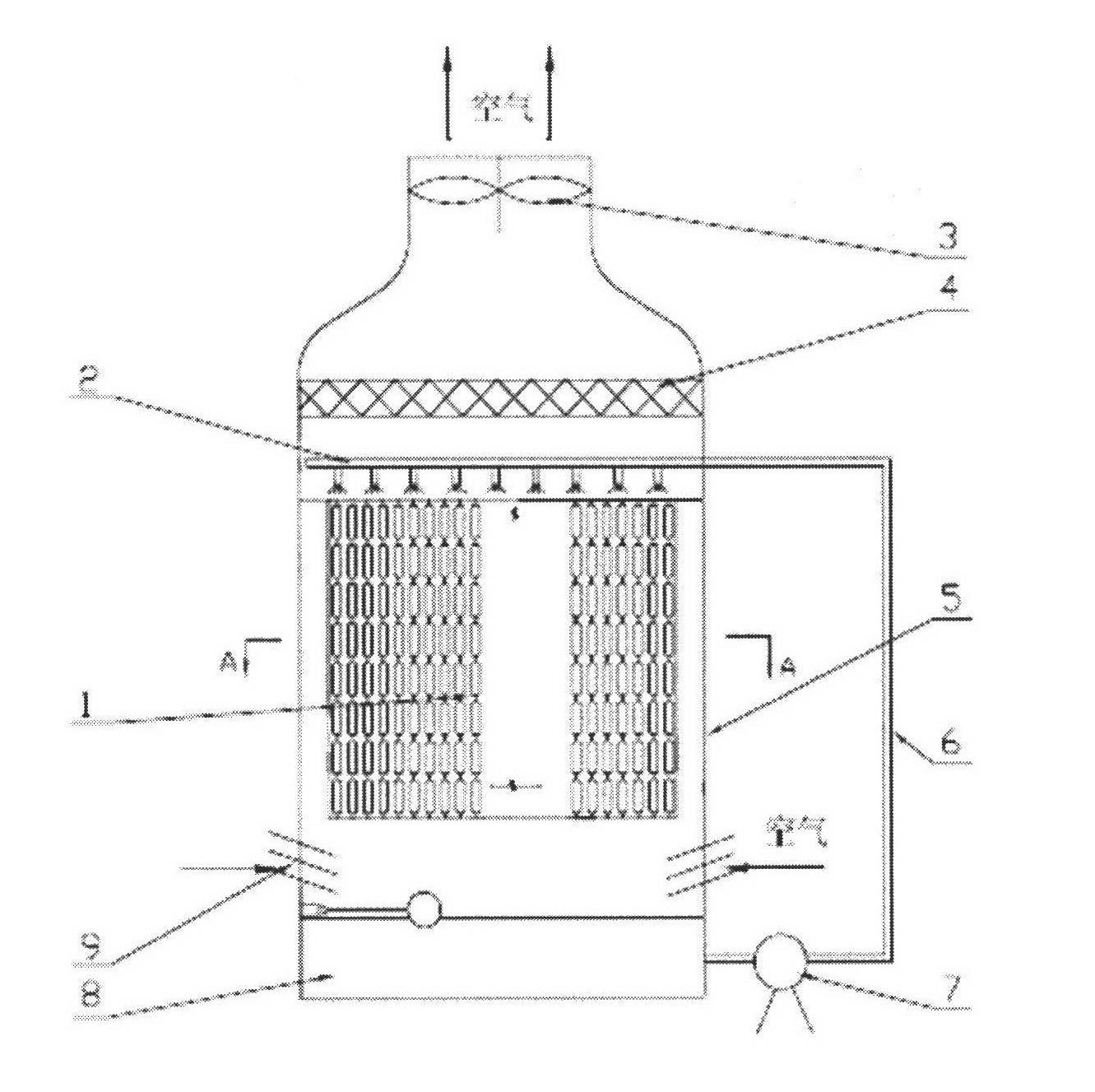

Nano-coating for unsaturated evaporation heat transfer surface

A nano-coating and heat transfer surface technology, applied in the field of enhanced heat transfer, can solve the problems that the water film is difficult to cover the tube surface evenly, cannot achieve unsaturated evaporation, and the scaling body reduces the heat transfer efficiency, etc., to increase the spreading area , increase the coefficient of heat transfer film, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

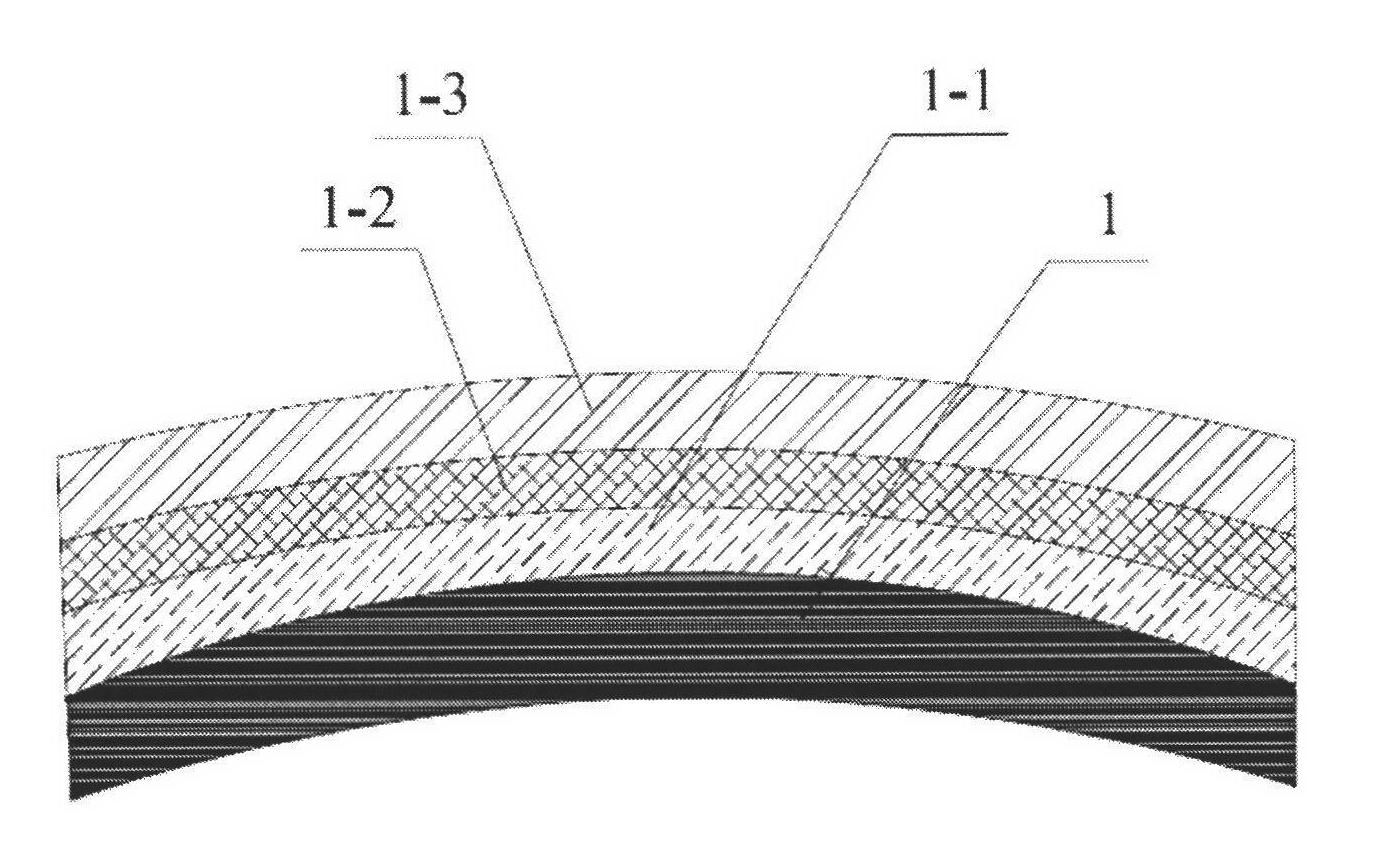

[0030] Preparation of hydrophilic layer: After preparing butyl titanate, absolute ethanol, acetylacetone, silver nitrate, and deionized water at a molar concentration of 1.0:30:1.0:0.05:2.0 to form a solution, stir for 15 minutes, and adjust the solution with nitric acid When the pH value reaches 5-6, stir evenly; the anti-corrosion layer uses a sodium phosphate solution with a concentration of 1.2mol / kg; the heat transfer layer uses a melt containing metal zinc;

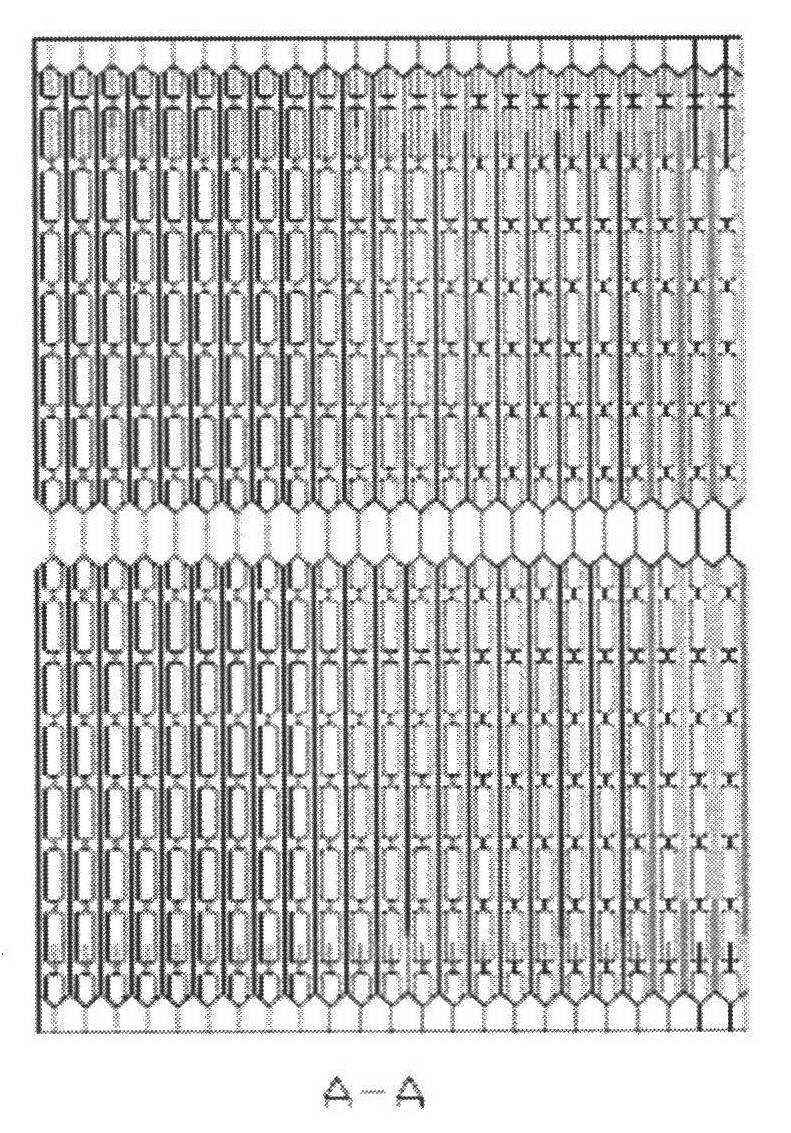

[0031] Stainless steel corrugated heat exchange plate tubes, coated to obtain image 3 In the coating structure shown, the thickness of the hydrophilic layer 1-3nm is 8, 15 and 35nm, the thickness of the anti-corrosion layer 1-1 is 2, 10 and 15nm, and the thickness of the heat transfer layer 1-2 is 2 , 5 and 10nm. The resulting three-layer structured coatings had a total thickness of 12, 30 and 60 nm. Use an ultraviolet lamp with a wavelength of 365nm and a power of 10W to irradiate the coating for 1h.

[0032] E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com