Distributing valve for concrete pump

A concrete pump and distribution valve technology, which is applied to the components of the pumping device for elastic fluid, pumps, piston pumps, etc. The effect of local force, better suction performance, and increased use volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

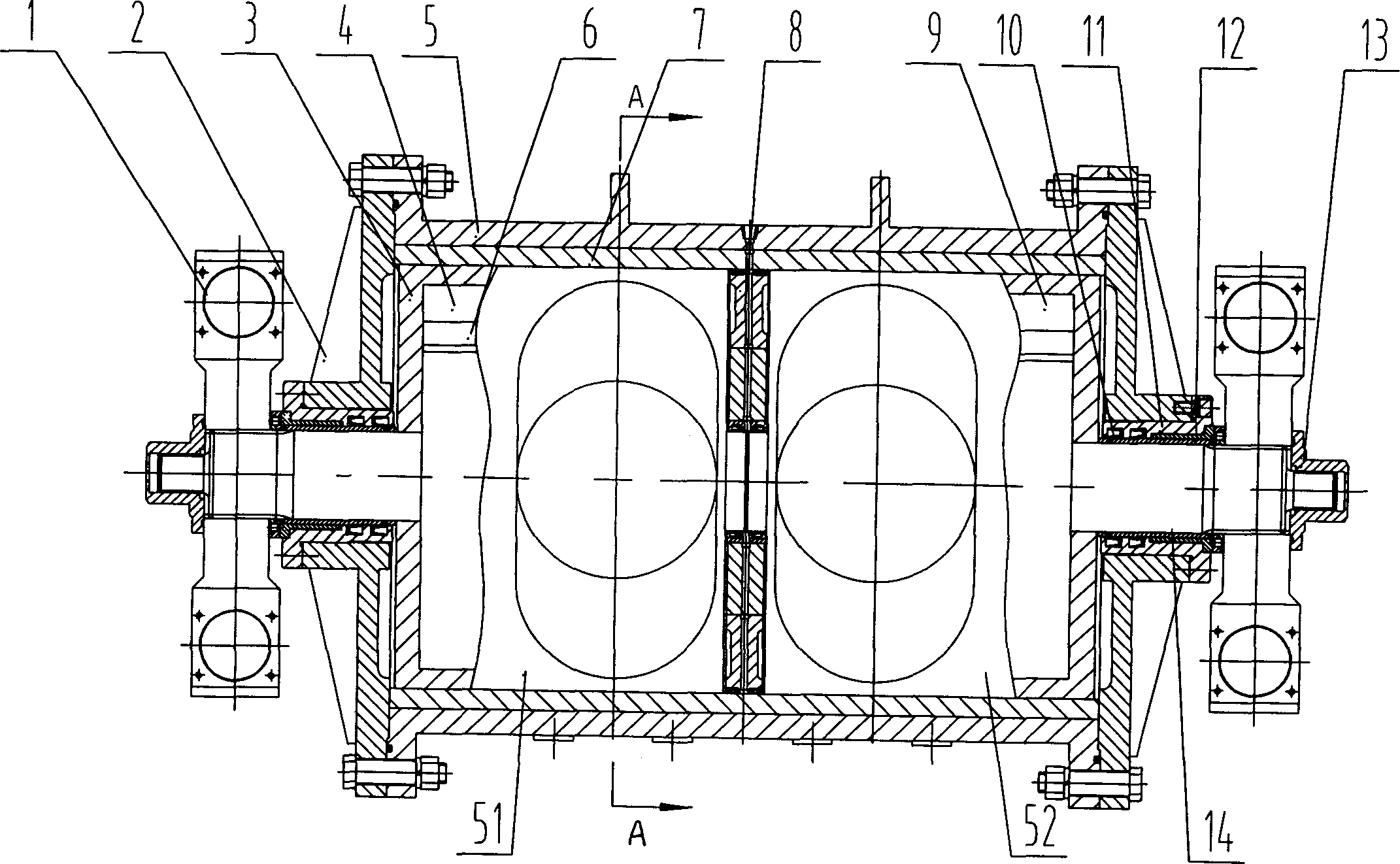

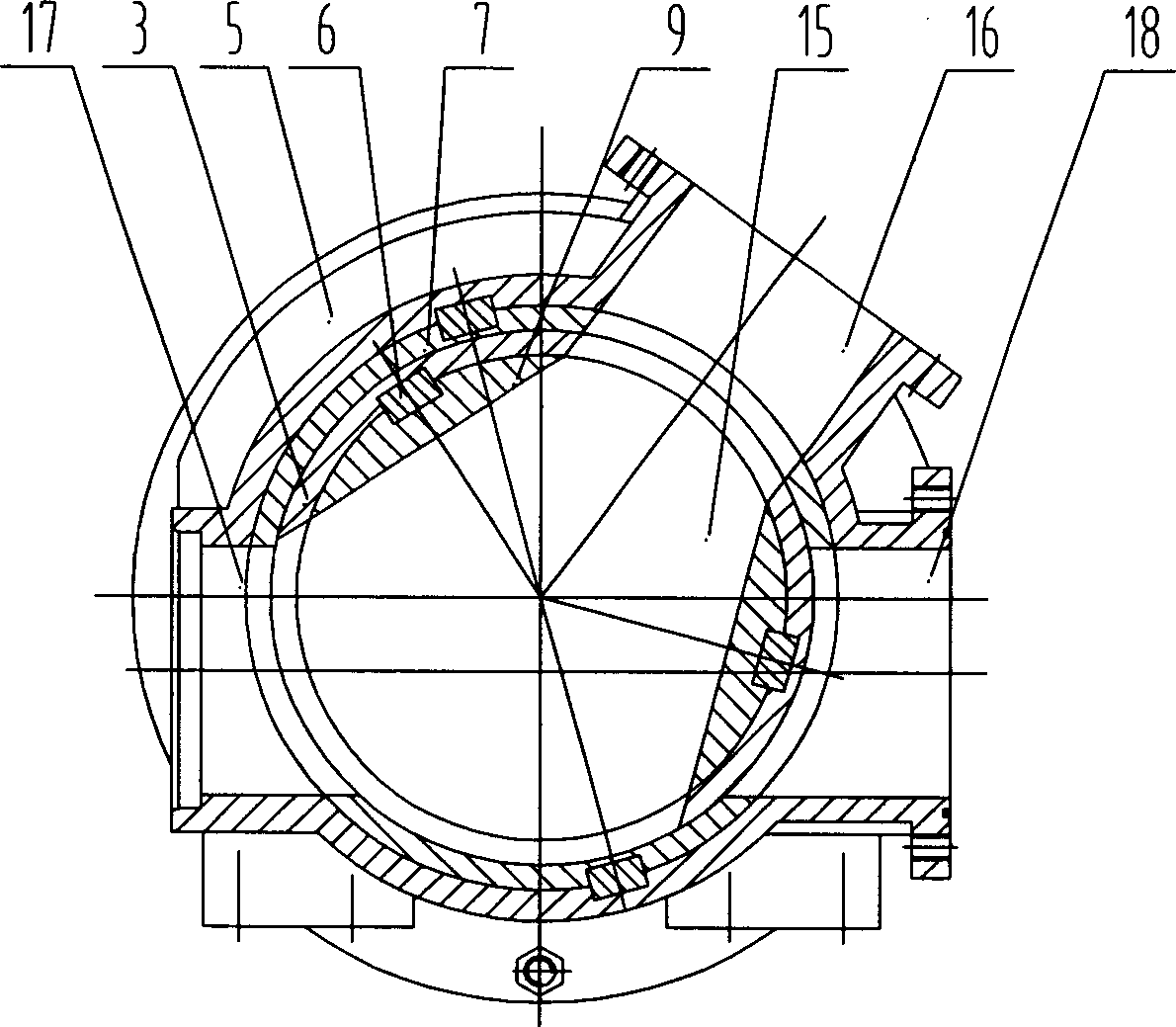

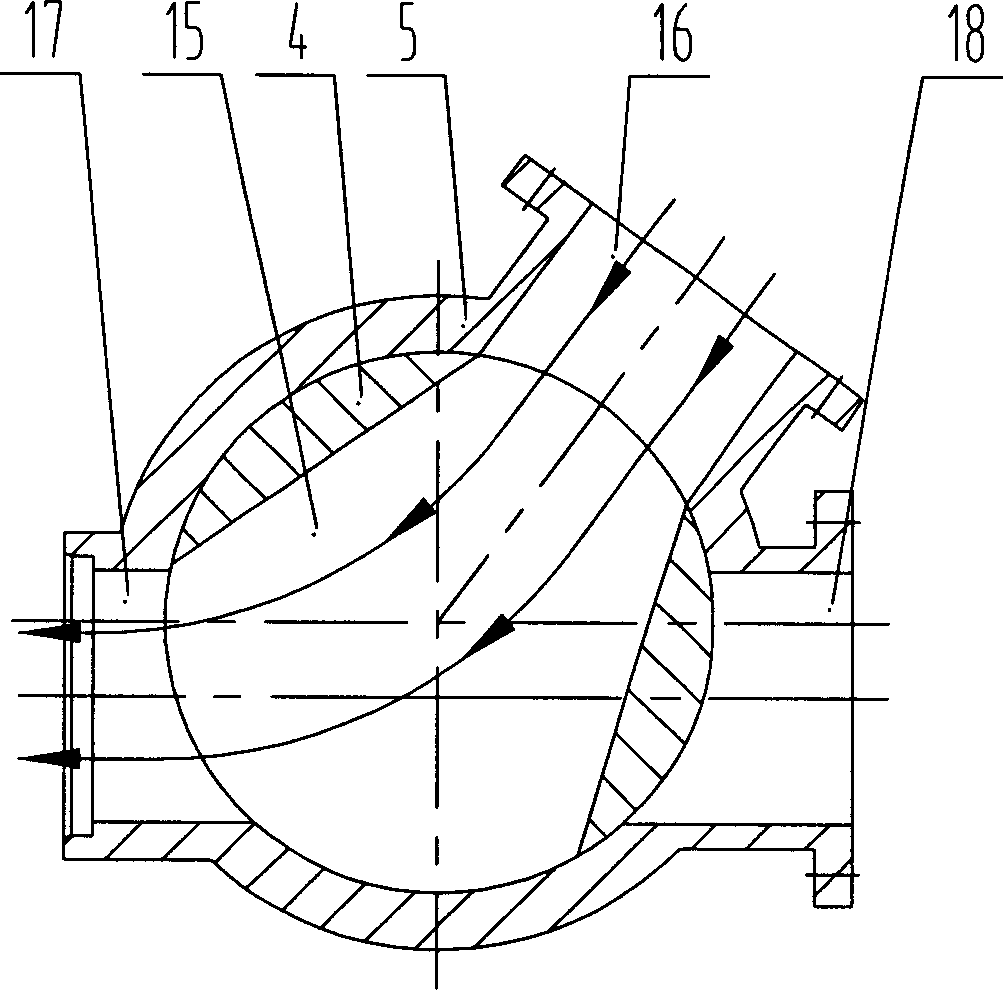

[0031] Such as figure 1 , figure 2 with Image 6 The distribution valve for concrete pump shown in the present invention includes a valve body 5, a rocker arm 1, an end cover 2, a left-turn valve 4 and a right-turn valve 9, and the end cover 2 is installed at both ends of the valve body 5 , divided into left valve cavity 51 and right valve cavity 52 in the cylindrical valve body 5 cavity, the left valve cavity 51 and right valve cavity 52 in the valve body 5 are separated by a spacer 8 or a partition, and the spacer 8 An oil injection channel is opened on the top to inject high-pressure lubricating oil to facilitate the lubrication of the valve body 5 and prevent the infiltration of concrete slurry. A seal is installed on the spacer 8 to prevent the two chambers from colluding; the left-turn valve 4 and right-turn valve 9 can be fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com