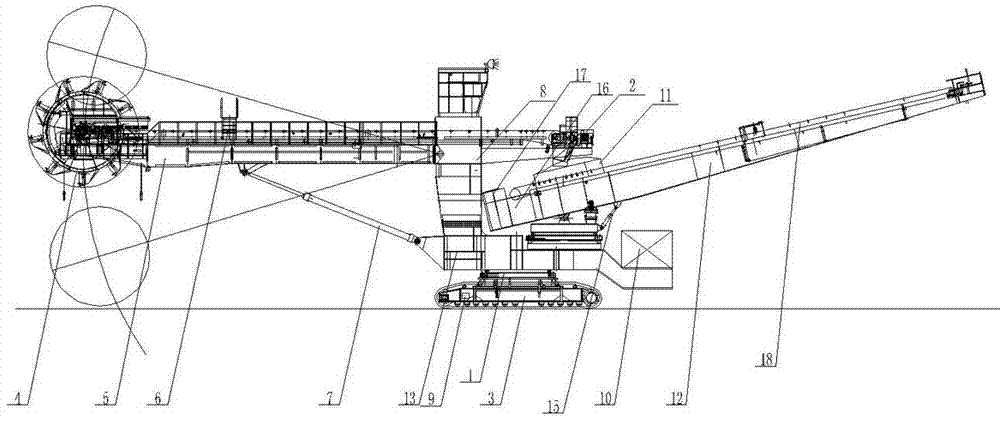

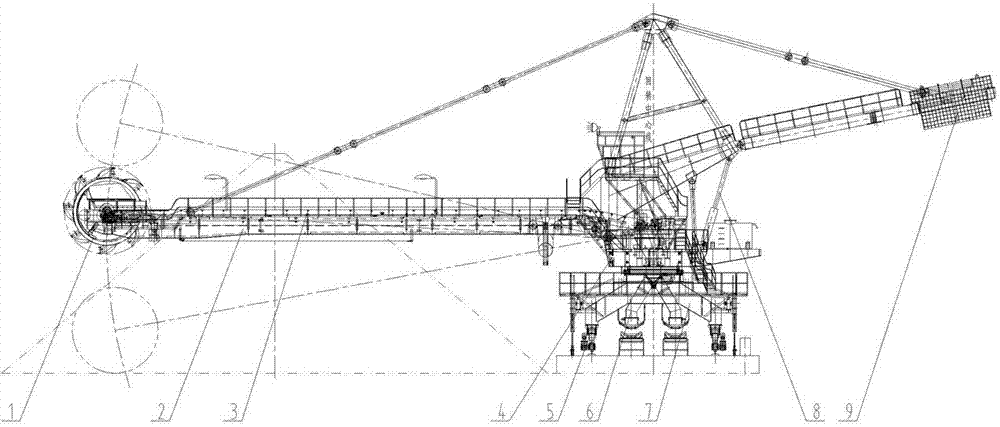

Crawler bucket-wheel reclaimer and reclaiming method thereof

A crawler-type, reclaimer technology, applied in the direction of transportation and packaging, loading/unloading, etc., to achieve the effect of improving reclaiming efficiency, improving utilization efficiency, and facilitating stacking and loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

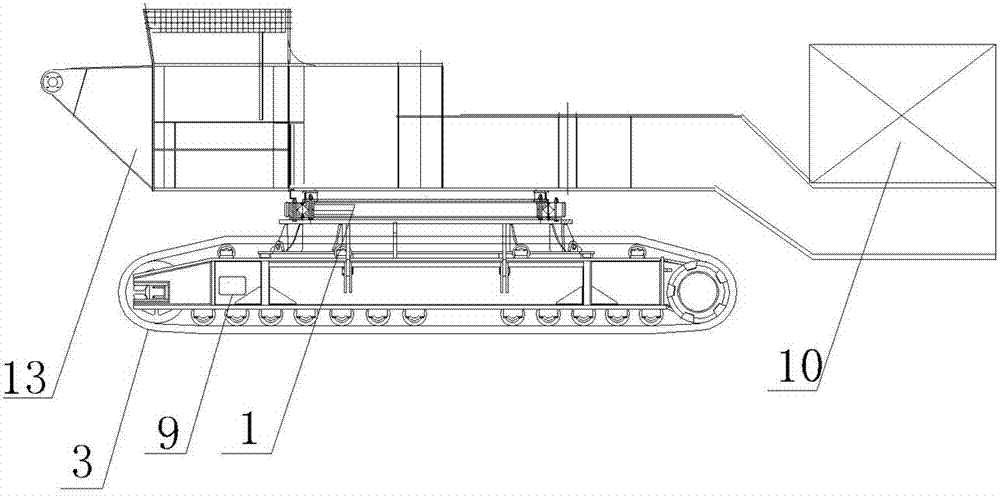

[0038] Both the first luffing mechanism 7 and the second luffing mechanism 15 are bendable support rods, and the middle part of the bendable support rods is provided with a bending angle limiting ring. The turntable structure 13 is also provided with a counterweight frame 16 matching the jib structure 5 , and a counterweight 17 is connected to the middle of the counterweight frame 16 . The running mechanism 3 is a crawler machine, and the turntable structure 13 is a turntable that can rotate 360 degrees.

Embodiment 2

[0040] Both the first amplitude-changing mechanism 7 and the second amplitude-changing mechanism 15 are telescopic support rods, and telescopic length control cylinders are arranged on the telescopic support rods.

[0041] A kind of material reclaiming method of crawler type bucket wheel reclaimer, comprises the following steps:

[0042] 1) The generator drives the traveling mechanism to the designated position, and the bucket wheel mechanism is controlled by the luffing mechanism to drop to the material picking position;

[0043] 2) The bucket wheel mechanism takes material. After the material is taken, the bucket wheel mechanism is controlled by the luffing mechanism to rise to the horizontal position;

[0044] 3) The material is conveyed to the central hopper through the belt conveyor;

[0045] 4) Then the material is transported to the stacking tray through the stacking belt;

[0046] 5) Finally, the materials on the stacking tray are stacked again or directly loaded int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com