Inner and outer ring machining device for producing cable reels

A technology for processing devices and inner and outer rings, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc. It can solve the problems that automatic lengthening cannot be realized, and the size of the inner and outer rings of cable reels cannot be automatically adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

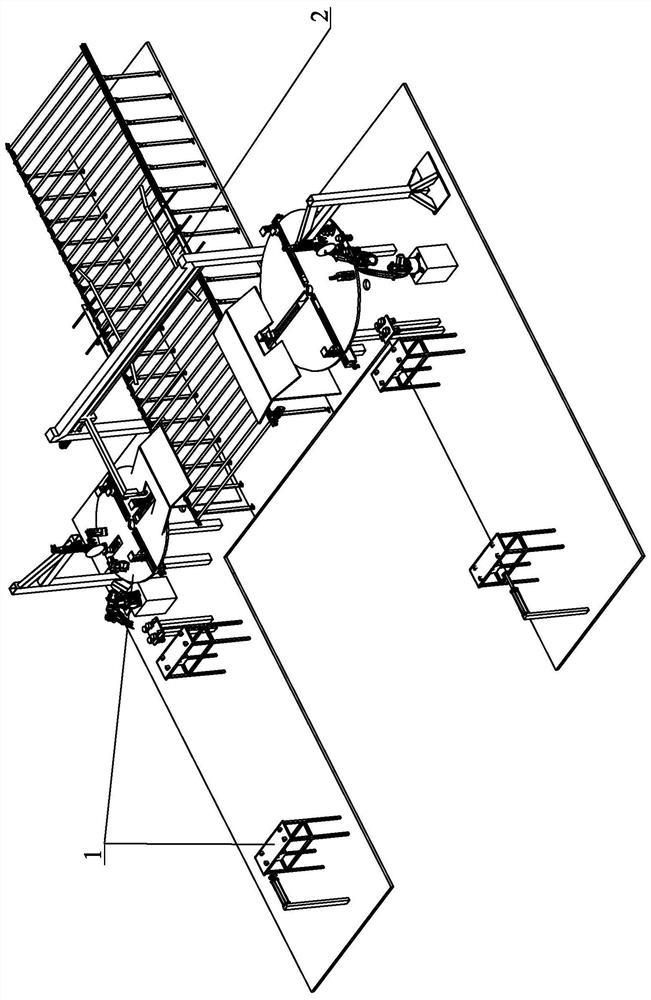

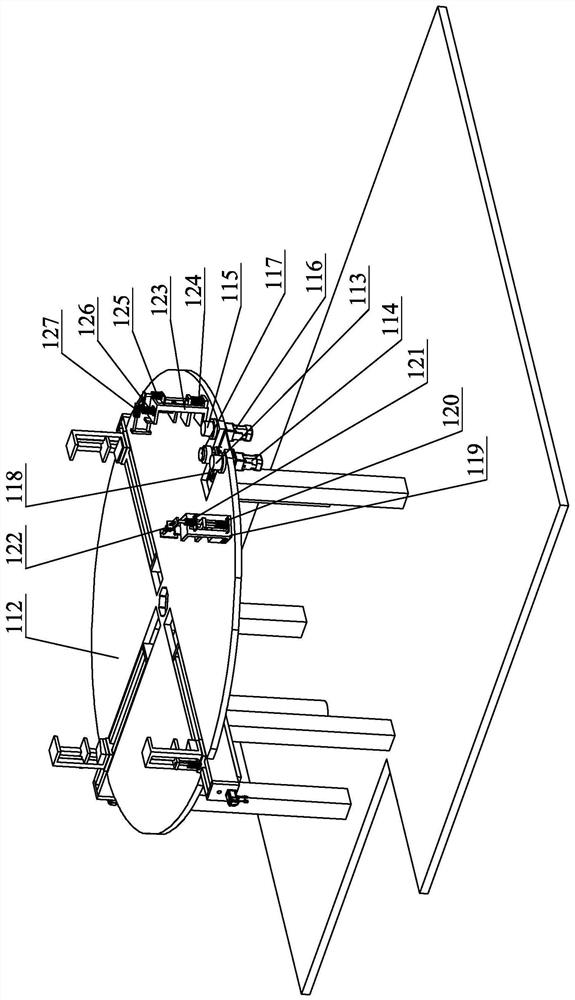

[0020] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this embodiment. The inner and outer ring processing device used for cable reel production described in this embodiment includes two sets of circle components 1 and discharge components 2. The two sets of circle components 1 are symmetrically arranged on the discharge component 2 for feeding On both sides of the end, the circle circle assembly 1 includes a feeding and extending mechanism and a circle circle mechanism, and the material feeding and extending mechanism is arranged on the rear of the circle mechanism feeding end.

[0021] In this embodiment, the ring assembly 1 is used to obtain the raw material ring of the cable reel and perform welding processing; the output assembly 2 is used to take out the welded inner ring and outer ring of the cable drum and transport them to other working areas. Two sets of ring components 1 process the inner ring and outer ring of the cable reel respectively....

specific Embodiment approach 2

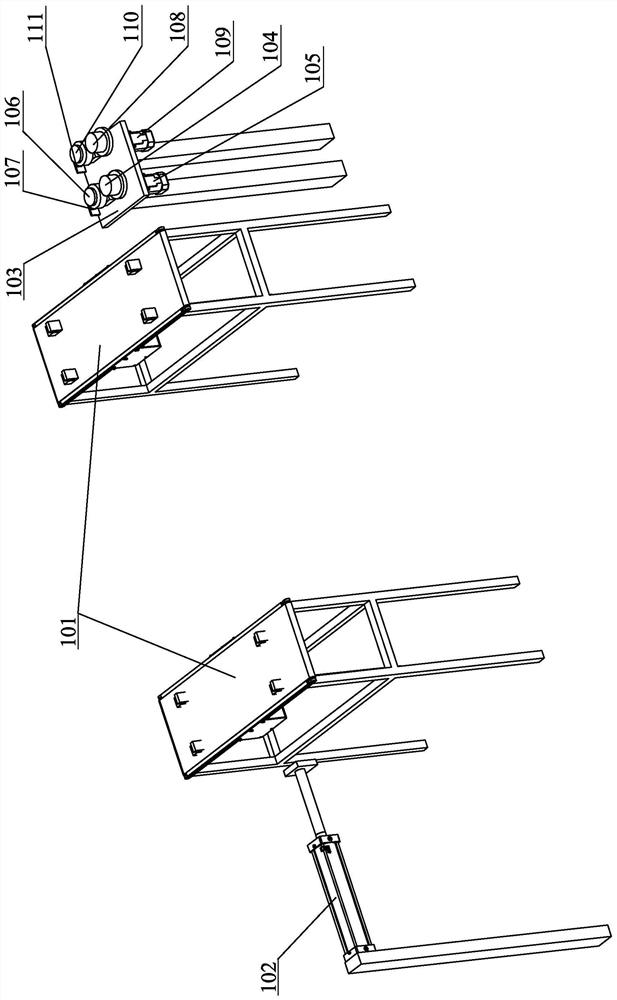

[0022] Specific implementation mode two: combination Figure 1 to Figure 10 Description of this embodiment, the feeding and lengthening mechanism described in this embodiment includes a conveyor belt group 101, a pusher 102 and a lengthening mechanism 103, and the pusher 102 is arranged directly behind the lengthening mechanism 103, and the pusher 102 is connected to the connecting mechanism 103. Conveyor belt sets 101 are arranged between the long mechanisms 103 , and the advance direction of the conveyer belt sets 101 is perpendicular to the advance direction of the pusher 102 . Other compositions and connection methods are the same as those in Embodiment 1.

[0023] The conveyor belt set 101 includes two conveyor belt mechanisms arranged side by side. Each conveyor belt mechanism is respectively driven by a conveyor belt motor, and the two conveyor belt mechanisms move synchronously for transporting raw materials.

[0024] The pusher 102 is fixedly connected to one side o...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination Figure 1 to Figure 10 Describe this embodiment, the lengthening mechanism 103 described in this embodiment includes a delivery platform, a first guide wheel set and a second guide wheel set, the first guide wheel set and the second guide wheel set are arranged side by side on the upper end of the delivery platform, and the second guide wheel set is arranged side by side on the upper end of the delivery platform. A set of guide wheels includes a first driving guide wheel 104 and a first passive guide wheel 106 oppositely arranged, a gap is provided between the first driving guide wheel 104 and the first passive guide wheel 106, and the lower end of the first driving guide wheel 104 is connected to There is a first driving guide wheel motor 105, a first passive guide wheel cylinder 107 is provided on one side of the first passive guide wheel 106, and a second guide wheel group includes a second driving guide wheel 108 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com