Press-riveting connection structure for stamped part

A technology for stamping and riveting connection, applied in the field of stamping and riveting connection structure, can solve problems such as affecting the quality of the outer surface of the product, the outer surface of the baking paint layer is heated and breaking holes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

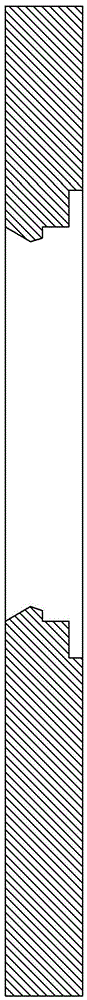

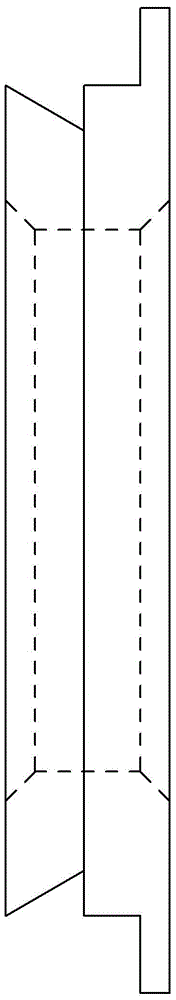

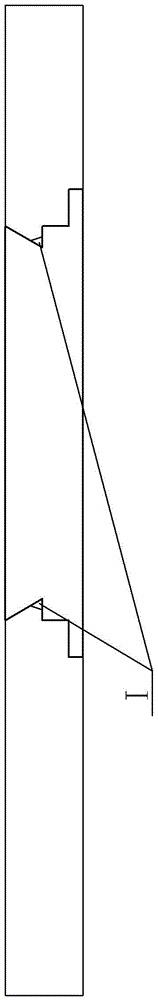

[0016] A pressure riveting connection structure for stamping parts, see Figure 4 ~ Figure 6 : It includes a stamped part with an inner hole 1, a rivet head 2, a rivet head 2 including a connecting hole 3 through the center, an outer ring surface for riveting the stamped part, and the outer ring surface of the rivet head 2 includes an outer ring surface The convex end positioning ring surface 4, the equal diameter positioning cylinder ring surface 5, the convex end positioning ring surface 4, the equal diameter positioning cylinder ring surface 5, the separation surface between the horizontal separation surface 6, the inner part of the stamping 1 The hole includes a large-diameter end 7 and a small-diameter end 8. The transition surface between the large-diameter end 7 and the small-diameter end 8 is a horizontal end surface 9, and the inner diameter of the large-diameter end 7 is equal to the convex end positioning ring surface 4 of the rivet head 2. The diameter of the large-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com