Rotating type raw material bar storing device

A technology for rotating drive devices and raw material rods, applied in tool storage devices, manufacturing tools, etc., can solve the problems of large occupied area, high labor intensity, difficult storage, etc., achieve small occupied plane area, reduce labor intensity, store and retrieve The effect of high material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

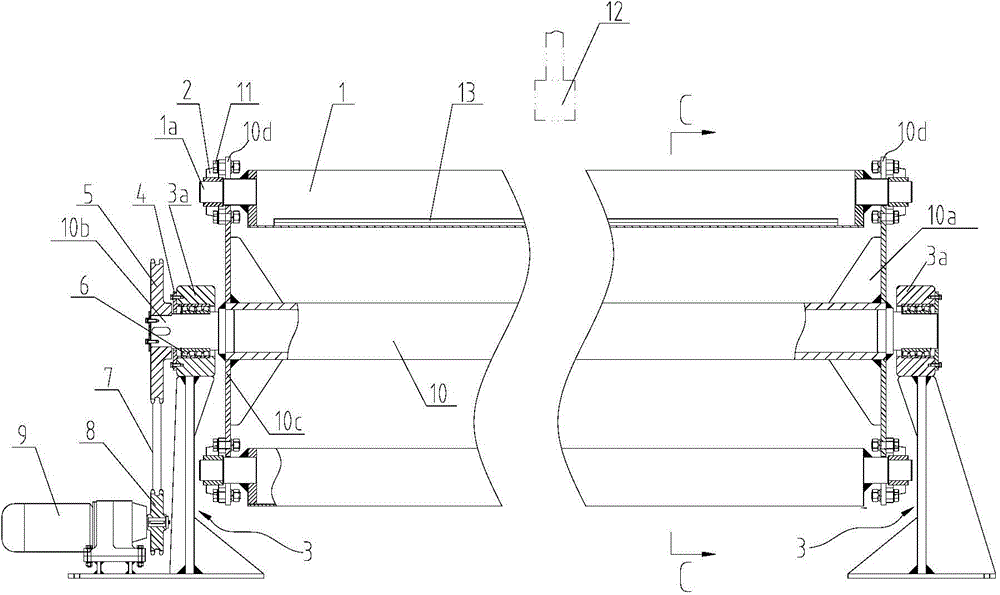

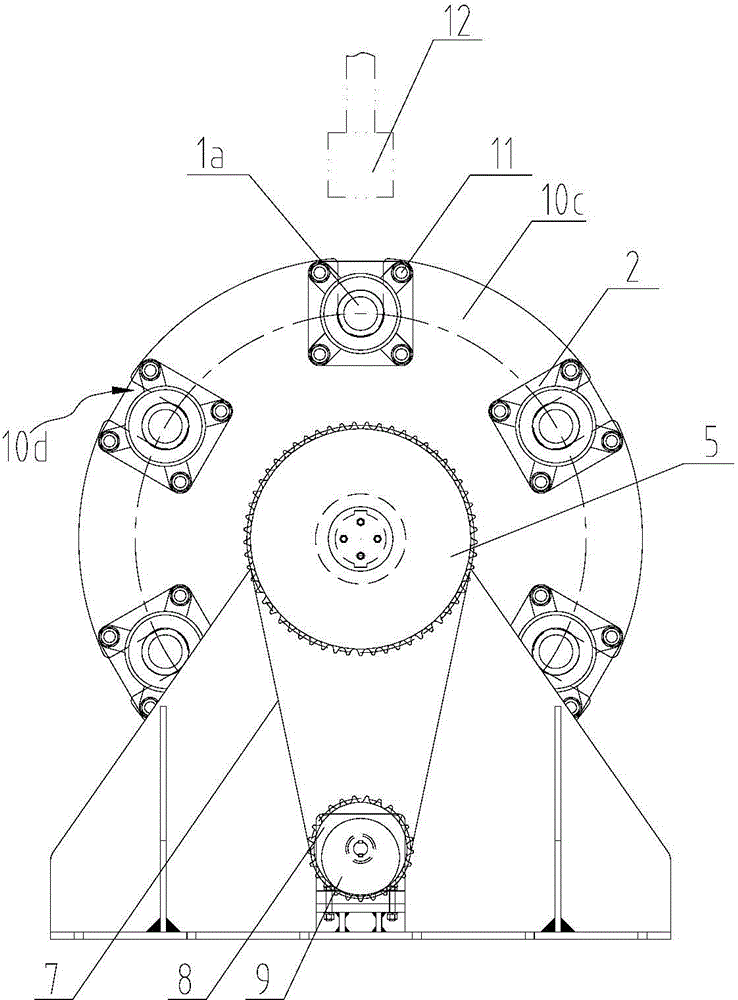

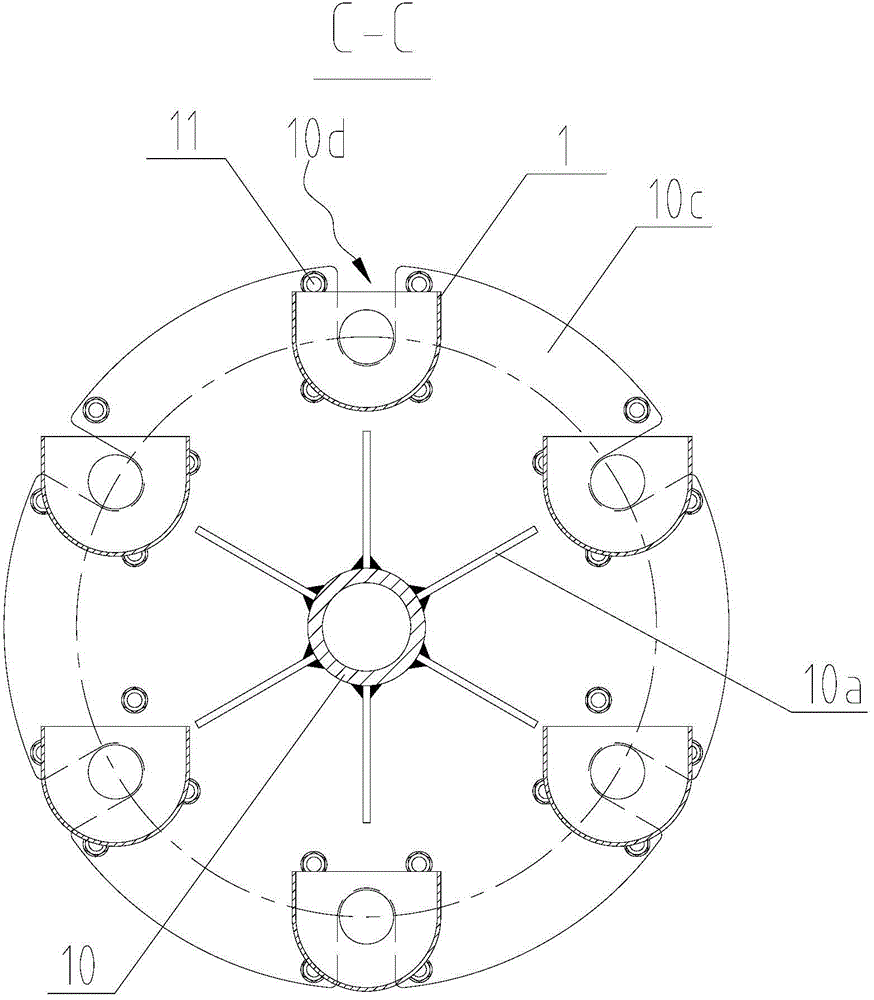

[0015] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] As shown in the figure, the present invention provides a rotary raw material rod storage device. The rotary raw material rod storage device includes: a rotating main shaft 10, and the two sides of the rotating main shaft 10 are respectively fixed at the same position Symmetrical rotating plate 10c, the two ends of the rotating main shaft 10 are respectively hinged in the bearing seat 3a on the upper part of the support frame 3, wherein one end of the rotating main shaft 10 passes through the bearing hole of the bearing seat 3a and connects a rotating drive device to drive the rotating main shaft 10 and two The rotary plate 10c rotates.

[0017] Between the above-mentioned two rotating plates 10c, a plurality of storage baskets 1 arranged at intervals are hingedly supported, and each storage basket 1 cross-section is a storage tank with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com