Radial tyre bladder and preparation method thereof

A technology of radial tires and capsules, which is applied in the field of polymer compound composition and its preparation, can solve problems such as low efficiency and long mixing time, and achieve the effects of improving uniform distribution, saving mixing time, and improving flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

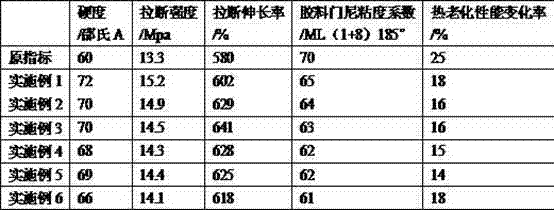

Examples

Embodiment 1

[0029] 90 parts of butyl rubber, 5 parts of neoprene, 4 parts of castor oil, 55 parts of carbon black, 1.2 parts of stearic acid, 0.5 parts of paraffin, 7 parts of resin, and 4 parts of zinc oxide.

[0030] The paraffin is microcrystalline wax. In addition to normal alkanes and isoparaffins, microcrystalline wax also contains many long-chain branched and cyclic saturated hydrocarbons, with high melting point and good plasticity, which can better improve the fluidity of the colloid.

[0031] The butyl rubber is 268 type butyl rubber.

[0032] The carbon black is made of high structure carbon black. The carbon black primary aggregates of high-structure carbon black are composed of a large number of primary particles with considerable branching and chaining. Higher surface area enhances the performance of carbon black. The resin is octyl phenolic vulcanized resin or p-tert-butylphenolic resin. The particle size of the carbon black is 30-50nm. The reinforcing effect of carbo...

Embodiment 2

[0042] The composition and weight ratio of the raw materials are: 100 parts of butyl rubber, 5 parts of neoprene, 4.5 parts of castor oil, 52 parts of carbon black, 1 part of stearic acid, 0.6 part of paraffin, 7.2 parts of resin, 5 parts of zinc oxide share.

[0043] The paraffin is microcrystalline wax. The butyl rubber is268 type butyl rubber. The carbon black is made of high structure carbon black. The resin is an octyl phenolic vulcanized resin.

[0044] For the preparation method of the radial tire bladder, the vulcanization temperature is 160°, and the rest are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0046] The composition and weight ratio of the raw materials are: 100 parts of butyl rubber, 5 parts of neoprene, 5 parts of castor oil, 50 parts of carbon black, 1 part of stearic acid, 0.8 part of paraffin, 9 parts of resin, 5 parts of zinc oxide share.

[0047] The paraffin is microcrystalline wax. The butyl rubber is 268 type butyl rubber. The carbon black is made of high structure carbon black. The resin is p-tert-butylphenol-formaldehyde resin.

[0048] For the preparation method of the radial tire bladder, the vulcanization temperature is 167°, and the rest are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com