A hybrid filling path generation method in arc fuse additive manufacturing technology

A technology of additive manufacturing and mixed filling, which is applied in the field of additive manufacturing and can solve problems such as low efficiency and poor external surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] A method for generating a hybrid filling path in an arc fuse additive manufacturing technology, comprising the steps of:

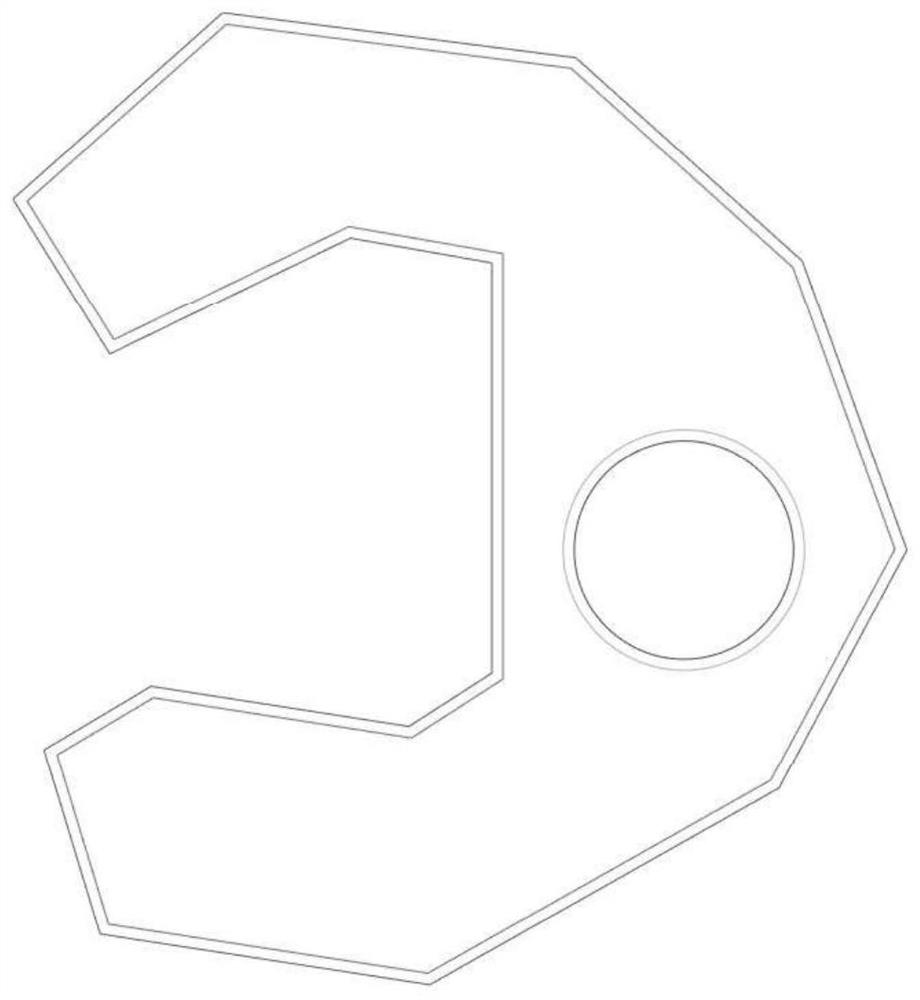

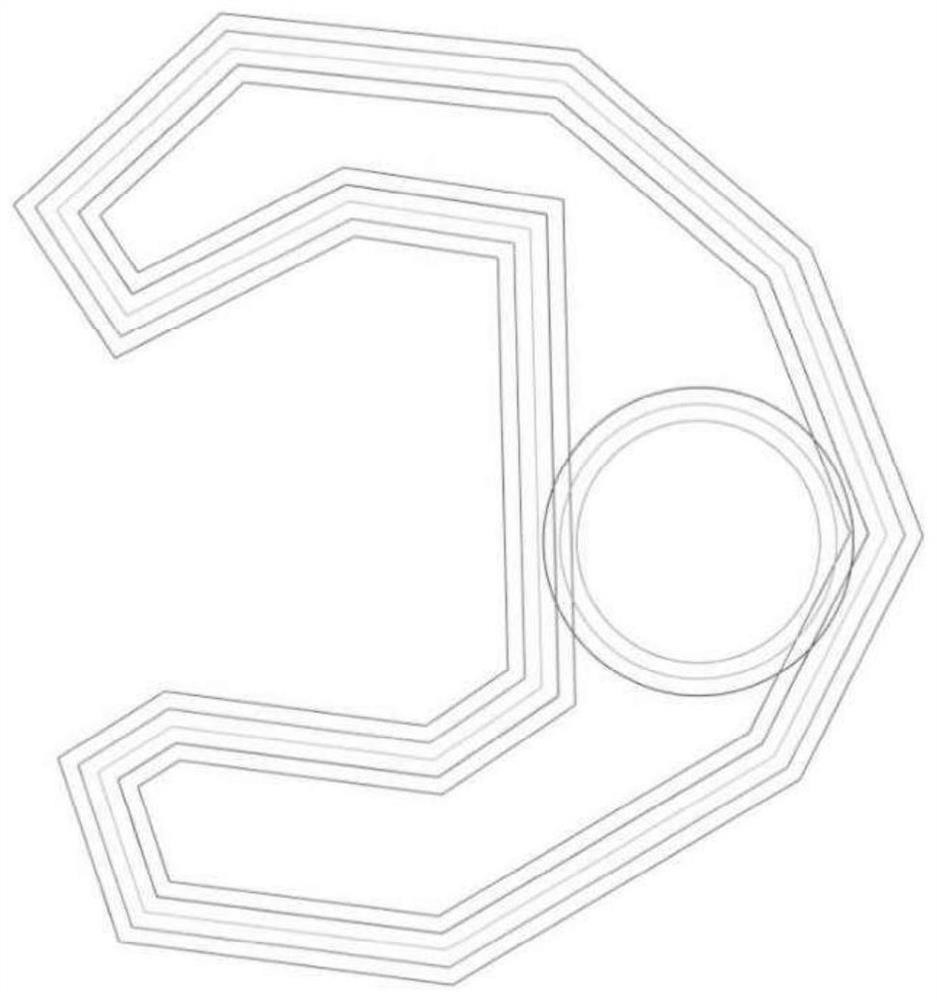

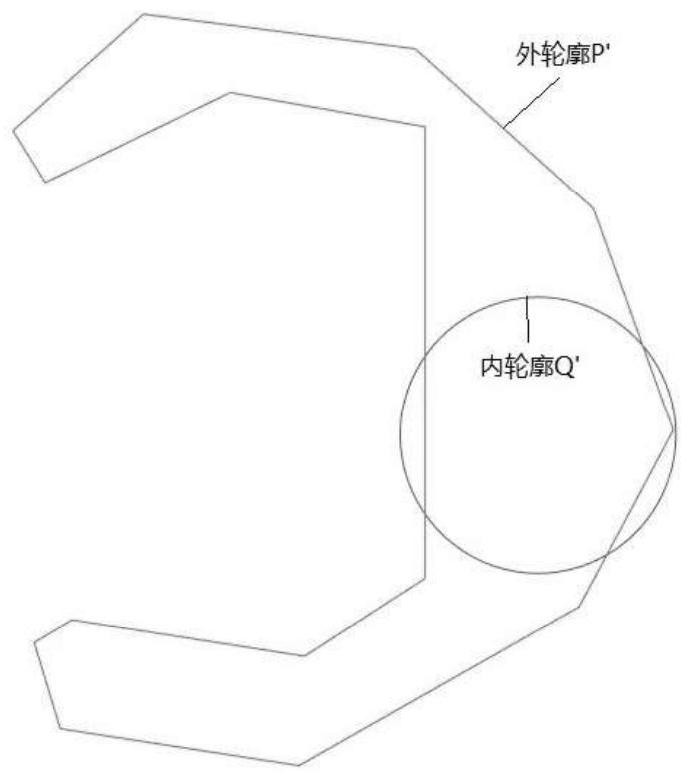

[0036] S1. Traverse the data points of the contour of the section edge and the edge of the hollow area and delete the collinear points on the contour. Specifically, set a vertex in the contour line as P i , looking clockwise along the contour line, the previous point is P i-1 , the latter point is P i+1 , the vector and The included angle is θ, we know If cosθ=0, then P i-1 , P i , P i+1 Three points are collinear, delete P from the contour line i points, and so on, traverse the data points of the contour, delete all collinear points, and only keep the vertices of the contour.

[0037] S2. Sort the data points on the contour clockwise or counterclockwise.

[0038] S3. According to the welding wire material used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com