Transverse pole plate circling type wet electrostatic precipitator and wet electrostatic precipitation method

A technology of wet electrostatic precipitator and polar plate, which is applied in the direction of external electrostatic separator, etc., can solve the problems of short residence time of flue gas, dead spot of dry spot anti-corona dust removal, uneven water film of anode plate, etc., so as to avoid local dry spot , avoid back corona phenomenon, prolong the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

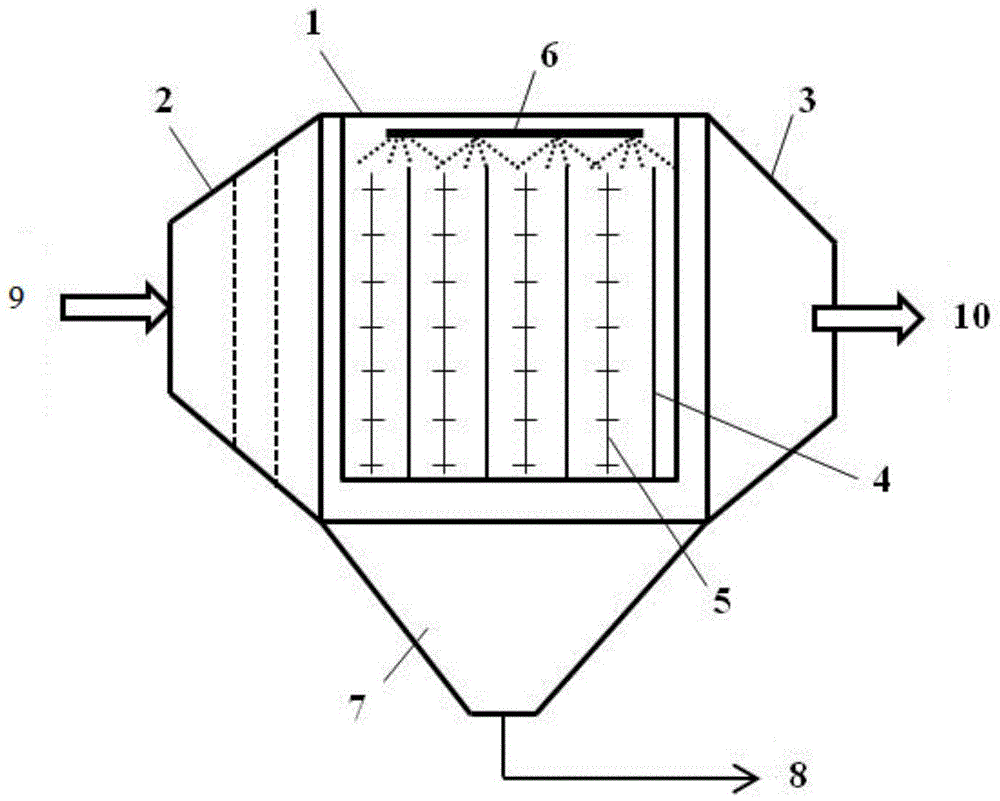

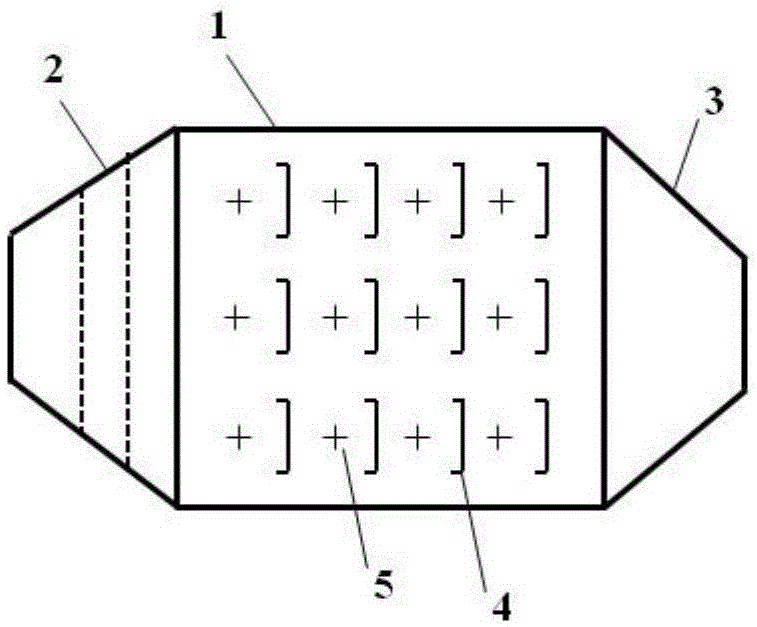

[0029] Such as figure 1 As shown, a horizontal plate-flowing wet electrostatic precipitator of the present invention includes a housing 1, and the left and right ends of the housing 1 are respectively provided with a horn-shaped air inlet 2 and an air outlet 3, and inside the air inlet 2 Arrange multi-layer gas distribution plates. An ash hopper 7 is arranged at the bottom of the housing 1, and a slurry outlet is arranged at the bottom of the ash hopper 7.

[0030] Inside the casing 1, an atomized water spray system 6 and a dust removal unit are arranged. The dust removal unit includes several rows of anode plates 4 and cathode lines 5 perpendicular to the flow direction of the flue gas. A plurality of anode plates 4, the distance between the edges of two adjacent anode plates 4 is 80mm, there are several sections perpendicular to the flow direction of the flue gas, the distance between two adjacent sections is 300mm, and the cathode lines 5 are arranged between the two adjac...

Embodiment 2

[0035] The rest are the same as in Embodiment 1, except that the distance between the edges of two adjacent anode plates 4 is controlled to be 50mm, the plate width of the anode plate 4 is 0.4m, the plate length is 5m, and there are several sections perpendicular to the flow direction of the flue gas. The distance between each section is 200mm.

[0036] The particle removal efficiency of the horizontal plate-flowing wet electrostatic precipitator can reach 99%, and the outlet emission concentration is lower than 5mg / m 3 ;SO 3 The removal efficiency can reach 80%, and the outlet emission concentration is lower than 5mg / m 3 ; Hg 0The removal efficiency can reach 85%, and the outlet emission concentration is lower than 5μg / m 3 .

Embodiment 3

[0038] The rest are the same as in Embodiment 1, except that the distance between the edges of two adjacent anode plates 4 is controlled to be 100 mm, the plate width of the anode plate 4 is 0.8 m, the plate length is 10 m, and there are several sections perpendicular to the flow direction of the flue gas. The distance between each section is 500mm.

[0039] The particle removal efficiency of the horizontal plate-flowing wet electrostatic precipitator can reach 99%, and the outlet emission concentration is lower than 5mg / m 3 ;SO 3 The removal efficiency can reach 80%, and the outlet emission concentration is lower than 5mg / m 3 ; Hg 0 The removal efficiency can reach 85%, and the outlet emission concentration is lower than 5μg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Board width | aaaaa | aaaaa |

| Board length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com