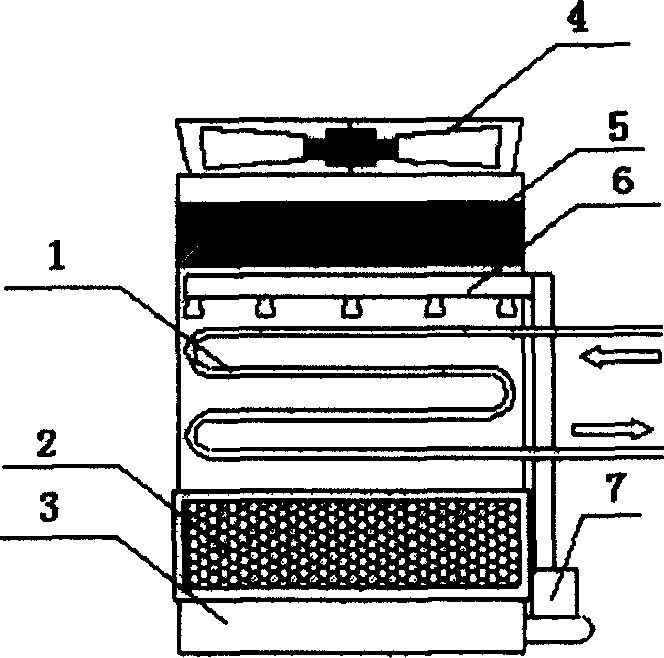

Nanometer coating on coiler surface of heat exchanger

A nano-coating and heat exchanger technology, applied in the field of heat exchange, can solve the problems of increased energy consumption of fans and water pumps, increased air resistance, and easy fouling, so as to improve heat exchange efficiency, increase service life, eliminate and corrode Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

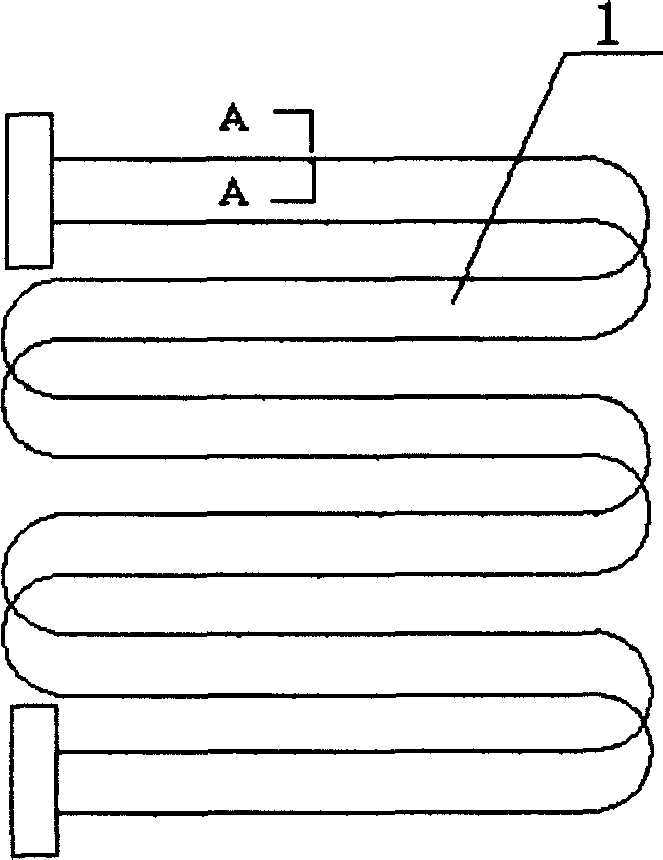

Embodiment 1

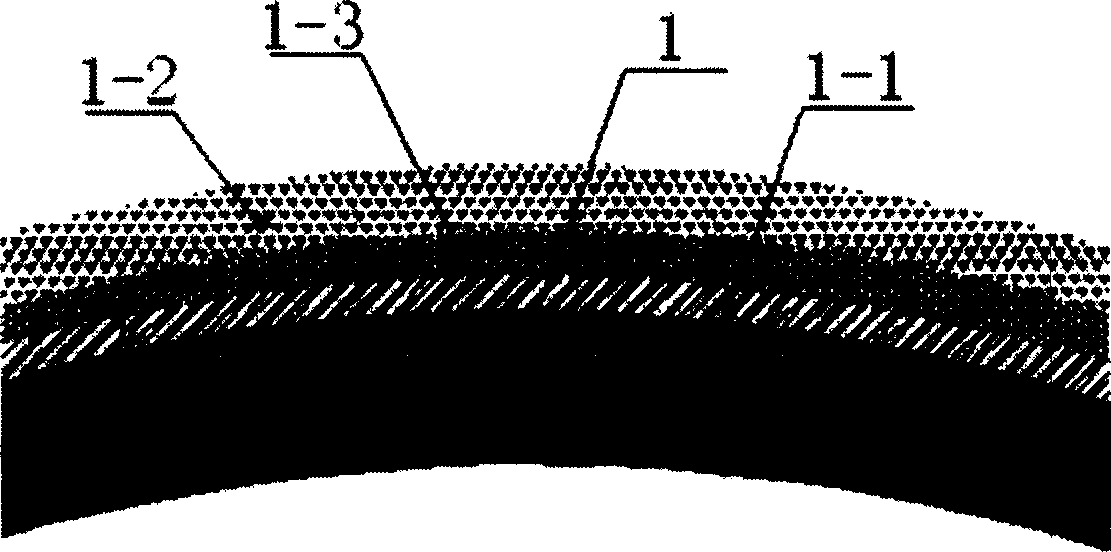

[0028] Using carbon steel circular coil, coated to get image 3 In the coating structure shown, the thicknesses of the hydrophilic film 1-2 are respectively 8, 15, and 35nm, the thicknesses of the anti-corrosion layer 1-1 are respectively 2, 10, and 15nm, and the thicknesses of the heat transfer layer 1-3 are respectively 2, 5, 10nm. The total thickness of the obtained three-layer structure coating is 12, 30, 60 nm.

[0029] Experiments have shown that the contact angles of the coil surface of the heat exchanger in this example are reduced to 8°, 2°, and 6° from 40°, 35°, and 38° of the existing coil light tube. The evaporative heat exchanger adopts the heat exchange coil with the coating of this example, the water saving is 13%, 23%, 18%, and the heat transfer performance is relatively improved by 18%, 30%, and 22%.

Embodiment 2

[0031] A copper circular coil is used to coat a two-layer coating structure, wherein the thickness of the hydrophilic film 1-2 is 8, 15, and 35nm respectively, and the thickness of the anti-corrosion layer 1-1 is 2, 10, and 15nm respectively. The total thickness of the obtained two-layer structure coating is 10, 25, 50 nm.

[0032] Experiments have shown that the contact angles of the nano-coated surface of the coil surface of the heat exchanger in this example are reduced from 38°, 36°, and 40° of the existing coil tubes to 9°, 3°, and 5°. The evaporative heat exchanger adopts the heat exchange coil with the coating of this example, the water saving is 12%, 25%, and 20%, and the heat transfer performance is relatively improved by 15%, 28%, and 21%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com