Flue-cured tobacco cup containing matrix seed direct sowing culture method and paper cup direct sowing carrier

A cultivation method and paper cup technology, which are applied in the field of live-direct cultivation of flue-cured tobacco cup-packed substrate seeds, can solve the problems of reduced tobacco quality, low emergence rate of tobacco seedlings, and reduced yield, and achieve improved success rate, good market prospects, economic benefits, and reduced tobacco consumption. The effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiment, the technical scheme of the present invention is the implementation steps as follows:

[0024] (1) Choose a tobacco field with a soil layer depth of more than 30cm and a gentle terrain, and plough deeply before raising the ridge. The depth of the plough layer is more than 15cm. After plowing, raked the soil evenly to remove the sundries in the tobacco field.

[0025] (2) Once the climatic conditions are ideal, ridges should be raised. Before raising the ridges, the flue-cured tobacco base fertilizer should be applied according to the required amount of high-quality tobacco leaves. The ridges should be as large as possible, with a ridge width of at least 60 cm and a ridge height of 25-30 cm. During the rainy season, the root system is well drained and provides an ideal rooting zone.

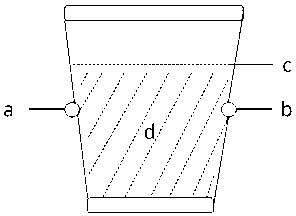

[0026] (3) Punch holes on the raised ridge body according to the plant spacing of high-quality tobacco leaves. The size of the hole is required to fit the cup with the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com