Preforming forging die of sector-shaped forge piece

A pre-forming and forging technology, which is used in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve the problems of unreasonable manufacturing process of fan-shaped forgings, and achieve regular and beautiful appearance and good machining efficiency. The effect of small amount and high material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

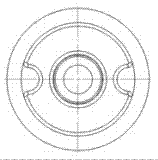

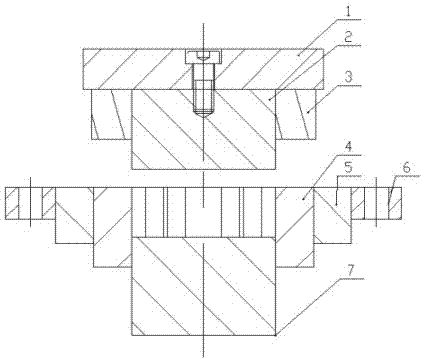

[0016] Such as figure 2 , the preformed forging die of the fan-shaped worm wheel forging, including a punch 2 and a die 4, a punch sleeve 3 is arranged outside the punch 2, a pressing plate 1 is arranged at the upper end of the punch; a prestressing ring 5 and a pressing plate 6 are arranged outside the die in sequence ; The punch extends into the cavity of the die, and the ejector device 7 is set in the cavity of the die, and the remaining space in the cavity of the die is the flow space of the blank.

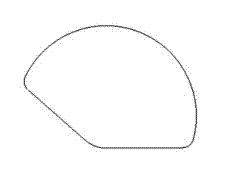

[0017] Such as figure 2 and image 3 , the bar is placed in the preforming mold, the material flows and deforms in the inner cavity of the die, and fills the cavity to form a fan-shaped preformed blank with a certain thickness.

[0018] Among them, the mold cavity should be sprayed with lubricant before and after pre-forming forging, and the mold cavity should be cleaned and lubricated with high-pressure air after each forging product. The specific method is: use a high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com