Fragile product packaging device, assembly and method

A technology for packaging components and fragile products, which is applied to the packaging of vulnerable items, special packaging items, packaging, etc., can solve the problems of long operation time, high cost, and fragility, and achieve good fixing performance, high packaging efficiency, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

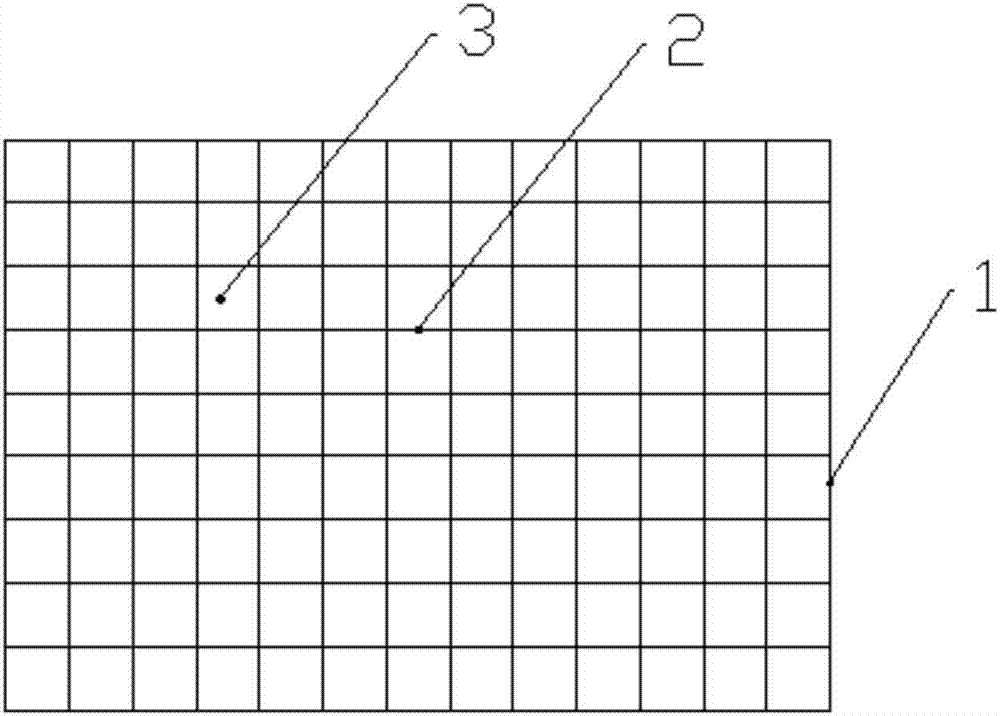

[0069] Such as figure 1 As shown, a packaging device for fragile goods includes a main body 1 made of flexible cushioning material, and one side of the main body 1 is provided with main body cutting marks 2, and the main body cutting marks 2 are distributed in a grid shape, so that the One side of the main body 1 is divided into a plurality of grid units 3 .

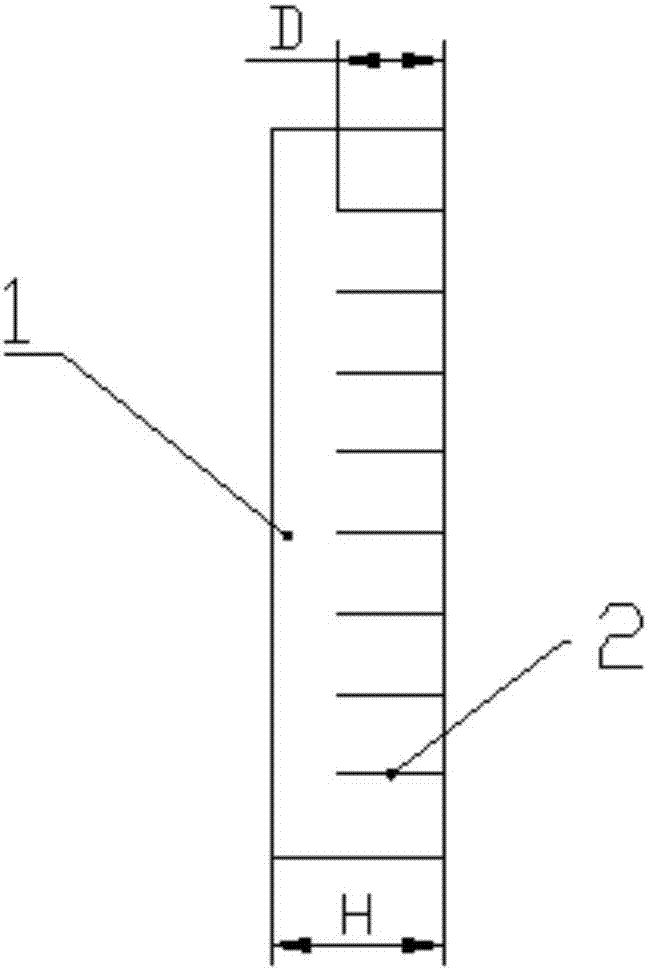

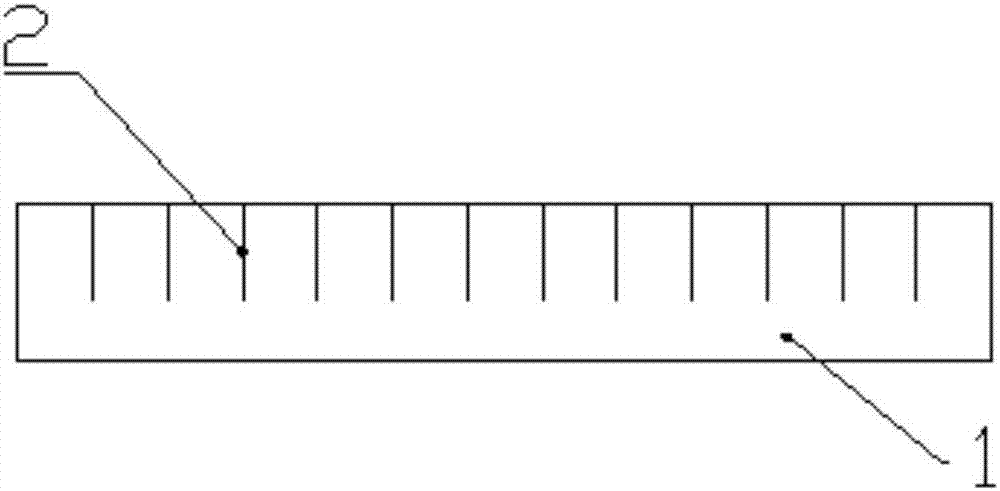

[0070] Such as figure 2 , image 3 As shown, the main body cutting mark 2 extends to the inside of the main body 1 along the thickness direction of the main body 1, the depth of the main body cutting mark 2 is D, and the thickness of the main body 1 is H, 0

[0071] In order to facilitate the wrapping of articles, the main body 1 is a sheet structure or a block structure.

[0072] Specifically, the main body 1 can be made of pearl cotton, sponge, space cotton, soft polyurethane foam, soft polyethylene material or a flexible cushioning material with similar properties to the above materials. The flexible cushio...

Embodiment 2

[0086] The features of this embodiment that are the same as those of Embodiment 1 will not be described again. The features of this embodiment that are different from Embodiment 1 are as follows: Figure 5 As shown, in this embodiment, at least one of the grid units 3 is provided with a longitudinal cut 4, and the longitudinal cut 4 divides the grid unit 3 into a plurality of secondary grid units 5; The longitudinal cutting marks 4 are parallel to the main body cutting marks 2, and the depth of the unit cutting marks 4 is d, where 0<d<D.

[0087] The overall size of the main body 1 of the present invention is standard, and the most commonly used specifications have the following three types:

[0088] 1. The main body size is 50cm*50cm*15cm, the thickness of the uncut side is 2cm to 5cm, and the size of the secondary grid unit in the middle is 3cm*2cm*10cm and 1.5cm*1.5cm*5cm.

[0089] 2. The main body size is 50cm*50cm*10cm, the thickness of the uncut side is 2cm to 5cm, and ...

Embodiment 3

[0096] The features of this embodiment that are the same as those of Embodiment 1 will not be described again. The features of this embodiment that are different from Embodiment 1 are as follows: Image 6 As shown, in this embodiment, at least one side of the grid unit 3 is provided with a transverse cutting mark 6; the transverse cutting mark 6 extends from the side of the grid unit 3 to its interior, and the transverse cutting mark 6 The depth is L, the size of the grid unit 3 in the depth direction of the transverse cutting mark 6 is h, 0<L<h.

[0097] The packaging components in this embodiment and the packaging method during use are the same as those in Embodiment 1, and will not be repeated here.

[0098]It can be understood that the technical features of Embodiment 2 and Embodiment 3 can be combined, and the transverse cutting mark 6 can also be arranged on the secondary grid unit 5. When the transverse cutting mark 6 is arranged on the secondary grid unit 5, its The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com