Zero-radius steering walking speed change box for combine harvester

A combine harvester, zero-radius technology, applied in the direction of harvester, steering mechanism, application, etc., can solve the problems of soil damage, increase the empty stroke and energy consumption of the combine harvester, and achieve improved mobility, compact structure, and energy consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

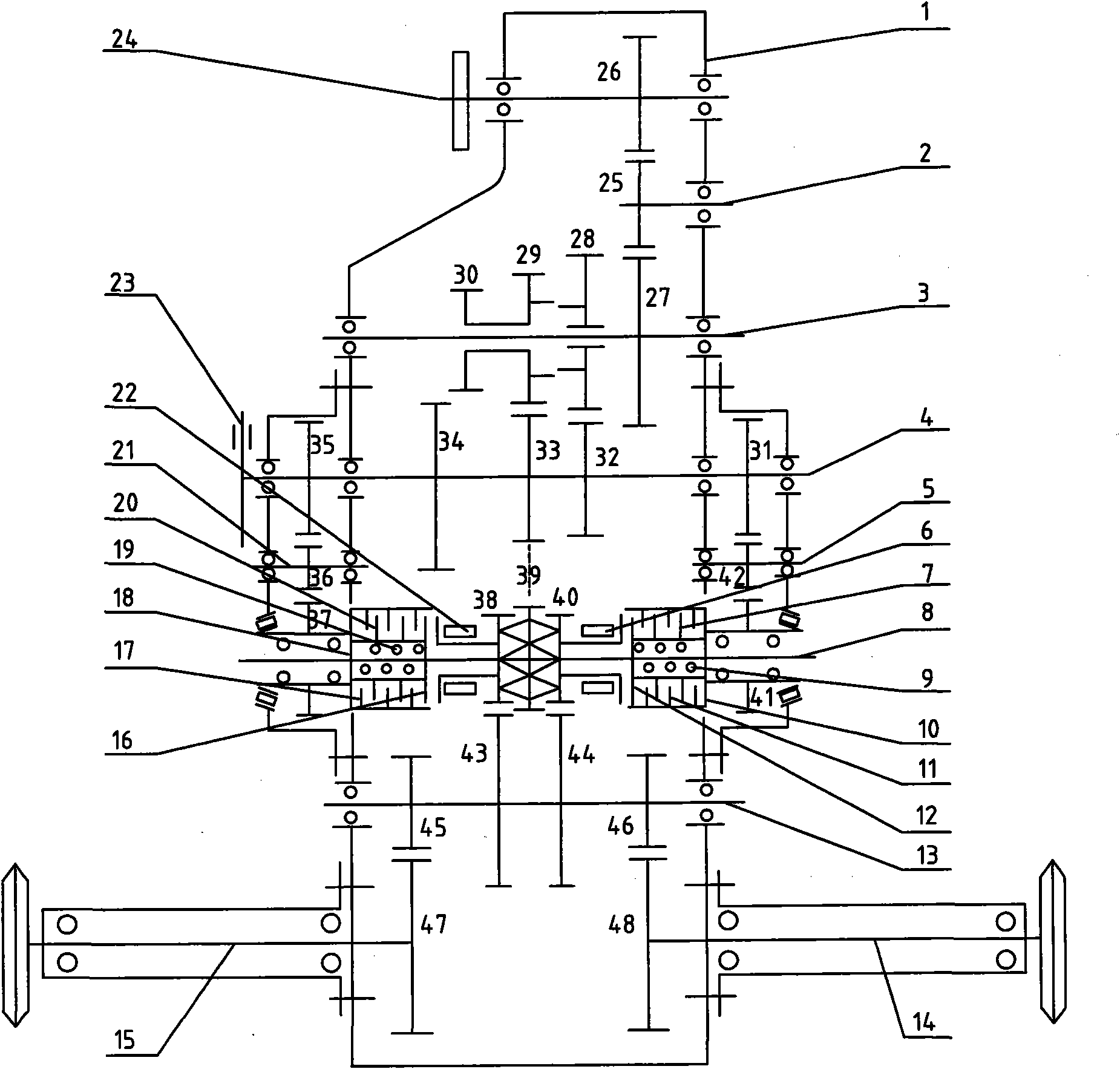

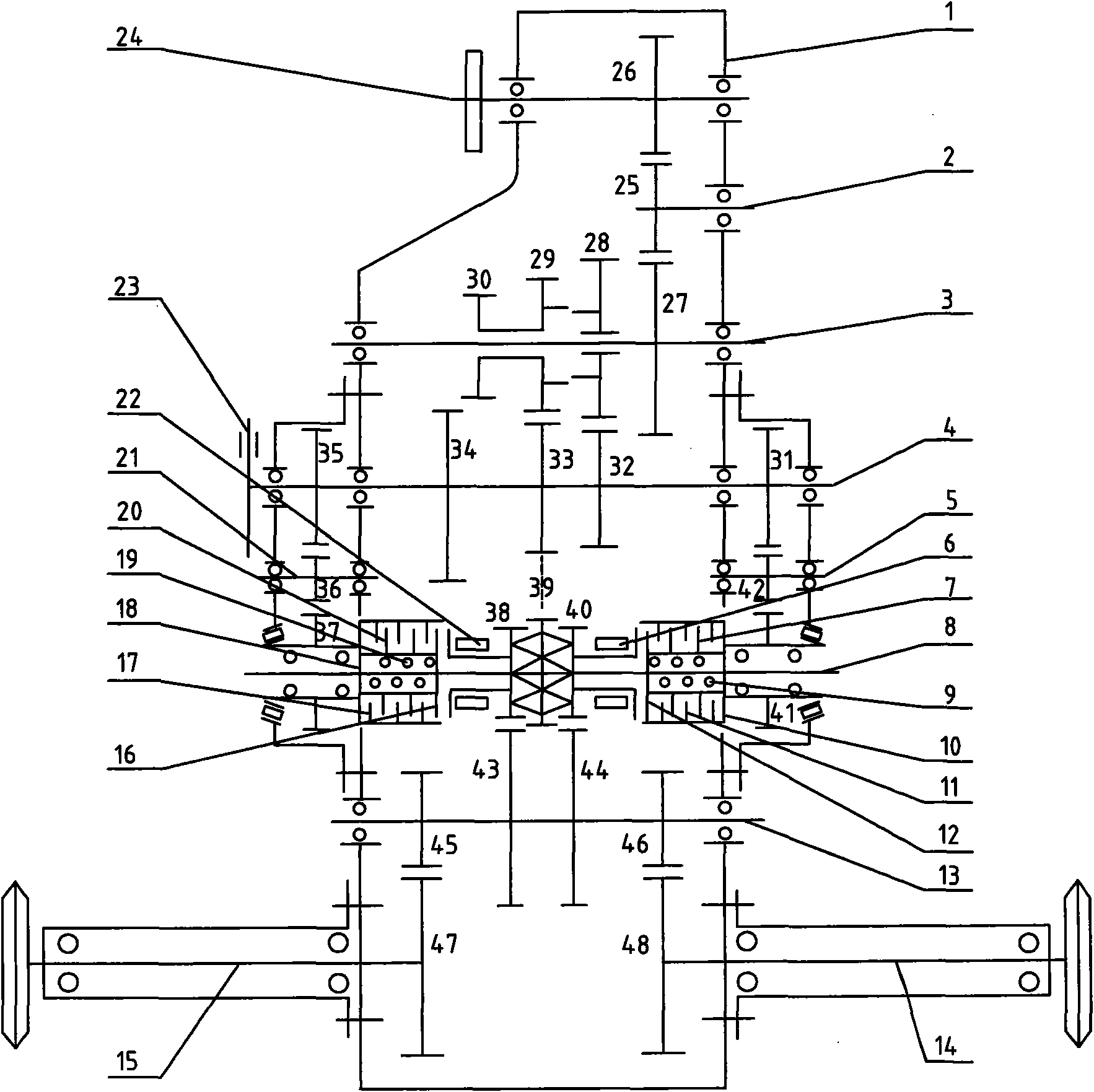

[0019] Such as figure 1 Shown, for the combine harvester of the present invention turns to the travel gearbox with zero radius, comprises gearbox body 1, is provided with speed change mechanism in the gearbox body 1, and speed change mechanism is connected with steering mechanism and deceleration mechanism successively, and speed change mechanism drives steering mechanism, The steering mechanism realizes the walking of the combine harvester through the reduction mechanism.

[0020] The speed change mechanism comprises a power input shaft 2, an auxiliary transmission shaft 3 and a driven transmission shaft 4. The power input shaft 2 is provided with a driving gear 25, and the driving gear 25 is constantly meshed with the harvesting part driving gear 26 of the combine harvester, driving the harvesting part to drive The shaft 24 runs, and the auxiliary transmission shaft 3 is provided with the running part drive gear 27 constantly meshed with the driving gear 25, and the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com