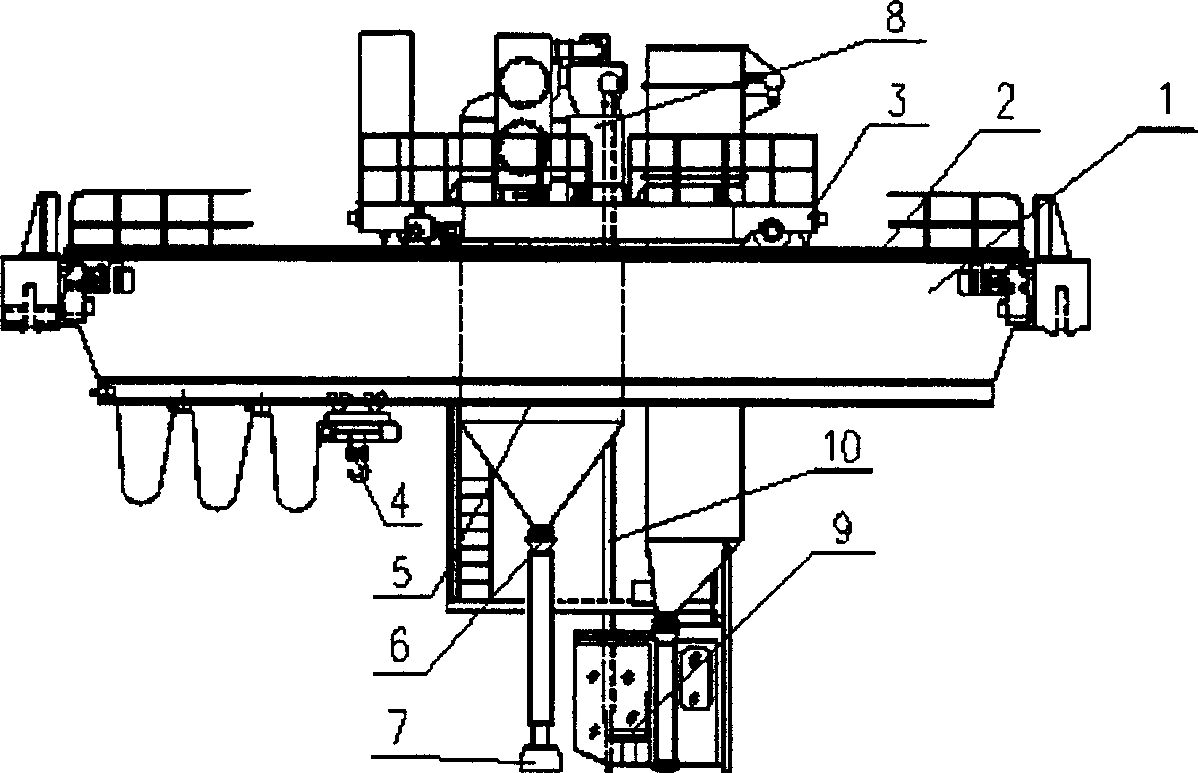

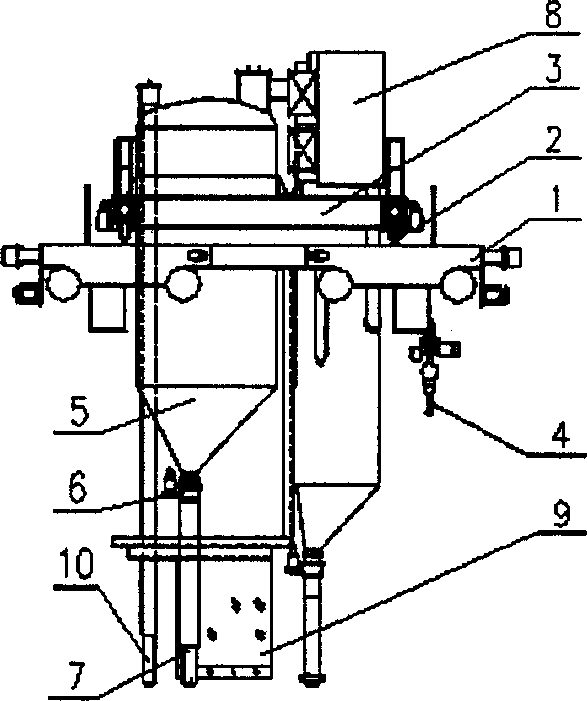

Carbon baking operation crown block

A crane and roasting technology, applied in the direction of electric charge control, furnace, lighting and heating equipment, etc., can solve the problems of poor operating environment and working conditions, large waste of energy consumption, pressure loss, etc., to improve working conditions and labor intensity, Improve the degree of mechanization and the effect of small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiment of the present invention: adopt double girder car as traveling crane (1), and traveling crane (1) is installed on the track of factory building, on traveling crane (1), with respect to the transverse direction of factory building, welding trolley track ( 2), install the operating trolley (3) on the track (2), the operating trolley (3) can move laterally, install the lifting device (4) at the lower end of the main beam of the traveling crane (1), and then operate the trolley (3) ), a storage bin (5) is welded on the top of the storage bin (5), a discharge valve (6) is connected at the bottom of the storage bin (5), and a distributing device (7) is connected to the lower end of the discharge valve (6). ) next to the vacuum device (8), a suction pipe (10) is installed on the vacuum device (8), and the suction pipe (10) extends vertically to the lower end of the operating trolley (3). An operating room (9) is isolated with steel plates and glass at the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com