Distributing valve for concrete pump and concrete pump

A concrete pump and distribution valve technology, applied in the direction of pumps, piston pumps, pump components, etc., can solve the problems of large rotating matching surface of the structure, enlarge the matching gap between the valve body and the valve core, and shorten the service life of the distribution valve, so as to improve the work efficiency. Reliability, prolonging the validity period of the seal, reducing the effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

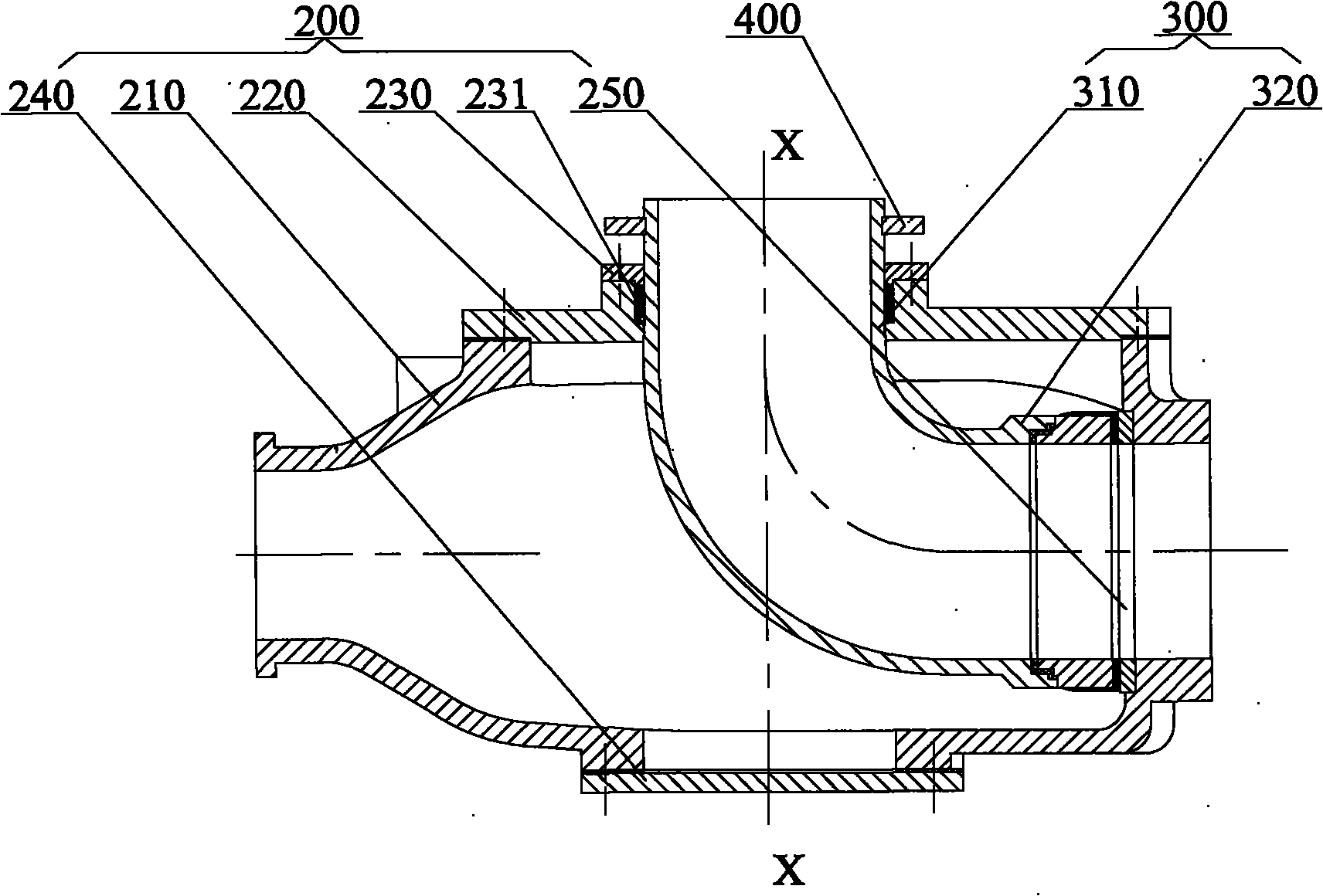

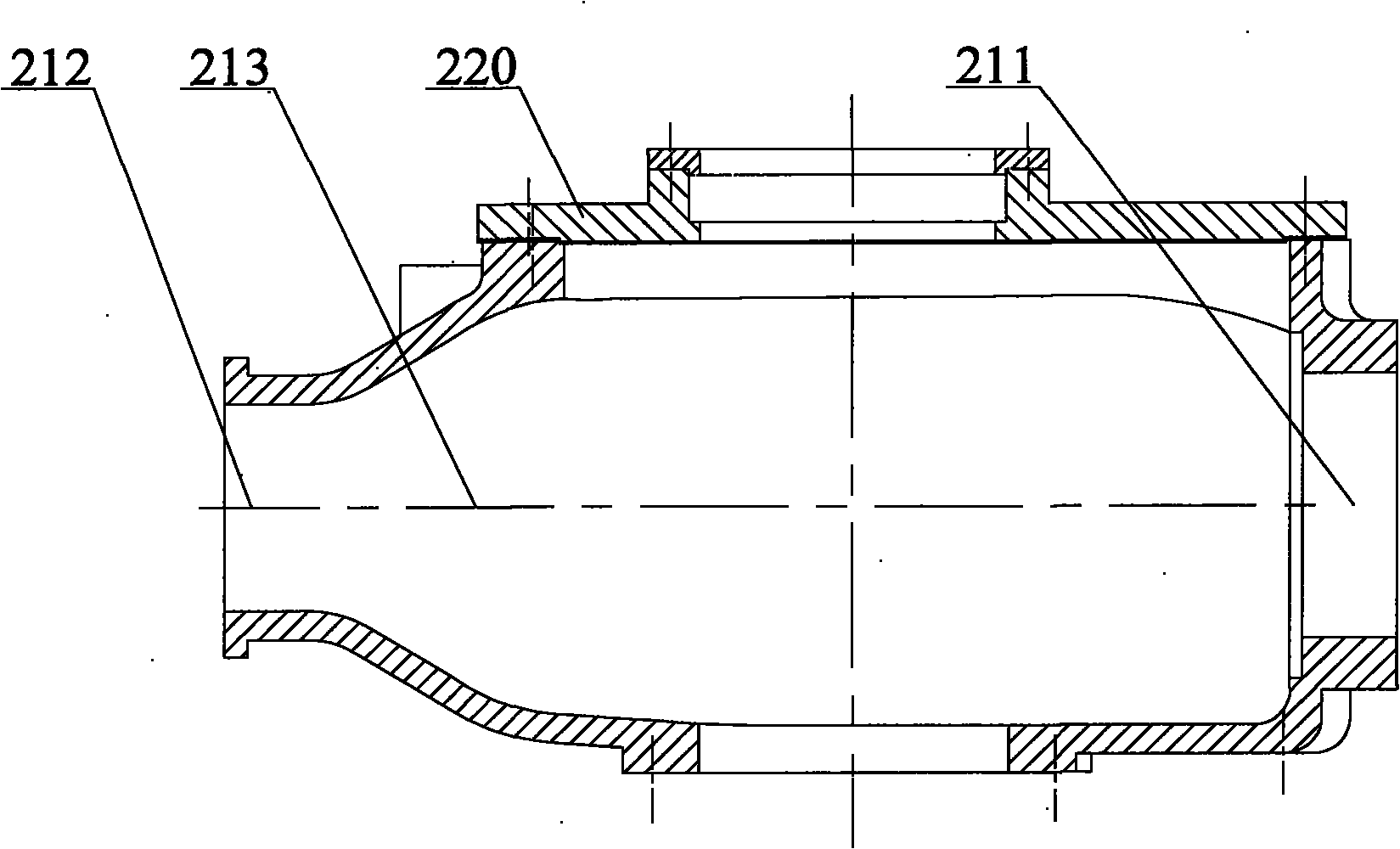

[0044] The distribution valve for a concrete pump provided in Embodiment 1 includes a valve body 200 and a valve core 300 . combine image 3 , the valve body 200 is a shell structure, including a front side wall, a rear side wall, a top wall and a bottom wall, and a cavity is formed inside it, and the cavity is a pumping cavity 213 . The front side wall has an opening 211 opposite to which a wear plate 250 is mounted. The rear side wall has a discharge port 212 connected with a delivery pipe, and the delivery pipe can deliver the concrete slurry to a predetermined position. The top wall includes a cover plate 220, and the cover plate 220 is provided with a feed inlet corresponding to the first pipe section 310; the bottom wall has a discharge plate 240, which can be disassembled or removed when the concrete pump stops running. to remove the concrete slurry lodged in the pumping chamber 213.

[0045] Please refer to Figure 4 and Figure 5 , Figure 4 It is a structural s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com