Material fetching mechanism for full-automatic cabin cleaning vehicle

A fully automatic, pusher plate technology, applied in the direction of mechanical equipment, transmission devices, gear transmission devices, etc., can solve the problems of miniaturization of facilities in the cabin, weak operation, huge structure, etc., and meet the requirements of miniaturization configuration, The overall structure is simple but not complicated, and the effect of high material retrieving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

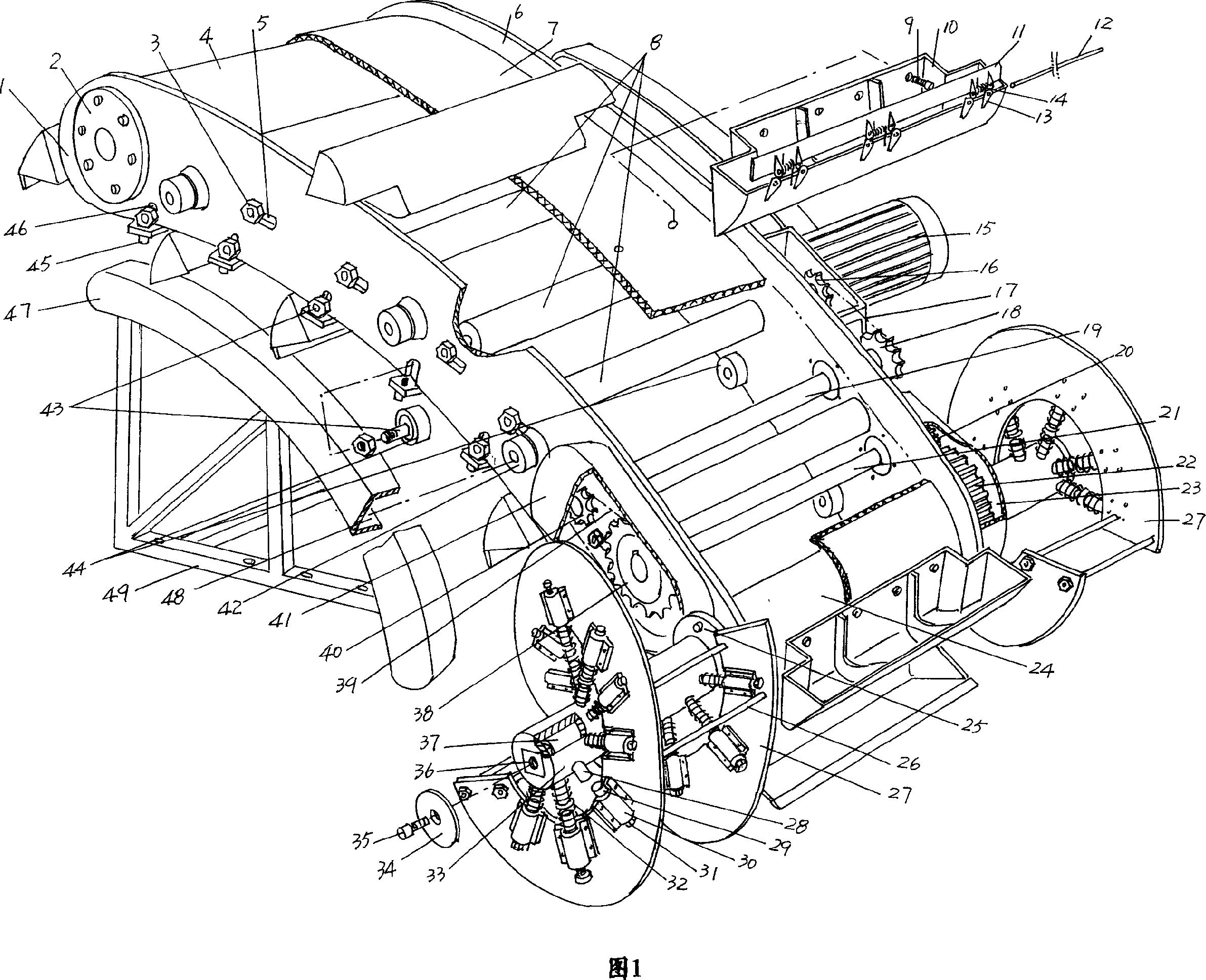

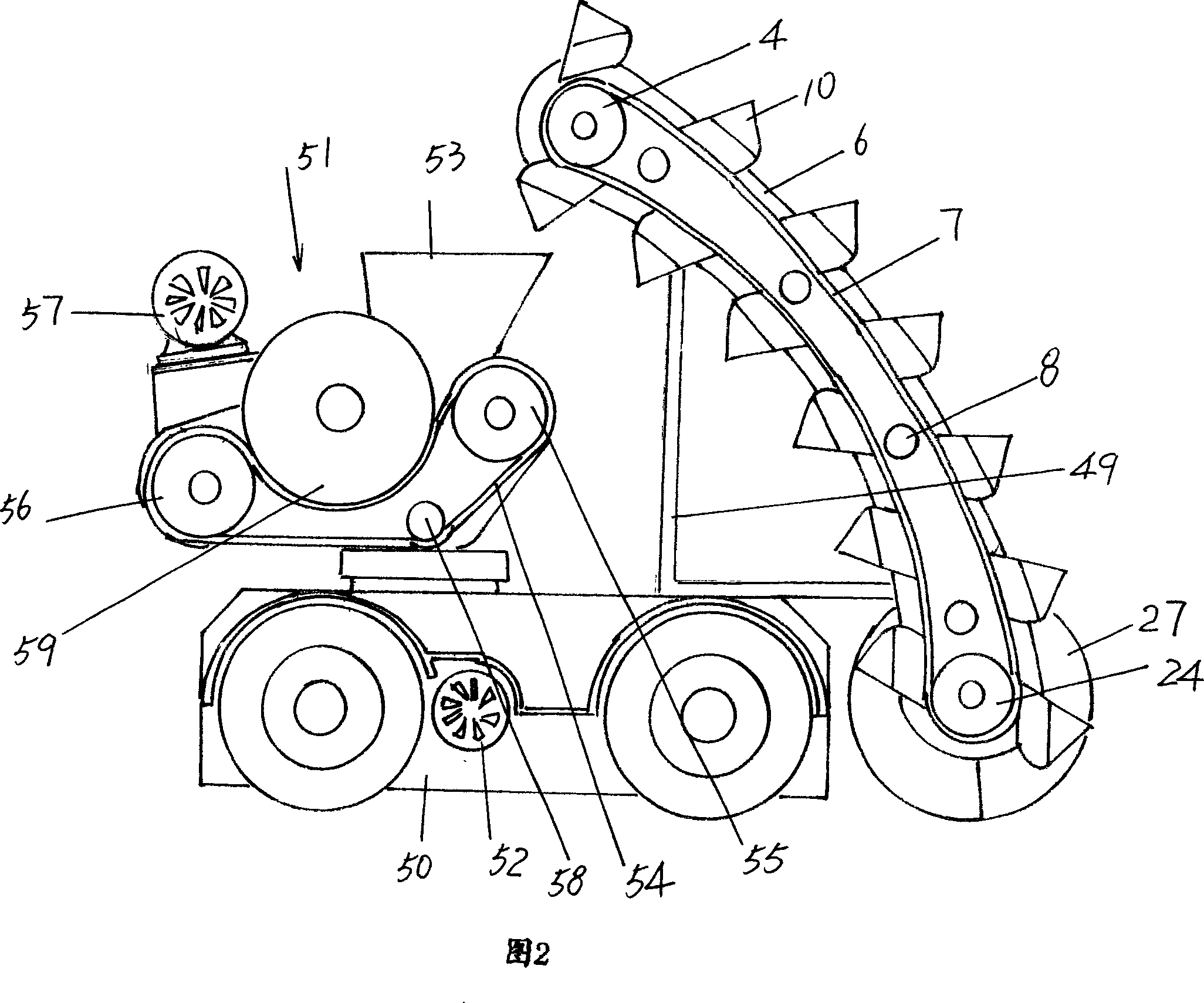

[0020] In Fig. 1, the left and right wallboards 1, 6 mentioned by the applicant are for the current position shown in the figure, and the overall shape of the pair of left and right wallboards 1, 6 is arched The banana shape or the crescent shape of the category, the two are in corresponding positions and have the same shape. The two ends of the rotary roller 4 are pivoted on the tail ends of the left and right wallboards 1, 6 through a pair of first roller shaft seats 2, and the middle part is integrally located between the left and right wallboards 1, 6, and the rotary roller The length of tube 4 promptly constitutes the phase distance between left and right wall panels 1,6. The driving roller 24 is pivotally placed on the front ends of the left and right wallboards 1, 6 through a pair of second roller bearing seats 25. As seen from the figure, the middle part of the driving roller 24 is integrally located on the left and right wallboards 1, 6. Between 6, yet its axle namel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com