Forming method for thermosetting polymer fiber composite workpiece

A fiber composite material and molding method technology, applied in the field of resin-based fiber-reinforced composite material molding, can solve the problems of air bubbles and dry spots, poor interface adhesion, poor fiber infiltration, etc., to prevent air bubbles or dry spots, rapid injection , The effect of uniform distribution of material and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

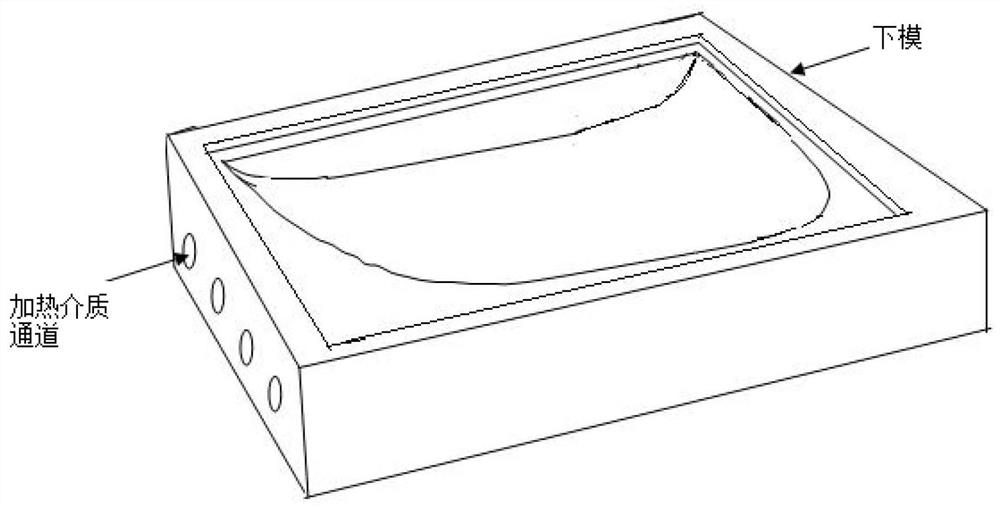

[0033] The molding die of the present invention is composed of a soft rubber upper die and a metal lower die (metal female die).

[0034] A. First, use ordinary carbon steel to make a set of molds for rubber soft mold manufacturing. The surface finish of the inner surface should reach 10 or more. The upper and lower molds of the mold are equipped with heat exchange devices and the temperature is controllable. The lower mold has heating medium channels. , The mold flanging width is more than 2mm, and a number of compression screw holes, injection ports and air extraction ports are set; an overflow groove with a width of about 1cm is set at a distance of about 1cm along the edge of the lower mold flanging plane. The tight screw hole is arranged outside the overflow groove, and cooperates with the pressure bar to seal the soft rubber mold.

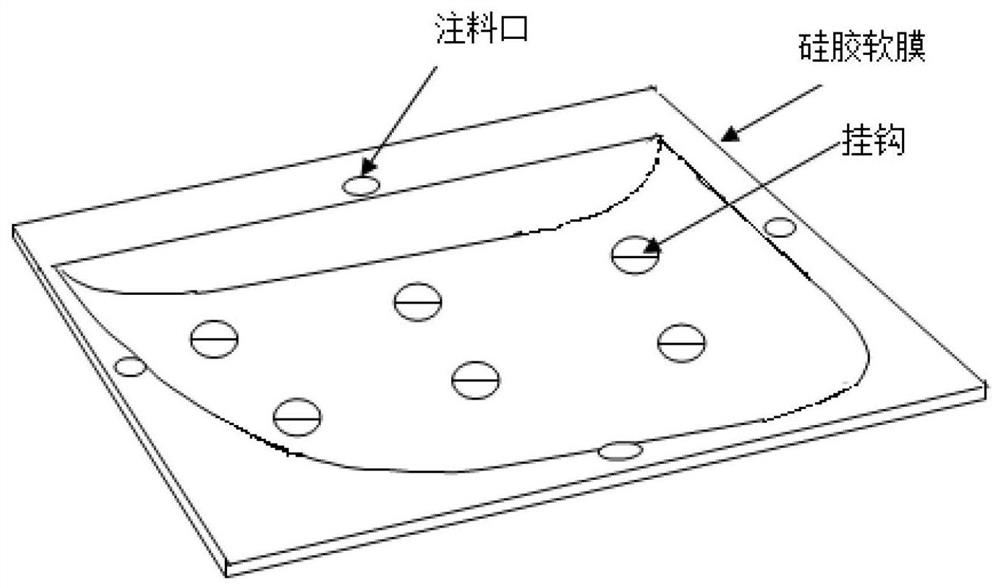

[0035] B. Choose a heat-resistant and high-strength rubber sheet with a thickness of 10-20mm, cut an appropriate size and place it in the above-m...

Embodiment 2

[0045] Metal mold manufacturing

[0046] According to the component structure on the actual device, a set of molds are made of ordinary carbon steel. The inner surface of the mold has a smooth finish of more than 10, and the width of the mold flanging plane is more than 2cm. An overflow groove with a width of about 1cm is set at a distance of about 1cm from the inner edge of the lower mold flanging plane, and a number of screw holes are processed outside the overflow groove to cooperate with the bead to seal the soft rubber mold. Heat exchange pipes are placed inside the upper and lower molds, and the temperature is controlled by a mold temperature machine.

[0047] When manufacturing the rubber soft mold, first seal the overflow groove with an O-ring, and select a 10-20mm thick raw rubber sheet to place in the lower mold. The area is based on the mold surface area plus the mold flanging area. Set the vulcanization pressure, temperature and time according to the vulcanization proc...

Embodiment 3

[0050] Rubber soft mold manufacturing

[0051] The following uses silicone rubber and nitrile rubber as examples to illustrate the soft mold manufacturing method.

[0052] 1. Silicone rubber soft mold manufacturing

[0053] Put the silicone rubber green sheet with a thickness of 10mm into the metal female mold, slowly lower the metal male mold, vulcanize at 5MPa and 130°C for 30 minutes, eliminate the vacuum, and raise the temperature to 220°C for 20 hours for secondary vulcanization. Take it out and cut it into a soft rubber mold.

[0054] 2. Manufacturing of nitrile rubber soft mold

[0055] Put a nitrile rubber green sheet with a thickness of 12mm into a female metal mold, slowly lower the male mold, and vulcanize at 3MPa and 180°C for 25 minutes. Take it out and cut it into a soft rubber mold.

[0056] 3. Fluorine rubber soft mold manufacturing

[0057] Put a 20mm thick fluororubber green sheet into a female metal mold, slowly lower the male mold, and vulcanize at 3MPa and 160°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com