Simulation system and simulation method for simulating manufacturing process of wind turbine blade mold

A technology for manufacturing wind turbine blades and molds, which is applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

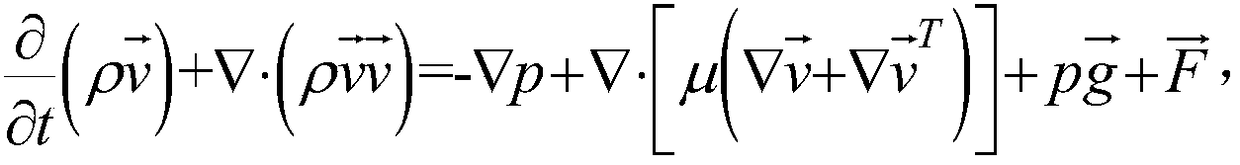

Method used

Image

Examples

Embodiment 1

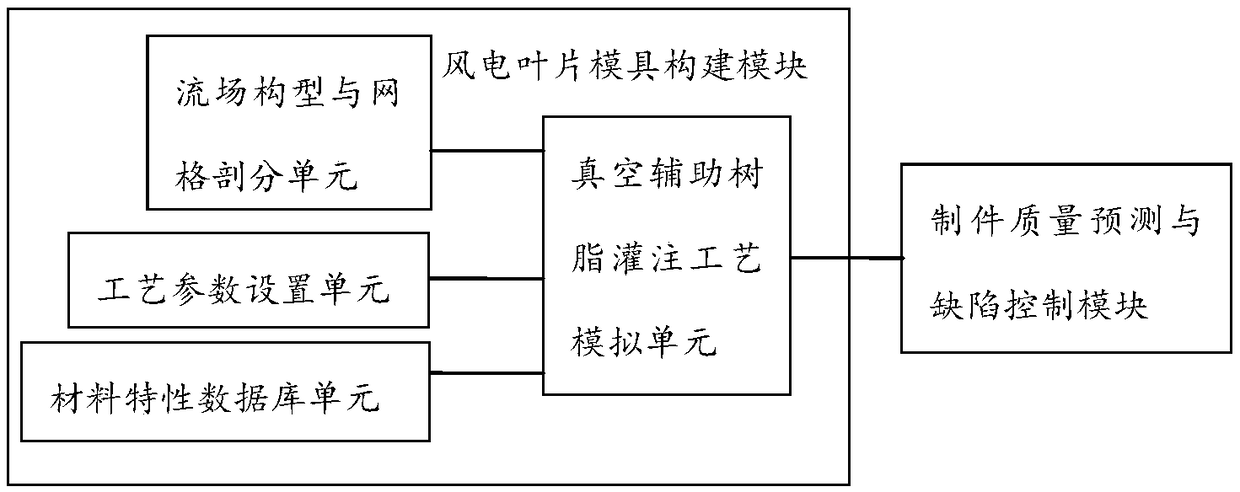

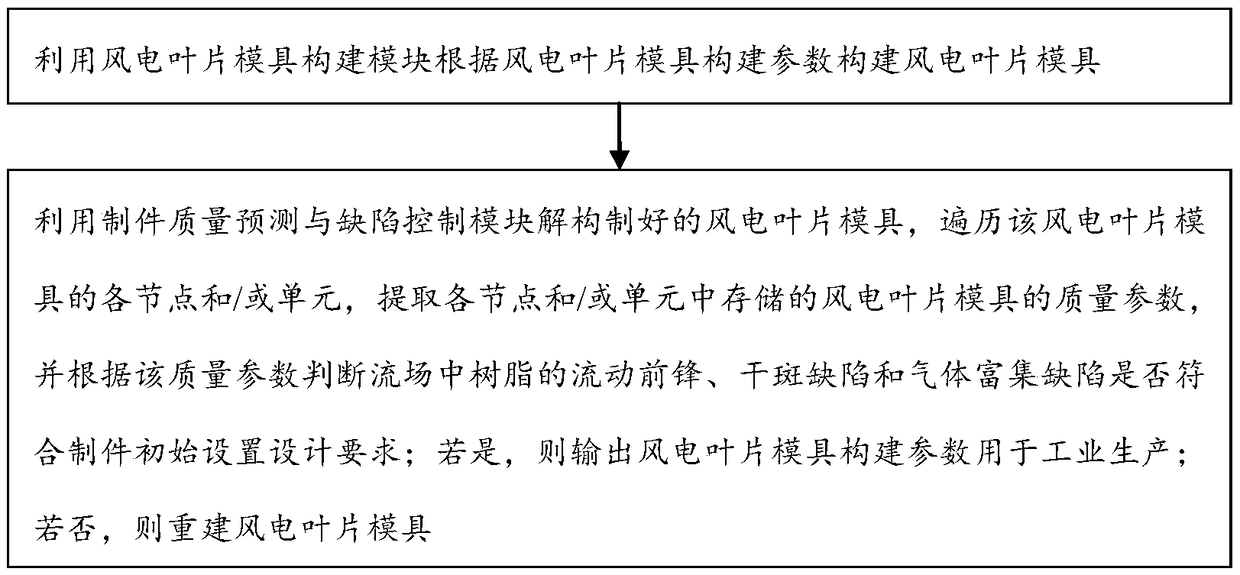

[0063] figure 1 It is a block diagram schematic diagram of a simulation system for simulating the manufacturing process of a wind blade mold of the present invention, as figure 1 As shown, the simulation system provided by the present invention for simulating the manufacturing process of wind power blade molds is a digital system that uses computers to predict resin flow and entrained gas enrichment in the vacuum-assisted resin infusion process, and realize defect control on this basis , including: a wind power blade mold building module, which is used to build a wind power blade mold according to the wind power blade mold construction parameters;

[0064] The product quality prediction and defect control module is used to deconstruct the manufactured wind power blade mold, traverse each node and / or unit of the wind power blade mold, extract the quality parameters of the wind power blade mold stored in each node and / or unit, and According to this quality parameter, it is judg...

Embodiment 2

[0106] This example is a simulation of the entrained air enrichment process and control of pore defects in a typical vacuum-assisted resin infusion process, the details are as follows:

[0107] Step 1: Pick a typical 3D component of the vacuum-assisted resin infusion process in the flow field configuration and meshing unit.

[0108] Graphical software can create a two-dimensional cross-sectional diagram of the flow field for easy observation. The software can obtain the flow field model with grids, and there will be a color 3D picture displayed on the display screen, and the flow field model with grids will be displayed. Save as a data file, that is to say, cut the 3D component, that is, the 3D flow field, into a 3D flow field composed of a limited number of grids, so that the data in each grid can be traversed later, and the 3D flow field with grids can be stored It is a flow field model for calculation and retrieval;

[0109] Step 2: Extract the process initial setting para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com