Automatic putting device of washing machine, washing machine and using method of washing machine

A technology for automatic feeding and washing machines, which is applied in washing devices, other washing machines, and sealing of engines. It can solve the problems of irregular shape of ink cartridges, easy blockage of the feeding port, complex structure, etc., and achieve regular and beautiful appearance, simple and reliable structure, Guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

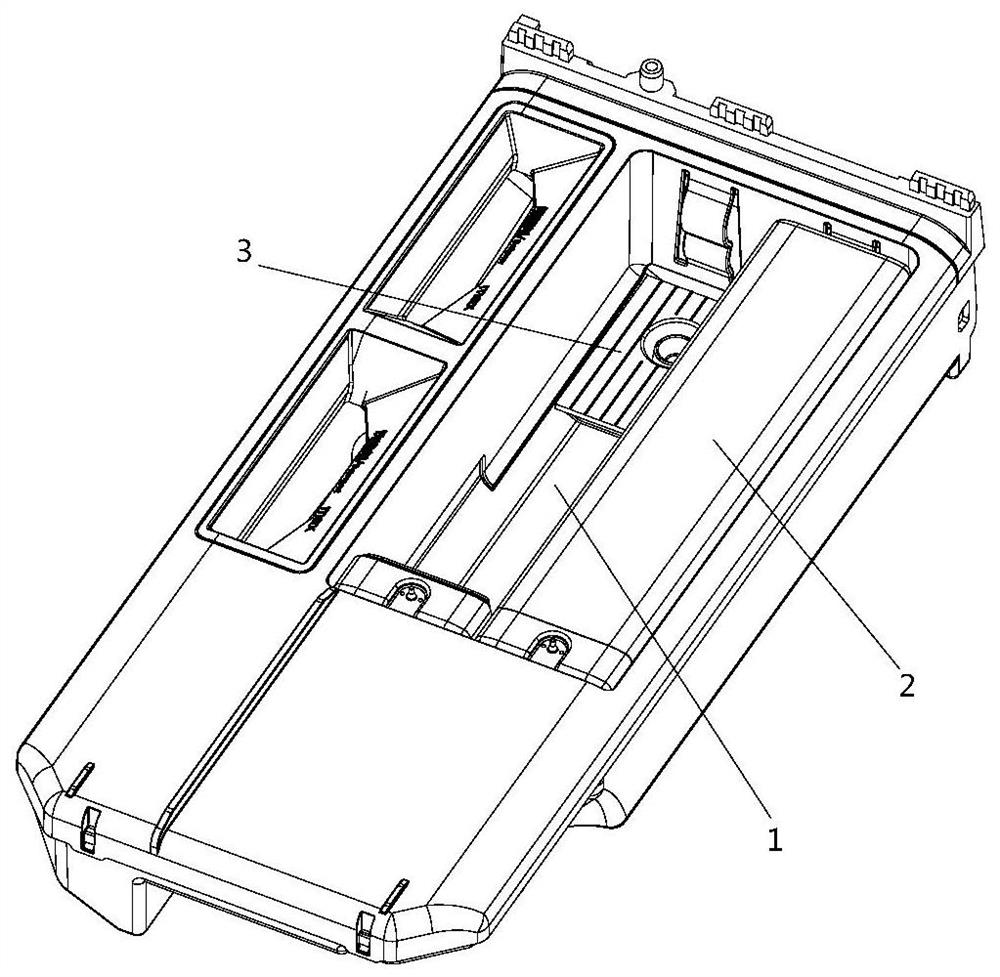

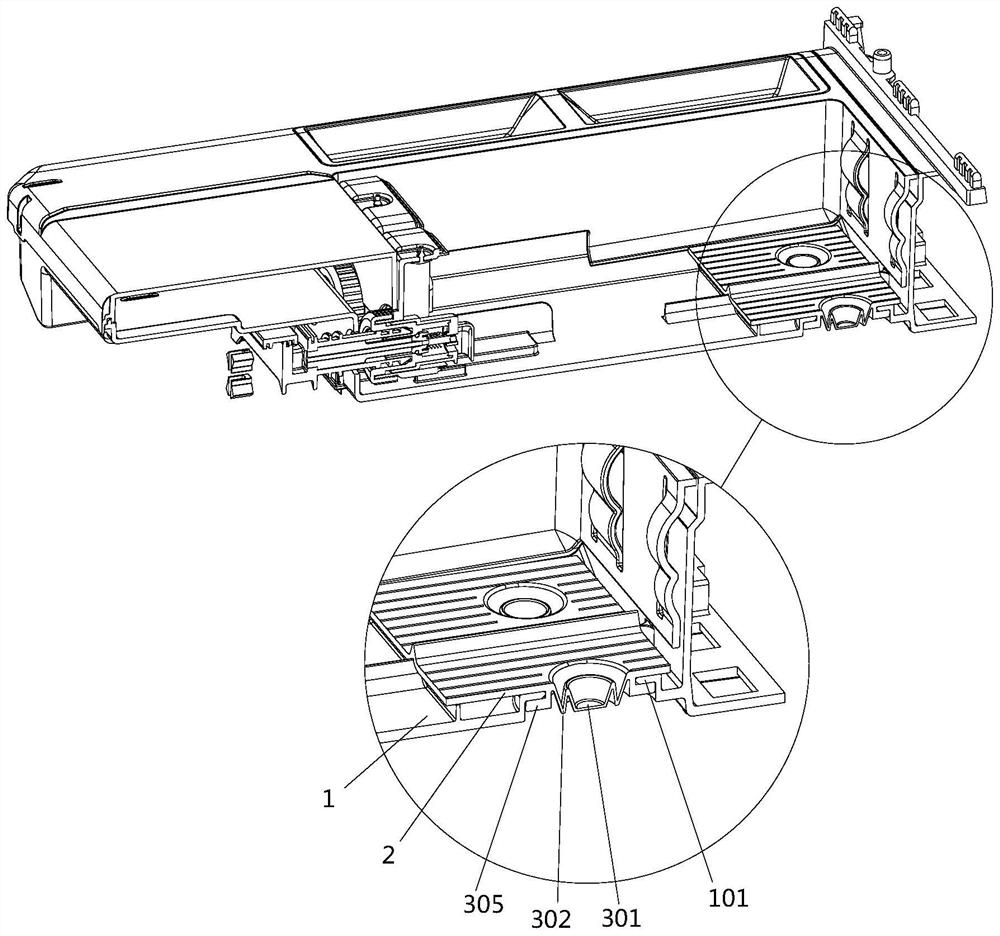

[0058] Such as figure 1 with figure 2 As shown, the automatic dispensing device of a washing machine described in this embodiment includes an accommodating chamber 1 disposed inside the washing machine and capable of moving between an open position and a closed position; an additive box 2 is disposed in the accommodating chamber 1 inside, used to store additives; the sealing structure 3 corresponds to the additive box 2 and cooperates with the bottom of the accommodating chamber 1, and the sealing structure 3 has a support unit that pushes up the additive box 2 under force .

[0059] Wherein, the supporting structure includes the ejection part 301 that deforms under the action of external force, and pushes the additive box 2 out of the containing chamber 1; A sealing portion 303 that forms a seal with the matching surface of the accommodating chamber 1 .

[0060] Further, the ejecting portion 301 forms a convex structure extending from the center to the outside of the bott...

Embodiment 2

[0064] Such as figure 1 with figure 2 As shown, the automatic dispensing device of the washing machine described in this embodiment, the ejection part 301 is arranged on the side close to the front end of the storage chamber 1; The ratio of the distance to the length of the additive box 2 is between 1:5 and 1:3.

Embodiment 3

[0066] Such as figure 1 with figure 2 As shown, the automatic feeding device of the washing machine described in this embodiment, the bottom of the accommodating chamber 1 is provided with an installation port 101 for installing the sealing structure 3; the sealing part 303 is connected with the installation port 101 The shape matches and wraps the installation port 101 for setting.

[0067] Further, the installation port 101 at the bottom of the accommodation chamber 1 is a groove-shaped opening extending toward the interior of the accommodation chamber 1; the ejection portion 301 of the sealing structure 3 is arranged In the groove formed by the installation port 101 at the bottom of the chamber 1 .

[0068] Furthermore, the sealing part 303 includes a first sealing ring 304 that fits inside the bottom of the containing chamber 1 ; a second sealing ring 305 that fits outside the bottom of the containing chamber 1 ; the first sealing ring 304 and the second sealing ring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com