Machining equipment and method for molded pulp product

A technology of pulp molding and machining, which is applied in textiles and papermaking, can solve the problems of high cost, affecting feeding and retrieving, and inconvenient feeding and unloading, etc., and achieves the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

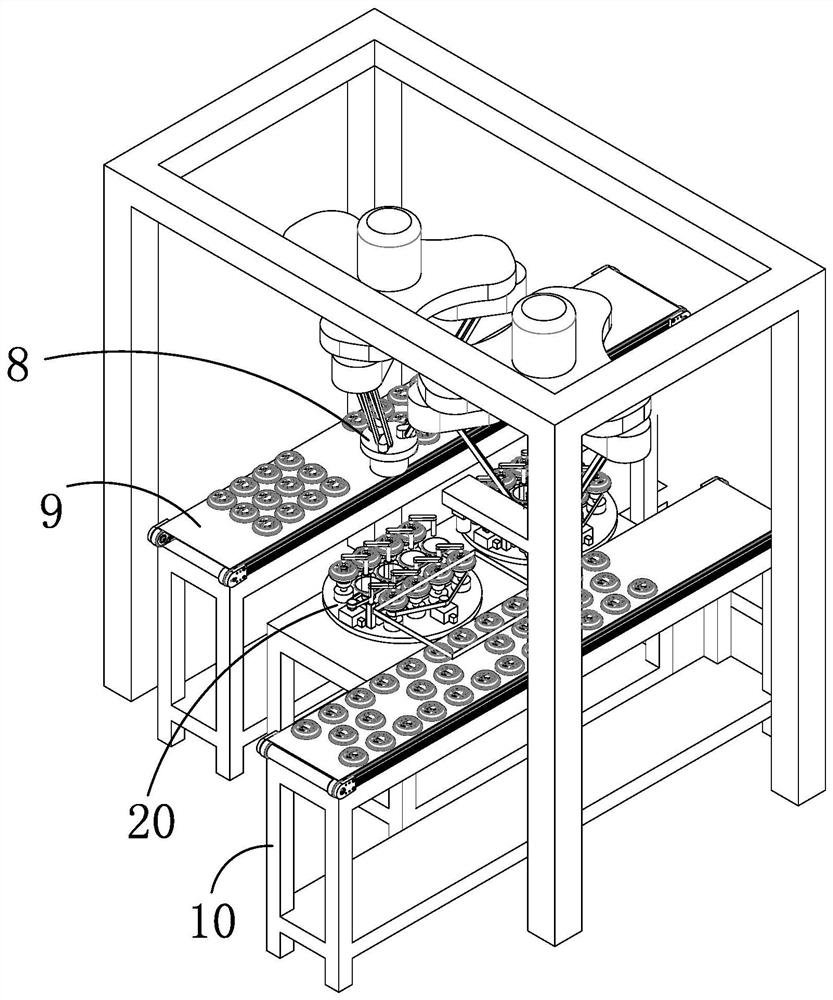

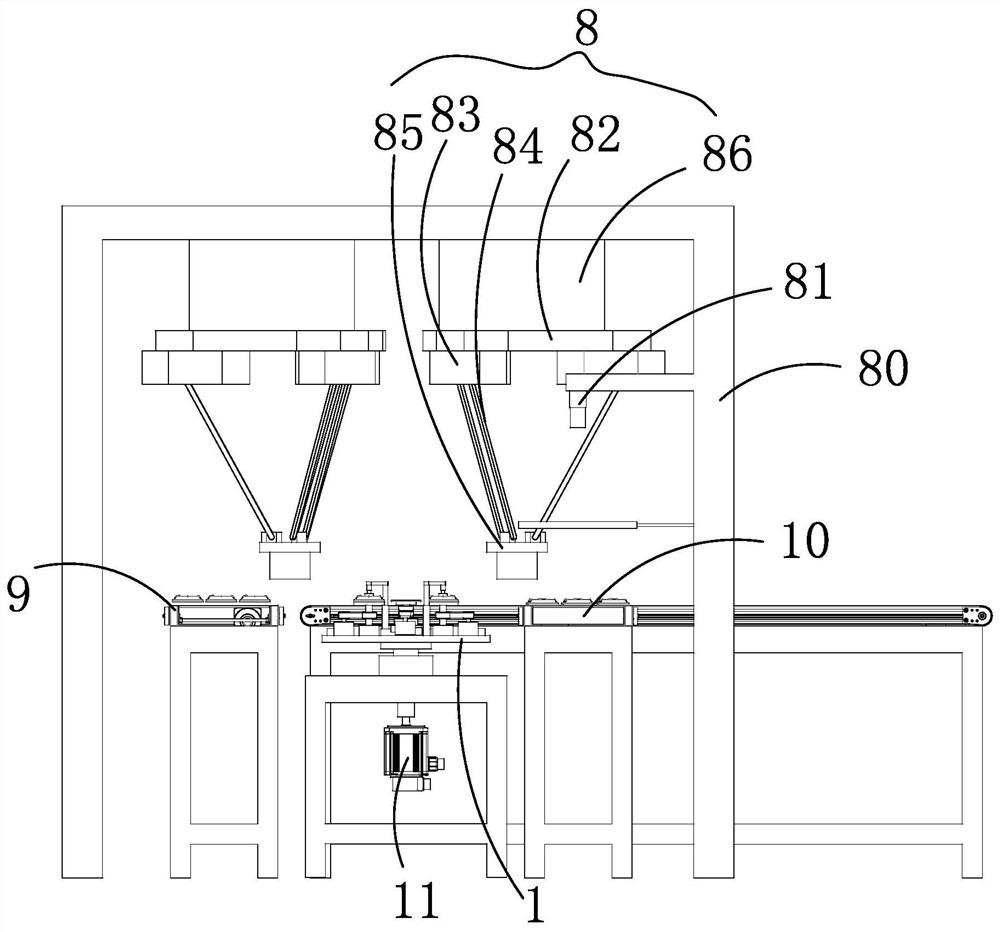

[0045] like figure 1 and figure 2 As shown, taking the processing of rolled pulp molded products as an example, a machining equipment for pulp molded products includes a feeding unit 10 for feeding and conveying unrolled pulp molded products; the feeding unit 10 for the conveyor belt.

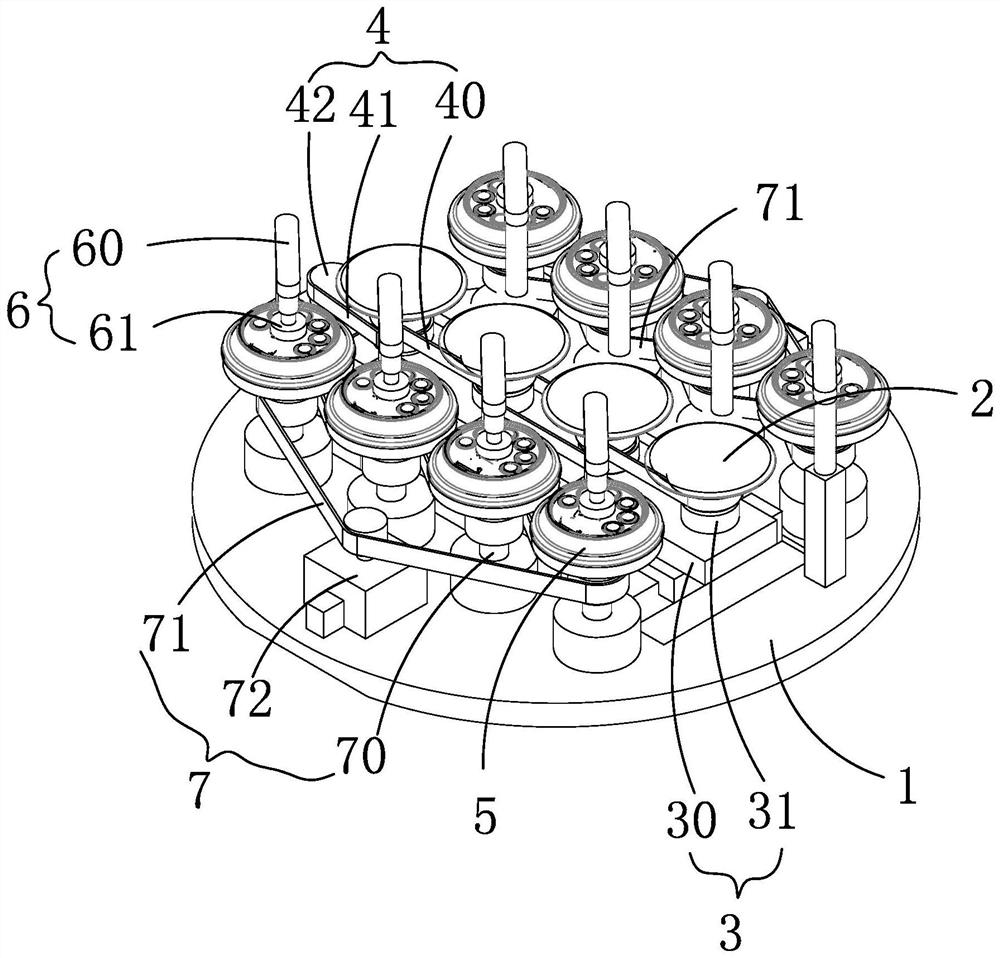

[0046] Rolling units 20 , preferably, there are two rolling units 20 in this embodiment and they are spaced in a straight line. The rolling units 20 are rotatably connected to the frame 21 . Specifically, the rolling unit 20 includes a horizontal turntable 1 rotatably connected to a frame, and a turntable drive motor 11 for driving the horizontal turntable 1 is provided on the frame.

[0047] At least one translation rolling wheel 2 is horizontally slidably connected to the upper surface of the horizontal turntable 1, and the translation rolling wheel 2 is connected to the translation driving mechanism 3 and the translation rolling wheel 2 is connected to the rotation driving mechanism 4. T...

Embodiment 2

[0072] The working principle and structure of this embodiment are basically the same as those of Embodiment 1, and the different structure is that there are 3-6 rolling units 20 .

Embodiment 3

[0074] The working principle and structure of this embodiment are basically the same as those of Embodiment 1. The different structures are: there is one rolling unit 20, and one loading and unloading unit, and the unloading action is performed after unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com