Pumping system and concrete pump truck having the same

A pumping system and pumping technology, which are applied in the pumping, construction material processing, construction and other directions, can solve the problems of occupying the storage space of the hopper 110, affecting the suction performance of the concrete pump, hindering the flow of concrete mud, etc., so as to improve the suction performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. The present invention will be described below with concrete pump as an example. It should be clearly stated that the technical solutions provided by the present invention can also be applied to pumping systems for pumping mud or other viscous materials with the same performance as concrete mud.

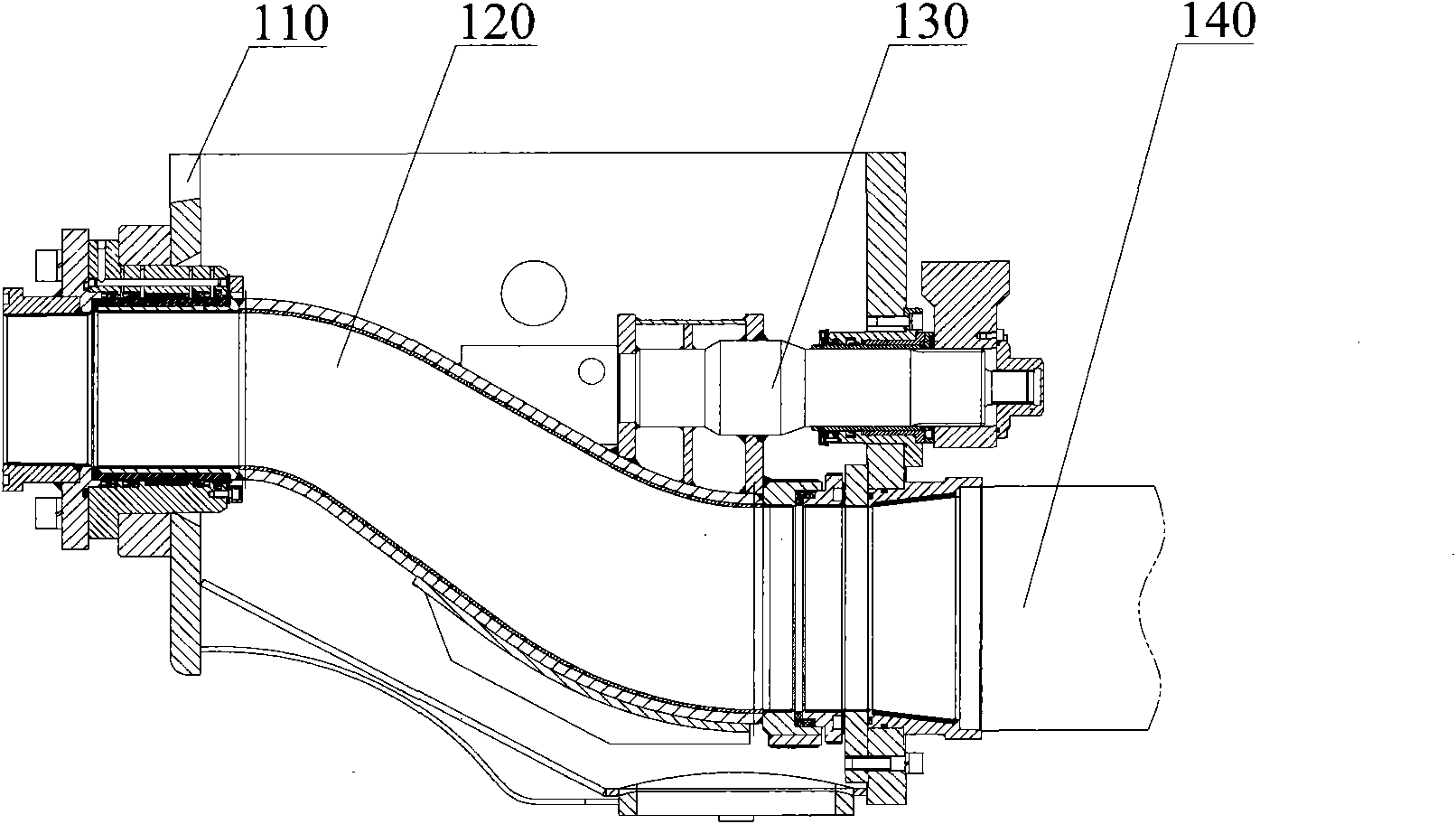

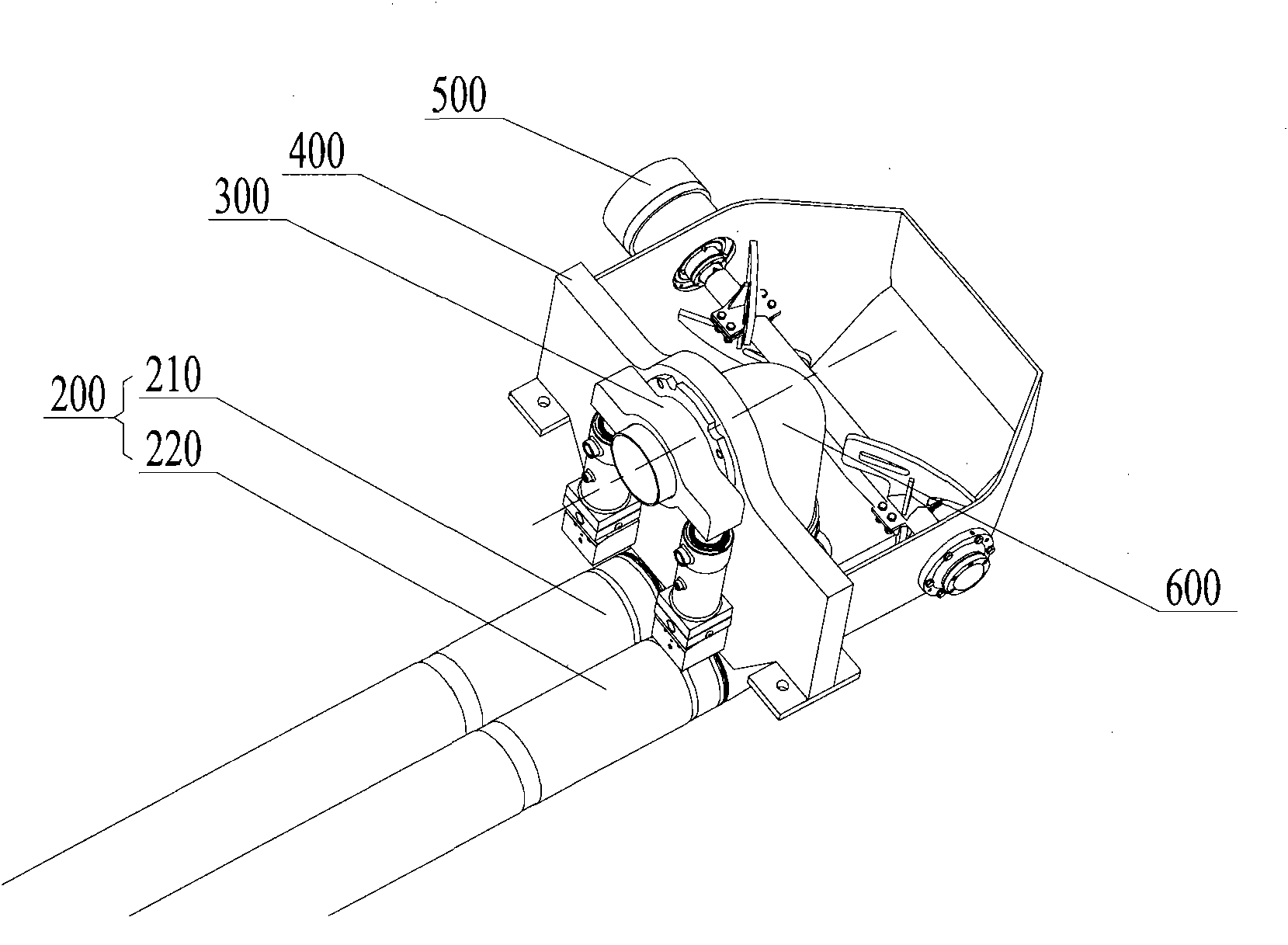

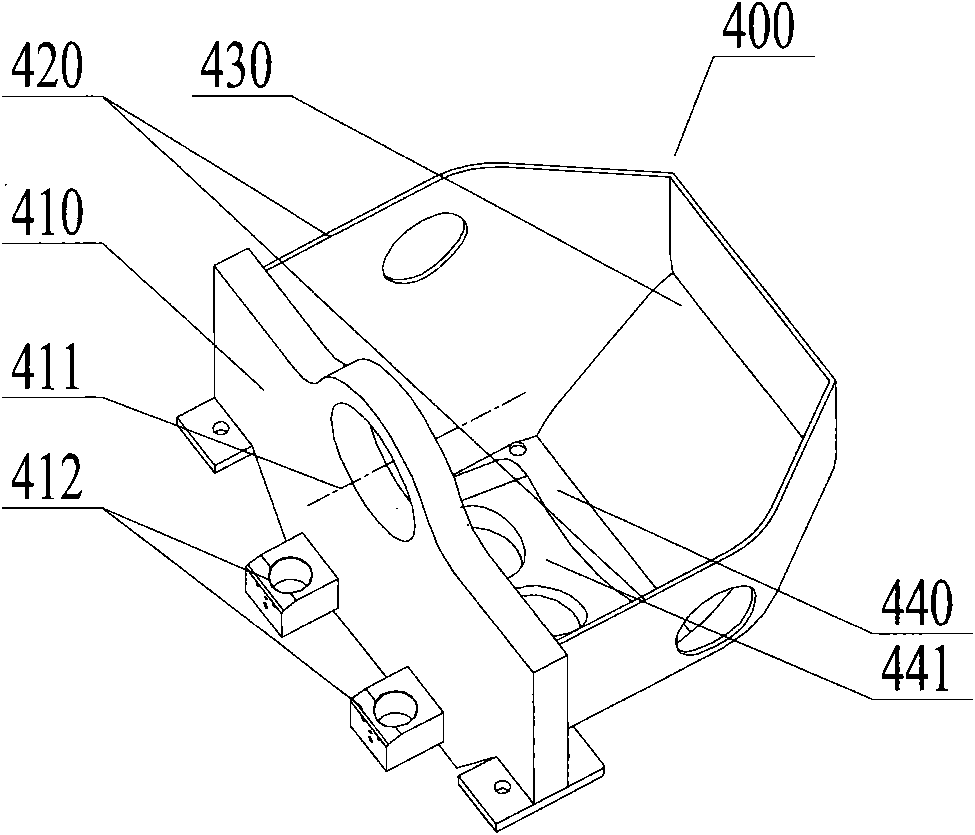

[0053] Please refer to figure 2 , which is a schematic diagram of the assembly structure of the concrete pump provided in Embodiment 1. The concrete pump provided in Embodiment 1 includes a hopper 400 , a stirring mechanism 500 , a distribution valve 600 , a swing valve mechanism 300 and a pumping power mechanism 200 . The hopper 400 is used to accommodate a predetermined amount of concrete slurry, and the stirring mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com