Detection equipment based on visual detection system and use method

A technology of visual inspection and inspection equipment, applied in the field of visual inspection, which can solve the problems of affecting detection efficiency, long cycle, and many turnover steps, and achieve the effects of avoiding air suction, less turnover steps, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

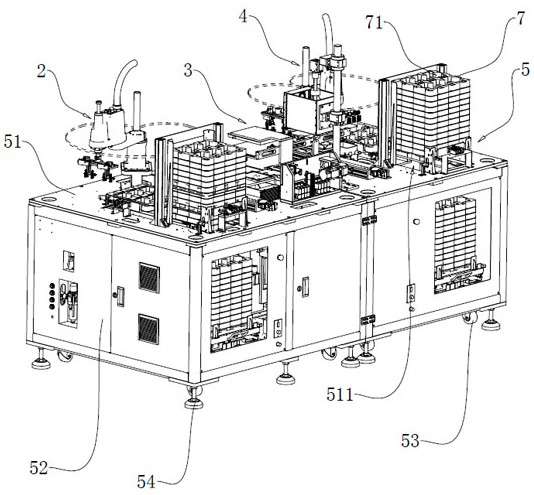

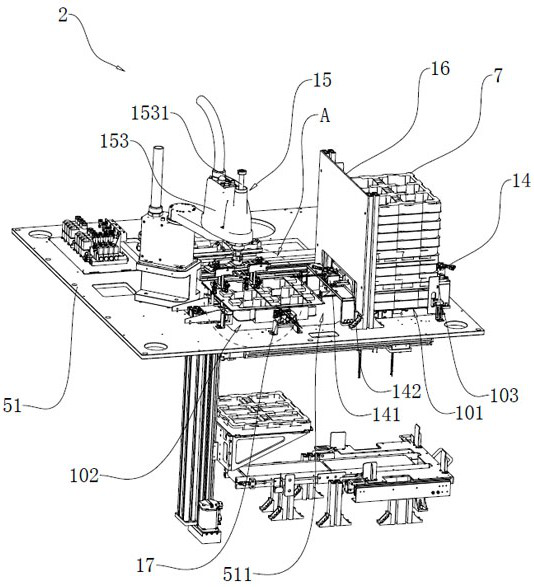

[0061] The embodiment of the present application discloses a detection device based on a visual detection system, which is used to take out the materials in the tray 7 for visual inspection, and then put them into the empty tray 7 . refer to figure 1 , in this embodiment, the tray 7 is a square plate body, which has six troughs 71 and is arranged in 2×3. Fifty pieces of materials can be stacked horizontally in each hopper 71 .

[0062] refer to figure 1 , the inspection equipment based on the visual inspection system includes a feeding area 2 , an inspection area 3 , a receiving area 4 and a workbench 5 . Wherein, the worktable 5 includes a worktable 51 , a table body 52 , universal wheels 53 and supporting feet 54 . Specifically, there is a component placement space inside the table body 52 , and the universal wheel 53 and the supporting feet 54 are installed under the table body 52 . The setting of universal wheel 53 facilitates the movement of the testing equipment; the...

Embodiment 2

[0111] The embodiment of the present application discloses a detection device based on a vision detection system and a method for using it. This embodiment is basically the same as Embodiment 1, except that the structure of the linear drive member 13 is changed.

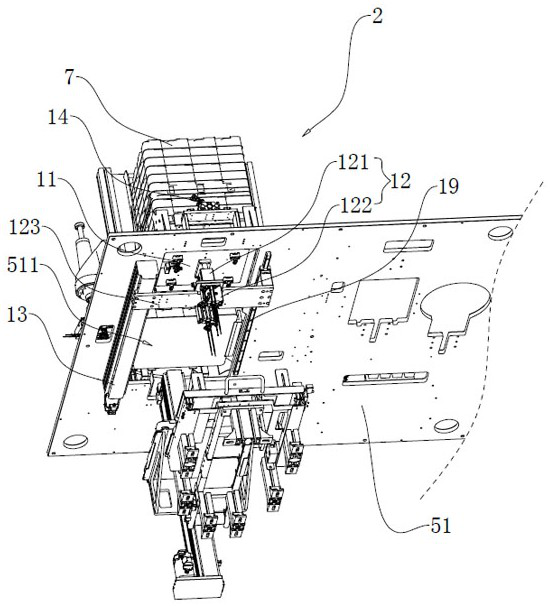

[0112] refer to Figure 11 , in the implementation of this embodiment, the linear drive member 13 is a driving cylinder, and is installed on the lower surface of the worktable 51; the telescopic direction of the piston rod of the driving cylinder is parallel to the length direction of the opening 511, and the piston rod and the connection Board 123 is connected. Simultaneously, on the lower surface of the worktable 51, a slide rail 19 (with a slider) is respectively installed outside the long sides of the opening 511; Parallel; both slide rails 19 extend from one end of the opening 511 to the other end. Both ends of the connecting plate 123 are installed on the sliders of the two slide rails 19 respectively. The ...

Embodiment 3

[0115] The embodiment of the present application discloses a detection device based on a vision detection system and a method for using it. This embodiment is basically the same as Embodiment 1, except that the structures of the tray supporting mechanism 14 and the tray fixing mechanism 17 are changed.

[0116] refer to Figure 12 and Figure 13 , in the implementation of this embodiment, the tray support mechanism 14 includes a first driving cylinder 141 and a first vacuum chuck 143 . The suction cup surface of the first vacuum suction cup 143 faces the palletizing position 101 , and the other side is affixed to the piston rod of the first driving cylinder 141 . During operation, the first driving cylinder 141 drives the first vacuum chuck 143 close to the side of the tray 7; through the vacuum adsorption of the first vacuum chuck 143 and the clamping effect of the two first vacuum chucks 143 on the tray 7, the support for the tray 7 is realized. .

[0117] Similarly, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com