Impeller, electric air blower using same, and electric cleaner using electric air blower

A blower and impeller technology, which is applied in the fields of impellers, electric blowers using the impeller and vacuum cleaners using the electric blower, can solve the problems of unrealistic, high cost, difficulty in mass production by casting method, etc. high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

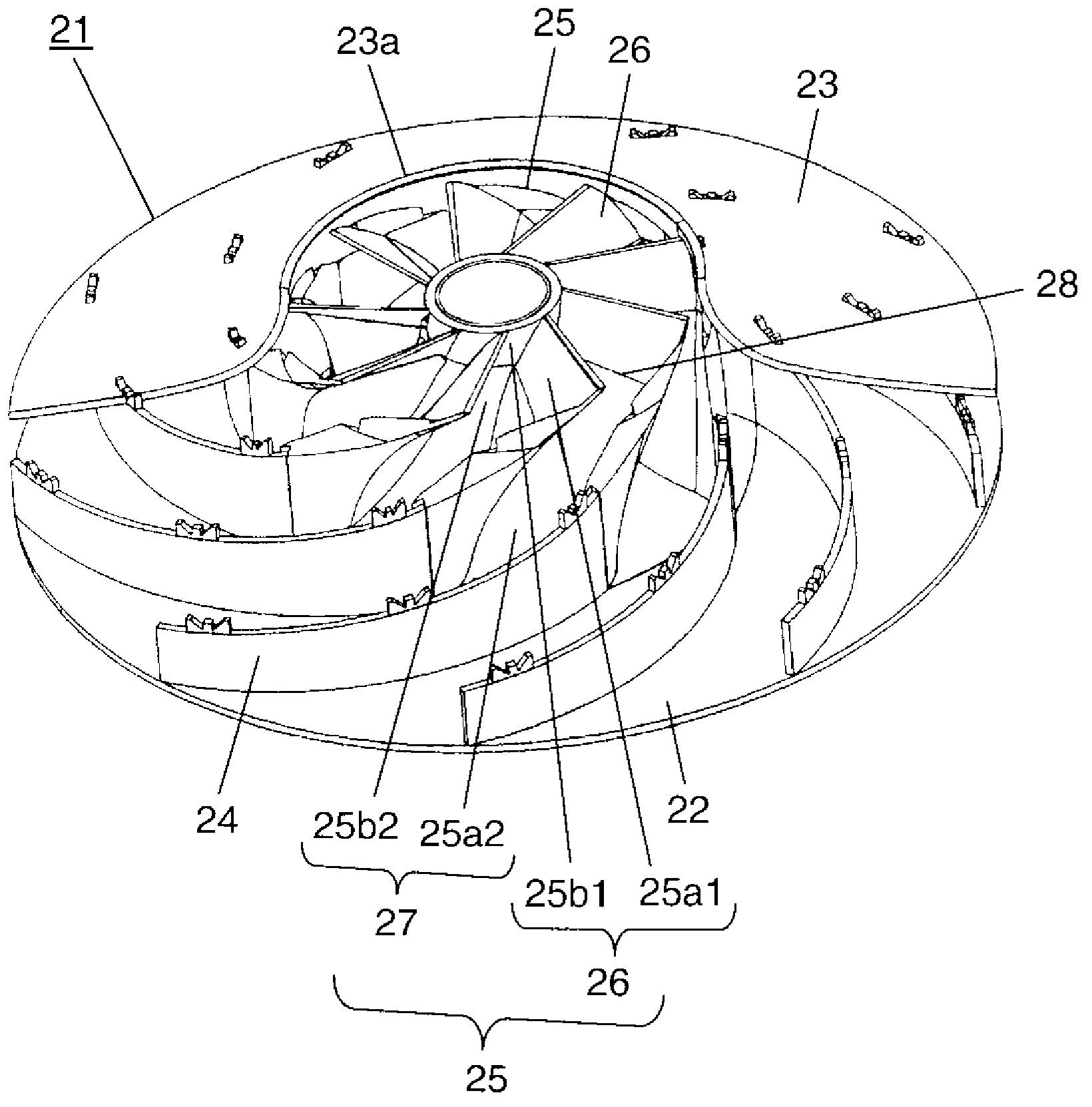

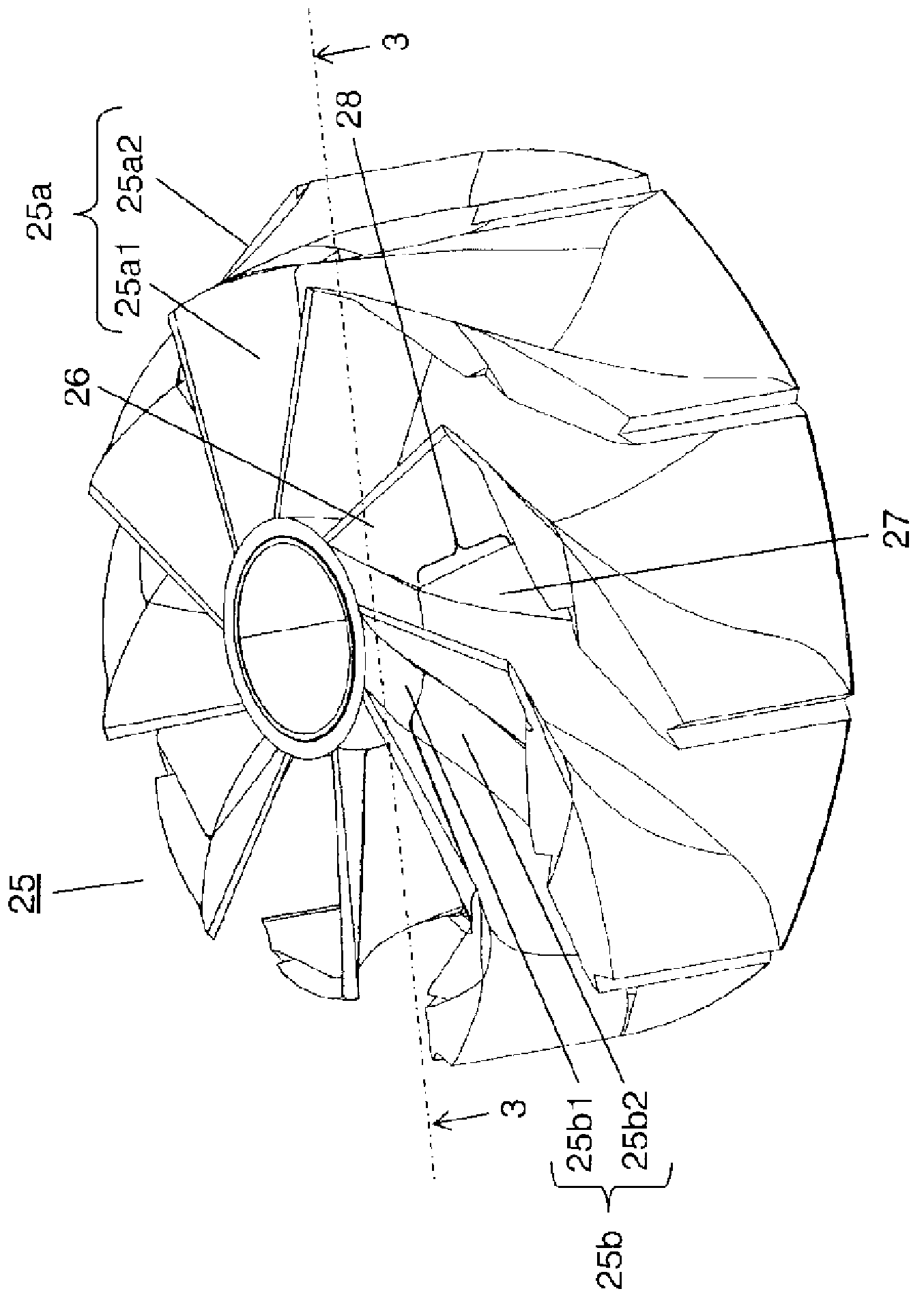

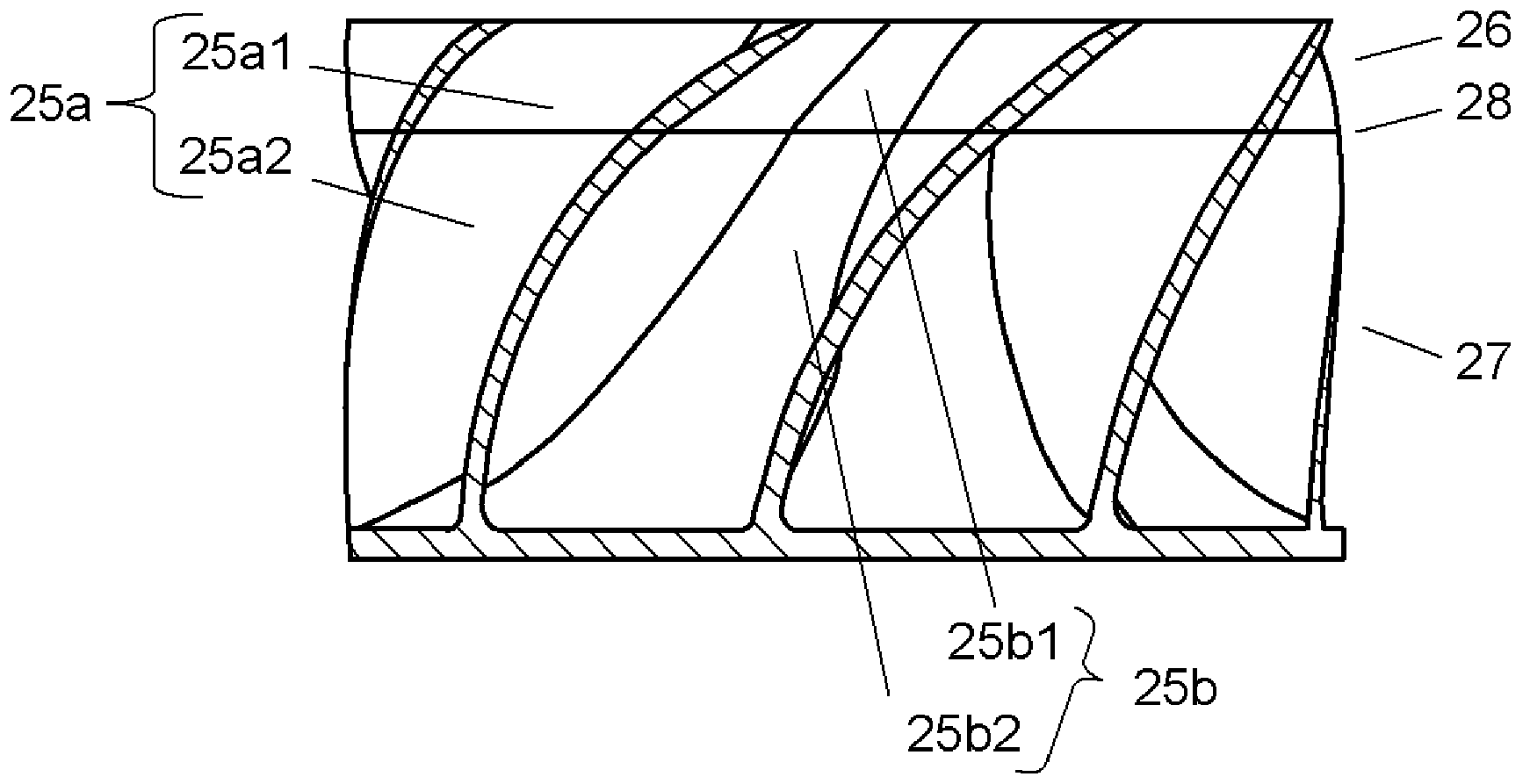

[0040] figure 1 It is a cutaway perspective view explaining the structure of the impeller in Embodiment 1 of this invention. figure 2 It is a perspective view of the inducer of the impeller in Embodiment 1 of this invention. image 3 of the impeller according to Embodiment 1 of the present invention figure 2 View of the 3-3 wire inducer. Figure 4 It is a plan view of the first inducer of the impeller according to Embodiment 1 of the present invention. Figure 5 It is a perspective view showing the second inducer of the impeller according to Embodiment 1 of the present invention. In addition, since the structure of the electric blower with the impeller installed on the motor is basically the same as that of the conventional electric blower, please refer to Figure 17 Be explained.

[0041] Hereinafter, the impeller mounted on the motor of the electric blower will be described in detail.

[0042] Such as figure 1 shown, is motor 7 (refer to Figure 17 ) The impeller...

Embodiment approach 2

[0066] Figure 9 is the inducer constituting the impeller according to Embodiment 2 of the present invention figure 2 3-3 line view.

[0067] The impeller of this embodiment differs from Embodiment 1 in that at least one side of the joint portion 28 between the first blade portion 25a1 of the first inducer 26 and the second blade portion 25a2 of the second inducer 27 is Grooves 29 are provided on the joint face. In addition, other structures are the same as those of Embodiment 1.

[0068] Such as Figure 9 As shown, the inducer 25 of the impeller 21 in this embodiment is provided with a groove 29 on the joint surface along the joint portion 28 between the first blade portion 25 a 1 of the first inducer 26 and the second inducer 27 . Then, an adhesive is applied in the groove 29 to bond the first blade portion 25 a 1 of the first inducer 26 and the second inducer 27 . At this time, since the adhesive flows along the grooves 29, the adhesive can be applied efficiently and ...

Embodiment approach 3

[0073] Figure 10 is the inducer constituting the impeller according to Embodiment 3 of the present invention figure 2 3-3 line view.

[0074] The impeller of this embodiment differs from Embodiment 2 in that the joint at least one side of the joint portion 28 between the first hub 25b1 of the first inducer 26 and the second hub 25b2 of the second inducer 27 is different from that of the second embodiment. Grooves 29b are provided on the surface. In addition, other structures are the same as those of Embodiment 2.

[0075] Such as Figure 10 As shown, the inducer 25 of the impeller 21 in this embodiment is provided with grooves 29b scattered or all over the joint surface along the joint surface of the first hub 25b1 of the first inducer 26 and the joint portion 28 between the second inducer 27. .

[0076] Then, when the first inducer 26 and the second inducer 27 are bonded together, from the outer peripheral portion of the first blade portion 25a1 and the second blade po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com