Method for fully stirring water and material of sprayed concrete

A technology of shotcrete and concrete, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of reducing the strength of shotcrete, harming the health of workers, polluting underground air and working environment, and improving the air and working environment. , improve strength and work efficiency, and prevent dry spots from being dense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

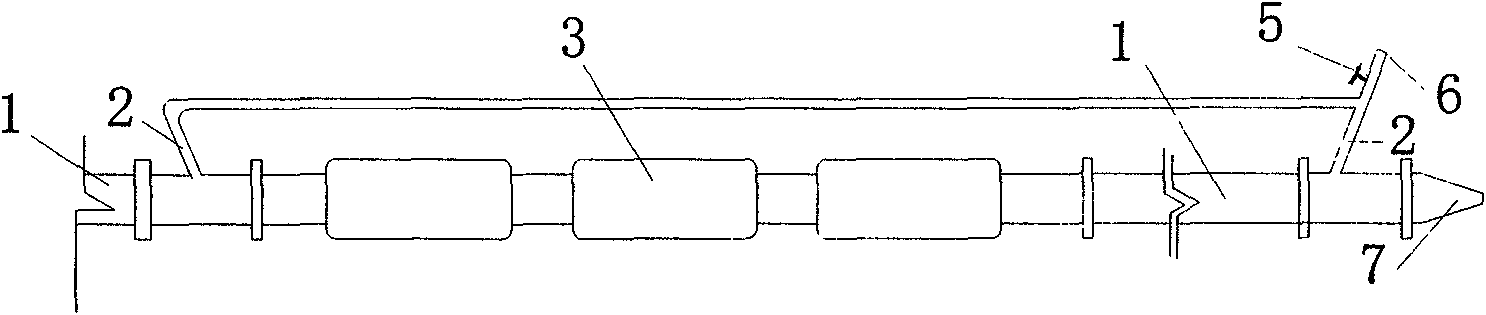

[0013] As shown in the accompanying drawings, the humidifying device used in the present invention is: a two-way water ring 2 with two water inlets and a three-section different-diameter pipe 3 with an inner diameter larger than the inner diameter of the feeding pipe are arranged on the feeding pipe 1 near the nozzle 7, and the two-way The water inlets at both ends of the water ring are inclined inwardly and communicate with the inner cavity of the feed pipe, and the reducer 3 is installed on the feed pipe section between the water inlets at both ends of the two-way water ring. Water is supplied to the two-way water ring from the water supply pipe 6, and a regulating water valve 5 is arranged on it.

[0014] It is used in the construction process of anchor shotcrete roadway in Kongzhuang Coal Mine of Shanghai Datun Energy Co., Ltd. The specific method is:

[0015] Part of the mixing water is added to the pre-feeding, and the amount of mixing water can be adjusted appropriatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com