Flow front prediction method of non-isothermal resin transfer molding based on mid-plane model

A resin transfer molding and flow front technology, applied in the field of computer numerical simulation, can solve the problems of not considering the coupled heat transfer of the impregnated fiber reinforcement, low precision, and not considering the change in the thickness direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings.

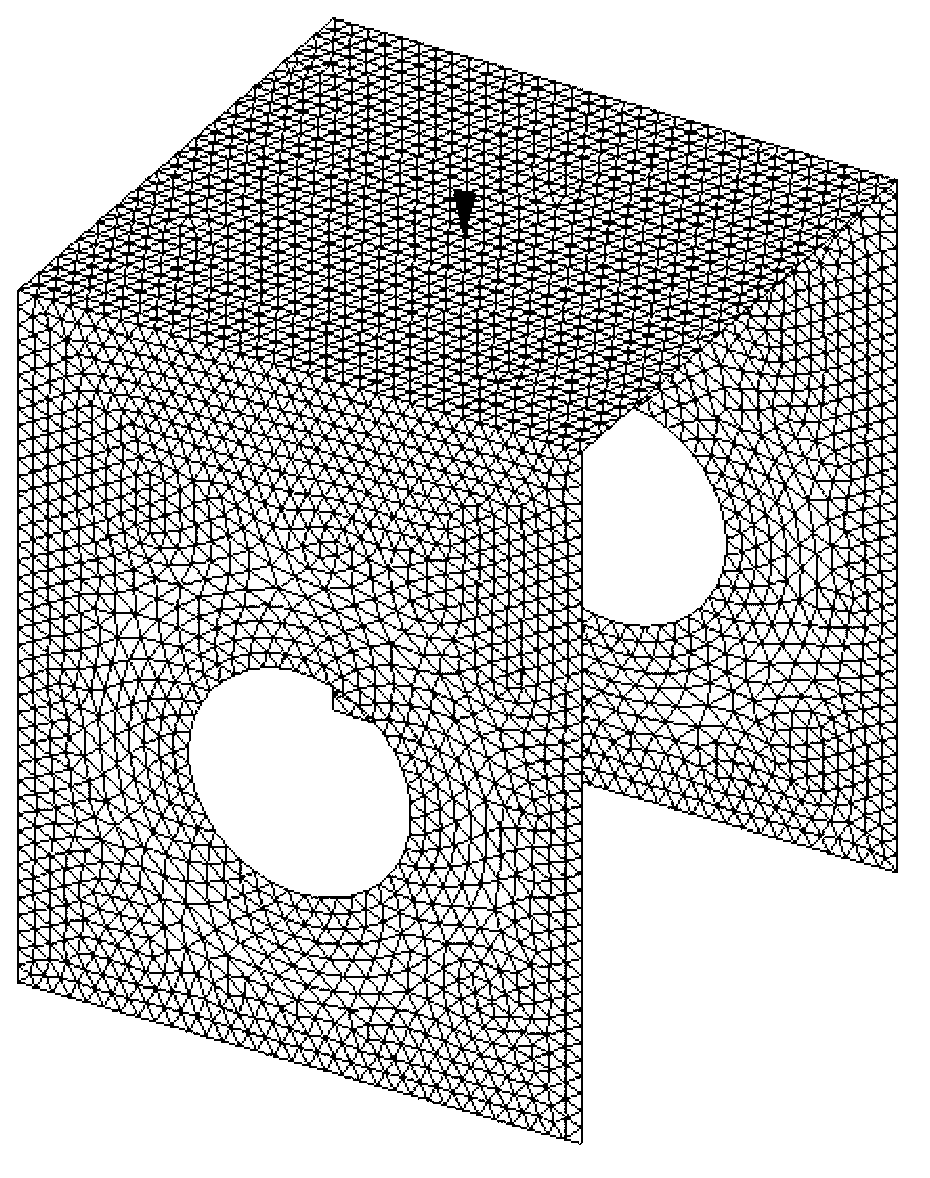

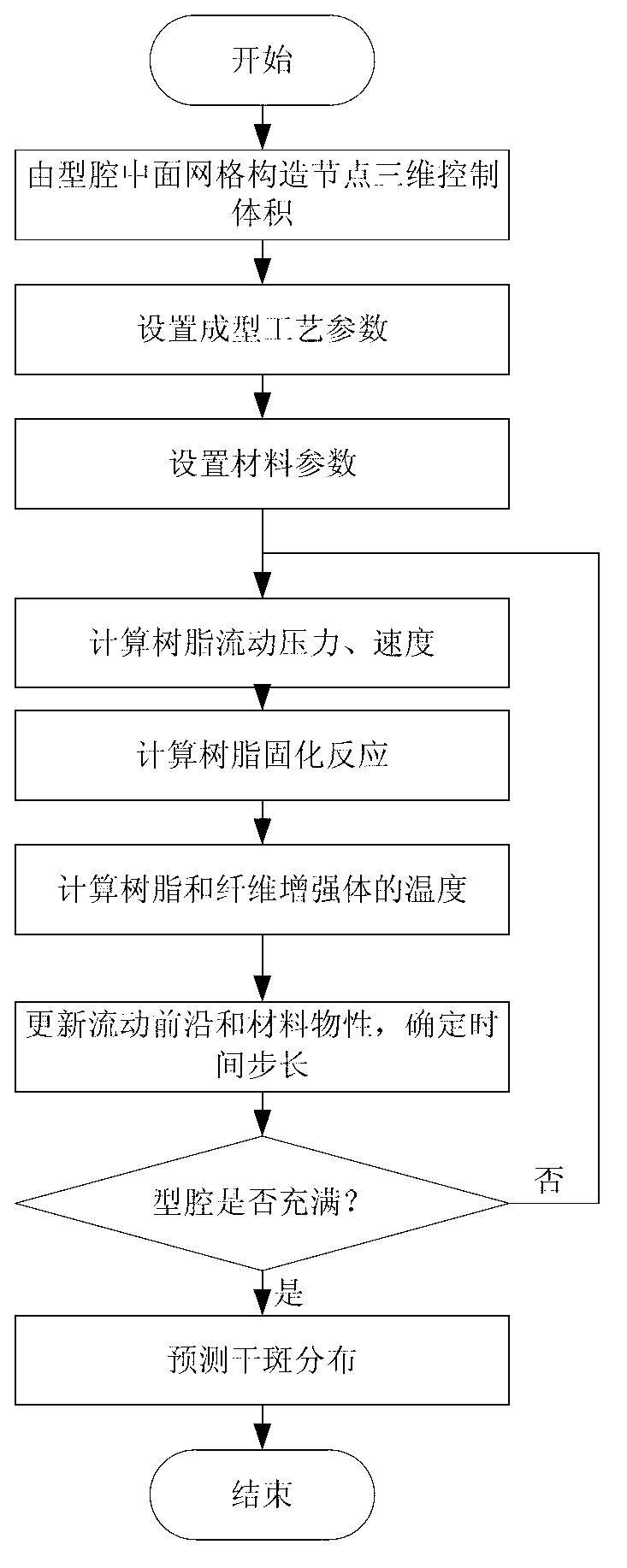

[0060] see figure 1 , which is a schematic diagram of the surface grid and gate position in the geometric model of a product, the thickness of which is 5mm. The steps to predict the flow front are as follows figure 2 As shown, the specific steps are as follows.

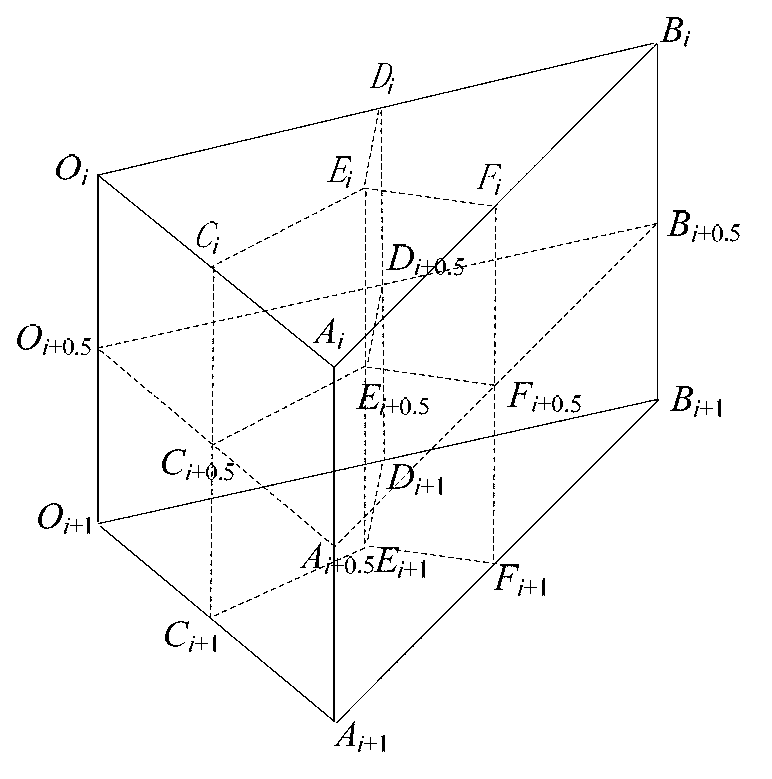

[0061] (1) The volume is controlled in three dimensions by the surface mesh construction nodes in the cavity. see image 3 , the subscripts i and i+1 in the figure (l≥i>0, l is the number of unit layers in the thickness direction of the mid-surface model, l=13 in this example) represent the i and i+1 layer nodes in the thickness direction, connected The corresponding nodes of the i and i+1 layer units are constructed into triangular prism units, and then the sub-control volumes of the nodes are constructed by connecting the body center, face center and edge midpoint of the triangular prism units, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com