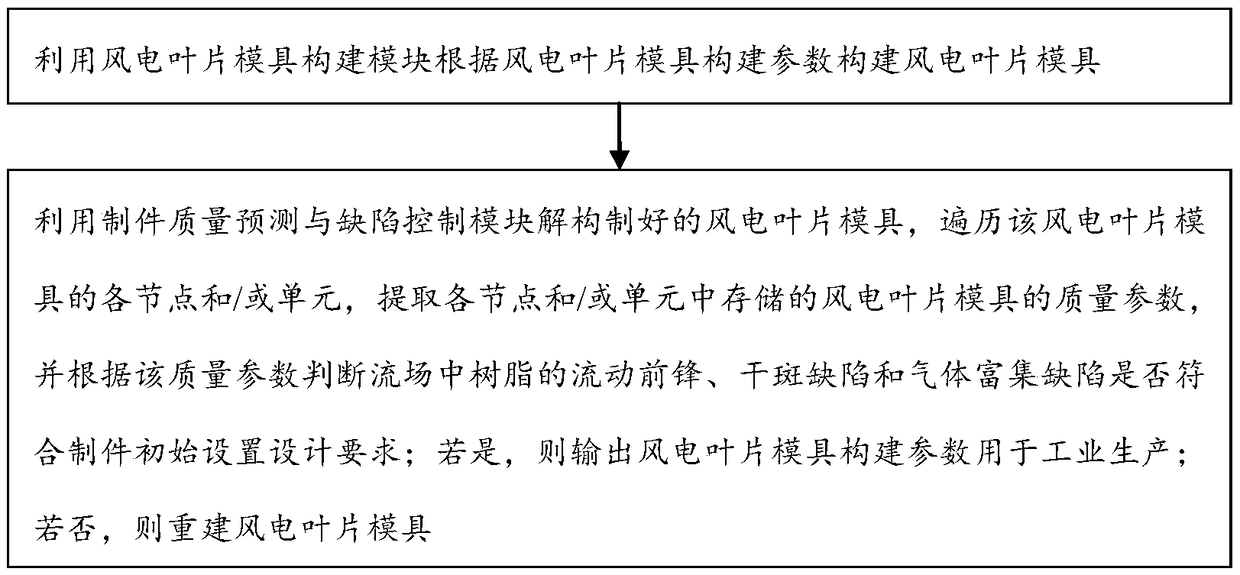

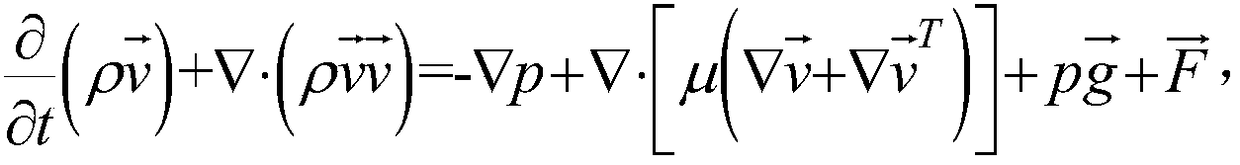

Simulation system and simulation method for simulating manufacturing process of wind turbine blade mold

ActiveCN109117512AReal-time adjustmentPredict Flow LawDesign optimisation/simulationSpecial data processing applicationsVacuum assistedTurbine blade

The invention relates to a simulation system and a simulation method for simulating a manufacturing process of a wind turbine blade mold. The system comprises a flow field configuration and a mesh splitting unit for receiving and storing input flow field configuration initial setting parameters. A process parameter setting unit for receiving and storing an input vacuum-assisted resin filling process initial setting parameter; a material property database unit for storing material data in the flow field; a vacuum-assisted resin injection process simulation unit for calculating quality parameters of a wind turbine blade mold; a part quality prediction and defect control unit used for judging whether the flow front, dry spot defect and gas enrichment defect of resin in the flow field conformto the requirements of the initial design of the product according to the calculation parameters, if not, optimizing and adjusting the initial parameters of the flow field configuration, the initial parameters of the vacuum-assisted resin pouring process and the data in the flow field. The system and the method of the invention can obtain the optimized parameters of the mould for producing the wind power blade.

Owner:北京玻钢院复合材料有限公司 +1

Immersed film type heat exchanger

ActiveCN104214995A"Film-forming" performance is goodGood film formingEvaporators/condensersPlate heat exchangerLithium bromide

The invention provides an immersed film type heat exchanger, and relates to the technical field of the exchanger. The problems that the traditional falling film type heat exchanger has high requirements on cloth liquid, easily generates dry spot phenomenon, and has high requirements on manufacturing and mounting are solved. The first scheme is that multiple heat exchanging units are sequentially arranged in a casing from top to bottom in an aligned way, and two adjacent heat exchanging units are arranged at the same direction; a slab joint type channel defined by an upper heat exchanging plate, a lower heat exchanging plate and two second baffle plate forms a second heat exchanging medium passage in the heat exchanging unit. The second scheme is that multiple heat exchanging units are sequentially arranged in the casing from top to bottom in an aligned way, and two adjacent heat exchanging units are arranged at the same direction; multiple heat exchanging pipes are tightly contacted and arranged in parallel to form a heat exchanging surface; the multiple heat exchanging pipes form the second heat exchanging medium passage in the heat exchanging unit. The immersed film type heat exchanger is used for an evaporator or an absorber in a lithium bromide refrigerating unit.

Owner:严格集团股份有限公司

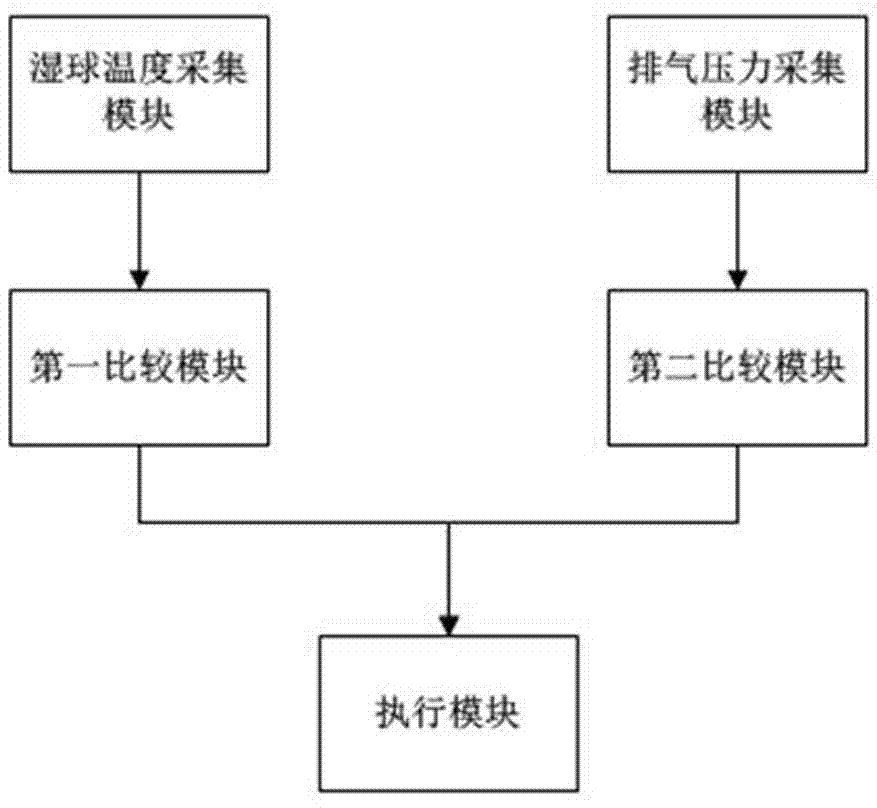

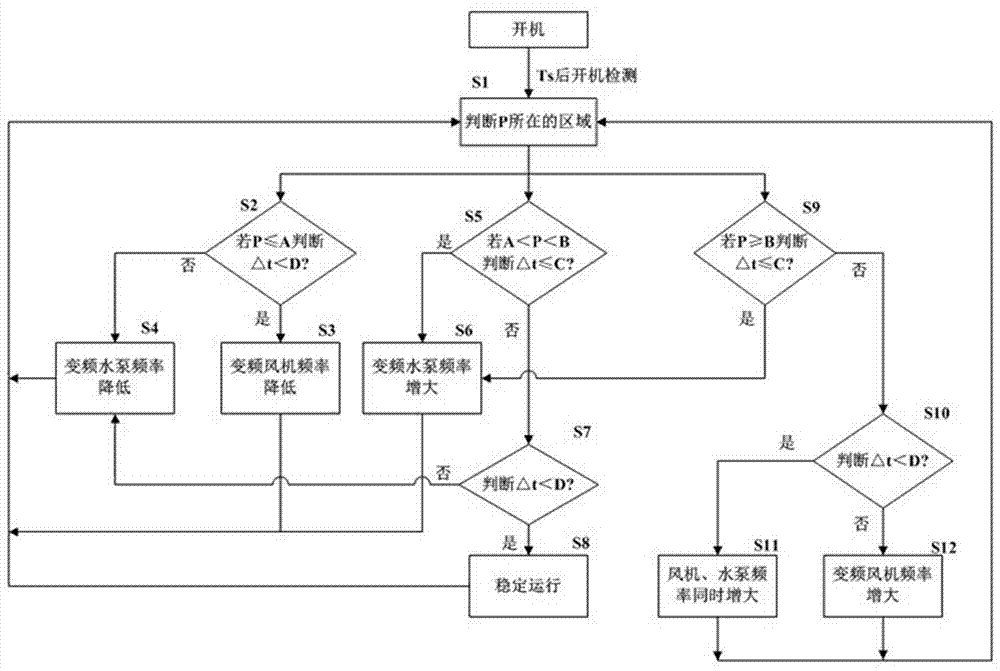

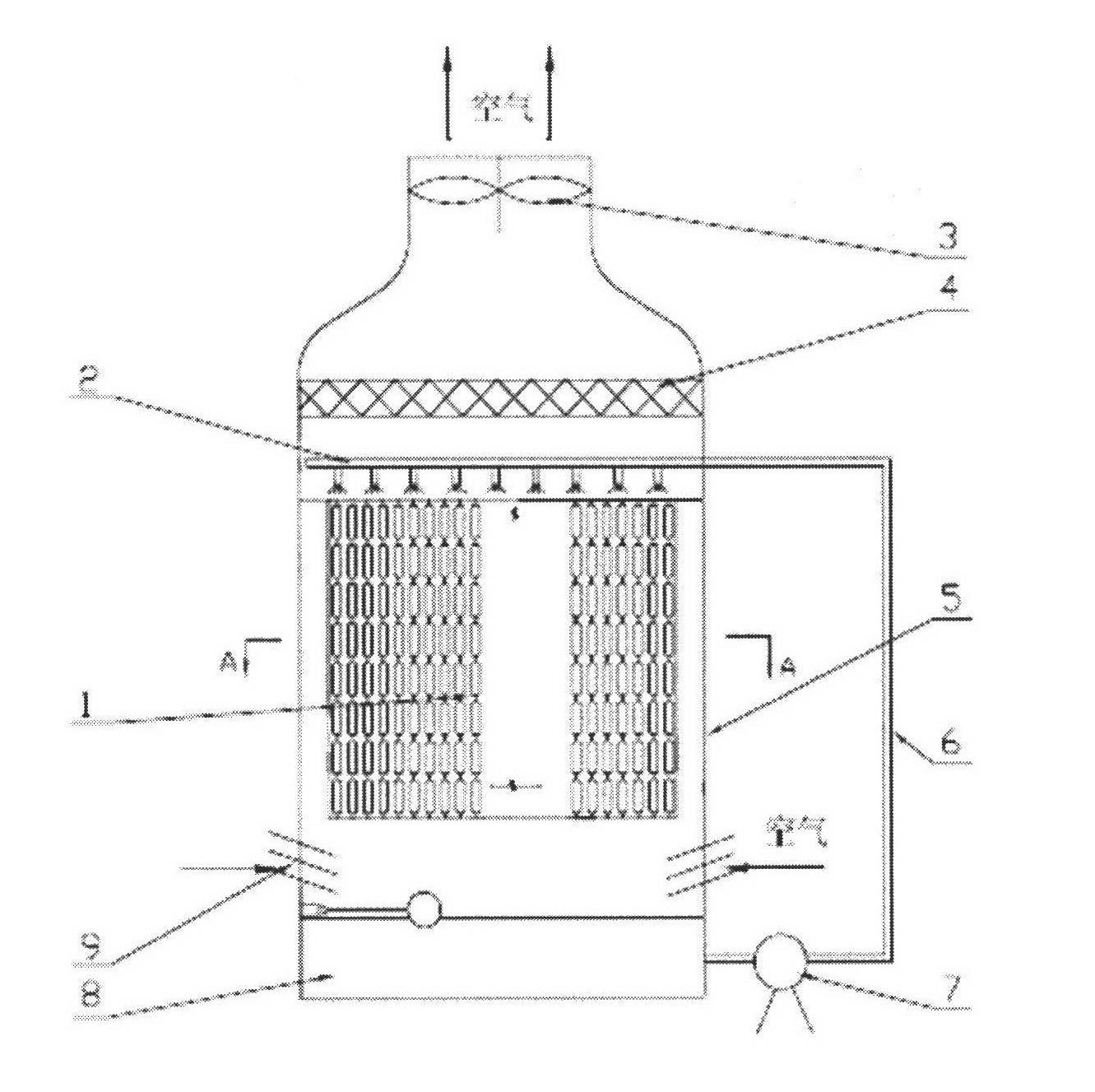

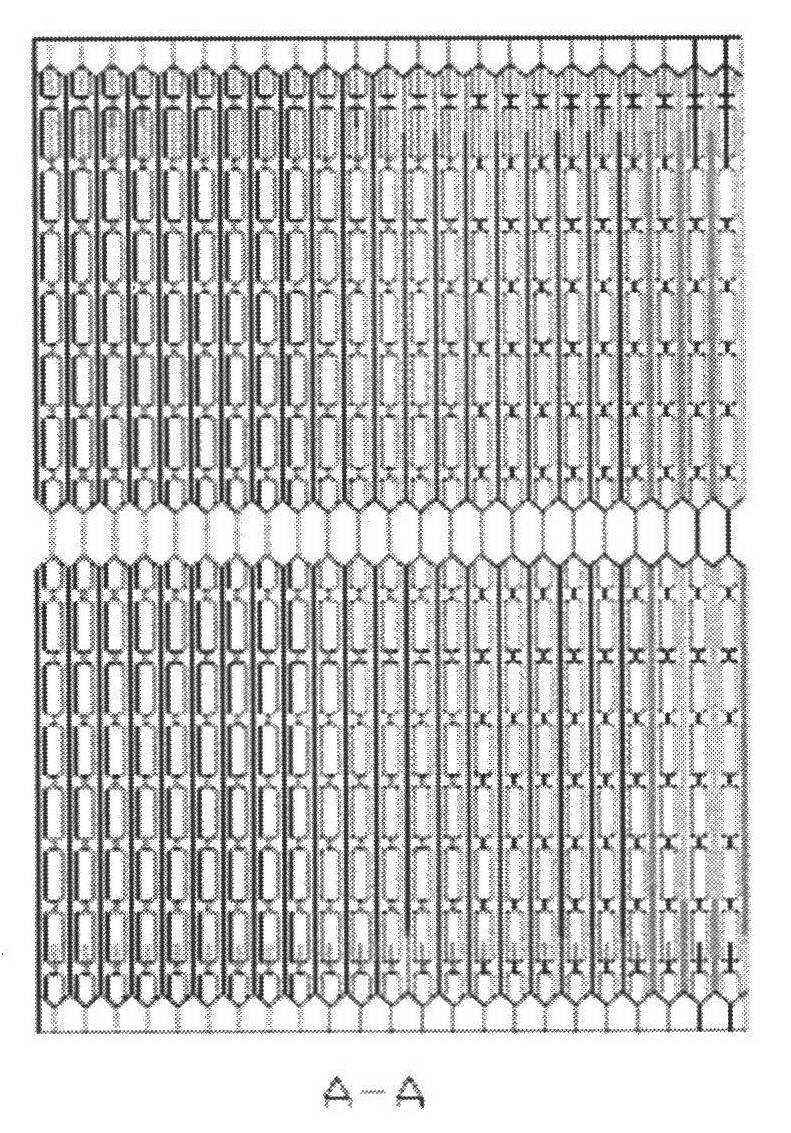

Evaporative cooling type water chilling unit as well as control method and control system thereof

ActiveCN108006919AAvoid high load operationGuaranteed comfortMechanical apparatusLighting and heating apparatusAir volumeWater volume

The invention discloses an evaporative cooling type water chilling unit as well as a control method and a control system thereof. The control method comprises steps as follows: detecting wet bulb temperature of inlet and outlet air of a condenser and exhaust pressure of a compressor, and controlling frequency of a variable-frequency fan and a variable-frequency water pump according to range of theexhaust pressure and wet bulb temperature value of the inlet and outlet air of the condenser. According to the invention, optimal energy efficiency of the compressor of the unit in a normal operatingrange can be guaranteed, and water waste is reduced; by means of control for water volume and air volume supply, the dry spot phenomenon on the surface of the heat exchanger is reduced, unstable operation state produced by high-voltage protection is reduced, and reliability of the unit after operation is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Nano-coating for unsaturated evaporation heat transfer surface

InactiveCN102492322AReduce tension differencesReduce thicknessAnti-corrosive paintsHeat transfer modificationCoated surfaceEvaporation heat transfer

The invention discloses a nano-coating for an unsaturated evaporation heat transfer surface. An anti-corrosion layer and a hydrophilic layer can be coated on the heat transfer surface in sequence; a heat transfer layer can be coated between the anti-corrosion layer and the hydrophilic layer; the coated heat transfer surface is irradiated with ultraviolet light for one hour, so that a contact angle between a coated surface and a water film is reduced to 0-5 degrees; the coating thickness of the anti-corrosive layer is 2-15 nanometers; the coating thickness of the hydrophilic layer is 8-35 nanometers; and ultraviolet light is used for irradiating intermittently every 2-3 days, so that the hydrophilicity of the coated surface is kept. The material characteristic of a heat exchange surface is improved, so that a spreading area on the heat transfer surface under the unit water amount of the water film is increased, distribution is more uniform, the phenomenon of 'dry spot' is avoided effectively, the scaling phenomenon of the heat transfer surface is delayed, heat and mass transfer coefficients between water and air are increased, and heat exchange performance is enhanced.

Owner:EAST CHINA UNIV OF SCI & TECH

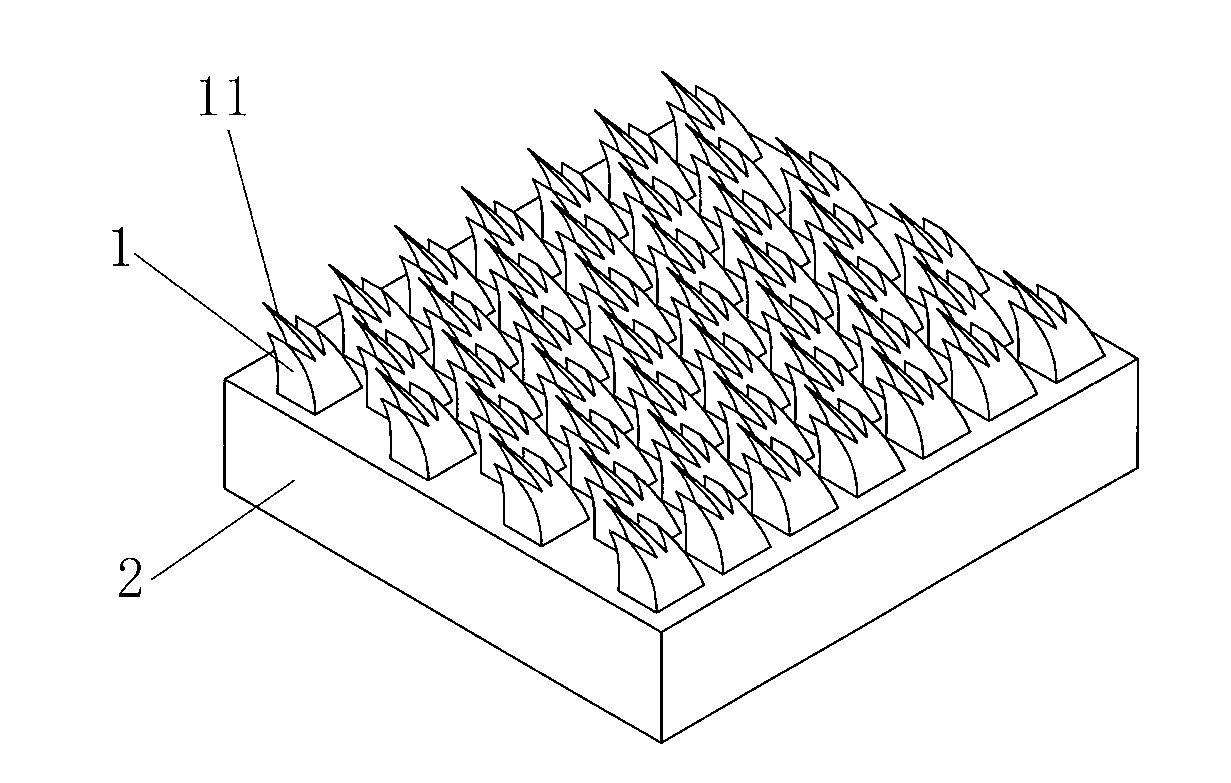

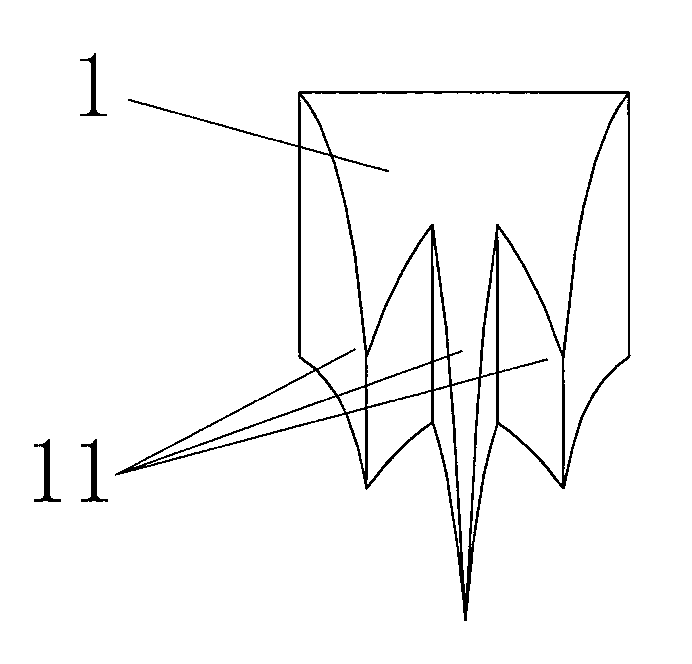

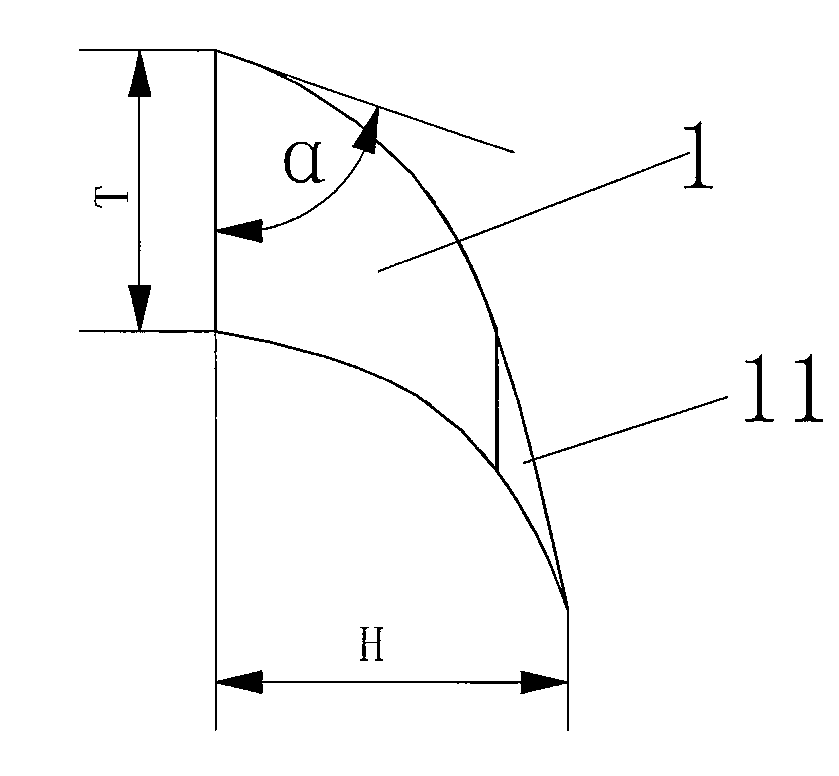

Bionic surface structure for strengthening evaporation heat exchanging of liquid film

InactiveCN103017593ASpread evenlyPrevent dry spotsHeat transfer modificationEvaporation heat transferEvaporation

The invention discloses a bionic surface structure for strengthening evaporation heat exchanging of a liquid film, which is characterized in that three-dimensional bionic zigzag unit bodies are distributed on the surface of a substrate of a heat transferring pipe or a heat transferring plate, and the structural size of each three-dimensional bionic zigzag unit body is nanometer grade or millimeter grade; the three-dimensional bionic zigzag unit bodies are obliquely arranged, the inclined direction of the three-dimensional bionic zigzag unit bodies is consistent with the flowing direction of the liquid film, and the inclined three-dimensional bionic zigzag unit bodies are mutually lapped with one another; a sharp part of each three-dimensional bionic zigzag unit body is provided with three micro-sized micro zigzag structures, and the three micro-sized micro zigzag structures are arranged in a manner that two lower micro zigzag structures are arranged on two ends and one higher micro zigzag structure is arranged in the middle, and the heights of the two lower micro zigzag structures are identical to each other; the three-dimensional bionic zigzag unit bodies are distributed in a rhombic shape or a rectangular shape; the three-dimensional bionic zigzag unit bodies are mutually lapped with one another, so that the liquid film can be uniformly spread, and dry spots or dry points can be prevented from appearing on the surface; and the zigzag structure surface can control the flowing direction of the liquid film, so that the thickness of the liquid film is reduced, the heat transferring resistance can be effectively reduced, and the evaporation heat transferring efficiency of the liquid film is increased.

Owner:JILIN UNIV

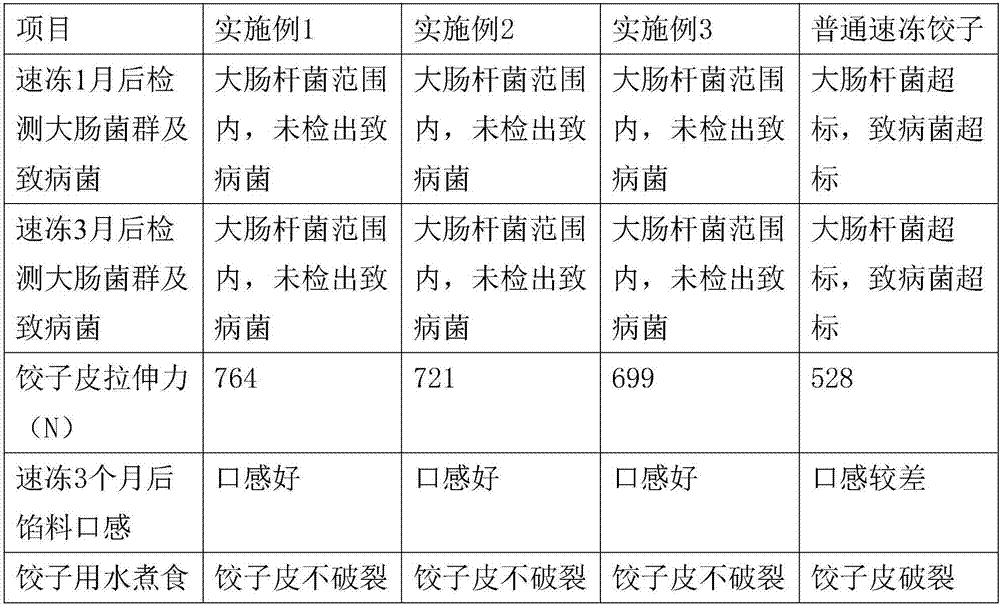

Improved method of fruit, vegetable and beef type quick-frozen dumpling

Owner:ANHUI HONGYUN FOOD

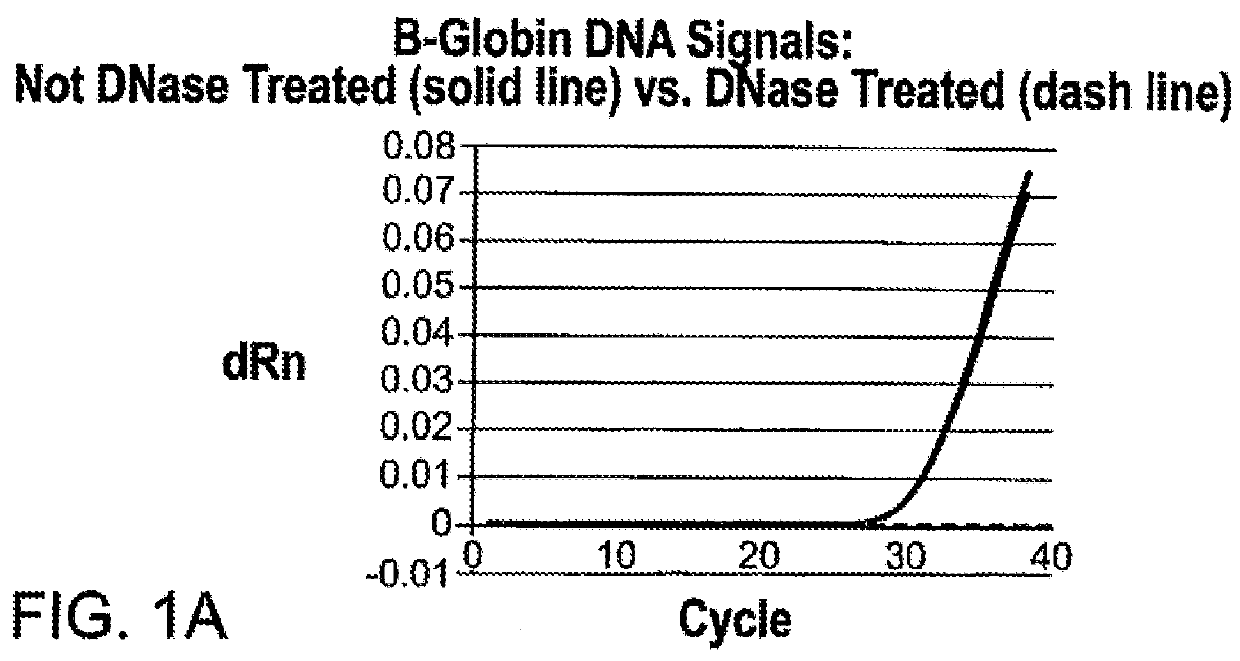

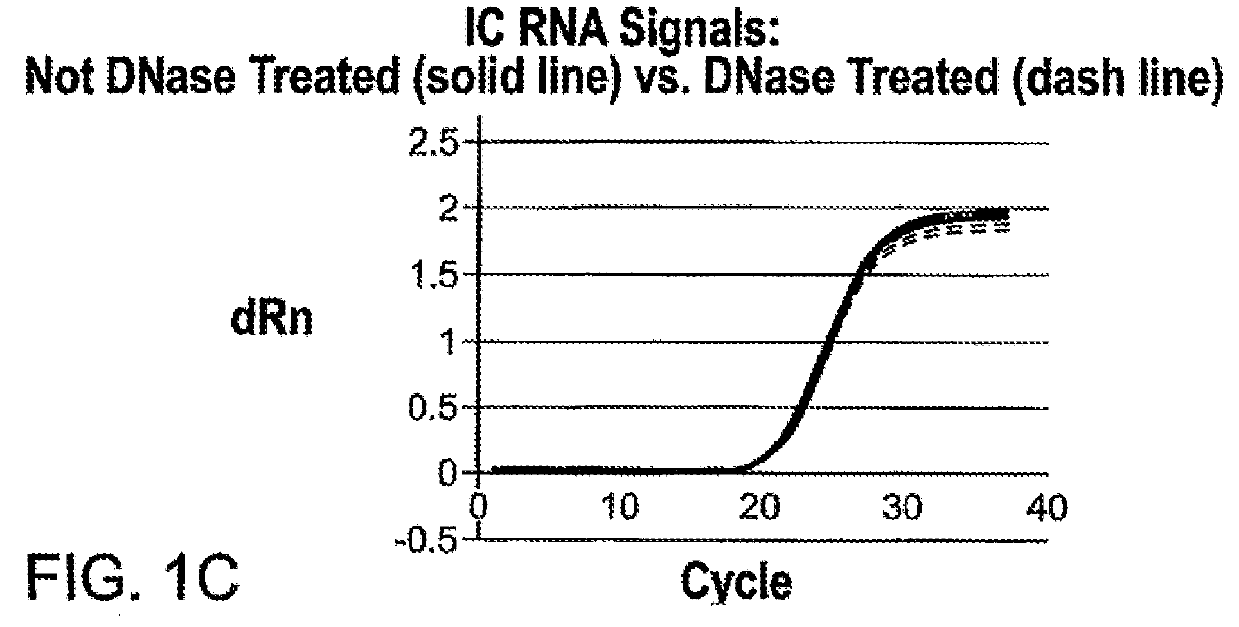

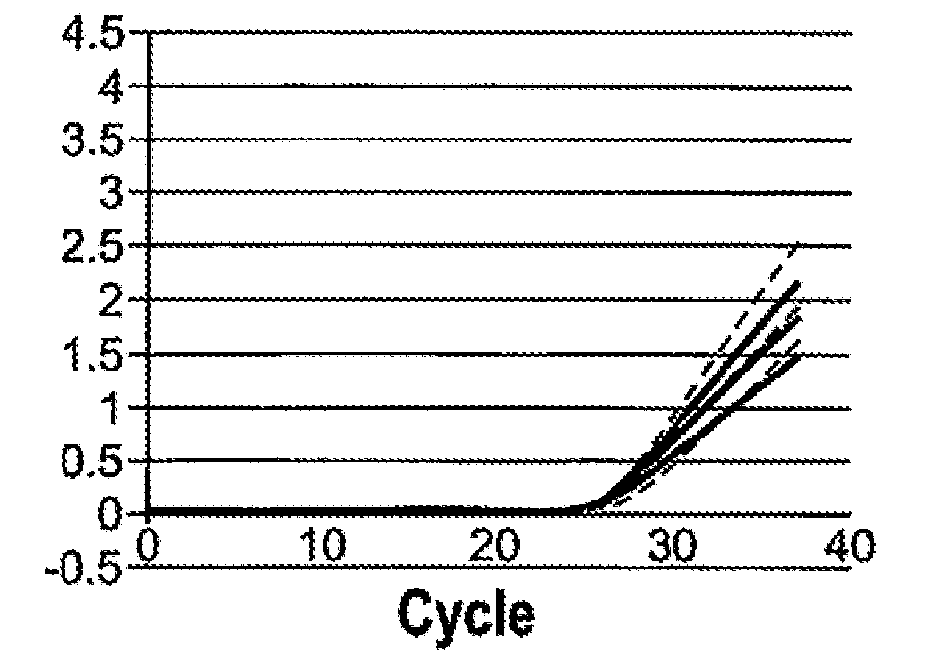

Automated hiv-1 viral load testing procedure for dried spots

ActiveUS20160053334A1Efficient degradationMicrobiological testing/measurementMaterial analysisDried Blood Spot TestingDry spot

The present invention provides novel and non-obvious improvements to dried blood spot testing for HIV-1 viral load useful for diagnosis and monitoring treatment progression.

Owner:ABBOTT MOLECULAR INC

Resin flow control method for RFI integral forming of cap type reinforced rib wallboard

InactiveCN111152479AShorten the timeImprove molding efficiencyResin-Based CompositeMechanical engineering

The invention belongs to the technical field of low cost manufacturing of high performance resin-based composite materials, and relates to a resin flow control method for RFI integral forming of a captype reinforced rib wallboard. In a conventional RFI process, a resin is divided at the root part of a cap type reinforced rib and flows to the cap top along layers between two sides of the cap typereinforced rib to generate dry spots at the cap top and the cap bottom, so that a part is scraped. By considering the structural characteristic of the cap type reinforced rib wallboard and the flowingcharacteristic of the resin in the RFI process, the cap type reinforced rib wallboard is decomposed into two structural units: an annular structure and a plate shaped structure, and a resin flow model suitable for resin flow control of the annular structure and the plate shaped structure simultaneously is established to form a resin flow model for RFI integral forming of the cap type reinforced rib wallboard. The resin is guided to flow in the RFI process course by paving the resin and arranging a gas circuit according to the established resin flow model, so that a preformed body of the cap type reinforced rib wallboard is infiltrated fully.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

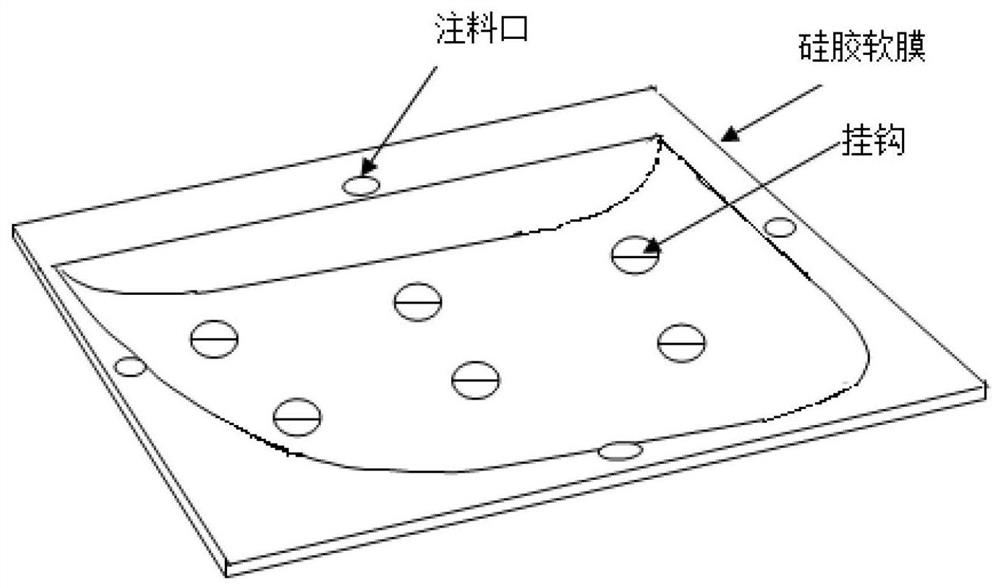

Forming method for thermosetting polymer fiber composite workpiece

The invention relates to a forming method for a thermosetting polymer fiber composite workpiece. The method comprises the following steps that a metal mold and a rubber soft mold are manufactured; a plurality of hooks are bonded to the front face of the rubber soft mold; supports capable of being automatically lifted are arranged at the periphery of a metal female mold; plurality of cross beams are arranged on the supports; ropes are fixed to the cross beams and used for being connected to hooks on the rubber soft mold; multiple pieces of fabrics are laid according to different directions andmove in the female mold as a whole, the rubber soft mold covers the fabrics, the peripheral flanges are tightly fixed to a plane around the female mold, and a polymer material is rapidly injected andcompacted, so that the material is completely infiltrated into the fiber fabric, the polymer material is heated to react until the polymer material is completely cured, and the workpiece is taken out.According to the method, the rapid injection of the polymer material and the uniform distribution and good infiltration of feed liquid are guaranteed, the flow state of the material can be directly observed, and the defects such as bubbles or dry spots and the like can be effectively prevented; and the method does not need a huge mold closing device, so that the investment and production costs are reduced, the efficiency is high, and the energy consumption is low.

Owner:长春三友智造科技发展有限公司

Novel synthetic hydrophobic sand formulation

Owner:MILLIKEN & CO

Gun water recycling device

ActiveCN104043612BImprove efficiencyLow costCleaning using liquidsFiltration circuitsFiltrationEngineering

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

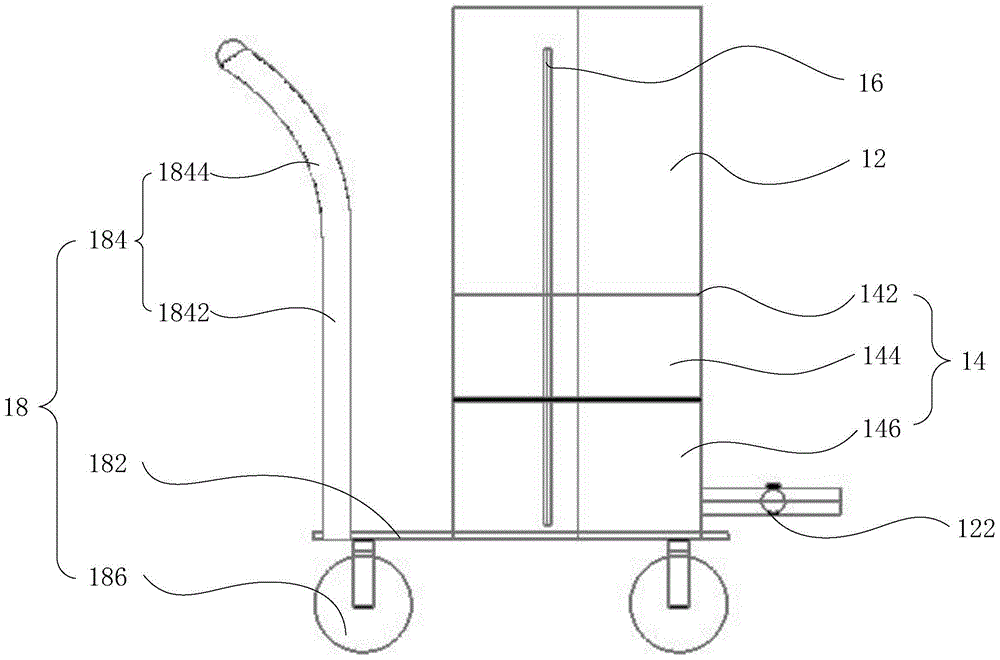

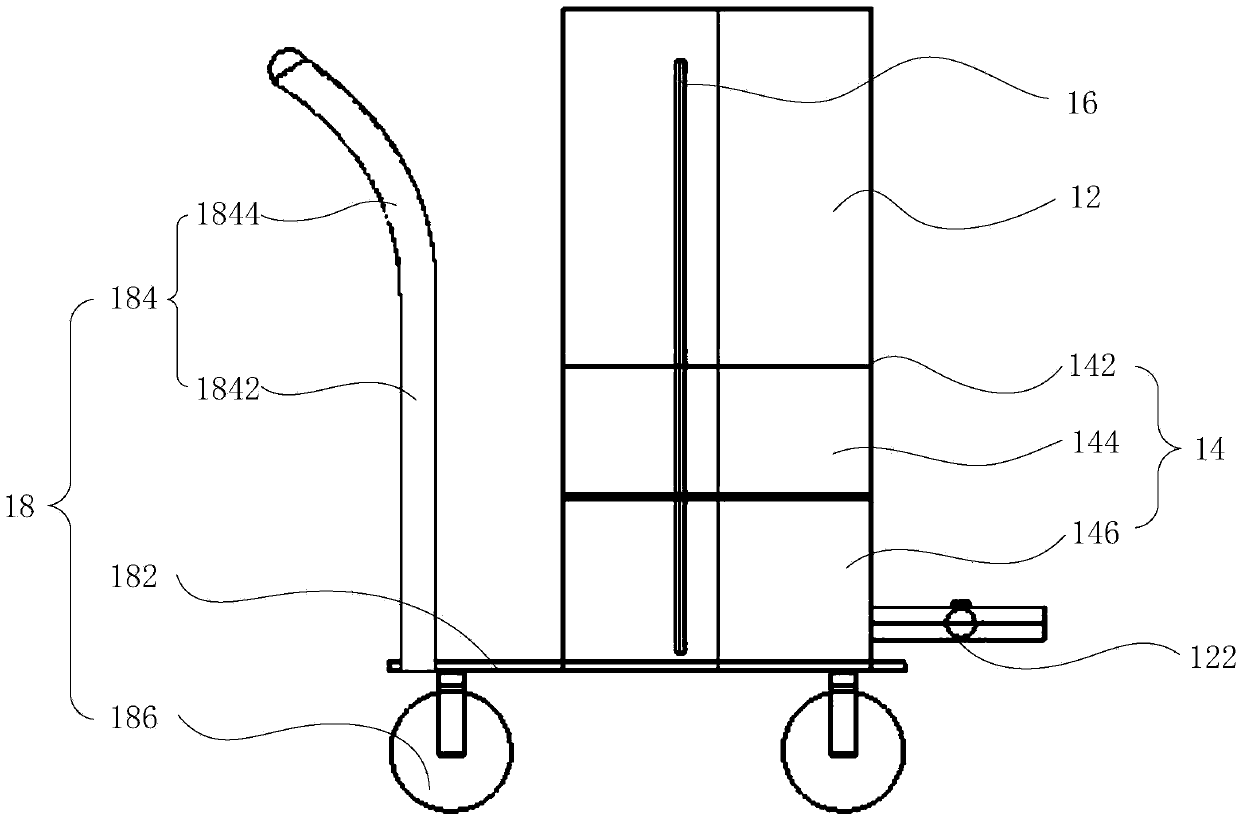

Dry spot lifter recycling device

ActiveCN104043612AImprove efficiencyLow costCleaning using liquidsFiltration circuitsFiltrationEngineering

The invention discloses a dry spot lifter recycling device. The dry spot lifter recycling device comprises a dry spot lifter container and a filter, wherein the dry spot lifter container is of the structure of a hollow barrel, the filter is contained in the dry spot lifter container, and comprises a fine filtration portion, a coarse filtration portion and a filter screen, and the fine filtration portion, the coarse filtration portion and the filter screen are arranged in a stacked mode from the bottom of the dry spot lifter container to the top of the dry spot lifter container. According to the dry spot lifter recycling device, the dry spot lifter is filtered through the filter screen, the coarse filtration portion and the fine filtration portion, accessory impurities mixed in dry spot dryer are separated and filtered so that the dry spot filter can be recycled, use efficiency of the dry spot lifter is improved, the cost is reduced, and the environment is protected.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

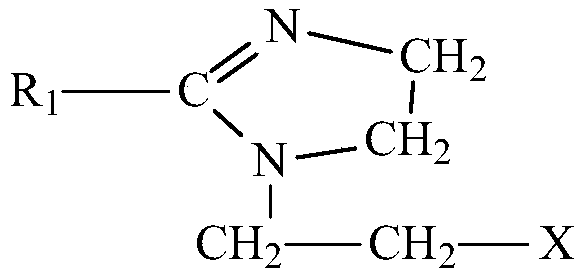

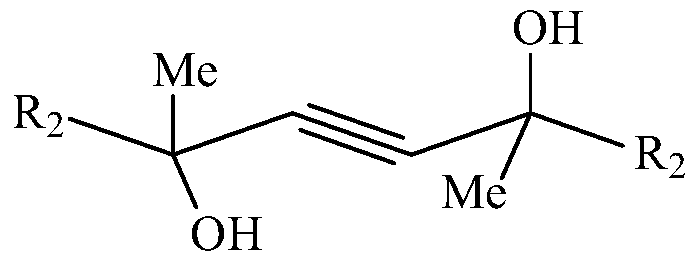

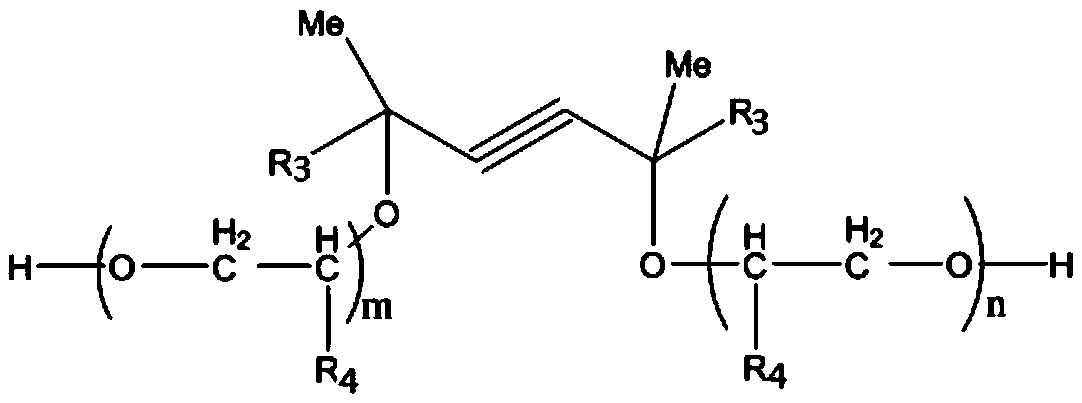

Dry-spot-preventing additive, preparation method and application thereof to waterborne cathodic electrophoretic paint

PendingCN109868000AImprove liquiditySpread evenlyPaints for electrolytic applicationsAcetyleneDry spot

The invention discloses a dry-spot-preventing additive, comprising 10-50 parts by weight of alkyl imidazoline, 10-50 parts by weight of acetylenic glycol compound, 10-50 parts by weight of acetylene glycol polyoxyethylene ether, 0-30 parts by weight of organosilicon polyoxyethylene ether and 0-30 parts by weight of alkanolamide compound. The additive is used in commercially available cathodic electrophoretic paint to avoid generation of dry spots.

Owner:TIANJIN WATONG CHEM PROD CO LTD

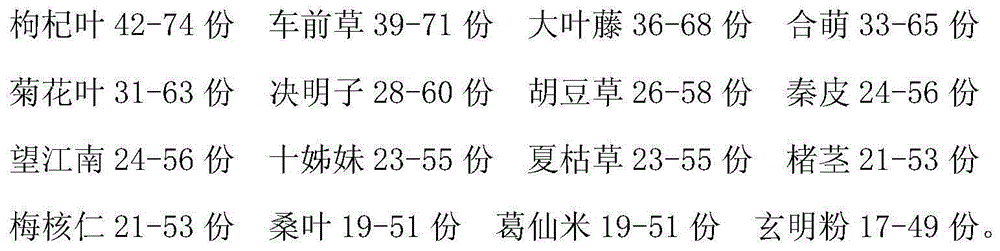

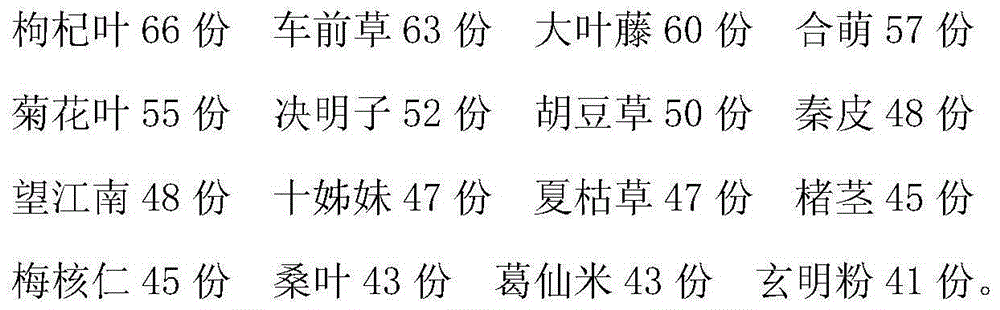

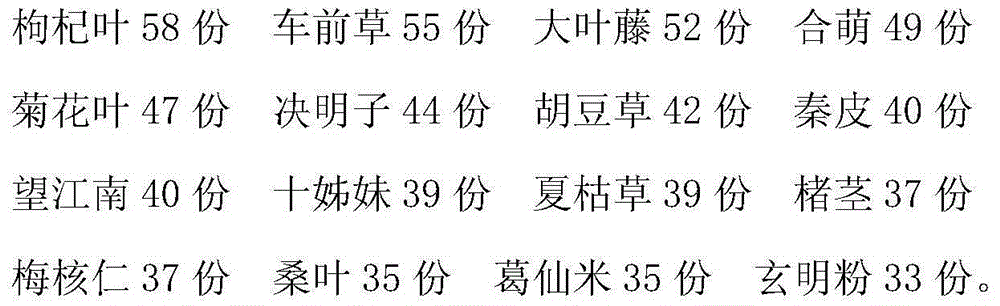

Traditional Chinese medicine preparation for treating dry eye disease and preparation method

InactiveCN105012525AQuick resultsHigh cure rateSenses disorderSulfur/selenium/tellurium inorganic active ingredientsDiseaseSide effect

The invention discloses a traditional Chinese medicine preparation for treating a dry eye disease and a preparation method, and belongs to the field of traditional Chinese medicines. The traditional Chinese medicine preparation is composed of the effective components of lycium barbarum leaves, plantain herbs, tonkin tinomiscium stems, common aeschynomene herbs, chrysanthemum leaves, cassia seeds, herbs of sessile skullcap, ash bark, coffee senna seeds, Japanese roses, selfheal, paper mulberry stems, seeds of Japanese apricot, mulberry leaves, Nostoc sphaeroides and mirabilitum dehydratum. According to the traditional Chinese medicine preparation for treating the dry eye disease, the medicine preparation is appropriate, the medicines are complemented with one another, the efficacy of clearing heat, brightening the eyes, dispelling wind and heat, relieving swellings and pains of the eyes, soothing the liver, benefiting the gallbladder, dispelling pathogenic wind for improving eyesight, dispersing blood stasis, stopping the pains and the like is achieved, the medicines are compatible and directly reach diseased regions, the traditional Chinese medicine preparation can treat the symptoms of glassy eyes, the eye-burn feeling, dry eyes, dry spots of corneas, swollen eyes, cracked and chapped skins, dryness and swollen with sore of eyes, fatiguability and the like caused by the dry eye disease, the traditional Chinese medicine preparation for treating the dry eye disease has the advantages of being rapid in efficacy, high in cure rate, free of toxic and side effects, safe, convenient, low in cost and easy to prepare.

Owner:刘雪梅

A soaked film heat exchanger

ActiveCN104214995B"Film-forming" performance is goodGood film formingEvaporators/condensersPlate heat exchangerLithium bromide

The invention provides an immersed film type heat exchanger, and relates to the technical field of the exchanger. The problems that the traditional falling film type heat exchanger has high requirements on cloth liquid, easily generates dry spot phenomenon, and has high requirements on manufacturing and mounting are solved. The first scheme is that multiple heat exchanging units are sequentially arranged in a casing from top to bottom in an aligned way, and two adjacent heat exchanging units are arranged at the same direction; a slab joint type channel defined by an upper heat exchanging plate, a lower heat exchanging plate and two second baffle plate forms a second heat exchanging medium passage in the heat exchanging unit. The second scheme is that multiple heat exchanging units are sequentially arranged in the casing from top to bottom in an aligned way, and two adjacent heat exchanging units are arranged at the same direction; multiple heat exchanging pipes are tightly contacted and arranged in parallel to form a heat exchanging surface; the multiple heat exchanging pipes form the second heat exchanging medium passage in the heat exchanging unit. The immersed film type heat exchanger is used for an evaporator or an absorber in a lithium bromide refrigerating unit.

Owner:严格集团股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com