Inflation tire

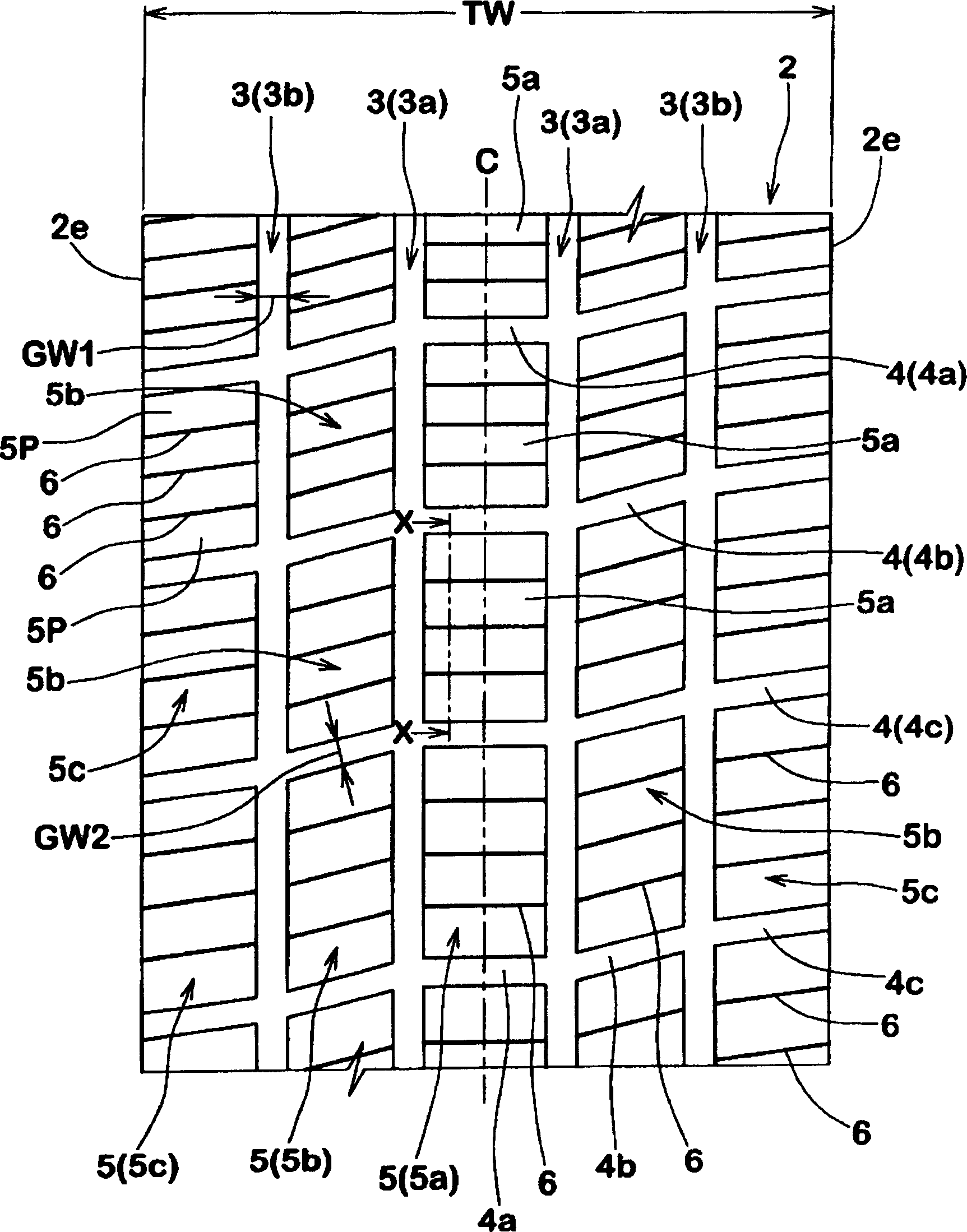

A technology of pneumatic tires and tire radius, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problem of insufficient water film suction effect, etc., to improve suction effect and improve driving performance , the effect of preventing occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

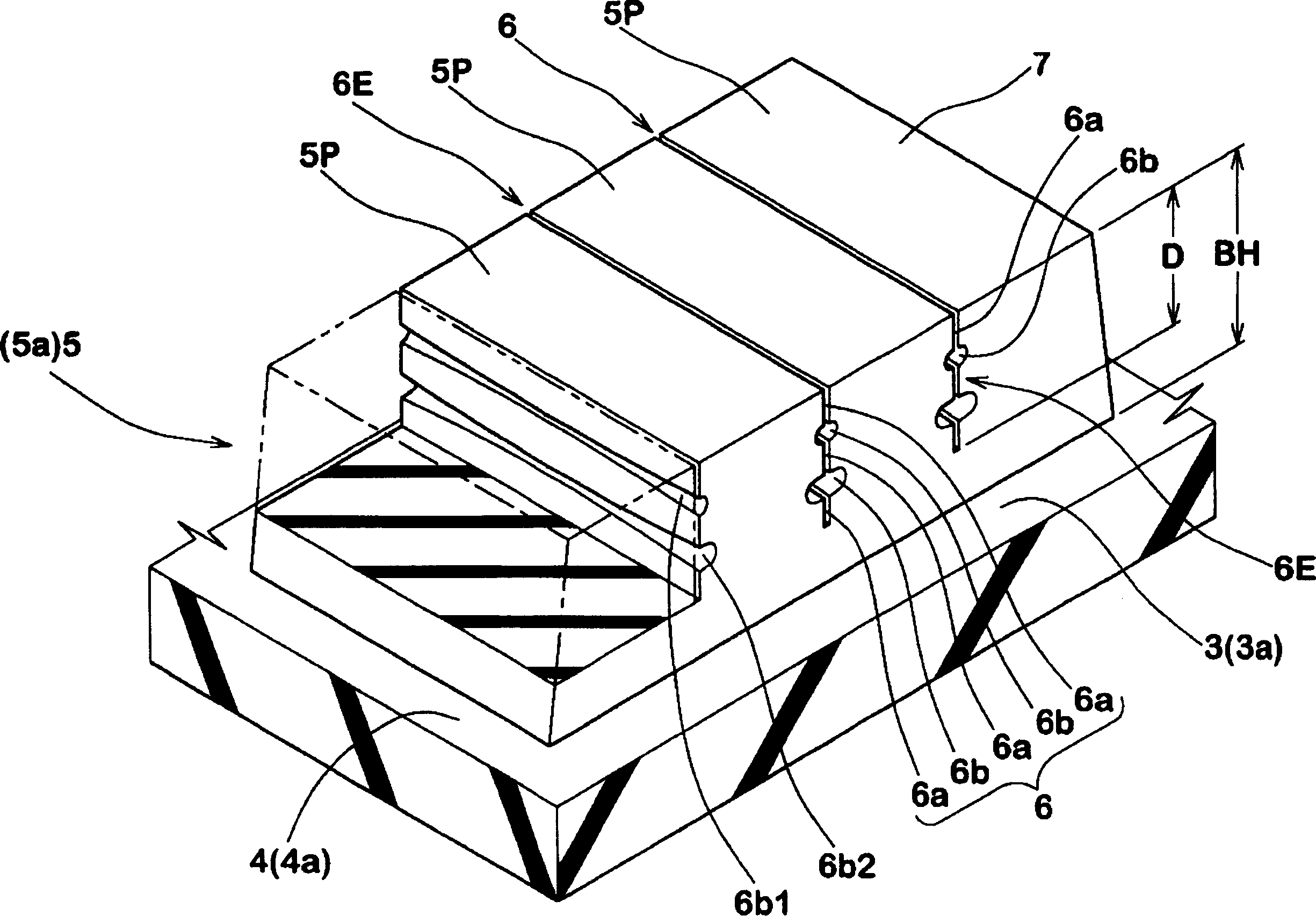

Method used

Image

Examples

Embodiment 1~2

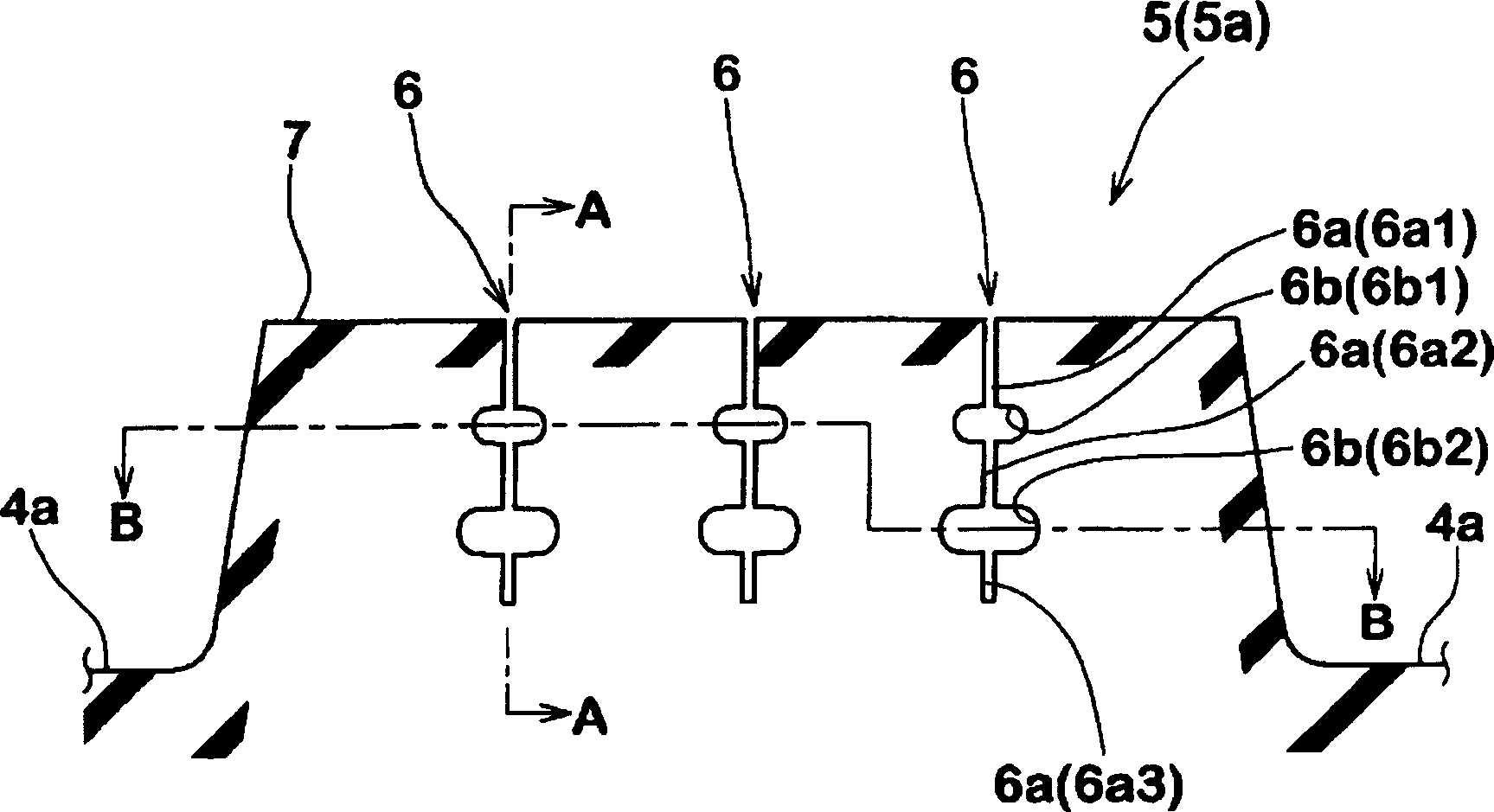

[0069] In Example 1 and Example 2, in all the blocks, the Figure 11 The dimension X of (A) is a half-open sipe-like narrow groove that is 0.7 times the block width BW. In Example 1, one widening portion was provided in one sipe-like narrow groove, and in Example 2, two widening portions were provided. The widening portions are all arranged in the aforementioned area Y.

Embodiment 3~6

[0071] In Examples 3 to 6, in all the blocks, the Figure 11 The dimension X of (A) is a fully open sipe-like narrow groove that is 1.0 times the block width BW. In Example 3, one widened portion was provided in one sipe-like narrow groove, in Examples 4 and 5, two widened portions were provided, and in Example 6, three widened portions were provided. In Example 5, the widened portion expands in diameter in a trumpet-like manner from the center side in the width direction of the block toward the side edge side. The widening portions are all arranged in the aforementioned area Y.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com