Method capable of reducing the surface defects of fiber reinforced thermoplastic composite products

A composite material and fiber-reinforced technology, which is applied in the field of reducing surface defects of fiber-reinforced thermoplastic composite materials and fiber-reinforced thermoplastic composite materials, can solve problems such as easy high-temperature oxidation, high viscosity, and poor fluidity, so as to reduce the effect and improve the qualified rate , The effect of speeding up the batch industrial production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

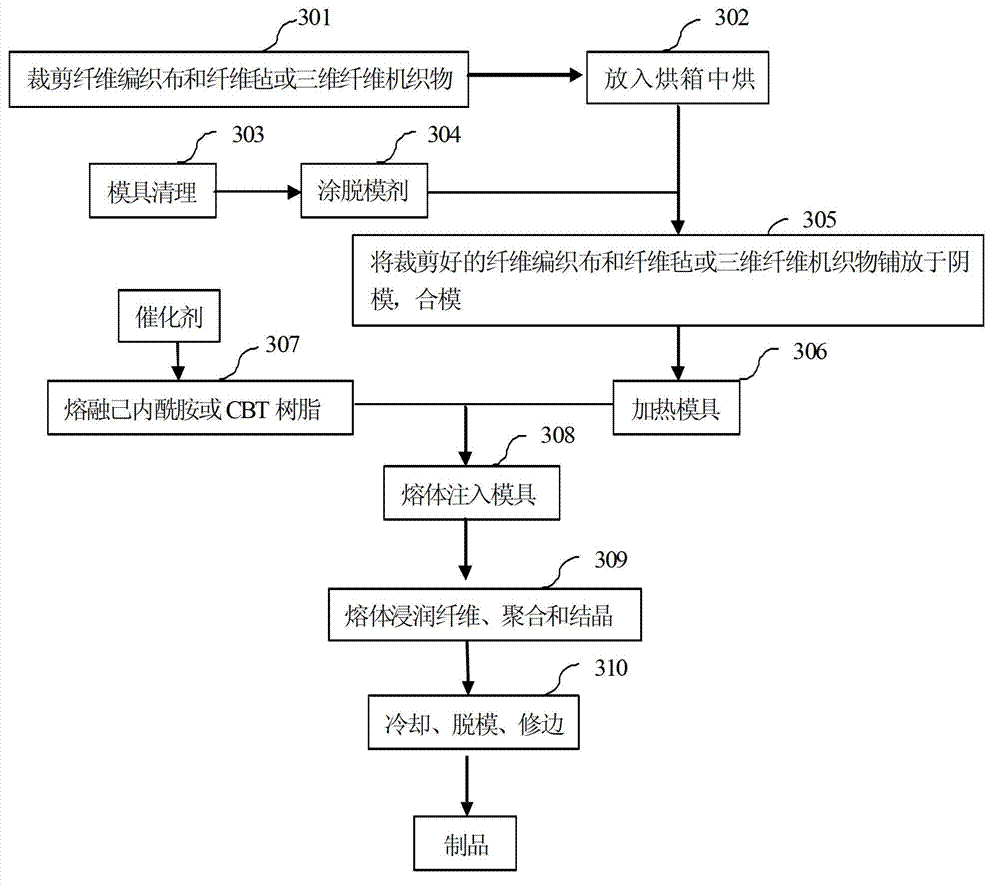

[0073] The implementation steps of the present embodiment method are as follows:

[0074] 1. Cut the fiberglass plain weave and fiberglass mat according to the size of the car floor mold.

[0075] 2. Put the cut glass fiber plain weave cloth and glass fiber felt in an oven for 3 hours at 120°C.

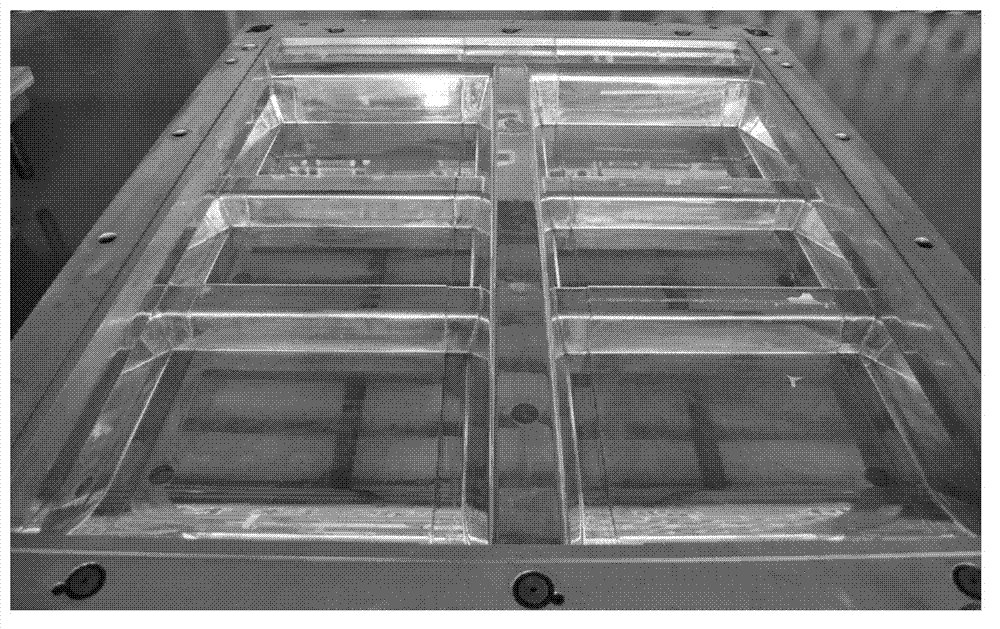

[0076] 3. Will be as image 3 The surface of the automobile floor mold shown is cleaned and polished smoothly, and the mold release agent is evenly coated on the surface of the mold.

[0077] 4. Lay the cut 6 layers of glass fiber plain weave cloth (referred to as cloth) and 8 layers of glass fiber felt (referred to as mat) in the female mold in the following stacking manner from top to bottom: cloth / felt / cloth / felt / felt / cloth / felt / felt / cloth / felt / felt / cloth / felt / cloth, and as shown in Table 1 below, the unit area grammage of the laminate formed after the lamination of the plain weave cloth and the fiber felt is 4000 ( g / m 2 ).

[0078] 5. Close the female and male molds.

[00...

Embodiment 2

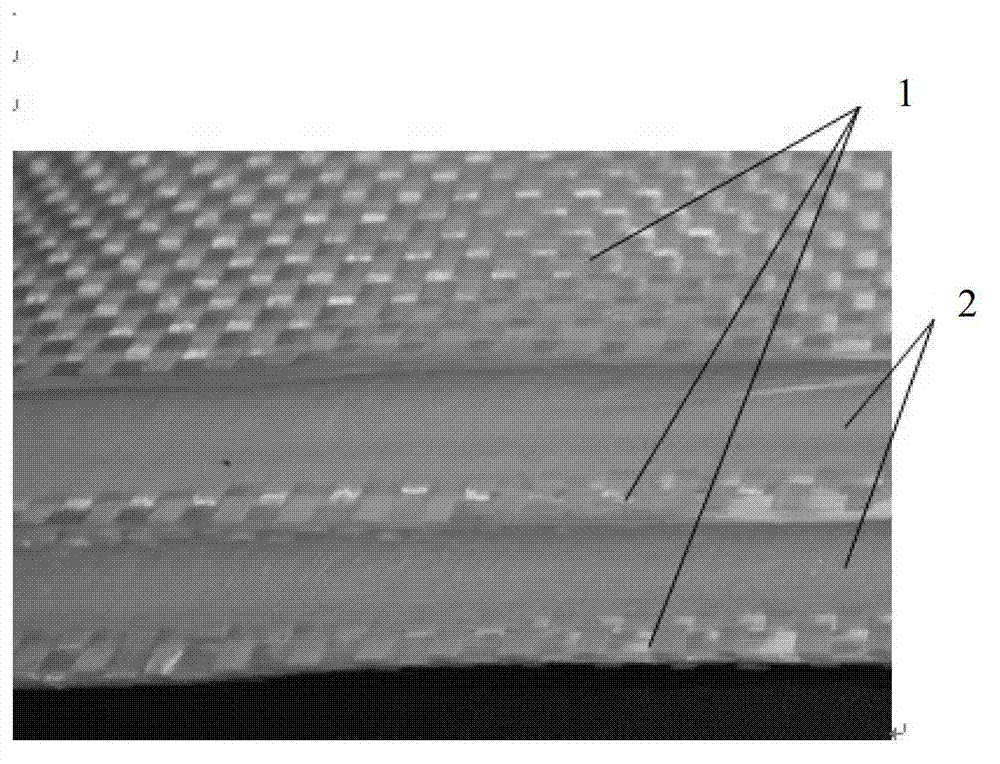

[0089] The implementation steps of the method in this embodiment are the same as in Example 1, except that the glass fiber plain cloth used in step 2 has only 5 layers, and the glass fiber mat has only 4 layers, and is laid on the female mold in the following stacking manner from top to bottom Middle: cloth / felt / cloth / felt / cloth felt / cloth / felt / cloth, as shown in Table 1, the weight per unit area of the laminate formed after the lamination of the plain weave cloth and the fiber felt is 2800 (g / m 2 ); the mold of step 1 and 3 is the automobile trunk lid mould; the product that step 10 obtains is as follows Figure 6 car trunk lid products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com