Vision-guided automatic mounting machine and using method thereof

A visual guidance, placement machine technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of complex operation of placement machines, slow placement speed, slow placement efficiency, etc., to avoid changes, improve placement accuracy, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

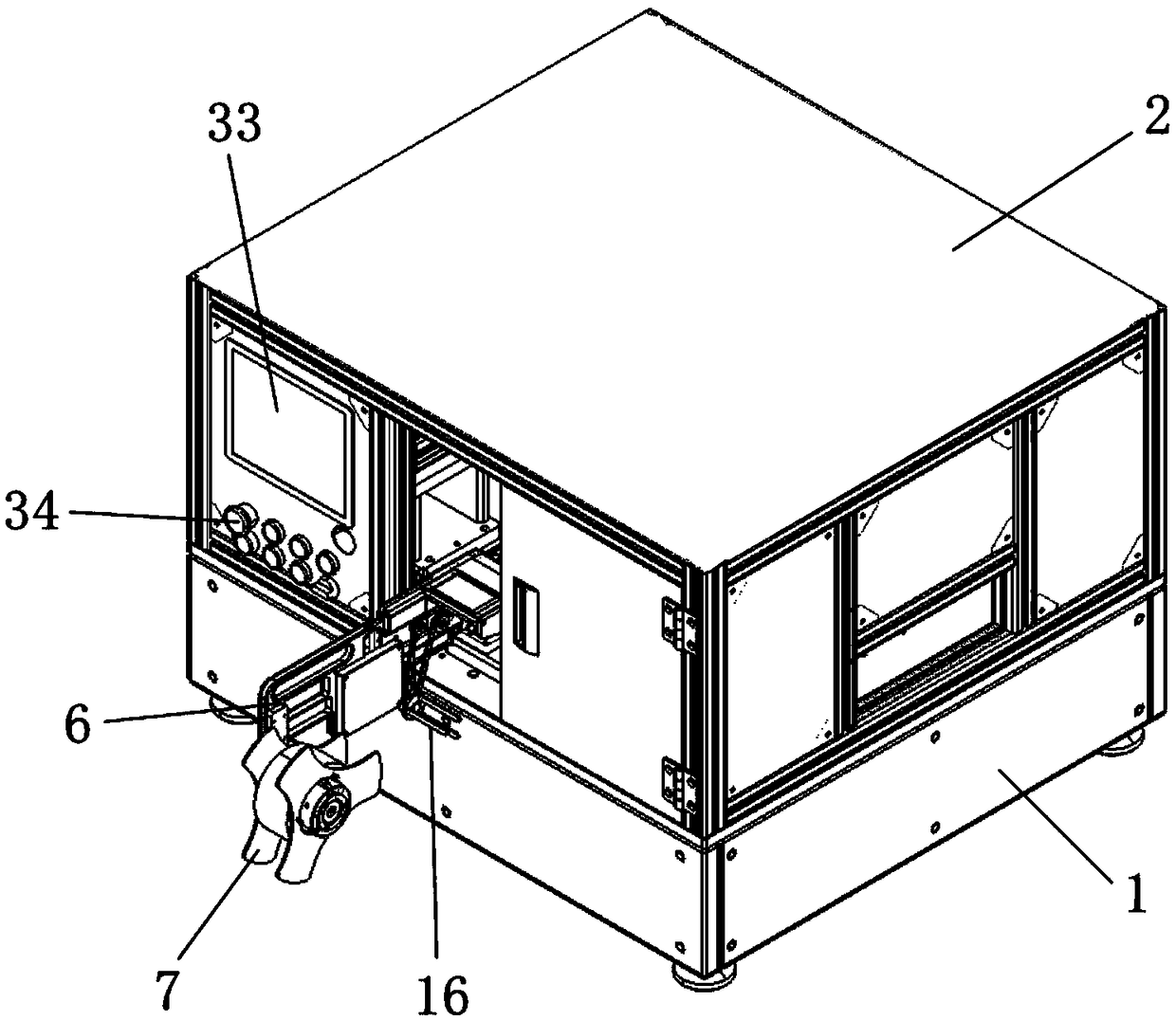

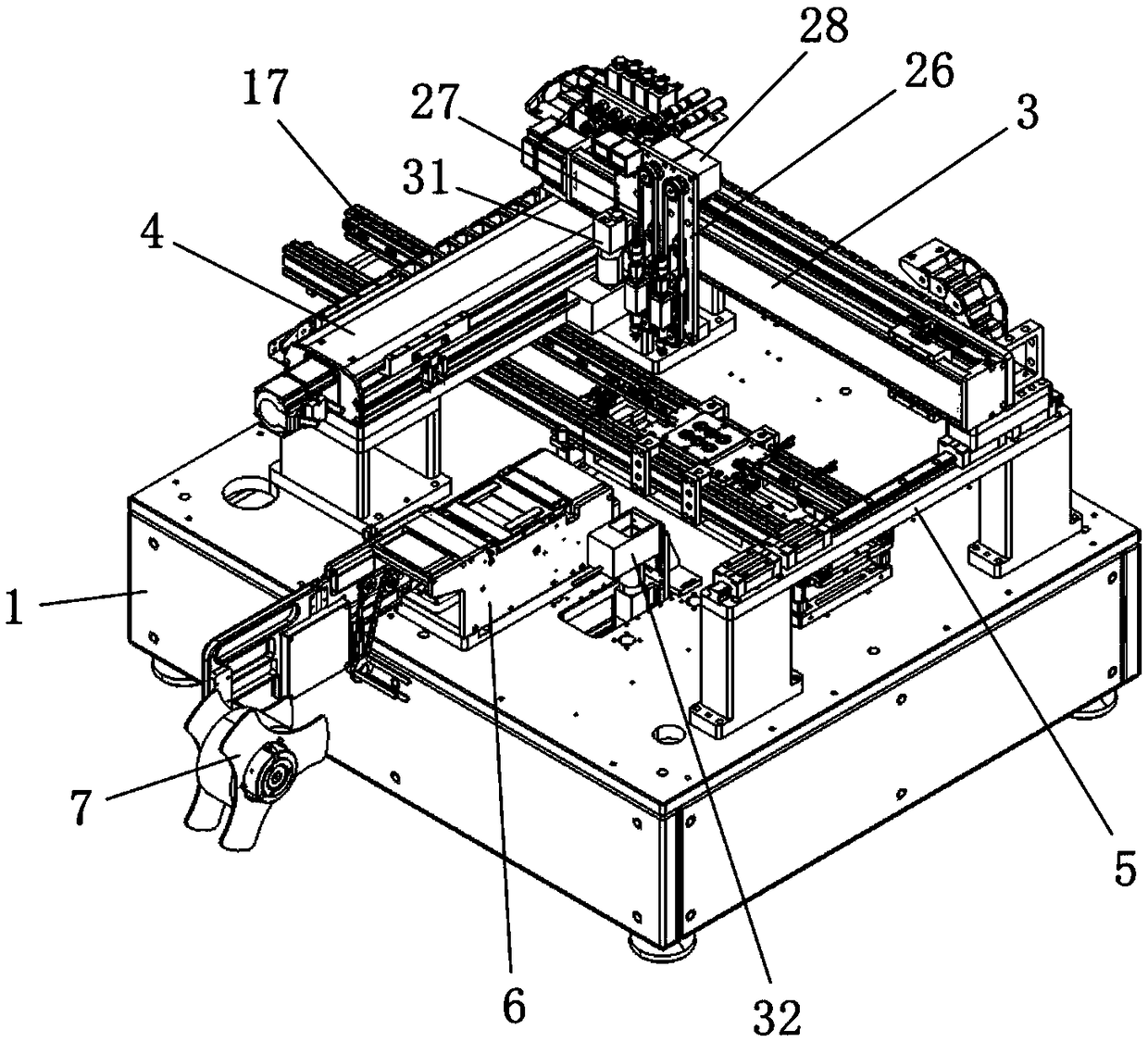

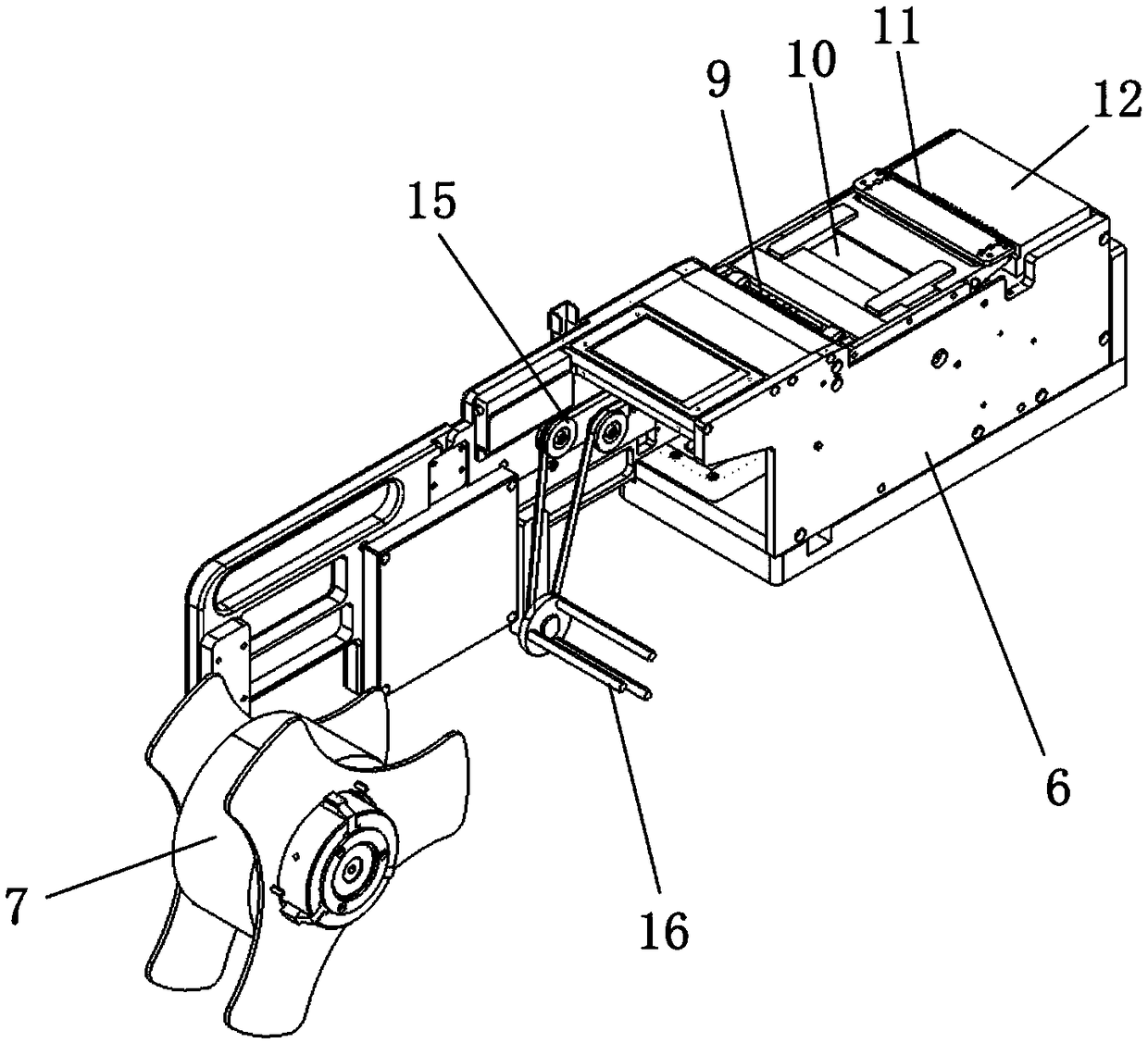

[0035] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0036] like Figure 1 to Figure 7As shown, a vision-guided automatic placement machine includes: a displacement mechanism, the displacement mechanism includes an X-axis slide table 3 and a Y-axis slide table 4; the X-axis slide table 3 can move along the length direction of the Y-axis slide table 4; The existence of the sliding table 3 and the Y-axis sliding table 4 can change the position of the mounting mechanism more quickly, realize accurate mounting of the pasted products, and improve the mounting accuracy. The feeding mechanism, the feeding mechanism and the Y-axis sliding table 4 parallel, the feeding mechanism includes a feeding seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com