Concrete distributing valve and concrete pumping mechanism

A technology for concrete pumps and distribution valves, which is applied to conveyors, parts of pumping devices for elastic fluids, pumps, etc., to achieve the effects of easy cleaning, good material feeding, and better suction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

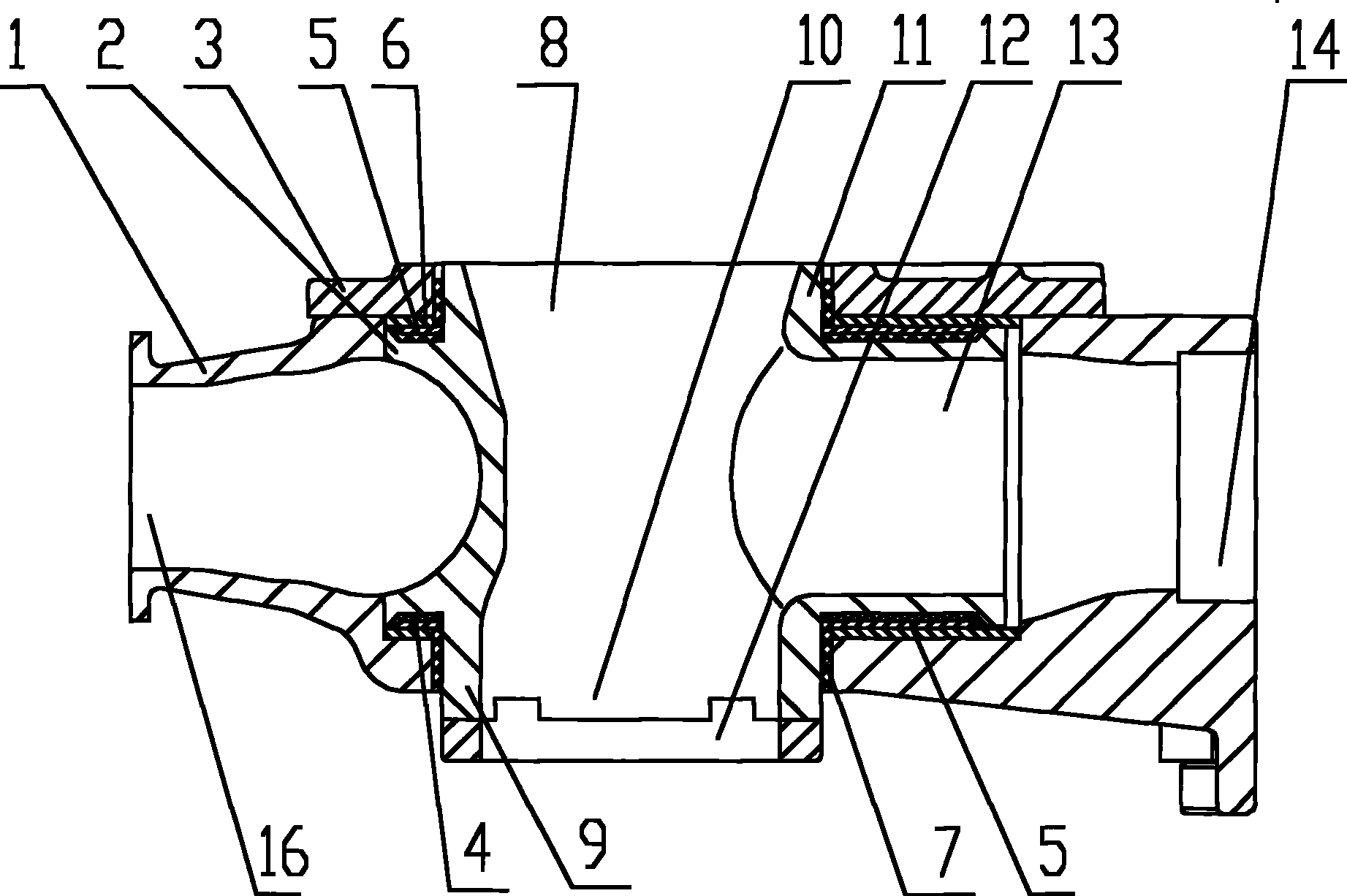

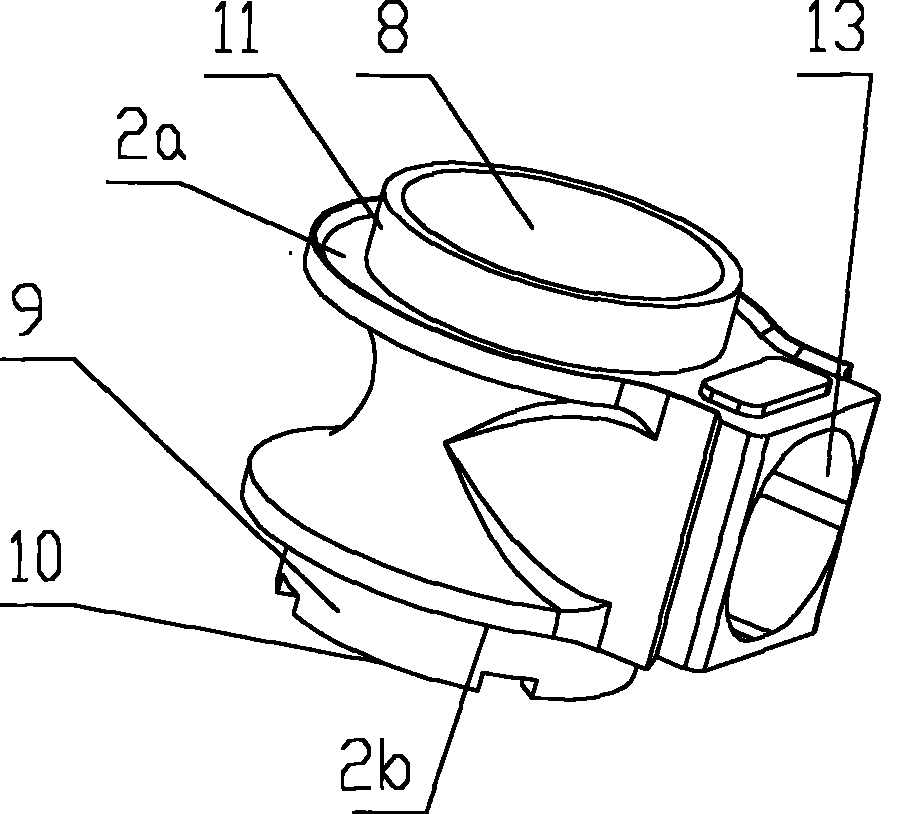

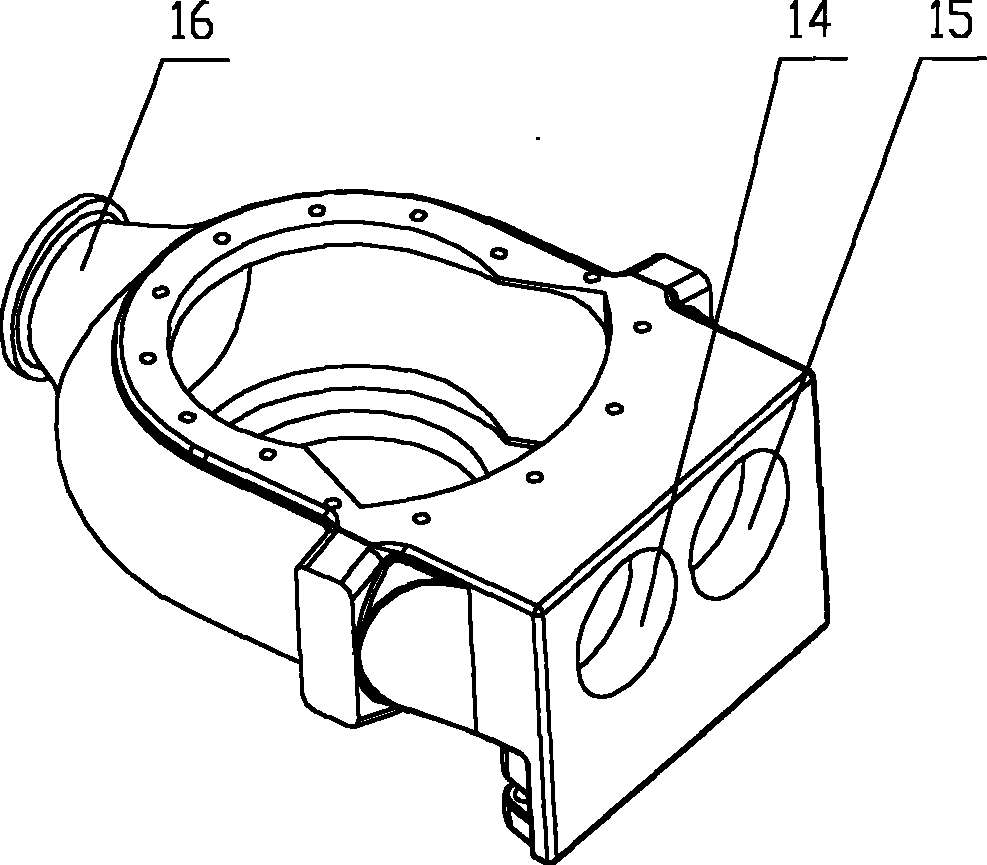

[0033] Between the valve core 2 and the valve body 1 there is a channel communicating with the first material suction port 14 , the second material suction port 15 and the material discharge port 16 .

[0034] Since the distribution valve and the hopper 17 are arranged separately, the use volume of the hopper 17 is increased, the blades of the hopper 17 are stirred more fully, and the feeding port 8 is arranged vertically downward, which is more conducive to feeding, especially for the pumping of coarse aggregate, Better suction performance, no accumulation of material, easy to clean. At the same time, in the process of pumping, because there is a passage between the valve body 1 and the valve core 2 of the distributing valve, which communicates with the first suction port 14, the second suction port 15 and the discharge port 16, a higher Pressure feeding process.

[0035] The side wall of the valve core 2 is provided with a concave annular groove which is in contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com