Machine case injection moulding production line

An injection molding and injection molding machine technology, applied in coating and other directions, can solve the problems of time-consuming and laborious feeding and reclaiming, affecting production efficiency, etc., to avoid burns, improve the efficiency of reclaiming, and improve the effect of feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

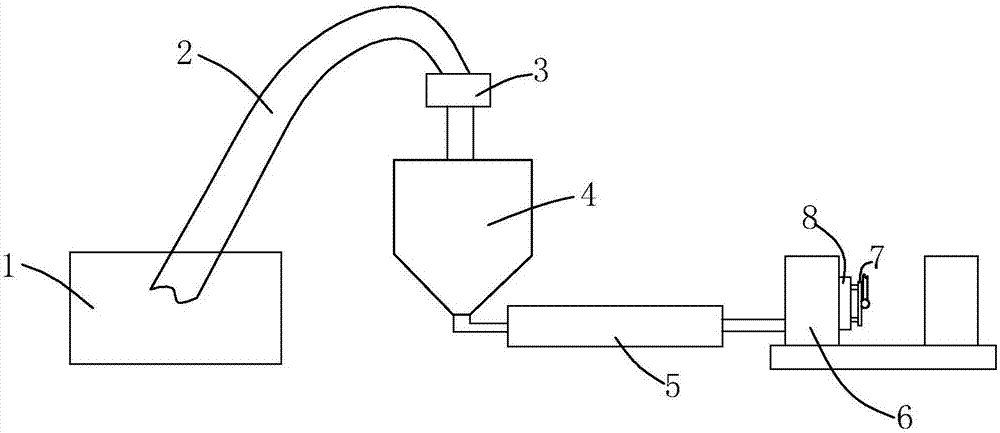

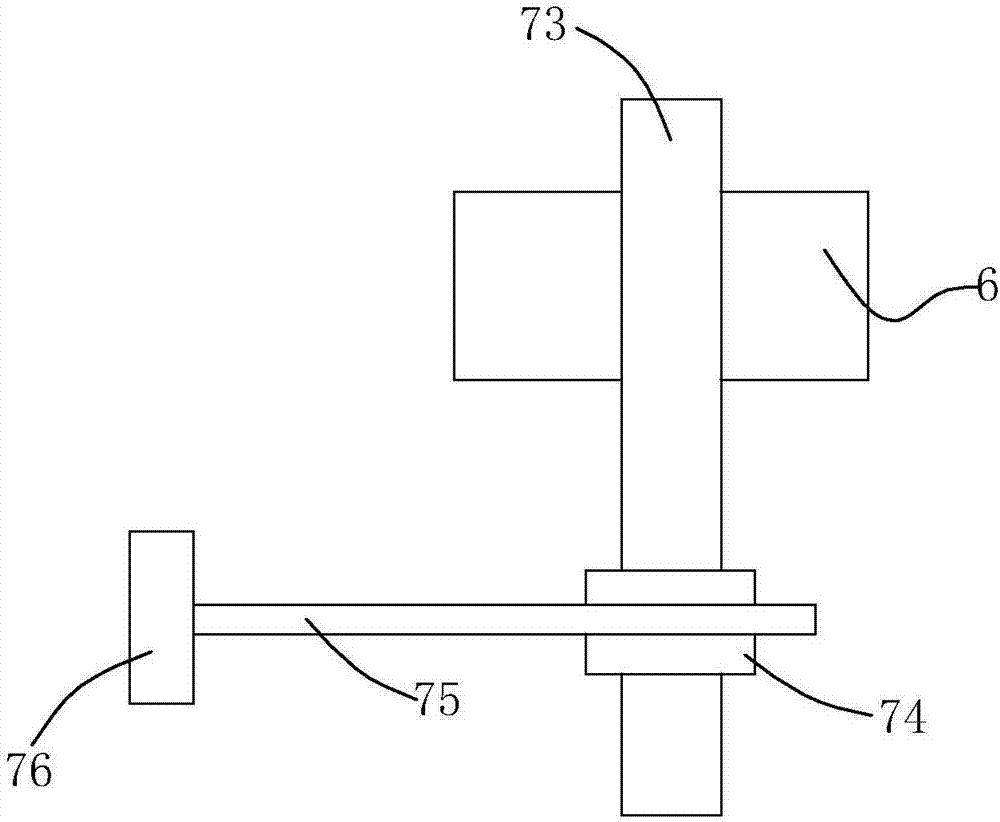

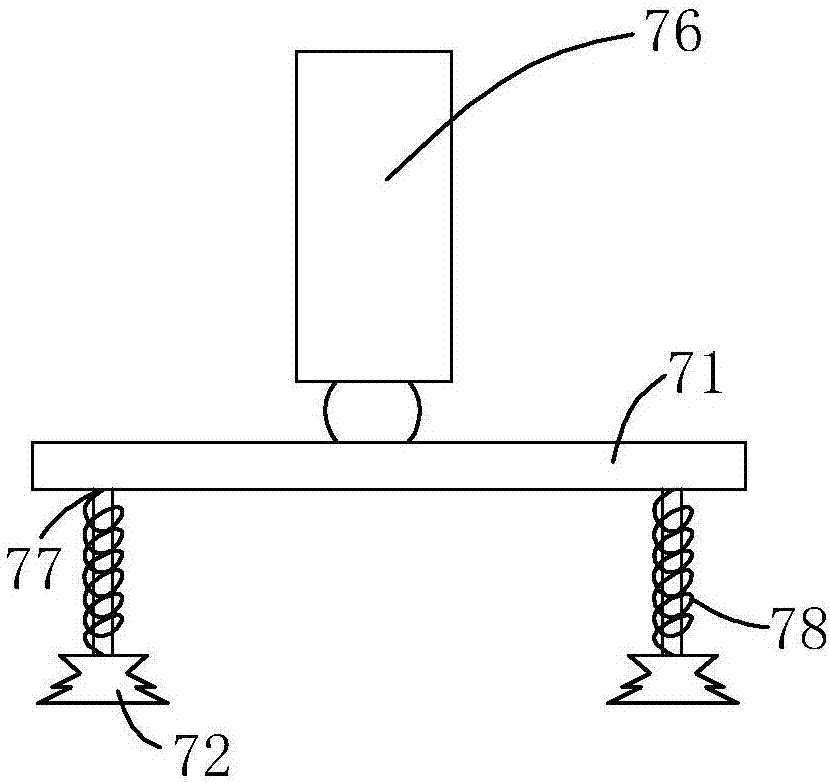

[0020] refer to Figure 1 to Figure 3 , a casing injection molding production line provided by the present invention is sequentially connected with a feeding funnel 4, a heating spiral tube 5, and an injection molding machine 6, and the feeding funnel 4 is connected with a raw material bin 1 through a feeding pipeline 2, and the A material suction device 3 is provided on the feed pipe 2; a retrieving manipulator 7 is provided on the injection molding machine 6, and the reclaiming manipulator 7 can remove the injection-molded casing 8 through spatial movement; it is also provided with Conveyor belt, the reclaiming manipulator 7 can send the removed casing 8 to the conveyor belt. The raw material bin 1 is connected to the feeding funnel 4 through the feeding channel, and under the action of the material suction device 3, the automatic feeding of raw materials is realized, and the feeding efficiency is improved; and the injection molding machine 6 is provided with a retrieving ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com