Sliding component

一种滑动组件、滑动面的技术,应用在发动机元件、滑动接触轴承、轴承元件等方向,能够解决无法应对、被密封流体变质、危险等问题,达到提高吸入效果及吐出效果、防止干扰的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

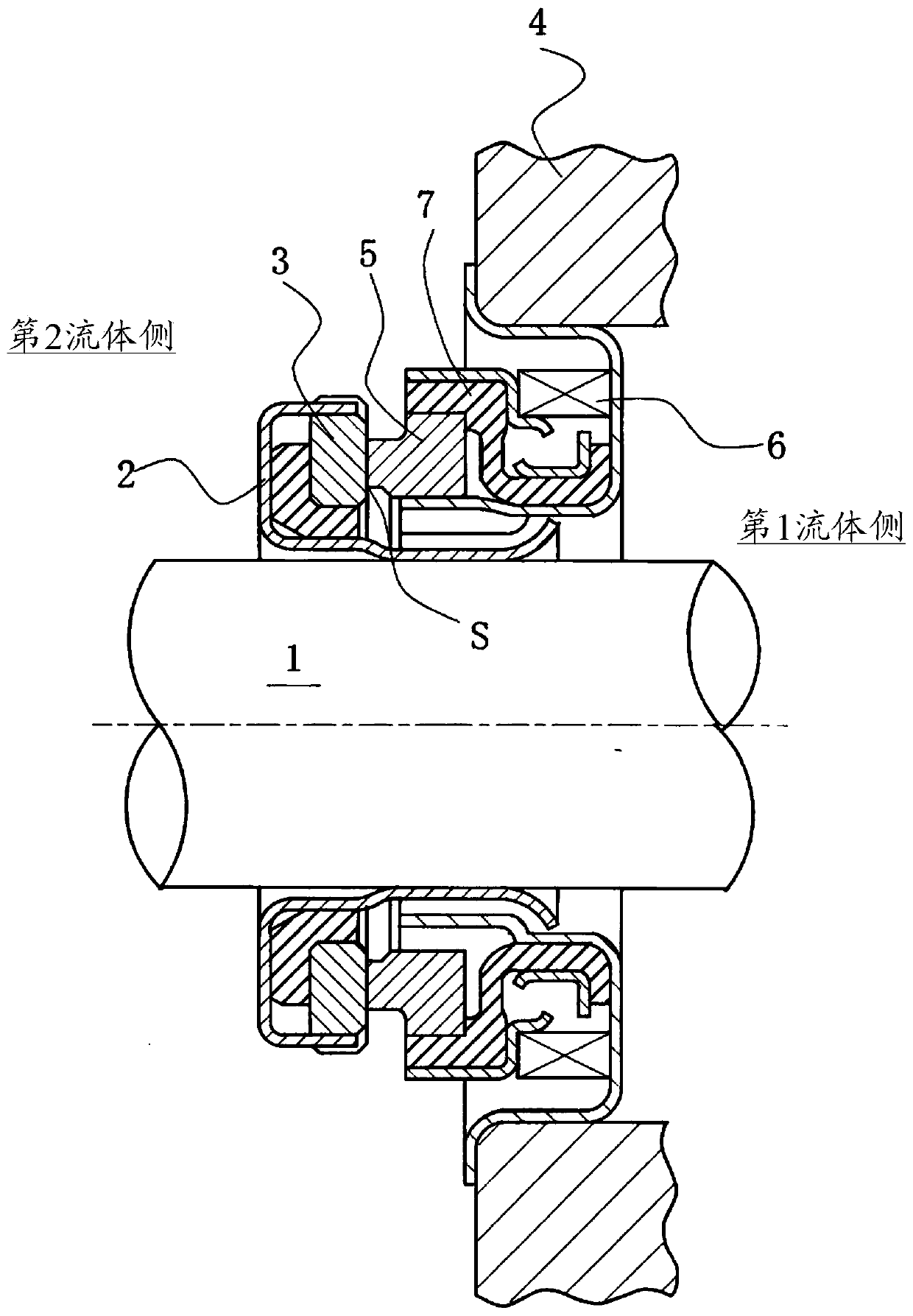

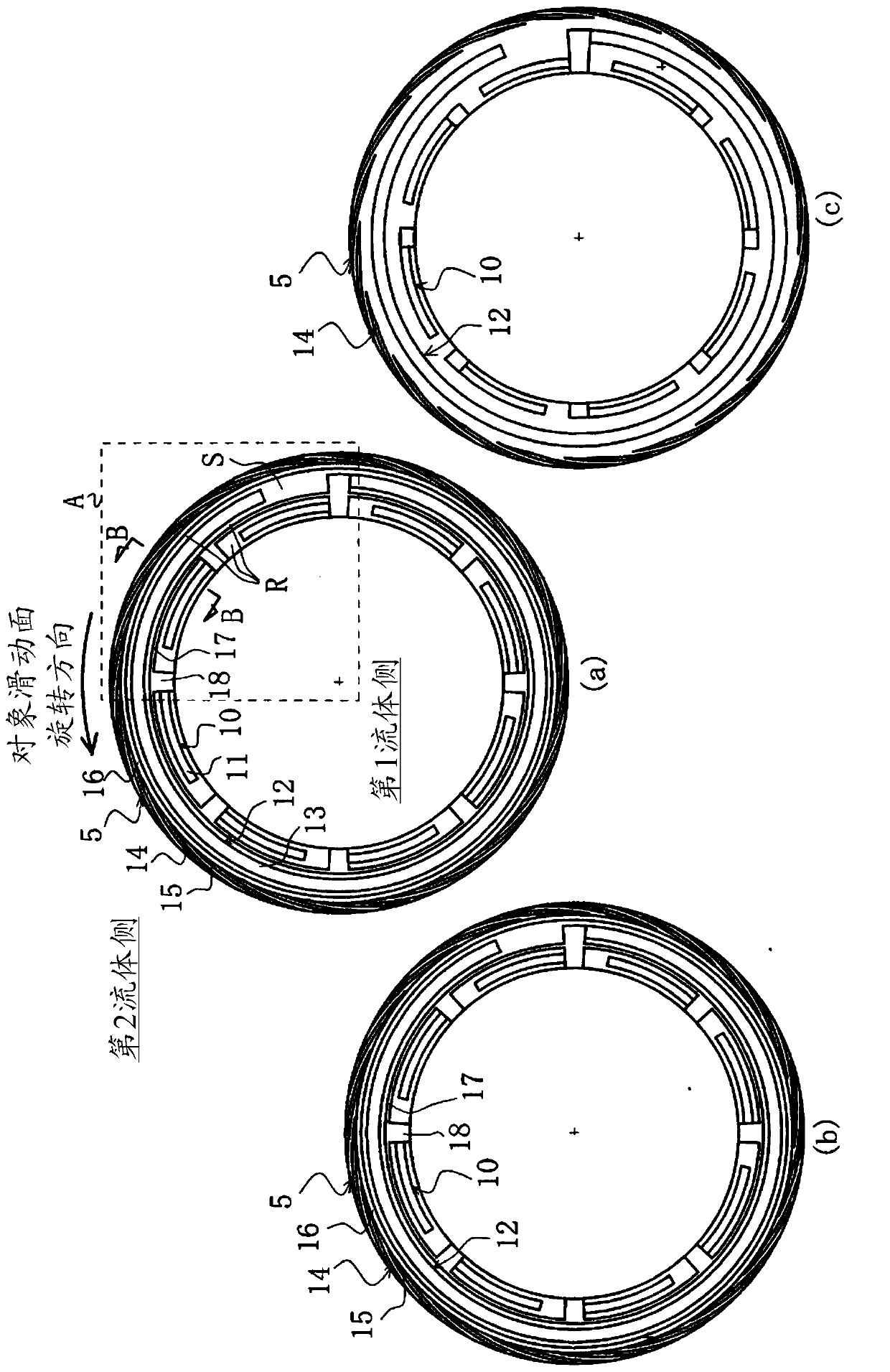

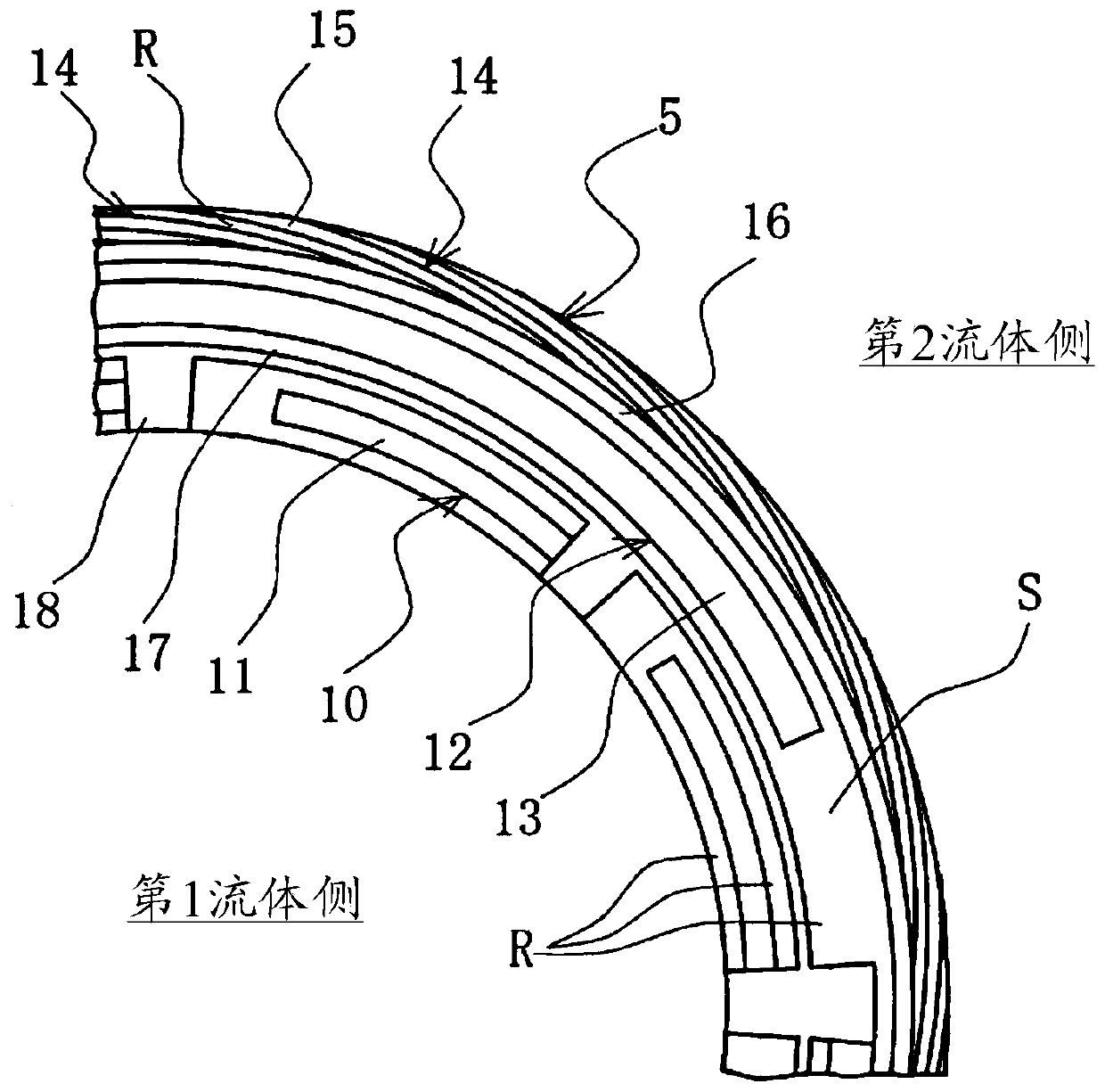

[0055] refer to Figure 1 to Figure 4 , the slide assembly according to Embodiment 1 of the present invention will be described.

[0056] In addition, in this embodiment, the case where the component constituting the mechanical seal is a slide component will be described as an example.

[0057] figure 1 It is a longitudinal sectional view showing an example of a mechanical seal. The first fluid exists on the inner peripheral side of the sliding surface S, and the second fluid exists on the outer peripheral side to achieve lubrication of the sliding surface and prevent the first fluid and the second fluid of different types from Mixing, for example, on the side of the rotating shaft 1 that drives the pump impeller (not shown) on the second fluid side, an annular rotating side seal ring 3 that can rotate integrally with the rotating shaft 1 through the sleeve 2, The annular fixed-side seal ring 5 provided in a non-rotating state and axially movable state in the pump casing 4 p...

Embodiment 2

[0101] refer to Image 6 , the slide assembly according to Embodiment 2 of the present invention will be described.

[0102] The difference between Embodiment 2 and Embodiment 1 is that the first fluid-side negative pressure generating mechanism is composed of a screw mechanism. The other basic structures are the same as Embodiment 1. The same components are marked with the same symbols, and repeated descriptions are omitted.

[0103] Image 6 Among them, the groove portion 21 of the screw mechanism 20 constituting the first fluid-side negative pressure generating mechanism has a curved (helical) shape that narrows toward the center from the upstream side toward the downstream side. Therefore, a negative pressure is generated in the groove portion 21 by sliding against the mating sliding surface, and the fluid sucked into the groove portion 21 is urged toward the first fluid side.

[0104] Image 6 In (a), the upstream end of the groove portion 21 is separated from the firs...

Embodiment 3

[0114] refer to Figure 7 , the slide assembly according to Embodiment 3 of the present invention will be described.

[0115] The difference between Embodiment 3 and Embodiment 2 is that the dynamic pressure generating mechanism is composed of a screw mechanism, and other basic structures are the same as Embodiment 2, and the same symbols are assigned to the same components, and repeated descriptions are omitted.

[0116] Figure 7 Among them, the groove portion 23 of the screw mechanism 22 constituting the dynamic pressure generating mechanism has a curved (helical) shape expanding from the upstream side toward the downstream side toward the second fluid side. Therefore, dynamic pressure (positive pressure) is generated in the groove portion 23 by sliding with the mating sliding surface, and the first fluid can enter between the sliding surfaces to increase the fluid film and improve the lubricating performance.

[0117] Figure 7 In (a), the upstream end of the groove por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com