Final-forming forging mold of fan-shaped forging

A technology for final forming and forging, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. It can solve the problems of unreasonable manufacturing process of fan-shaped forgings, and achieve regular and beautiful appearance, which is beneficial to Machining, the effect of small machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

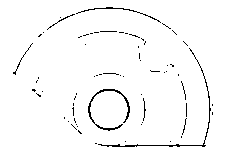

[0017] Such as Figure 4 , the final forming die of the fan-shaped forging, including a punch 2 and a die 4, a punch sleeve 3 is arranged outside the punch, a pressing plate 1 is arranged at the upper end of the punch; a prestressing ring 5 and a pressing plate are arranged in sequence outside the die 4 6. The punch extends into the inner cavity of the die, and the ejector 7 is arranged in the inner cavity of the die. The lower end of the punch, the upper end of the ejector and the inner cavity of the die form a flow space for the preformed blank.

[0018] Such as Figure 4 , combined with figure 2 and image 3 , the preformed blank is placed in the final forming mold, and the blank flows and deforms in the cavity of the die to the surroundings, filling the cavity and forming the outer ring flange and the center hole of the final forming blank of the fan-shaped worm gear.

[0019] Among them, the mold cavity should be sprayed with lubricant before and after the final formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com