Patents

Literature

52results about How to "Avoid outflow situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On-duty flame stabilizing cavity of trapped vortex combustion chamber and oil-gas matching device

ActiveCN111706879AAvoid outflow situationsImprove the mixing effectContinuous combustion chamberAviationThermodynamics

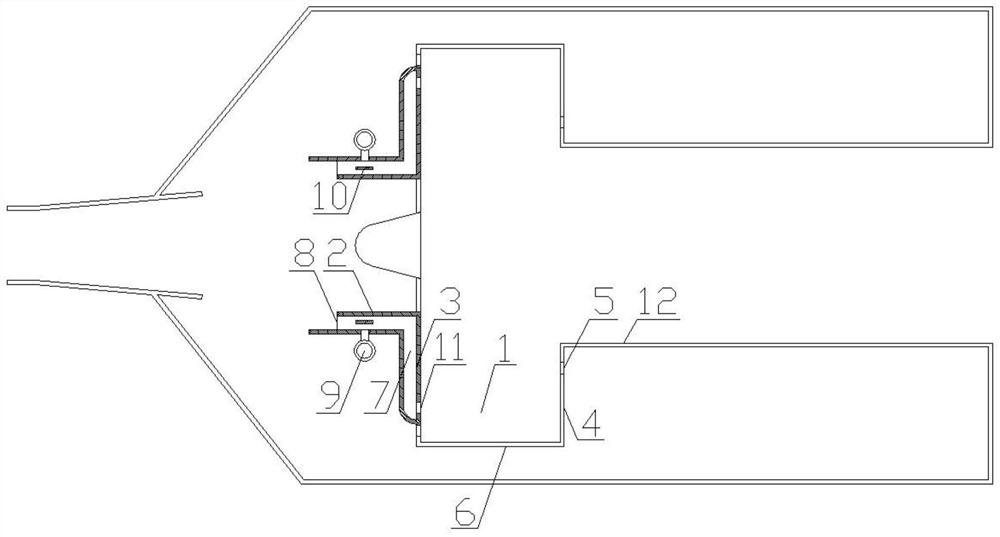

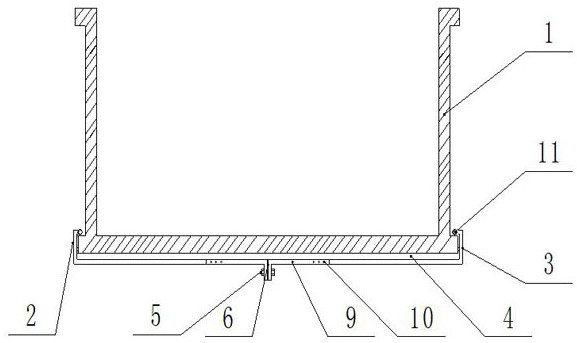

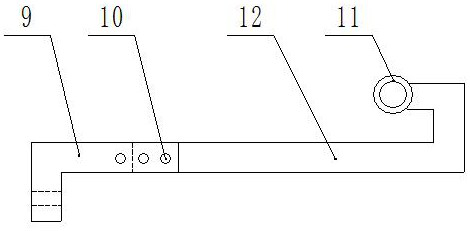

The invention discloses an on-duty flame stabilizing cavity of a trapped vortex combustion chamber and an oil-gas matching device, and particularly relates to the technical field of aviation gas turbine combustion. The on-duty flame stabilizing cavity of the trapped vortex combustion chamber and the oil-gas matching device comprise a cavity and a flow guide plate located on the front wall surfaceof the cavity, wherein a premixing cavity is formed between the front wall surface of the cavity and the flow guide plate; a first air inlet is formed in the premixing cavity; an oil supply pipe and oil splashing plates arranged outside the oil supply pipe at intervals are arranged on the premixing cavity; an oil spraying hole communicating with the cavity is further formed in the premixing cavity; and the oil spraying hole is far away from the bottom wall of the cavity. By the adoption of the technical scheme, the problem that oil-gas mixing of an existing trapped vortex combustion chamber isnot ideal is solved, and the stability of flames under the low oil-gas ratio and the combustion efficiency of on-duty classes under the high oil-gas ratio can be improved.

Owner:CHINA AERODYNAMICS RES & DEV CENT

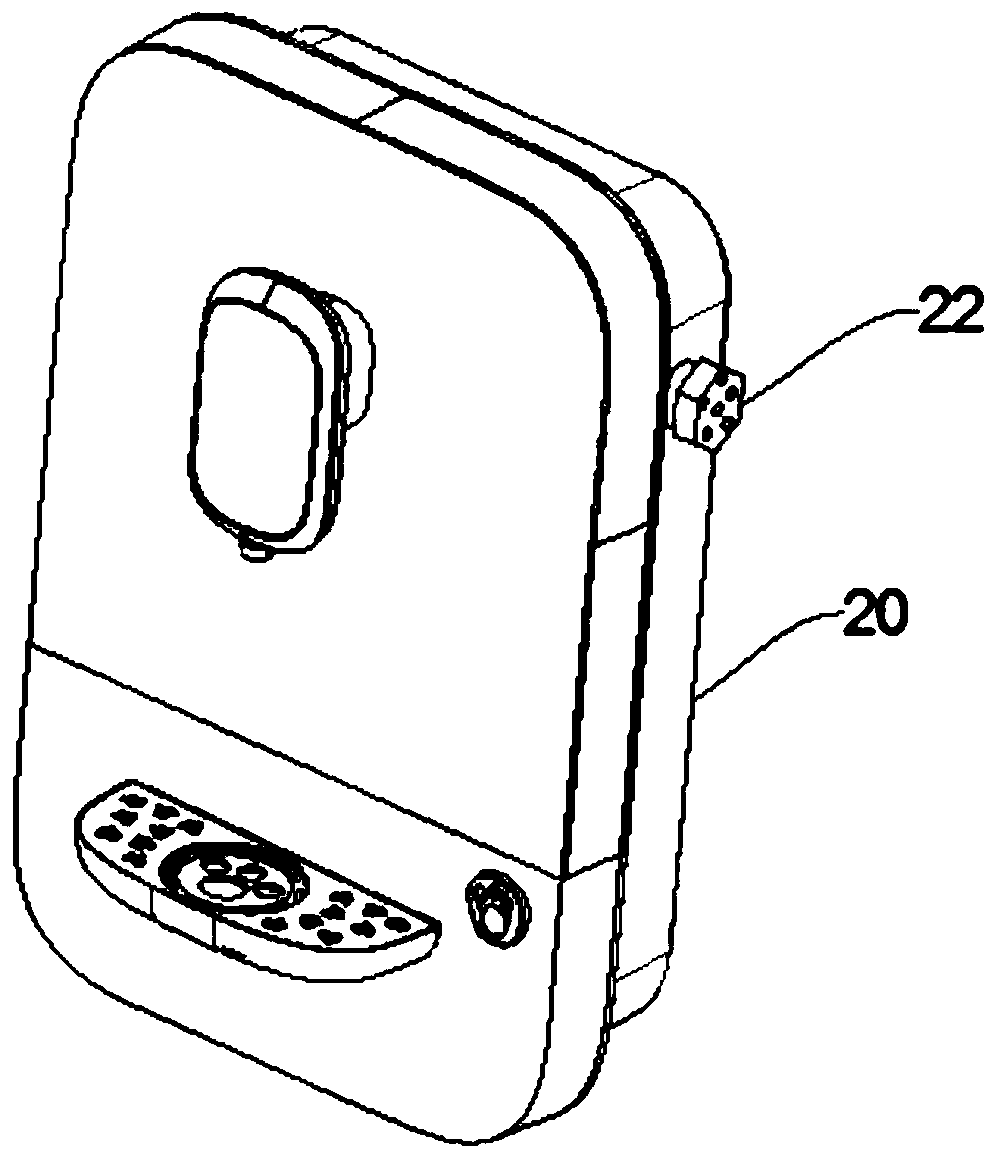

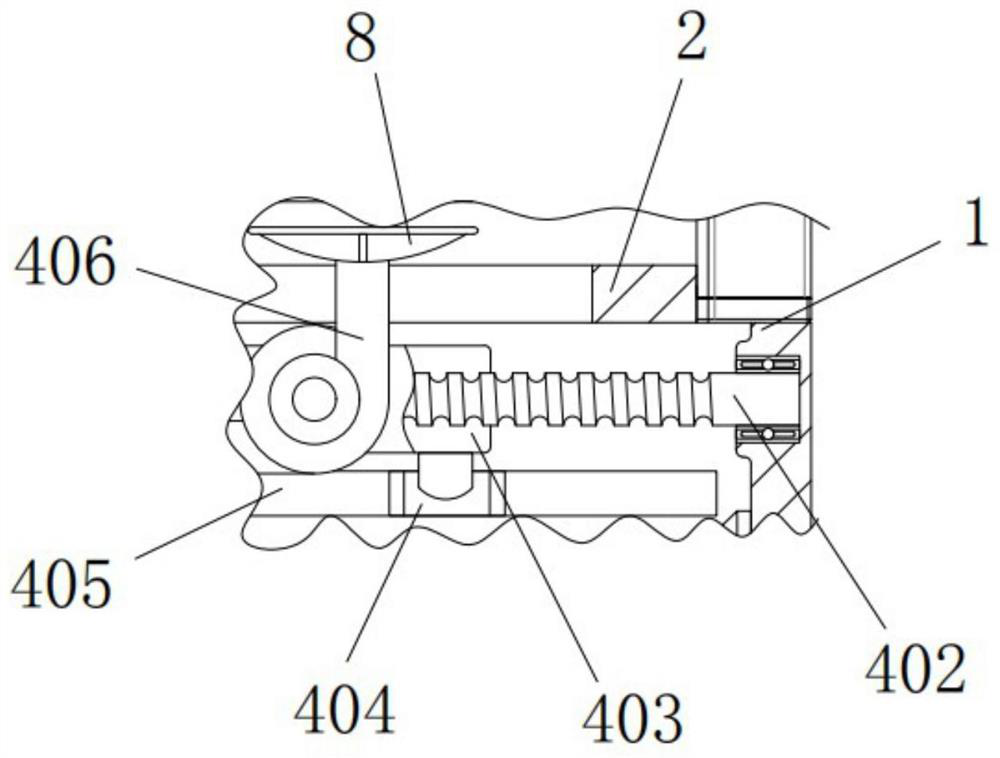

Back-suction type water drinking switch

ActiveCN105520643AWill not affect the situation of scalding the userAvoid outflow situationsBeverage vesselsWater flowWater drinking

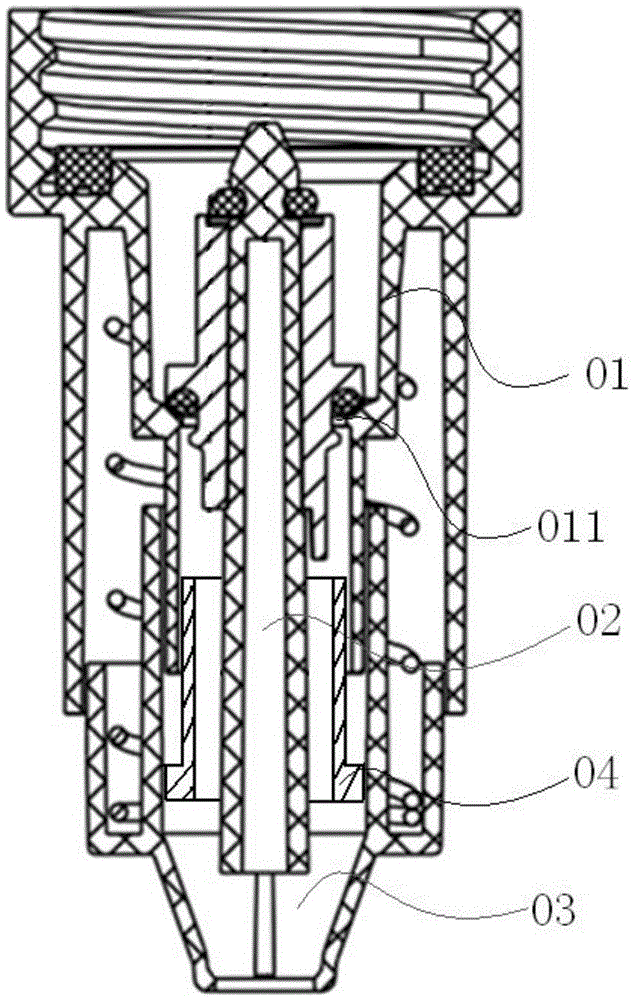

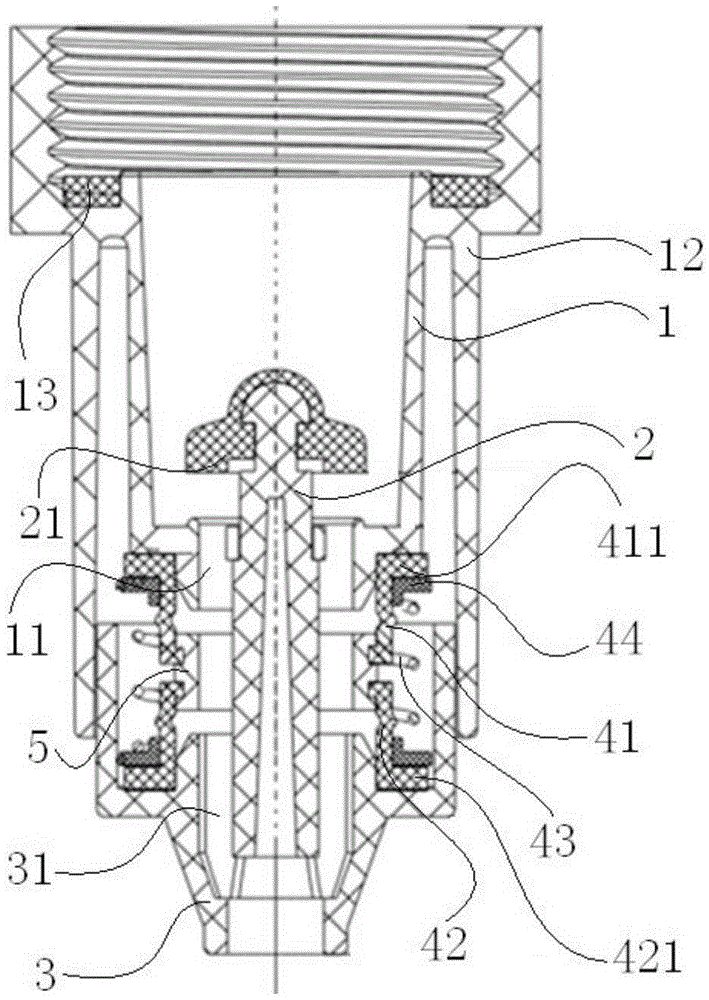

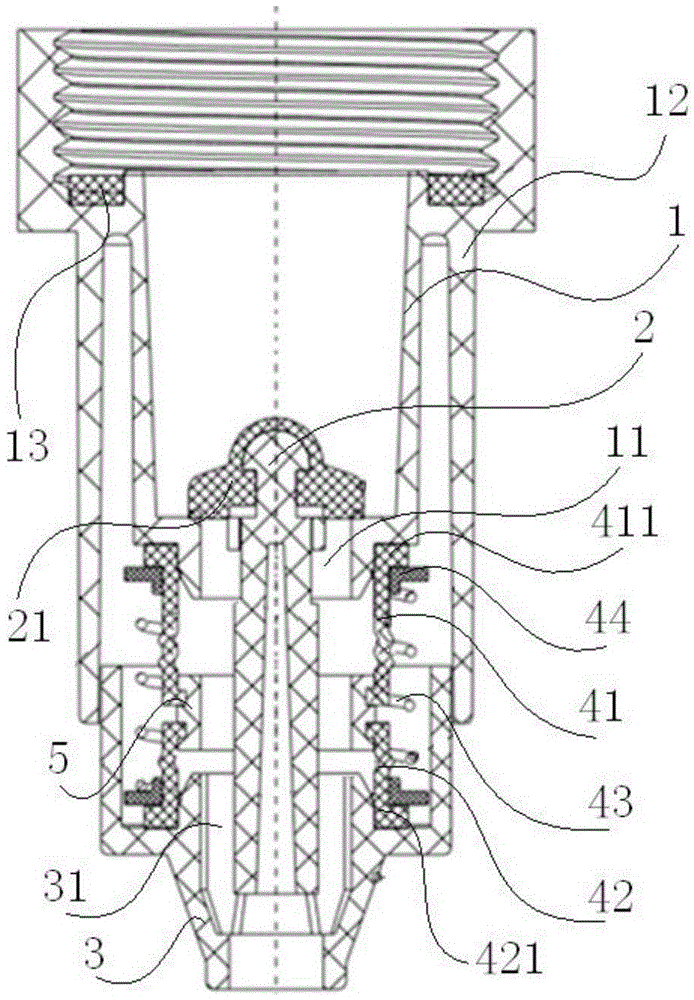

The embodiment of the invention provides a back-suction type water drinking switch, and relates to the technical field of a household appliance provided with the water drinking switch; the invention aims at solving the problems of a water drinking switch in the prior art, which is low in reliability and high in production cost when being closed to avoid the discharge of residual water. The back-suction type water drinking switch comprises a water drinking pipe, a valve element and a water outlet nozzle, wherein a water outlet is formed in the lower end of the water drinking pipe; one end of the valve element extends into the water outlet and the other is located outside the water outlet and is connected to the water outlet nozzle; the valve element is capable of moving between an opened position and a closed position; a first telescopic seal cartridge, a connecting pipe and a second telescopic seal cartridge are sequentially arranged between the water outlet and the water outlet nozzle from top to bottom; a water flow passage is defined by the inner wall of the first telescopic seal cartridge, the inner wall of the connecting pipe, the inner wall of the second telescopic seal cartridge and the outer wall of the valve element; and the water flow passage communicates with a water outlet passage of the water outlet nozzle. The back-suction type water drinking switch is applicable to the household appliance provided with the water drinking switch.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

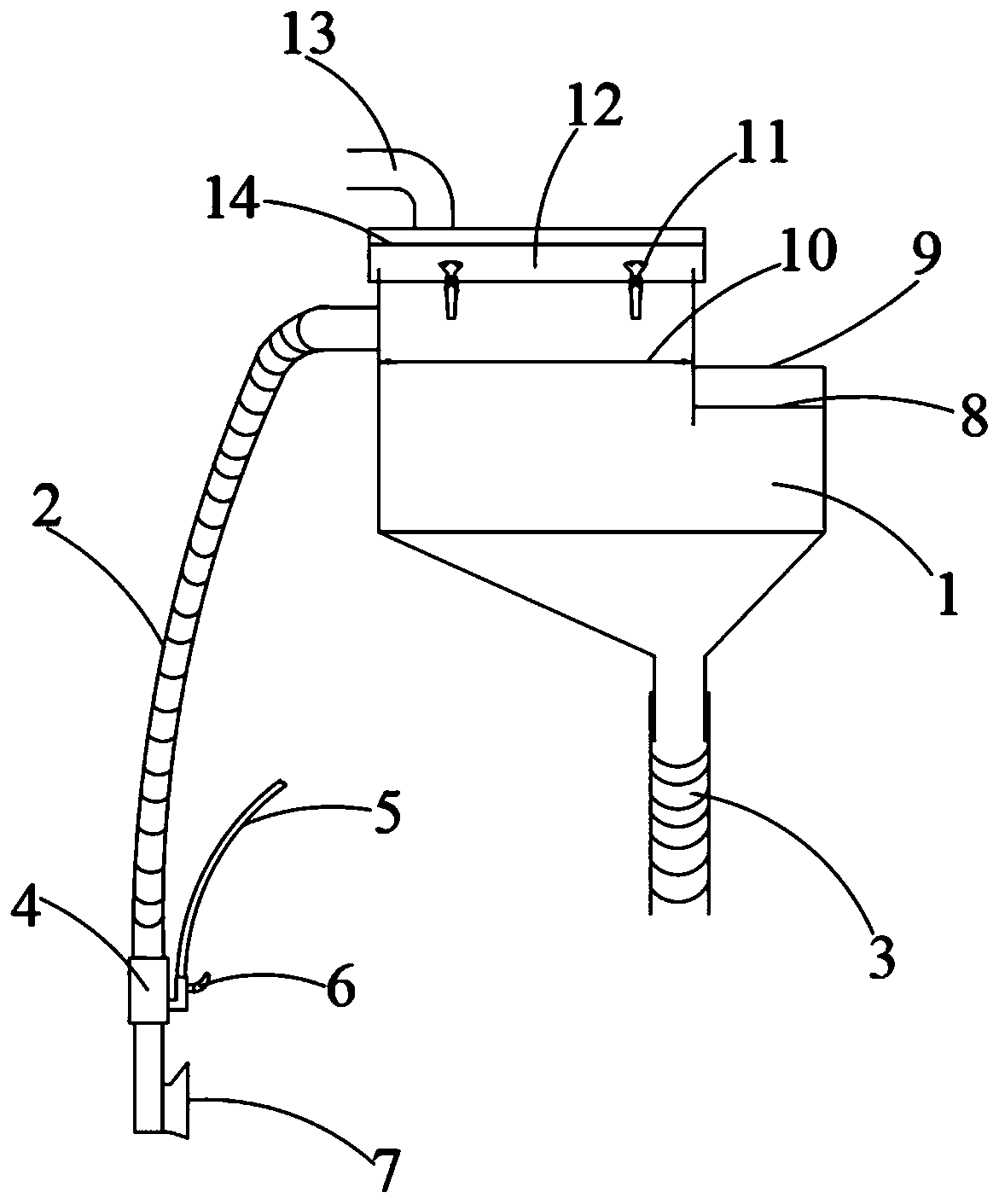

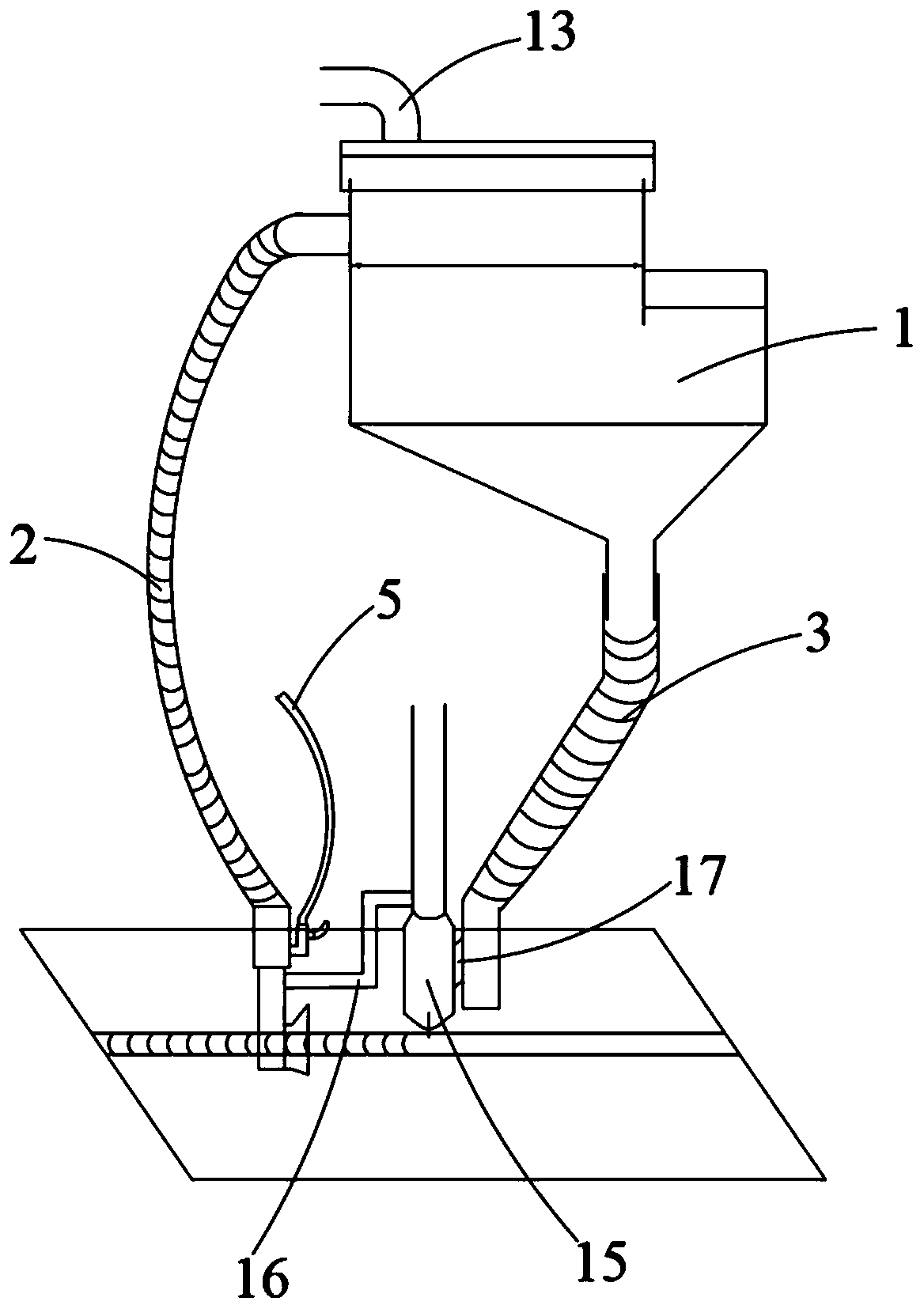

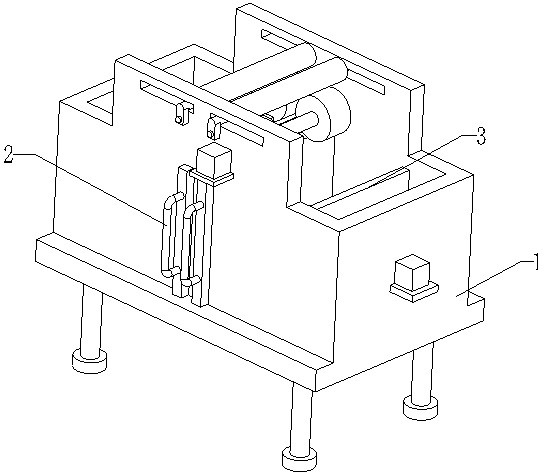

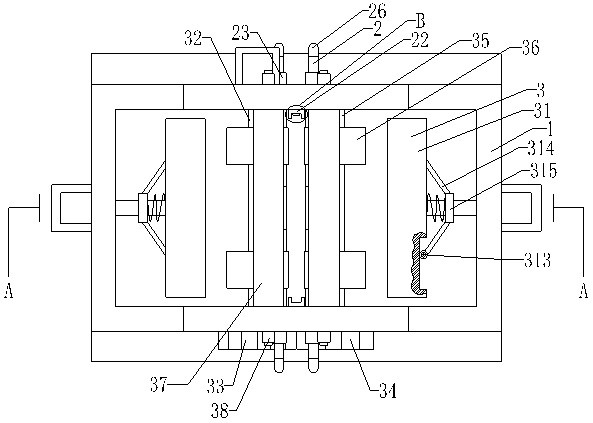

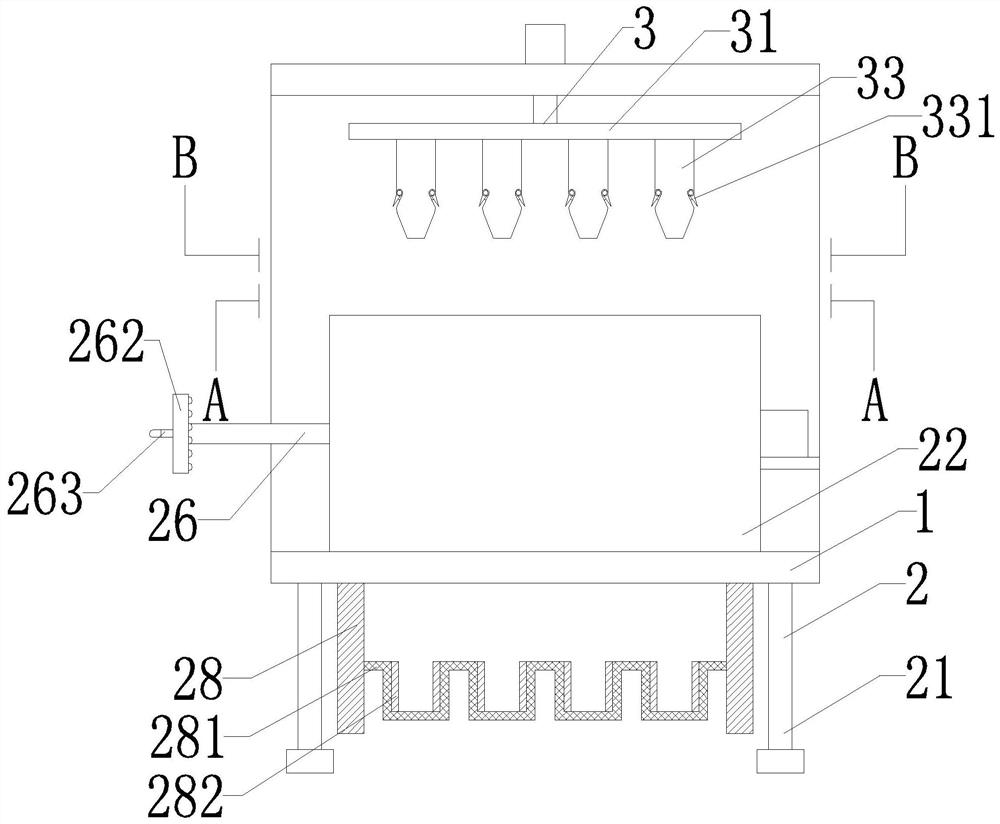

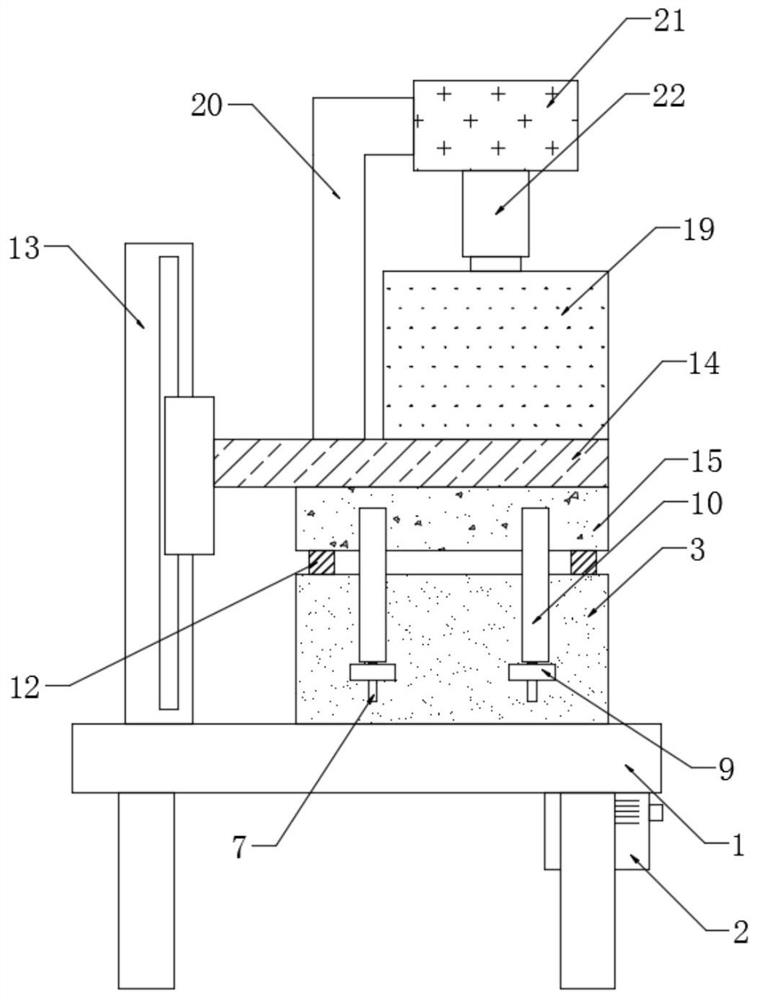

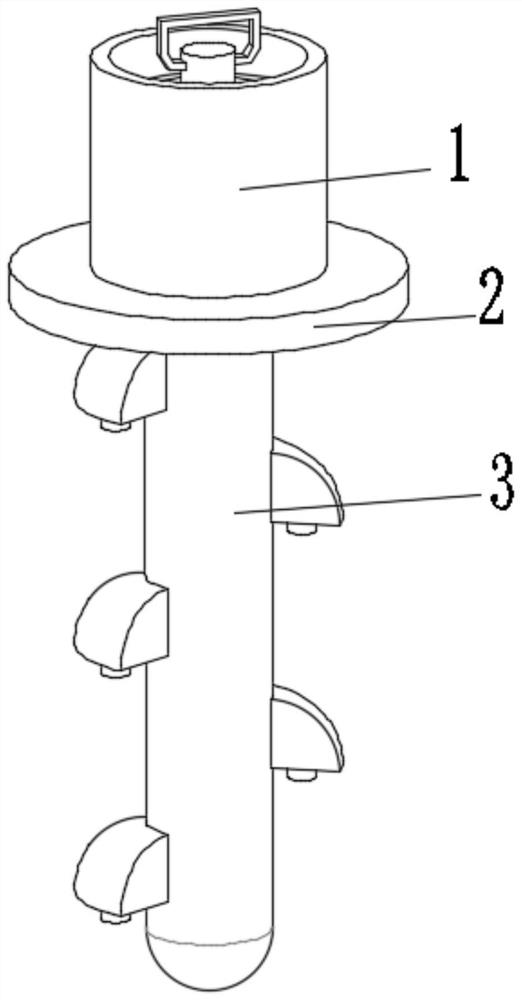

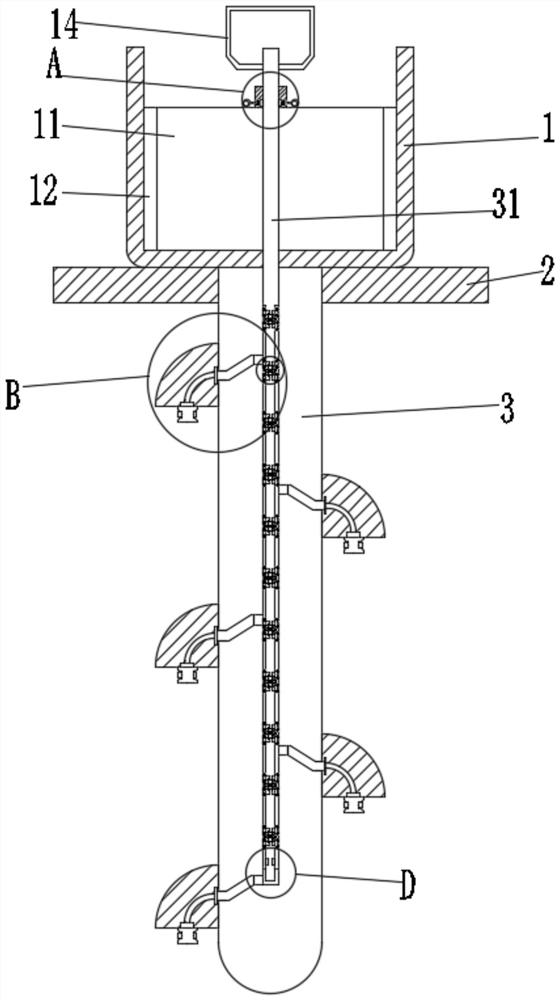

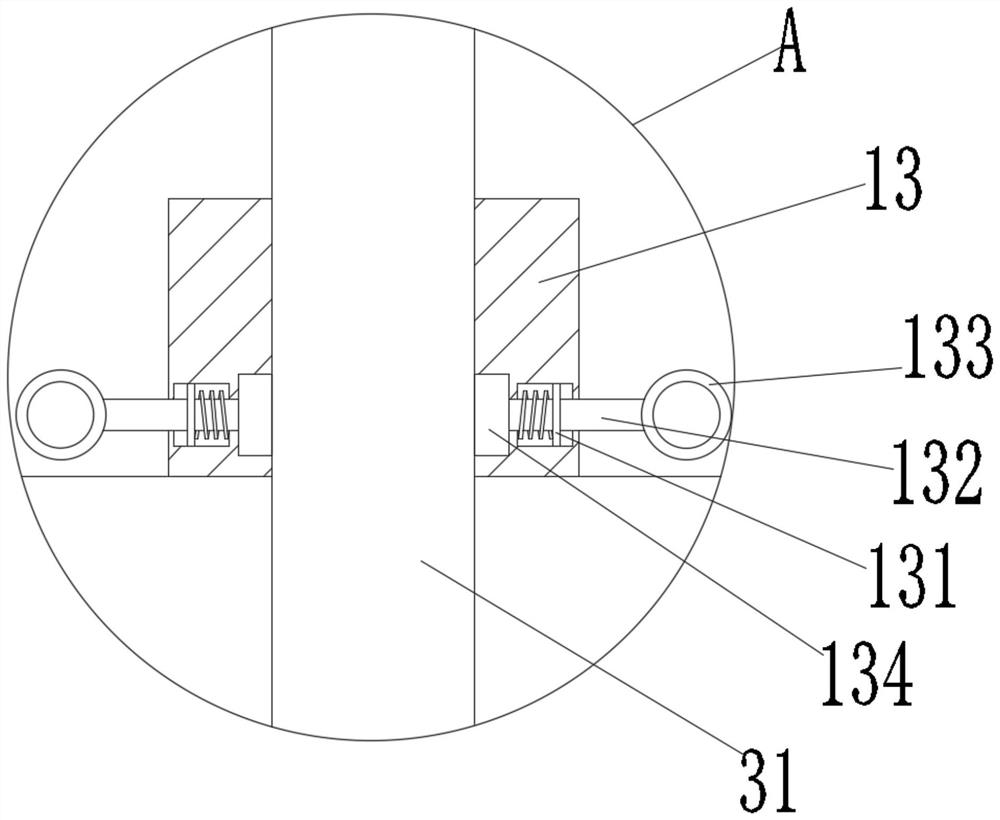

Welding device for synchronously recycling welding flux

InactiveCN110449702AConvenient supplementImprove recycling efficiencyWelding accessoriesEngineeringAirflow

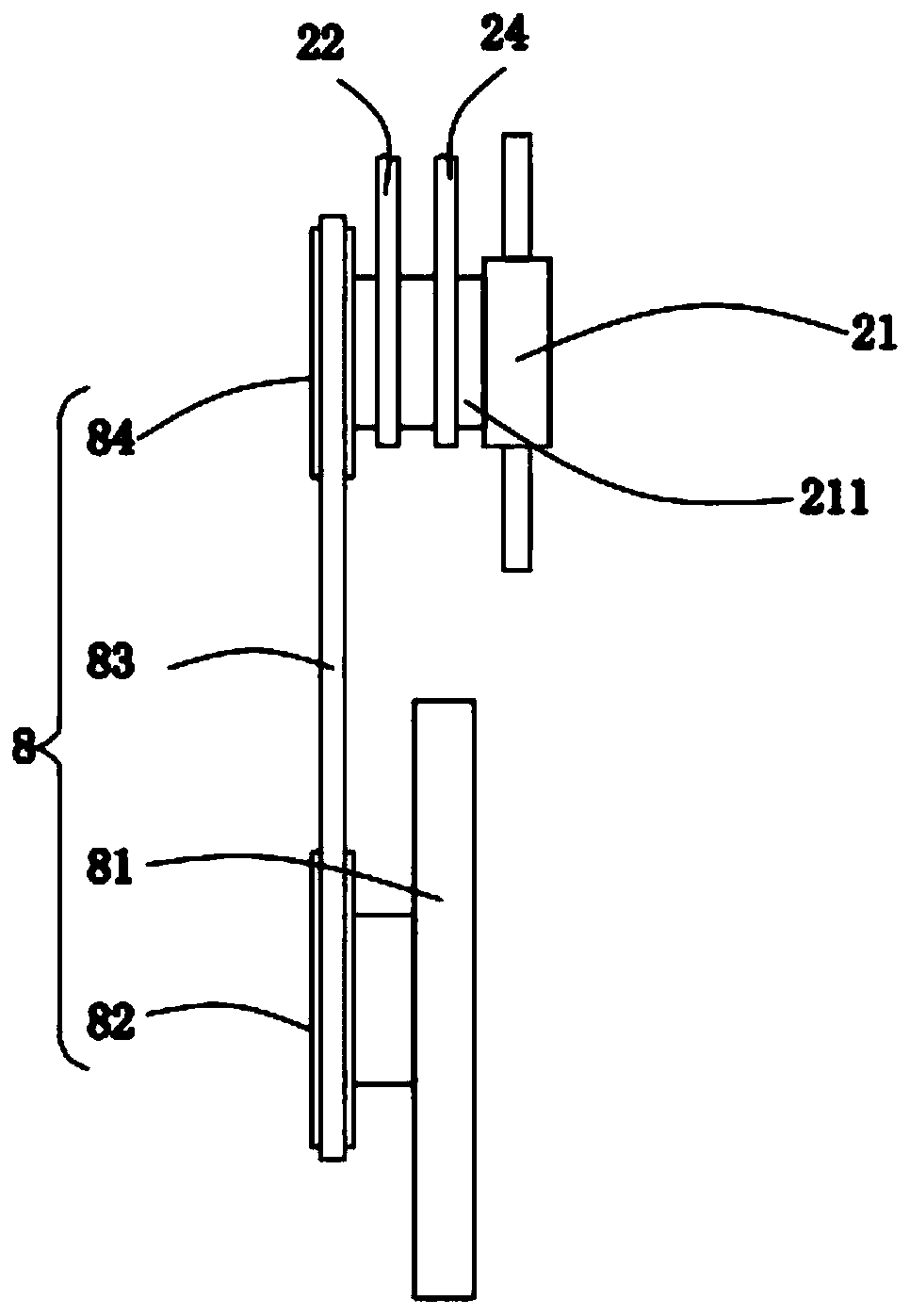

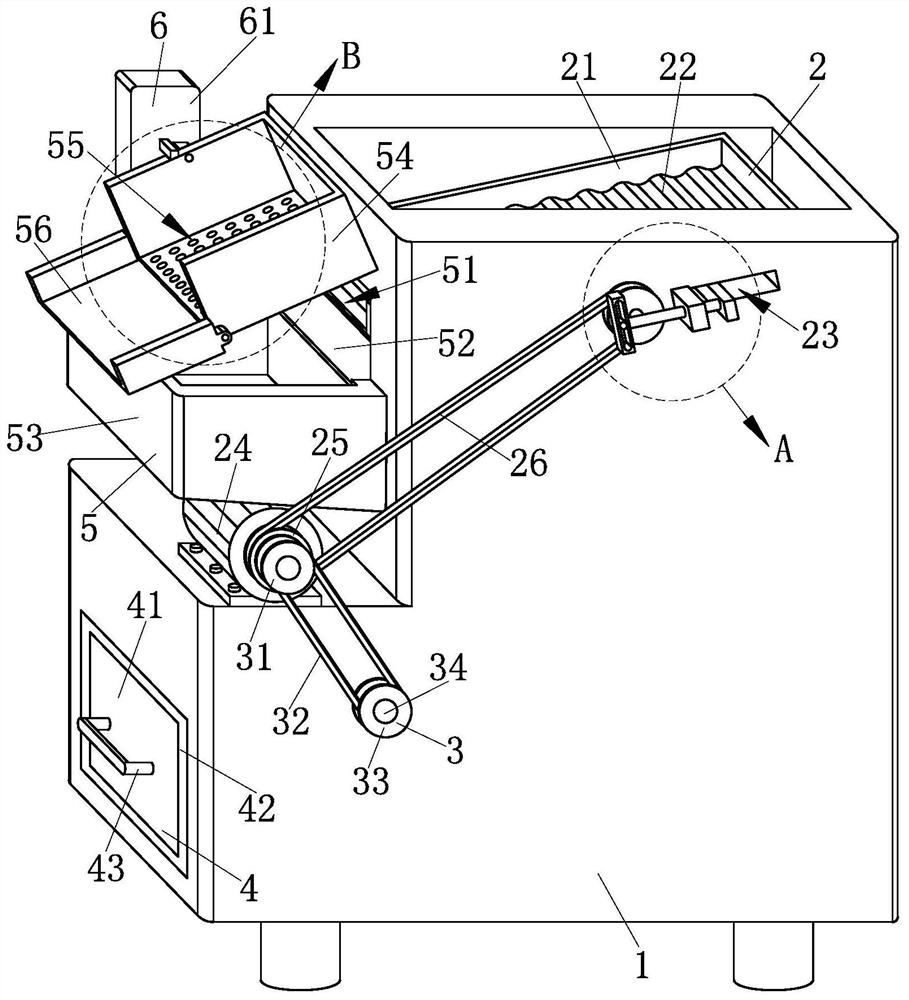

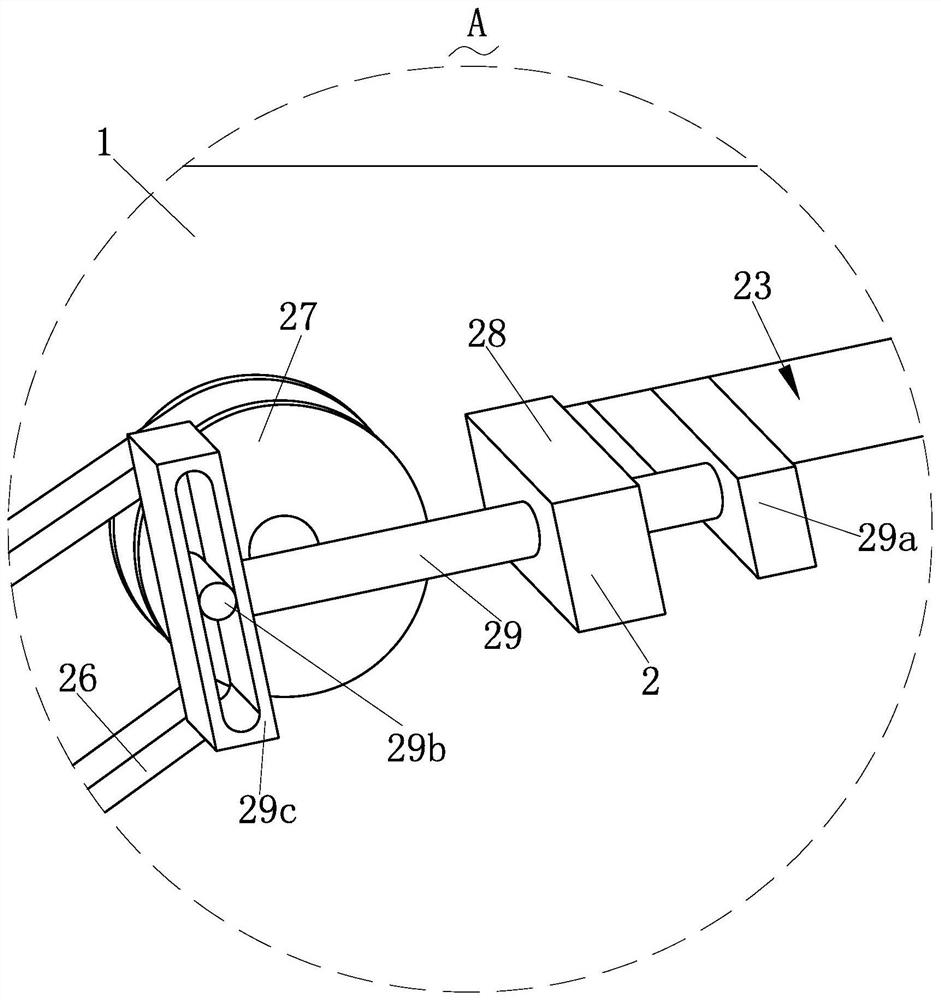

The invention relates to the technical field of welding equipment, in particular to a welding device for synchronously recycling welding flux. The welding device comprises a welding flux box for storing welding flux and an airflow power device, wherein a discharging pipeline and a recycling pipeline are arranged on the welding flux box; a discharging port for discharging the welding flux is arranged on the discharging pipeline; a sucking port for recycling the welding flux into the welding flux box is arranged on the recycling pipeline; the airflow power device is used for forming negative pressure at the sucking port to suck the welding flux into the recycling pipeline, and forming a conveying airflow in the recovery pipeline to convey the sucked welding flux into the welding flux box; and the welding flux box is also provided with a charging port. By means of the welding device, on one hand, the welding flux in the welding flux box can be supplemented and supplied; and on the other hand, the recycling efficiency of the welding flux is accelerated.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

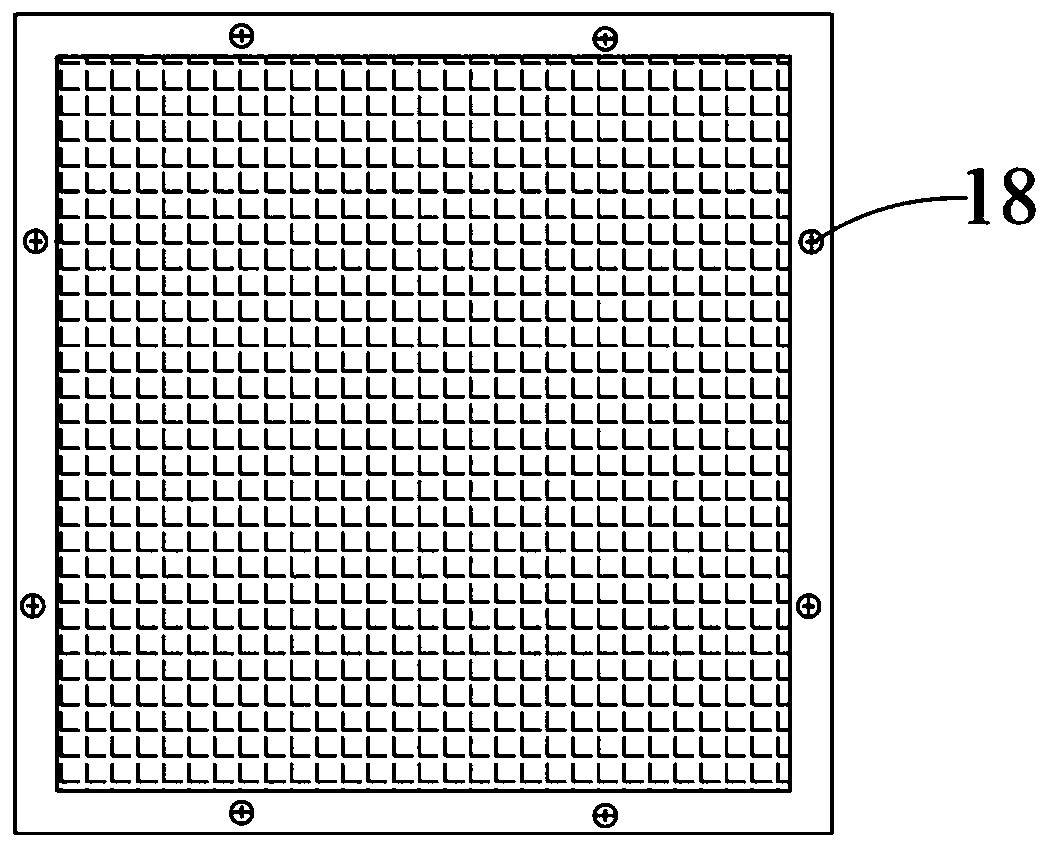

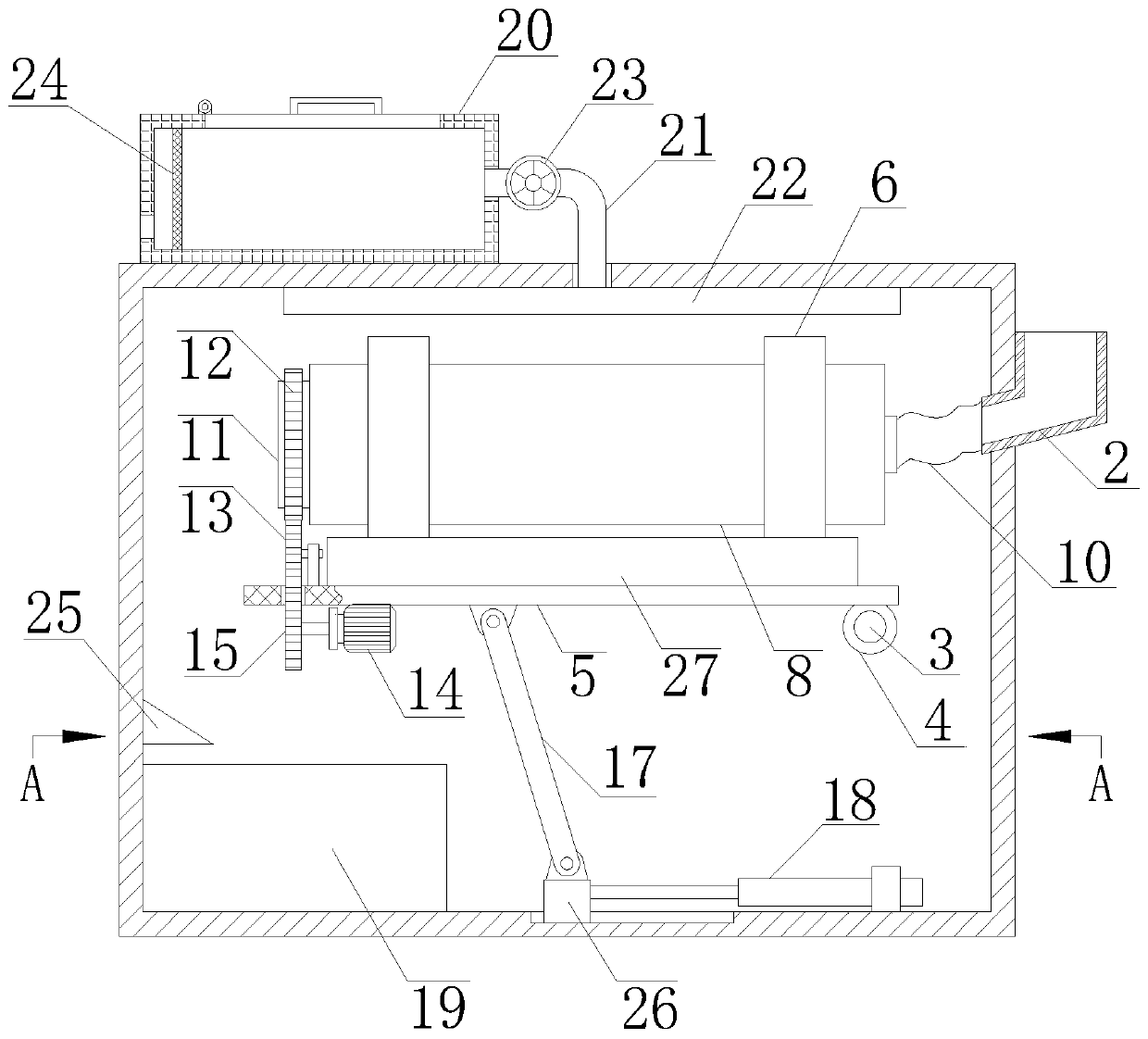

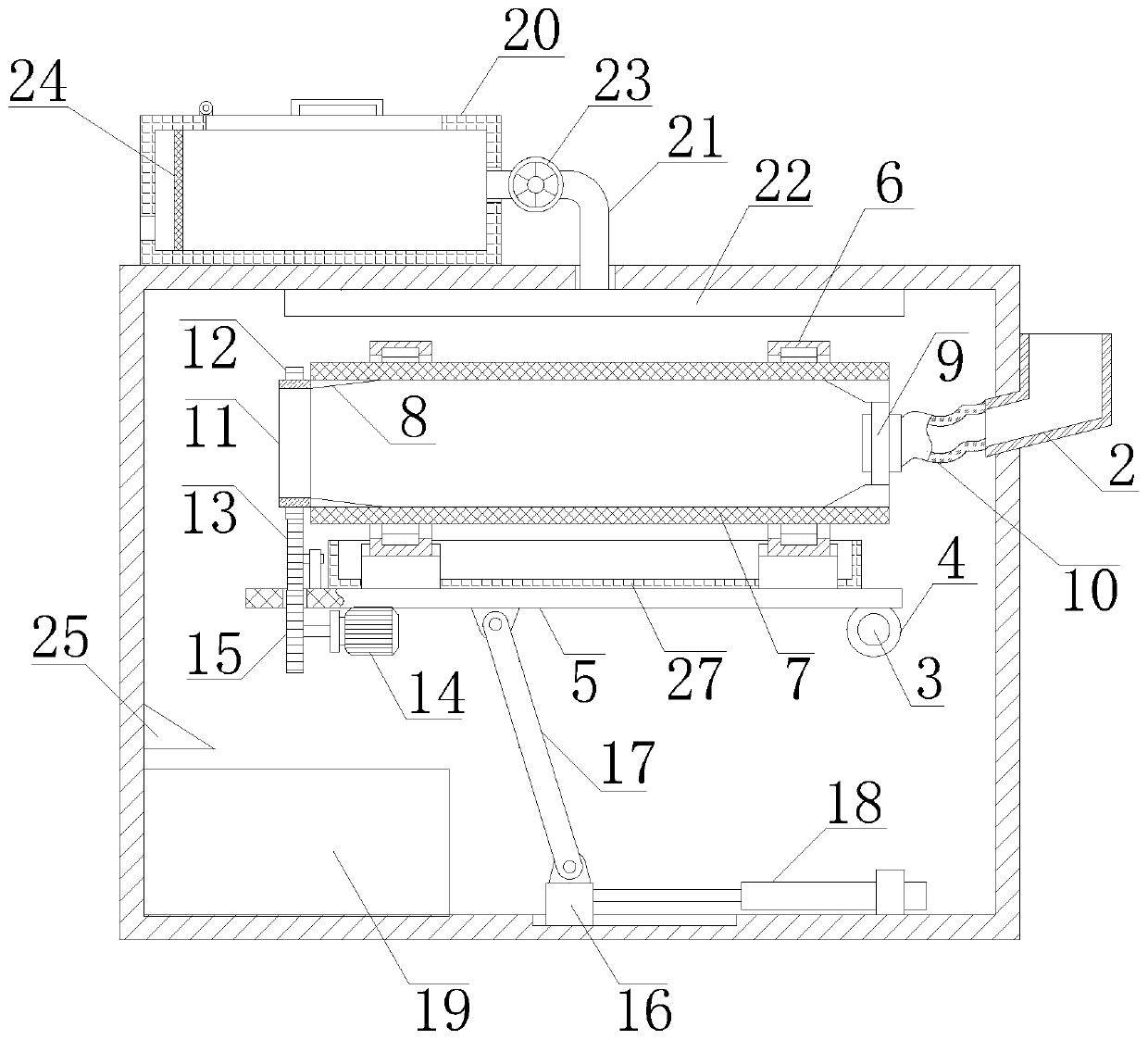

Automobile sheet metal repairing method

InactiveCN112570497AIncrease workloadSlow down productivityVehicle componentsMetal working apparatusStructural engineeringMechanical engineering

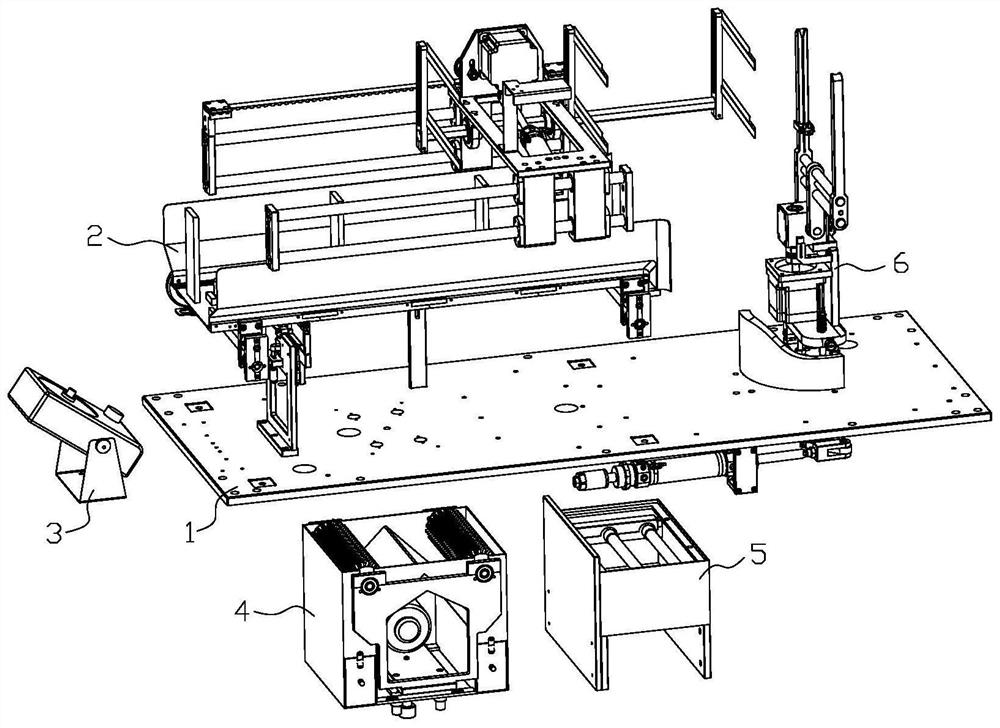

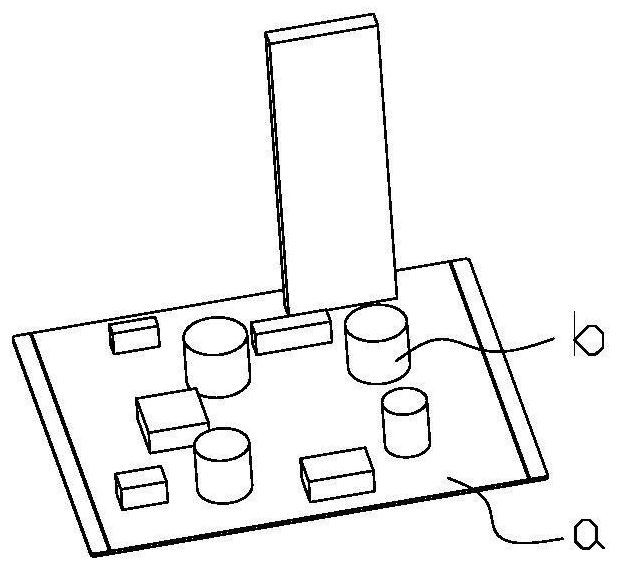

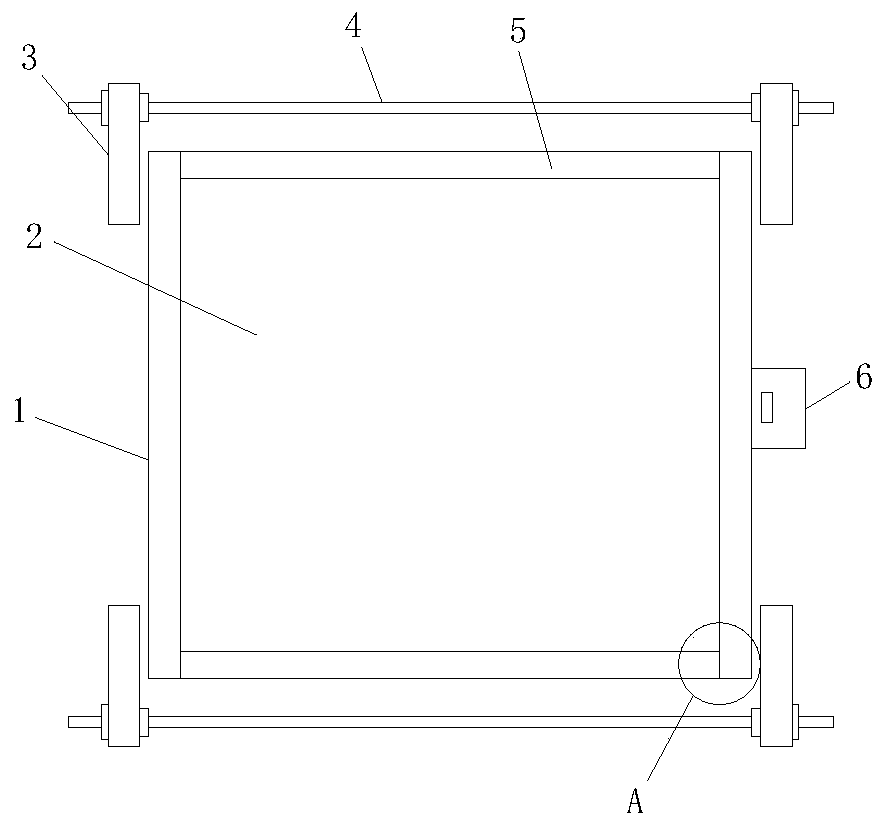

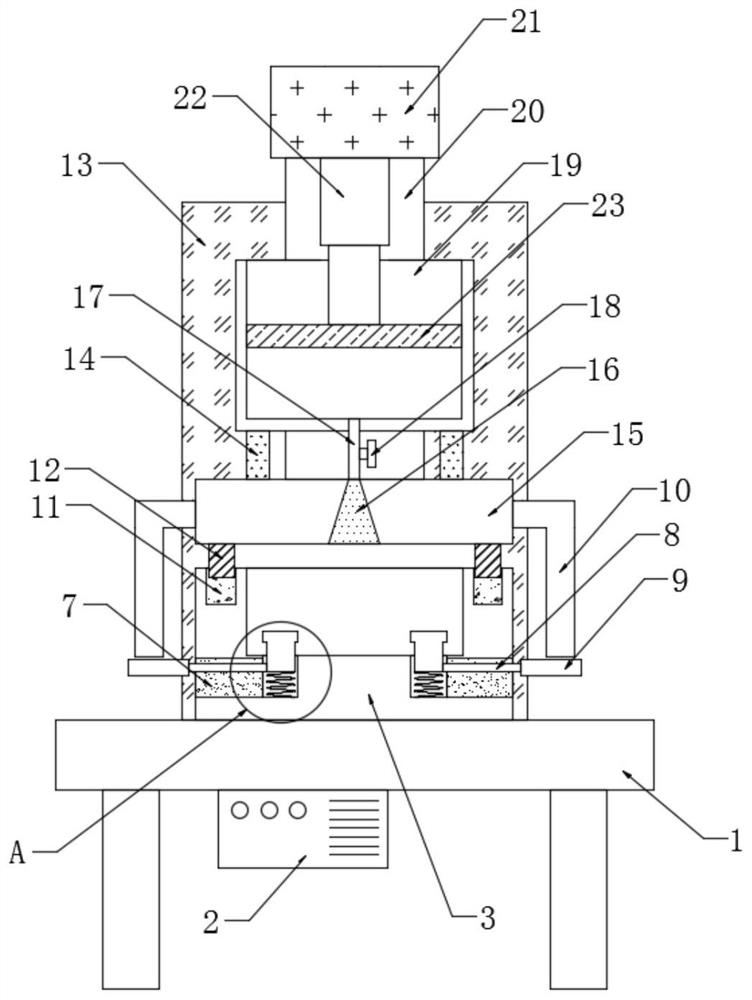

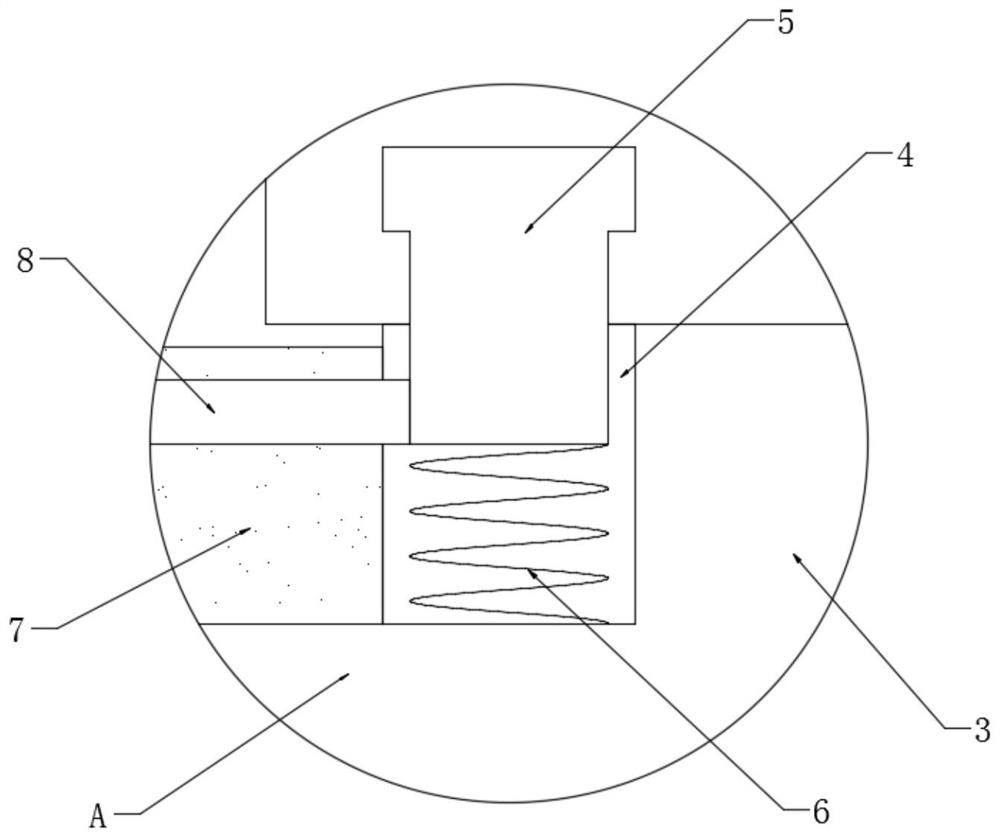

The invention relates to an automobile sheet metal repairing method, which mainly comprises the following steps: equipment inspection, plate fixing, plate detection, plate repairing and plate taking.Automobile sheet metal repairing equipment comprises a mounting frame, a detection kit and a repairing kit, and the detection kit and the repairing kit are sequentially arranged on the mounting framefrom inside to outside. The automobile sheet metal repairing device provided by the invention can solve the following problems existing in repairing treatment of an existing automobile plate: a, during repairing treatment of the existing automobile plate, repairing is often carried out in a manual knocking manner, so that the situation of omission or uneven repairing often occurs in deformation ofthe automobile plate, the repairing effect is influenced, and the workload of staff is increased; and b, after the existing automobile plate is knocked and repaired, tiny pits still exist on the surface of the automobile plate and are not easily observed by naked eyes in time, so that a reworking phenomenon is easy to occur during production, the workload of staff is greatly increased, and the production efficiency is slowed down.

Owner:朱波

Environment-friendly cylindrical screen for grain screening

InactiveCN111346808AAvoid outflow situationsEffective scrollingSievingDispersed particle filtrationFixed bearingStructural engineering

The invention relates to the technical field of grain screening, and discloses an environment-friendly cylindrical screen for grain screening. The environment-friendly cylindrical screen for grain screening comprises a box body, a feeding hopper is fixedly mounted at the upper end of the right side wall of the box body, the discharging end of the feeding hopper penetrates through and extends to the inside of the box body, and a rotating rod is fixedly installed between the front wall and the rear inner wall of the box body, a round sleeve is connected to the outer round surface of the rotatingrod in a sleeving mode, a supporting plate is fixedly arranged at top of the round sleeve, two fixed bearings are fixedly installed at the top of the supporting plate through fixing blocks, a same round screen bucket is fixedly installed between the inner rings of the two fixed bearings, circular rings with slopes are fixedly installed on the inner walls of the left end and the right end of the round screen bucket, and the inner wall of the circular ring located on the right is rotatably connected with a connecting pipe through a bearing seat. The problems of low screening efficiency and poorscreening effect of an existing grain vibrating screen for parallel vibration of grains are solved.

Owner:安徽宇特机械有限公司

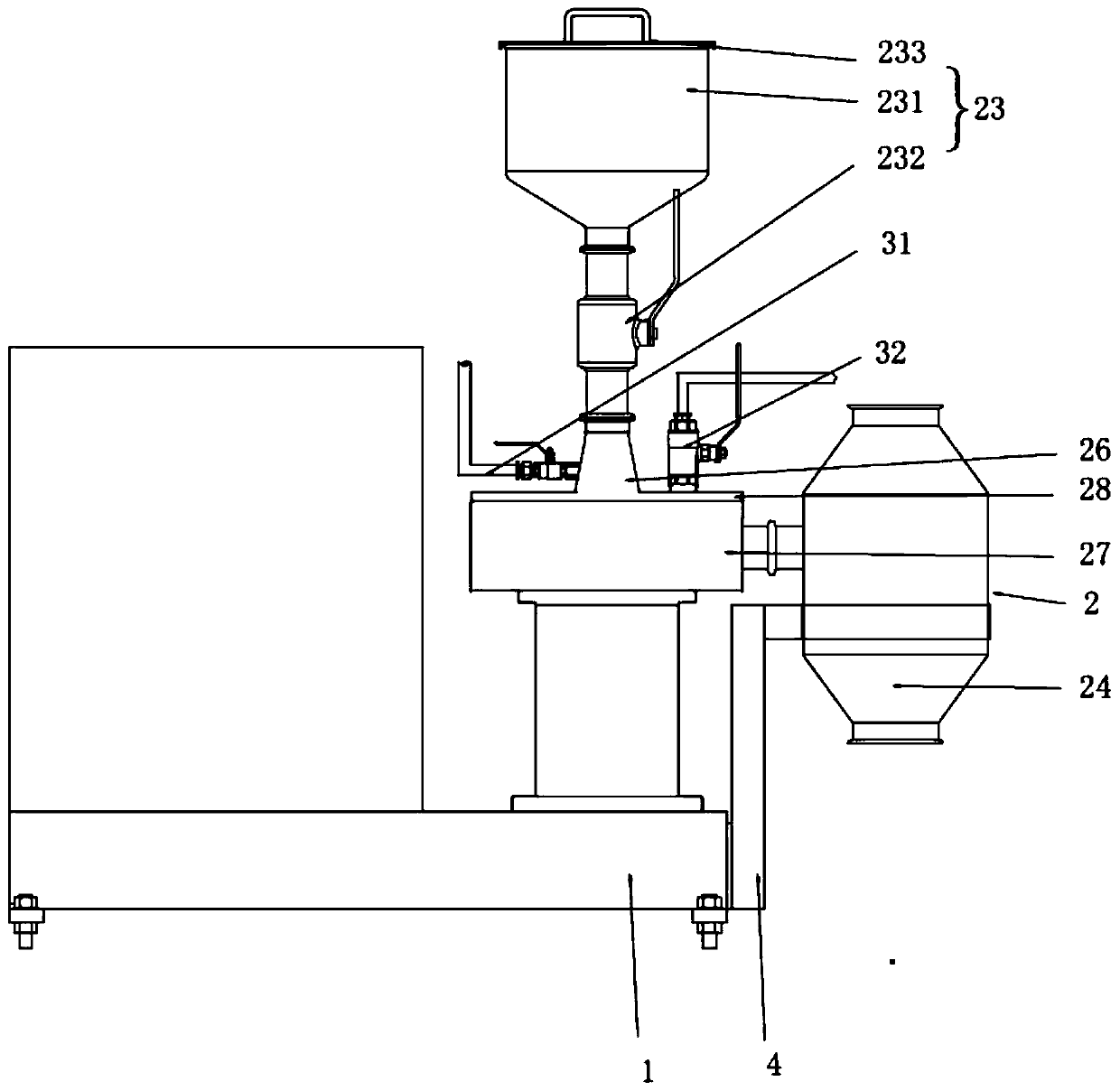

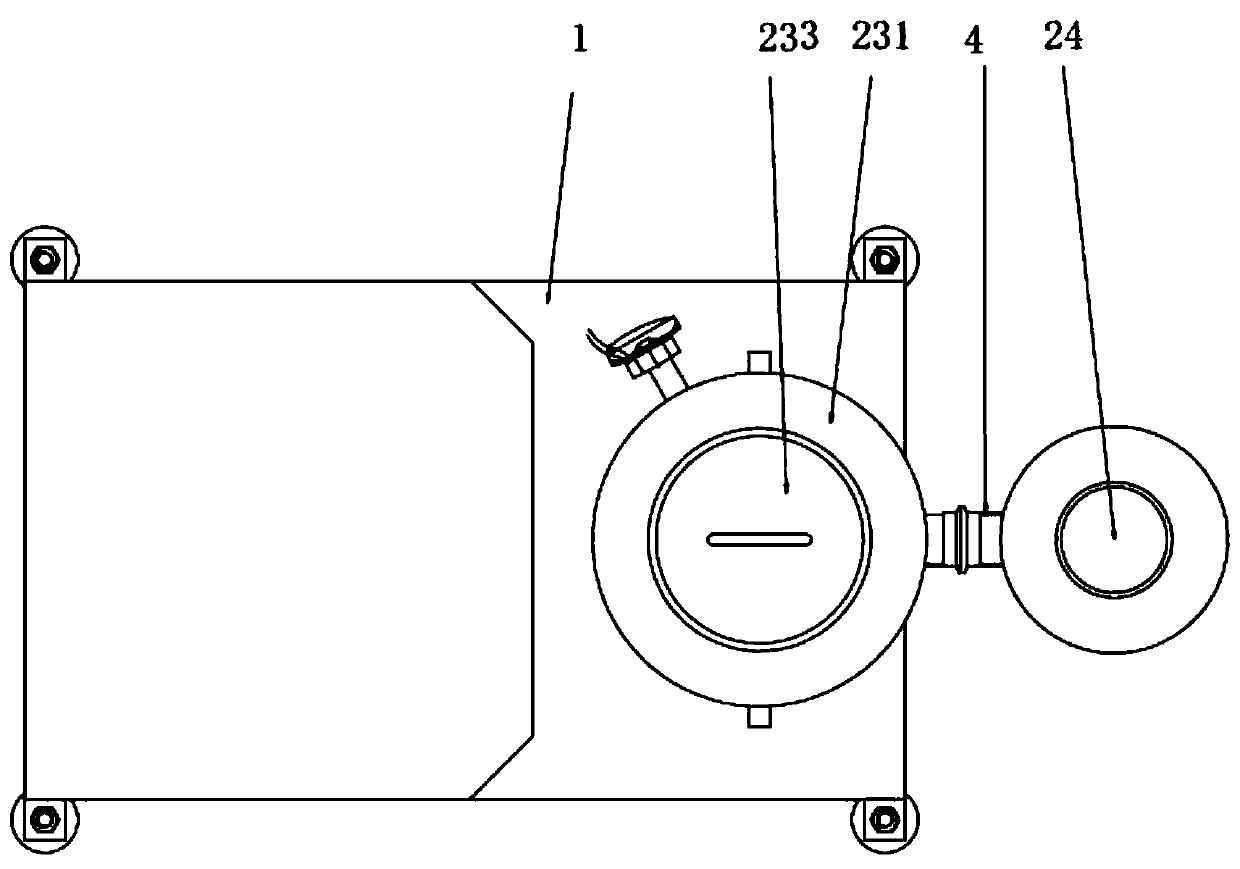

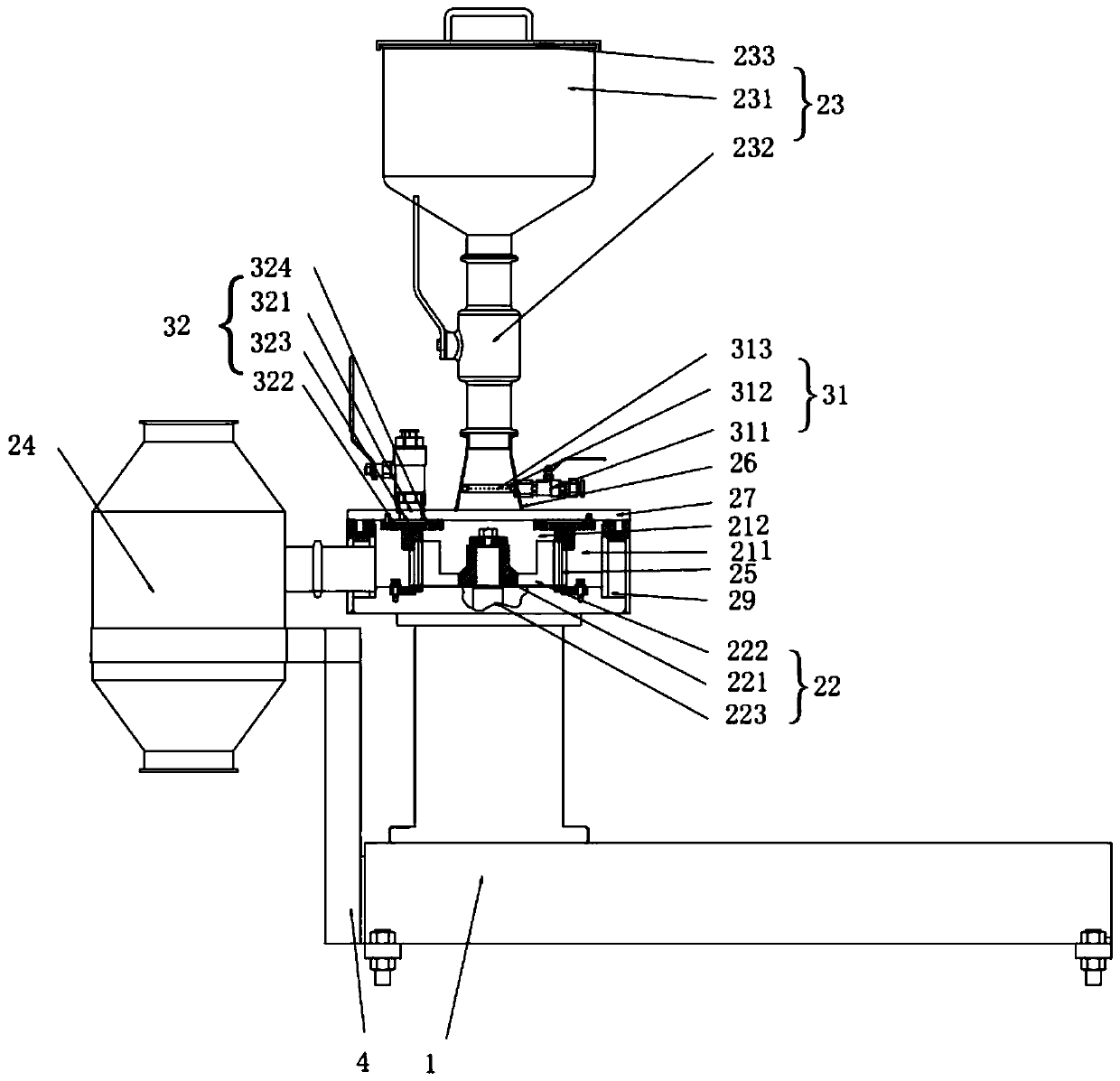

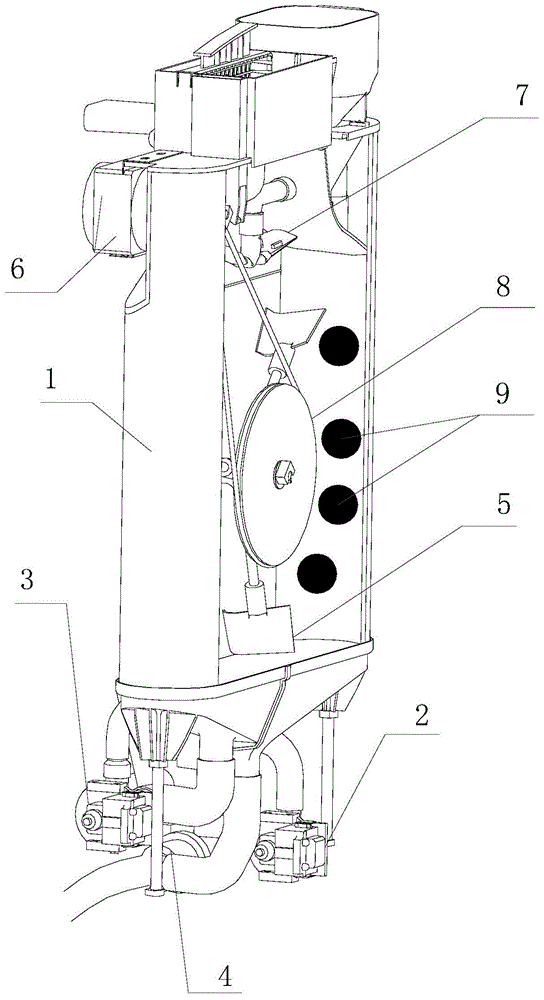

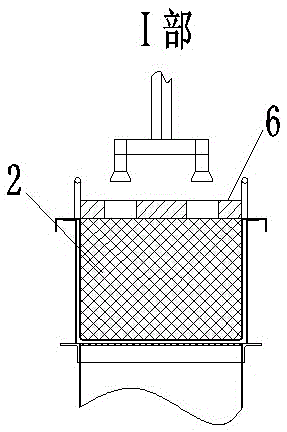

Wet pulverizer

ActiveCN111001482AImprove stabilityAvoid outflow situationsGrain treatmentsThermodynamicsEngineering

The invention discloses a wet pulverizer. The pulverizer comprises a rack, a pulverizing device and a gas flow device, wherein a pulverizing cavity is formed in the pulverizing device, a pulverizer head is arranged in the pulverizing cavity, the feeding end of the pulverizing cavity communicates with a feeding mechanism, and the discharging end of the pulverizing cavity communicates with a gas-liquid separation bin; the gas flow device is provided with a first jetting mechanism and a second jetting mechanism, the first jetting mechanism is installed on the feeding end of the pulverizing cavity, and nitrogen jetted by the first jetting mechanism forms a gas seal on the feeding end of the pulverizing cavity; and the second jetting mechanism is installed in the pulverizing cavity, and nitrogen flow jetted by the second jetting mechanism forms a gas flow barrier on the circumferential side of the pulverizer head. According to the low-temperature pulverizer, the gas seal formed through jetting of the first injection mechanism and the gas flow barrier formed through jetting of the second injection mechanism are utilized, so that the pressure stability of the inner side and the top of thepulverizing cavity can be kept, the vibration phenomenon caused by high and low difference of pressure values inside and outside the pulverizing cavity due to feeding and discharging is relieved, andthe operation stability of the pulverizer is improved.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

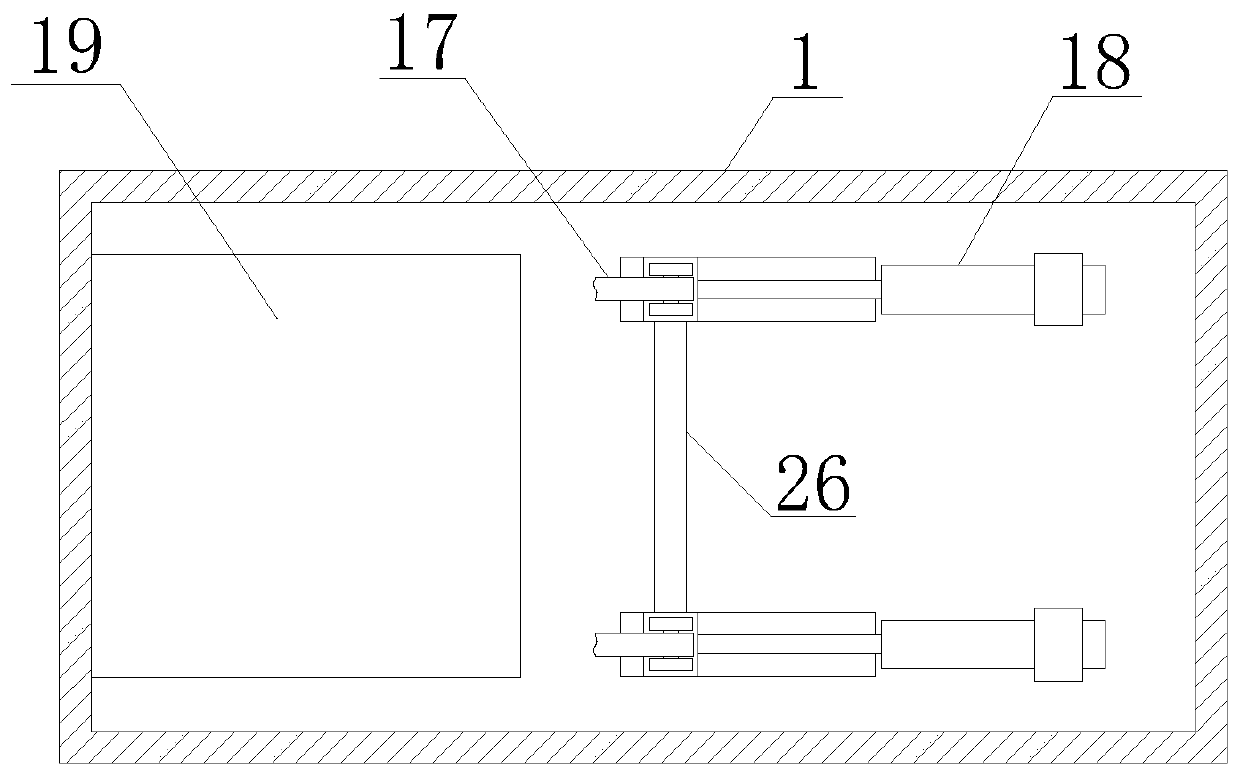

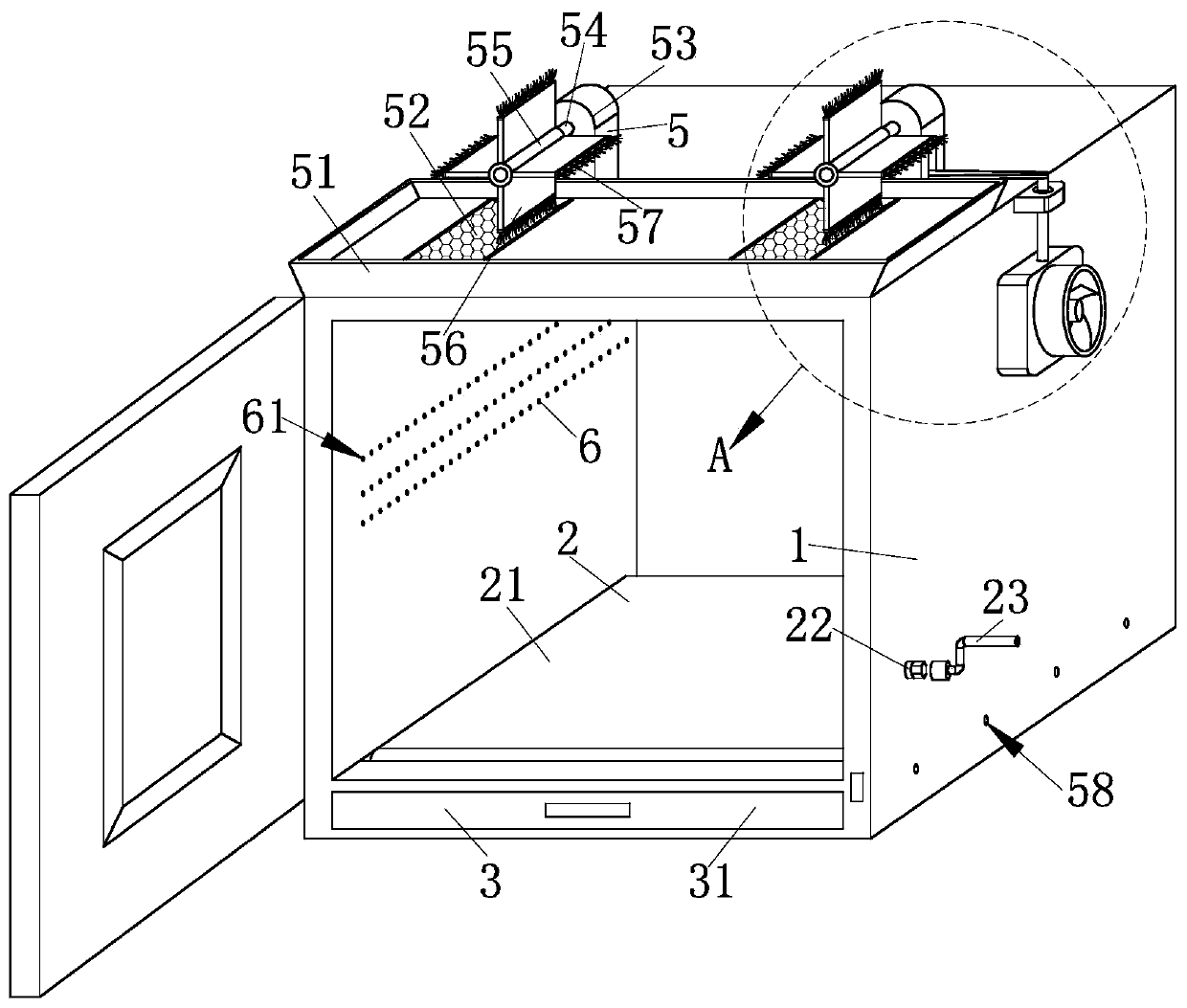

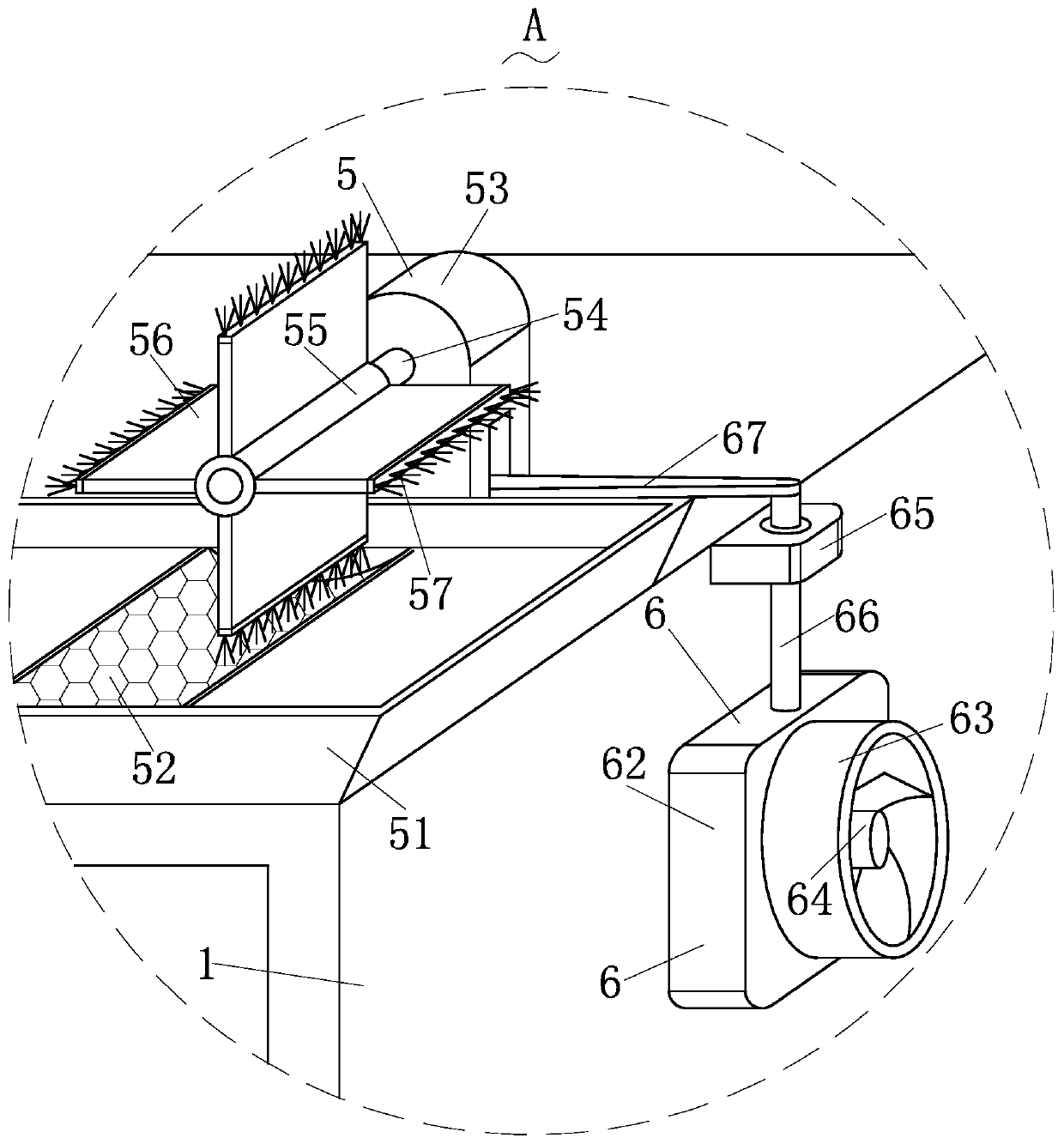

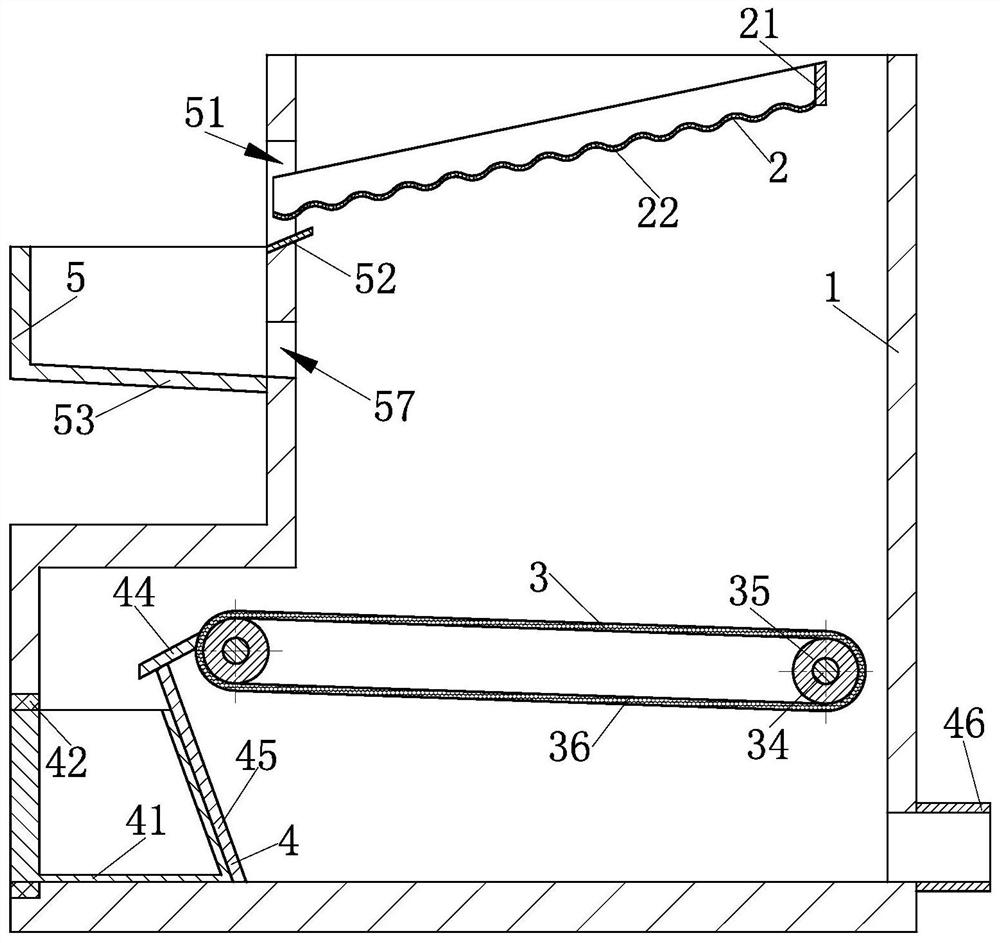

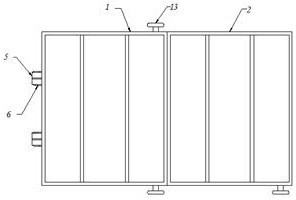

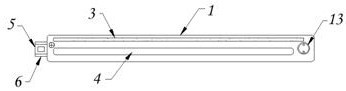

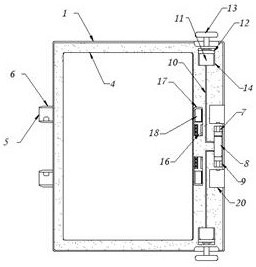

5G test shielding box

InactiveCN111257657AClean and comprehensivePlay a supporting roleElectromagentic field characteristicsStructural waterWater flow

The invention relates to the field of 5G test shielding devices, in particular to a 5G test shielding box which comprises a box body, a rotating structure, a cleaning structure, a sealing structure, awater cooling structure and an anti-blocking structure. By arranging the rotating structure, the ground in the box body can be moved, a cleaning structure is arranged, the ground in the box body canbe comprehensively cleaned, and therefore, dust on the ground in the box body is prevented from influencing the test precision, the cleaning structure can also act on the sealing structure while performing installation work, by adopting seal arrangement, a gap between the cleaning structure and the bottom end of the box body can be filled to increase the sealing effect, the situation that water atthe bottom end of the box body flows out is avoided, normal work of the cleaning structure is guaranteed, it can be kept that water exists at the bottom end of the box body all the time to cool the interior of the box body, and rainwater can be collected and cool the interior of the box body by installing the water cooling structure at the top end of the box body.

Owner:浙江新铭智能科技有限公司

LED circuit structural part and welding process thereof

InactiveCN111906400AImprove welding qualityAvoid damagePrinted circuit assemblingMetal working apparatusLED lampLED circuit

The invention relates to the technical field of welding processes, and discloses an LED circuit structural part and a welding process thereof. The welding process comprises the following steps that 1)a welder must wear anti-static gloves, anti-static wrists and anti-static work clothes, an electric soldering iron must be grounded, a workbench is an anti-static workbench, LED lamps to be welded andPCBs are flatly placed on the workbench, and bare-handed touch of two terminal pins of each LED lamp is strictly forbidden; and 2) the LED lamps are inserted into wire holes in the PCBs according tothe original circuit diagram design, and then welding is conducted one by one from left to right or from top to bottom. According to the LED circuit structural part and the welding process thereof, welding discs of the PCBs and the pins of the LED lamps are accurately preheated, so that the situation that the LED lamps are damaged or welding points do not reach the standard in the welding processis avoided; and finally through appearance inspection and repair treatment, the situation that welding does not reach the standard or products which do not reach the standard flow out is avoided, andthe effect of simple, convenient, efficient and accurate welding is achieved.

Owner:福州市长乐区巧通工业设计有限公司

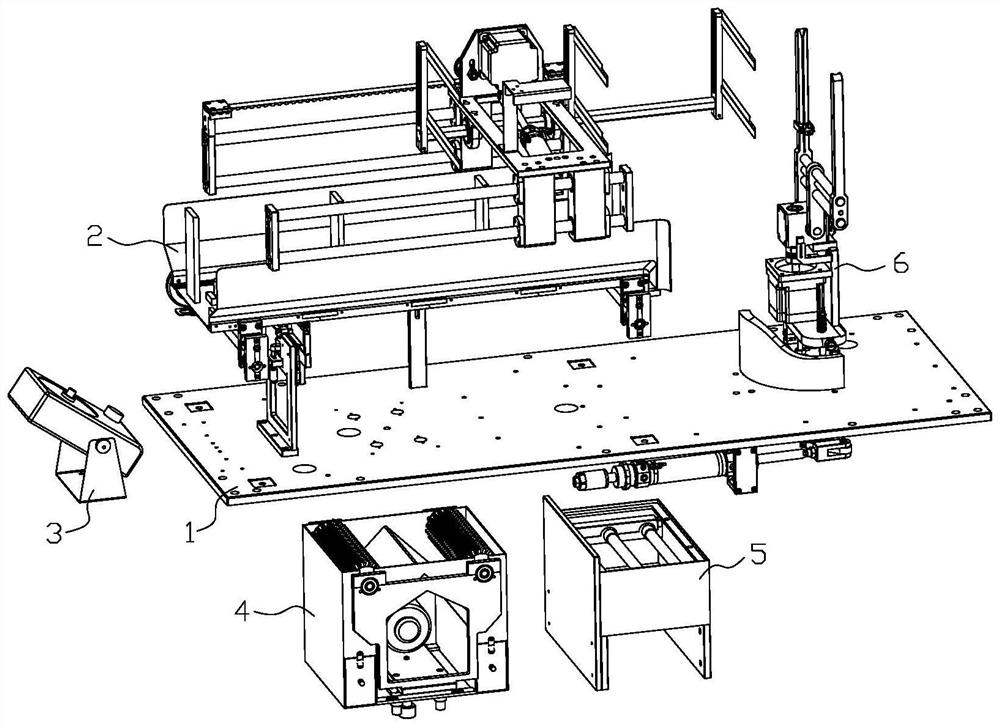

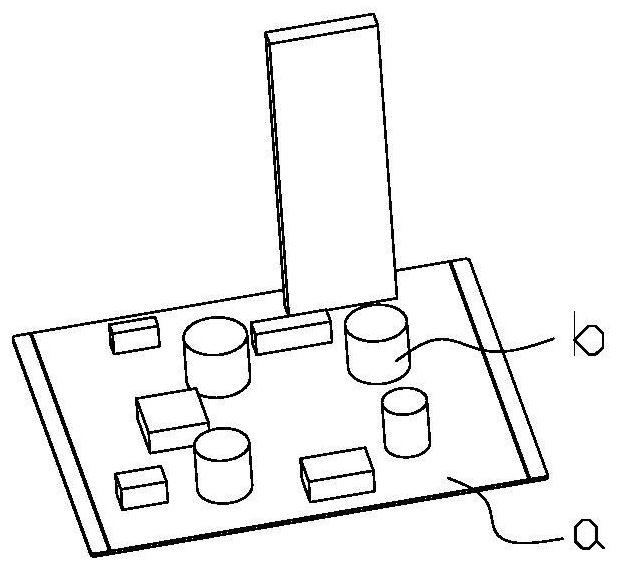

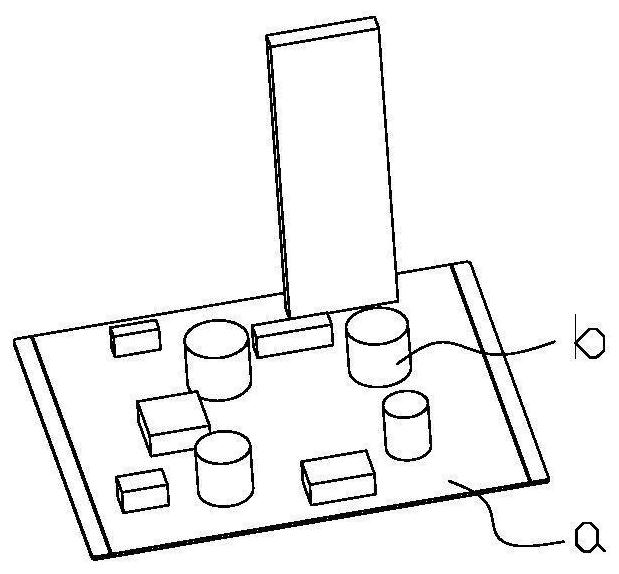

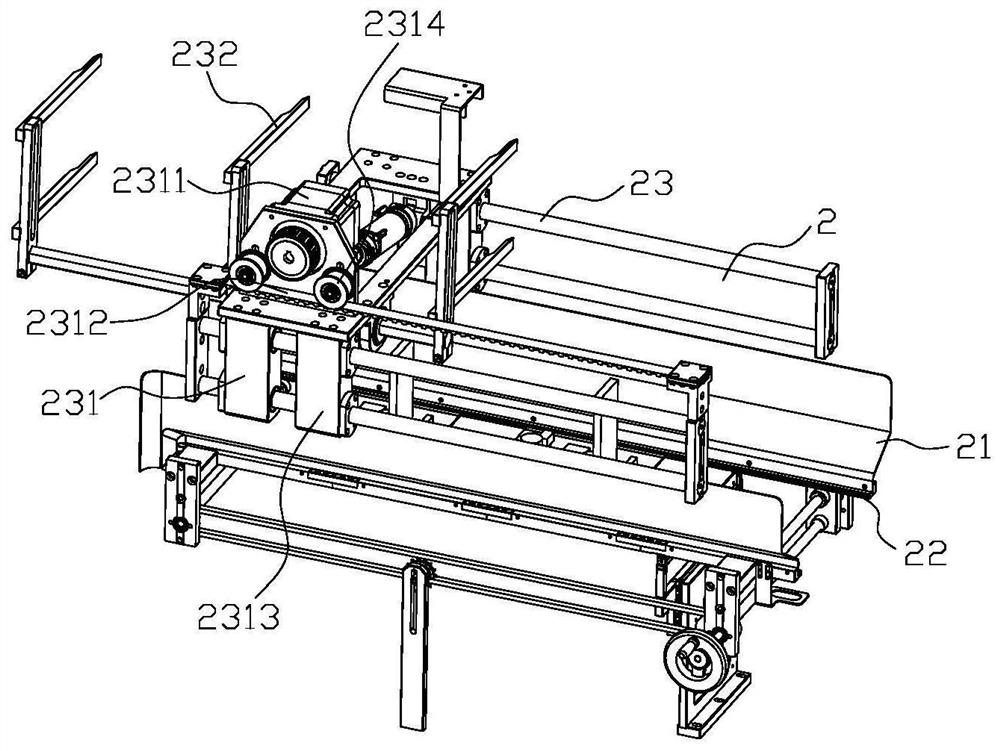

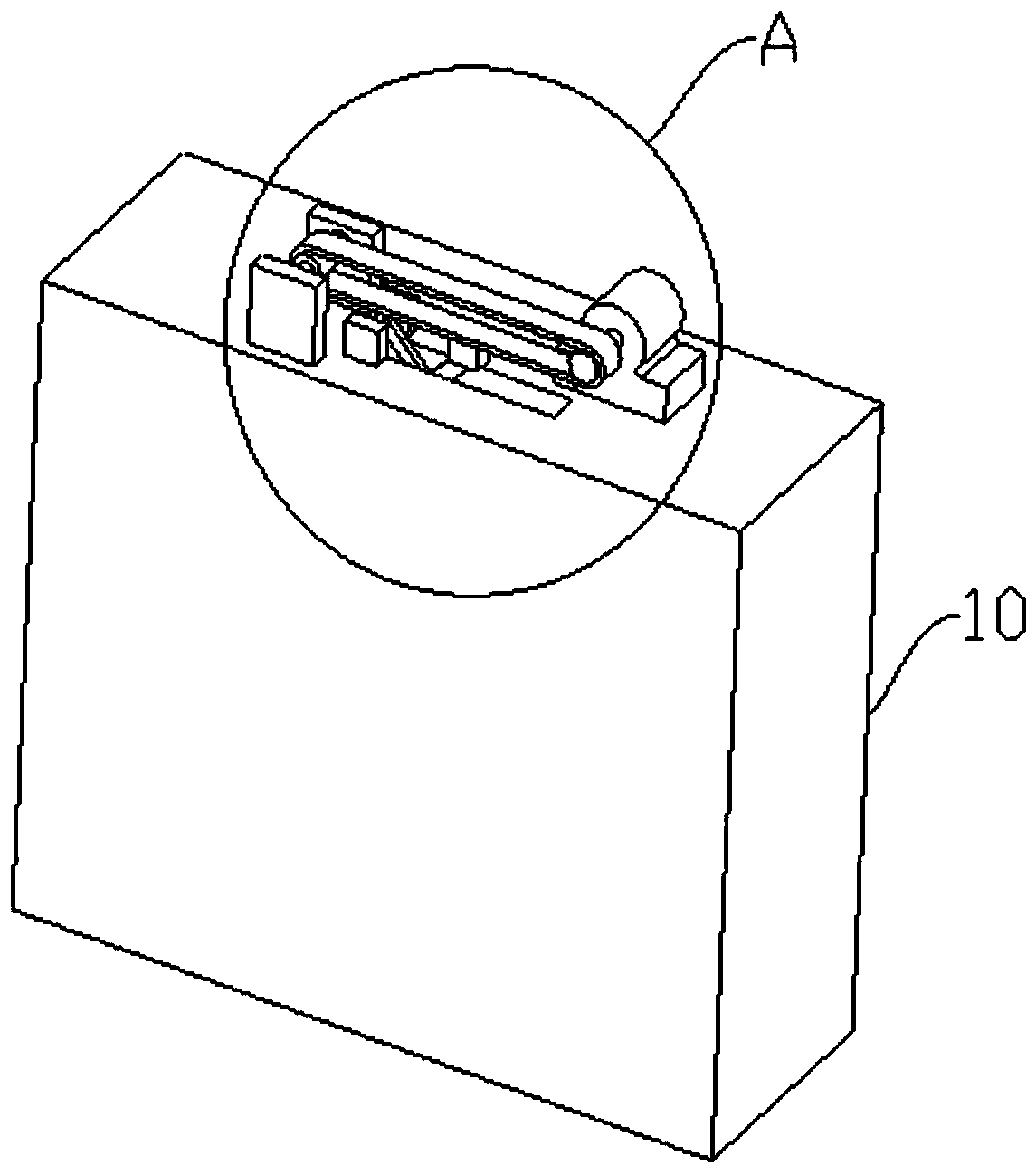

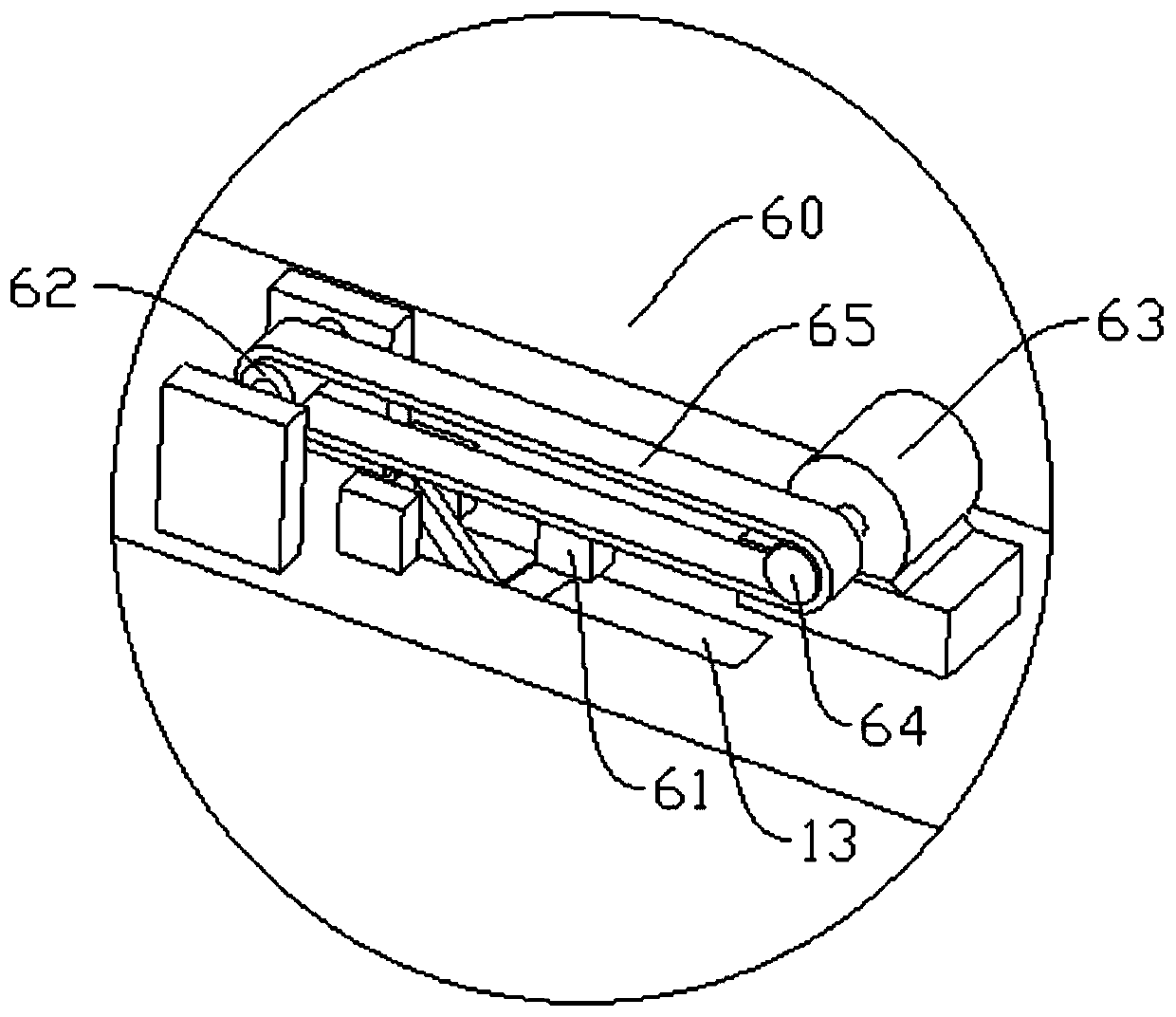

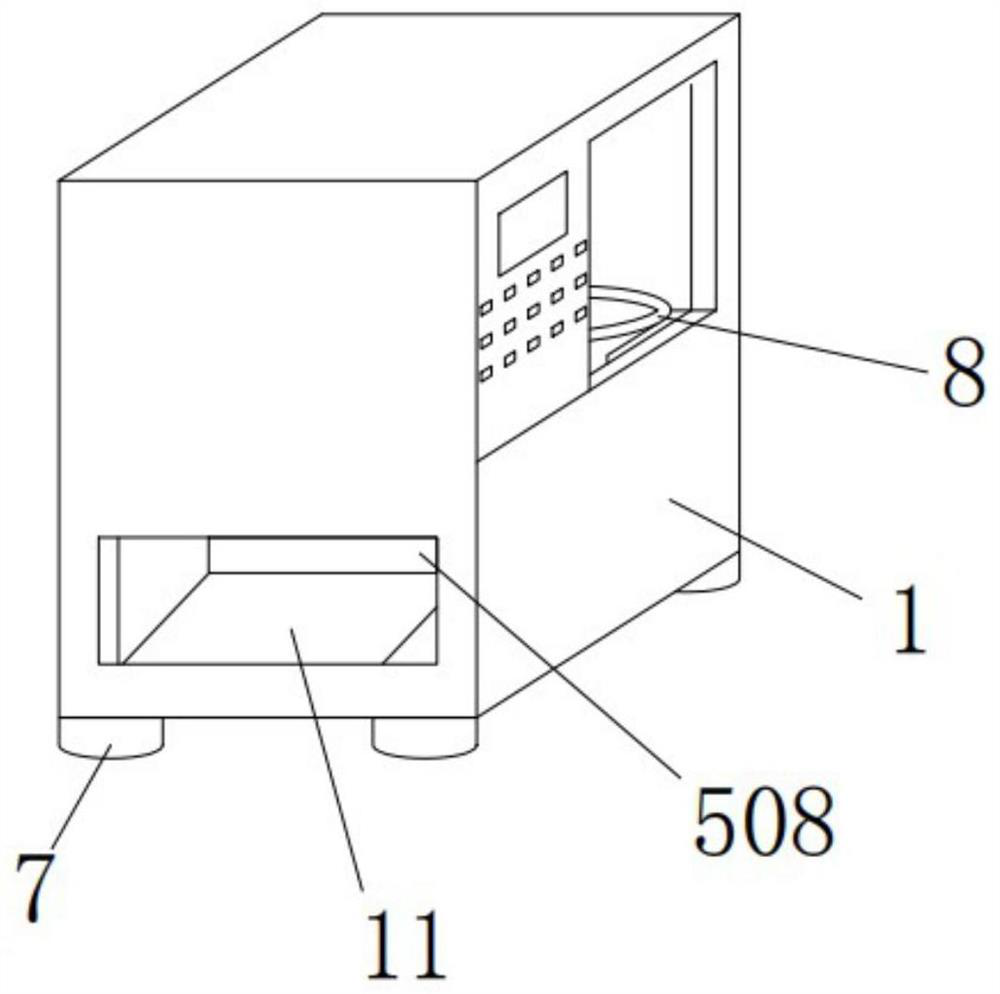

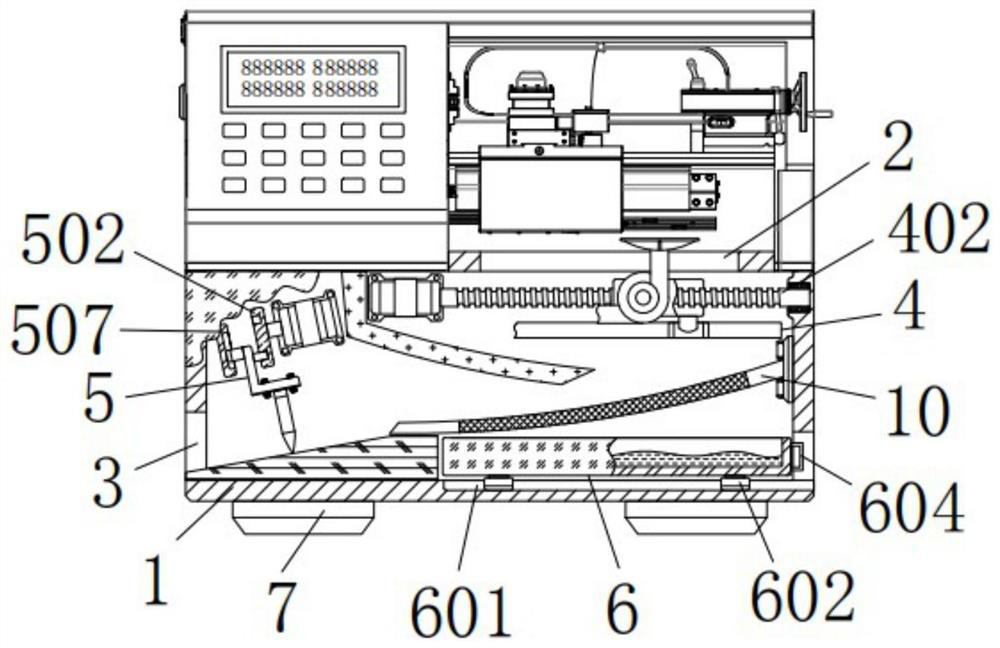

PLC circuit board conveying device and conveying method

InactiveCN111891625AReduce occupancySmall footprintCharge manipulationConveyor partsControl engineeringMechanical engineering

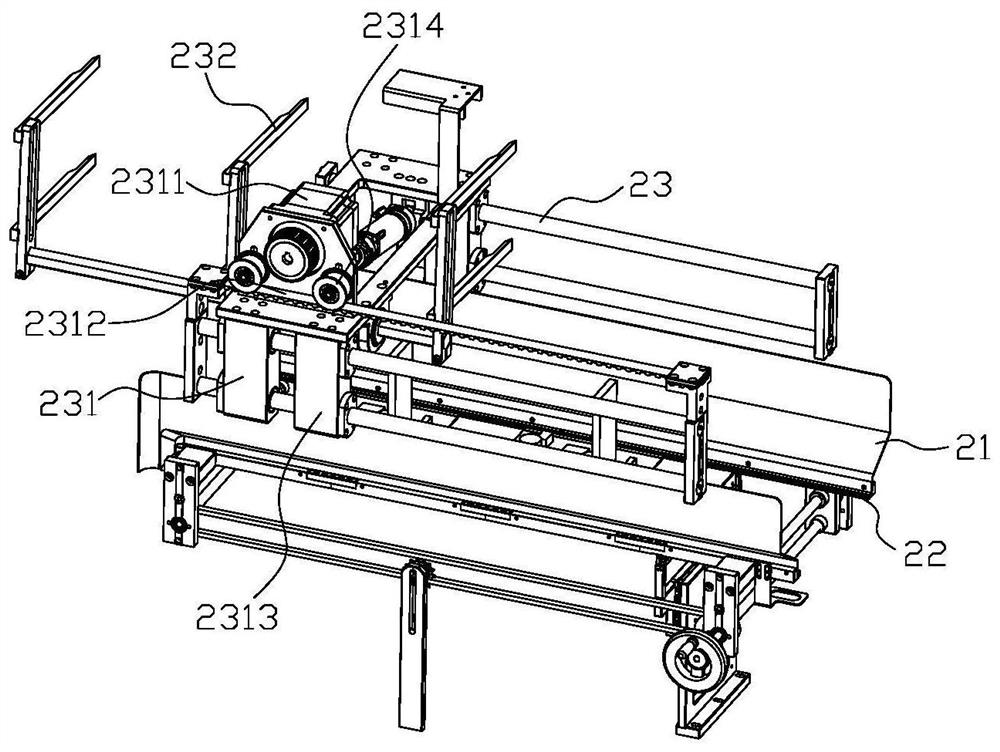

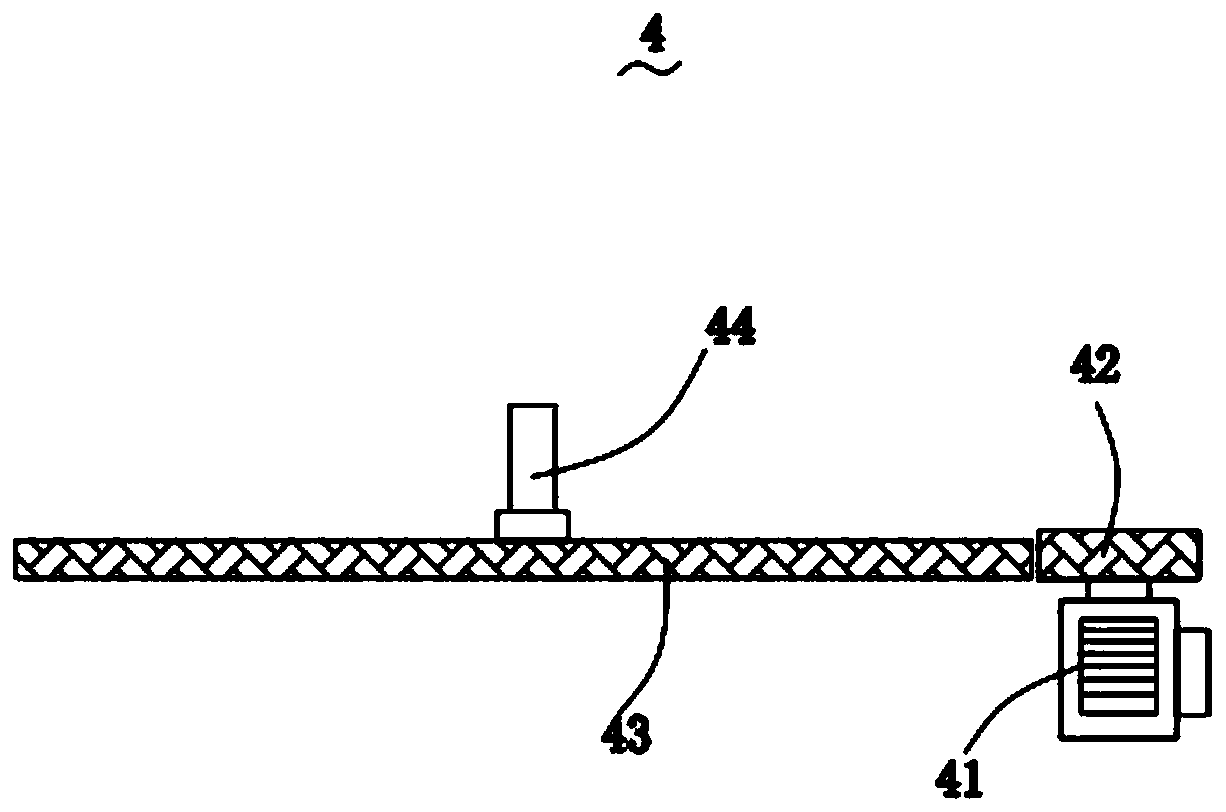

The invention relates to the field of PLC circuit boards, and discloses a PLC circuit board conveying device. The PLC circuit board conveying device comprises a circuit board conveying rack, a circuitboard conveying sliding groove and a circuit board shifting mechanism, wherein the circuit board conveying sliding groove and the circuit board shifting mechanism are fixed to the circuit board conveying rack; the conveying rack is fixed to a workbench; the circuit board conveying sliding groove is matched with a plurality of PLC circuit boards, and the circuit board conveying sliding groove is connected with an electrostatic eliminating device, a circuit board washing device, a circuit board drying device and a circuit board overturning and air-drying device; the circuit board shifting mechanism is in contact with the PLC circuit boards and is connected with the circuit board conveying sliding groove; the circuit board conveying sliding groove is used for embedding a plurality of PLC circuit boards; and the circuit board shifting mechanism is used for shifting the plurality of PLC circuit boards to be conveyed forwards. By arranging the circuit board shifting mechanism, the size of the whole conveying device is reduced, and the occupied space of equipment is reduced.

Owner:张俊

Industrial wastewater discharging, purifying and recycling device

ActiveCN111888832AImprove efficiencyGuaranteed processing efficiencyTreatment involving filtrationFiltration circuitsIndustrial wastewater treatmentProcess engineering

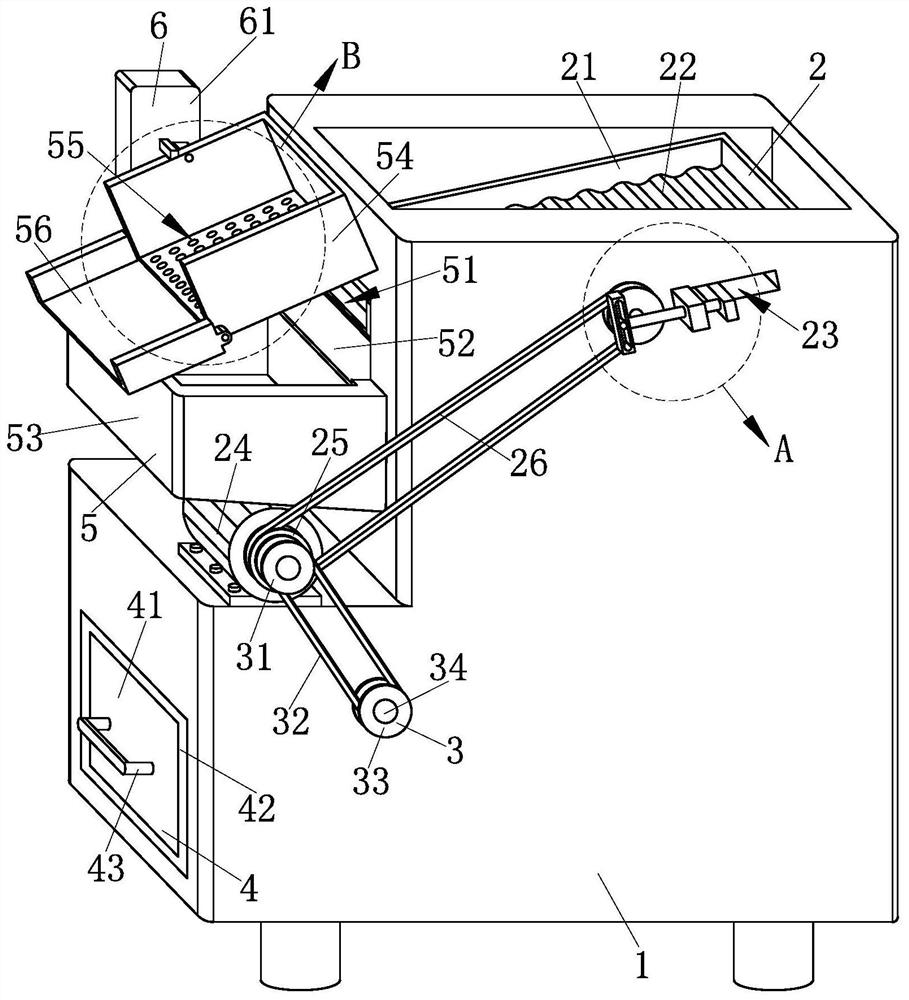

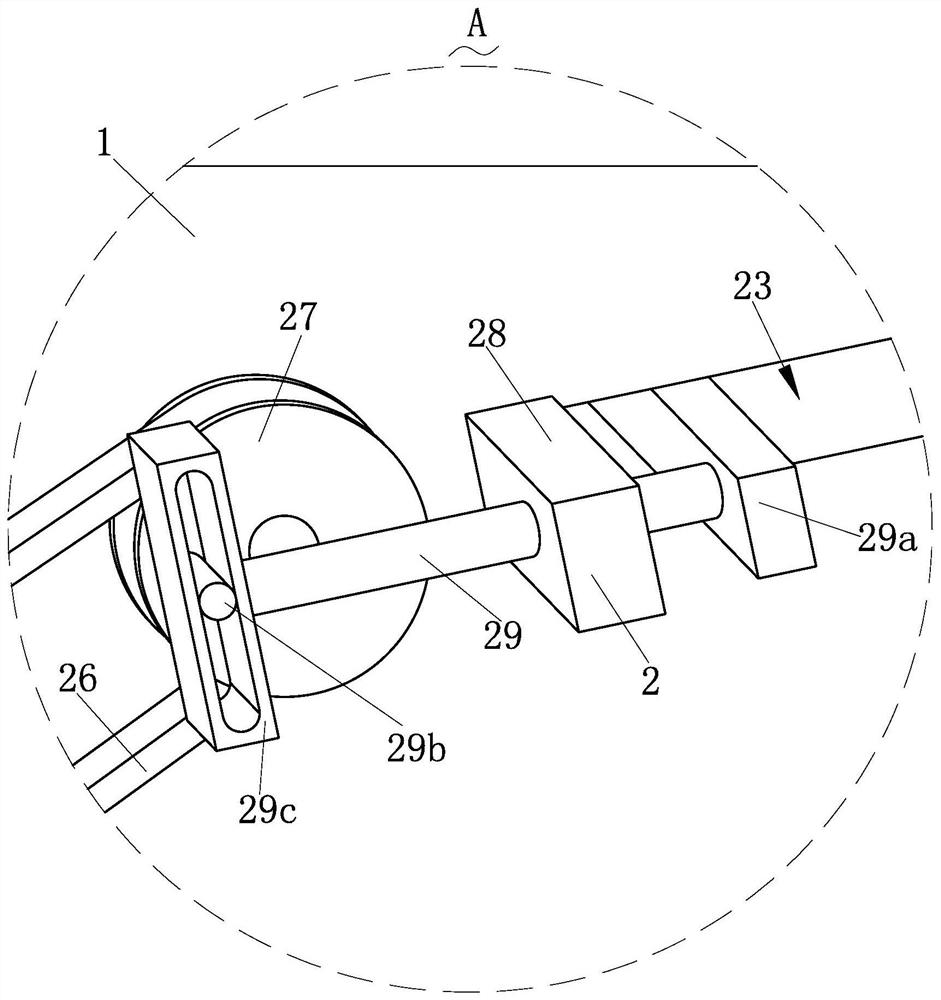

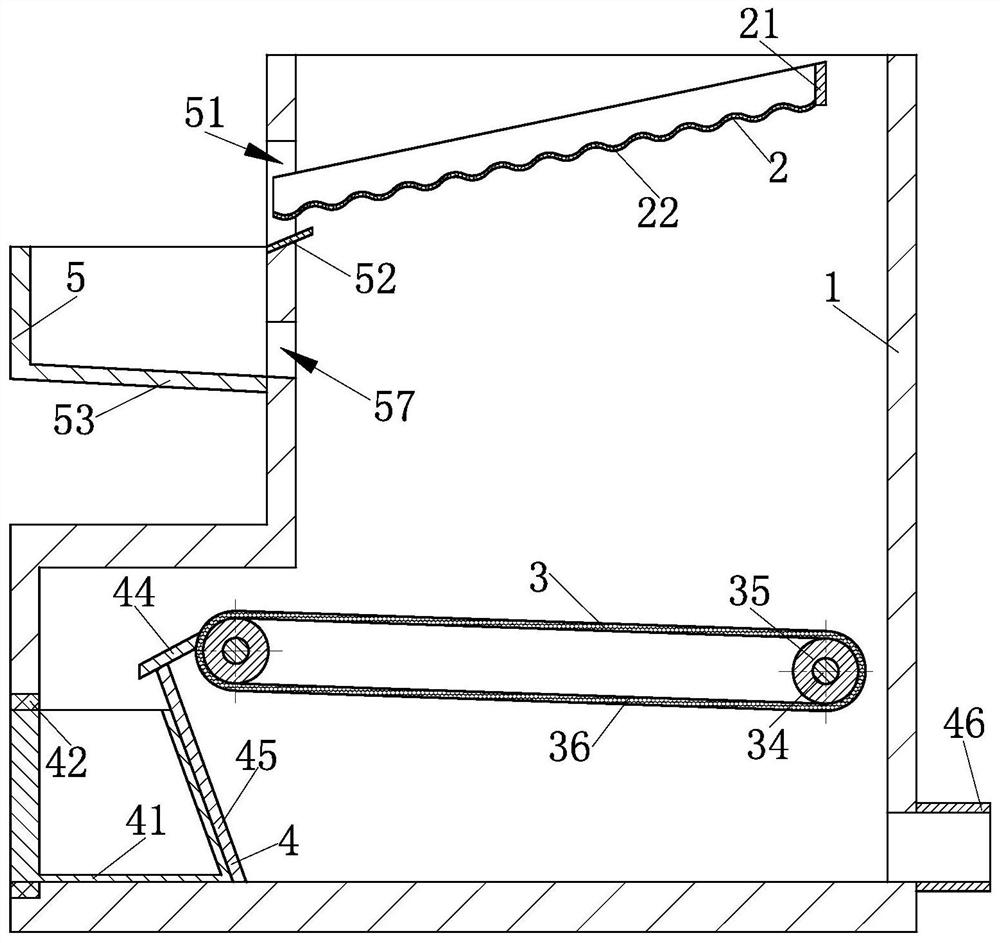

The invention relates to the field of industrial wastewater treatment devices and relates to an industrial wastewater discharging, purifying and recycling device. The device comprises a box body, a screening structure, a filtering structure, a cleaning structure, a collecting structure, a lifting structure and a limiting structure; the screening structure is adopted, so that blocky stone chippingsin stone cutting wastewater can be screened out in advance, and therefore, the blocky chippings can be prevented from entering a subsequent process to increase the treatment pressure of the subsequent process, and the purification treatment efficiency of the wastewater can be improved; the screening structure can drive the filtering structure to work while carrying out screening work; the filtering structure can work, so that stone mud in the wastewater can be further filtered out, the treatment efficiency of the wastewater can be ensured, and the wastewater can be easily recycled; the filtering structure can further act on the cleaning structure while working; and with the cleaning structure adopted, the stone mud filtered out on the filtering structure can be scraped and collected, andthe blockage of the filtering structure can be avoided.

Owner:YIYANG SHENGLI CHEM IND

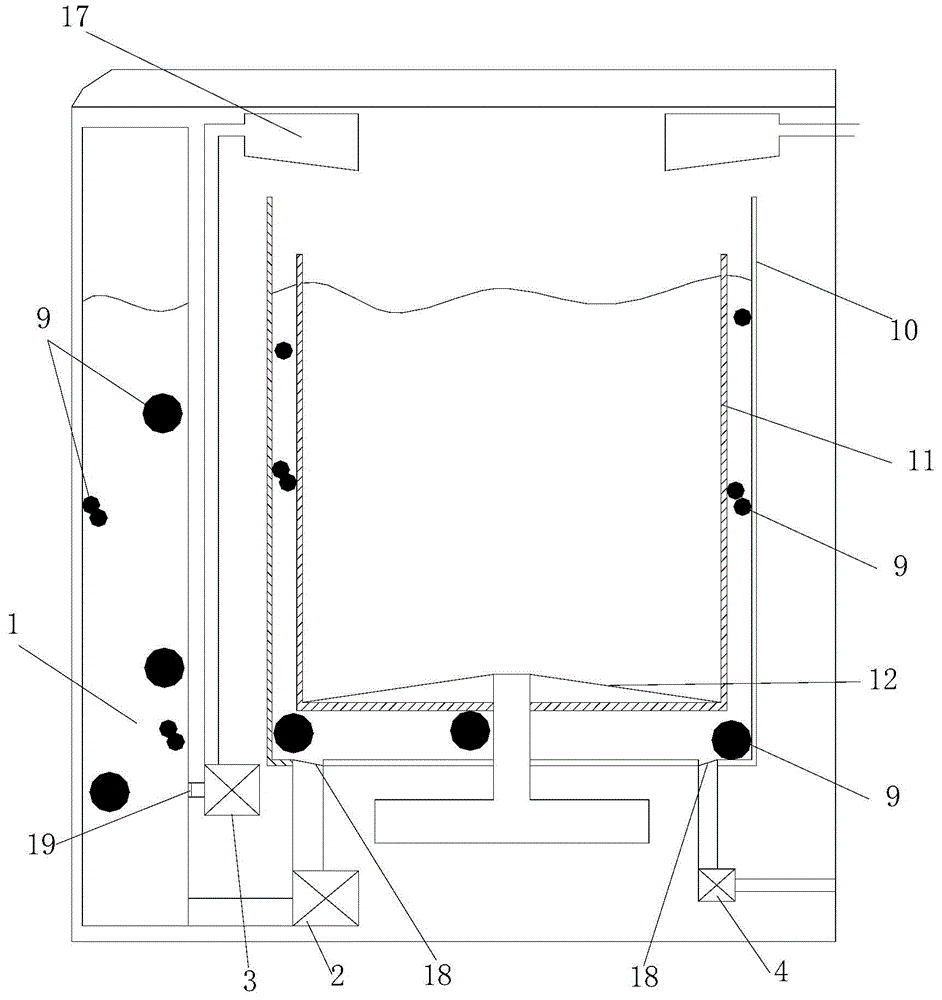

Constant-temperature oscillation device for medical test tube

PendingCN112844164ARealize constant temperature vibration workRealize regular workShaking/oscillating/vibrating mixersTransportation and packagingEngineeringTest tube

The invention relates to an oscillation device, in particular to a medical test tube constant-temperature oscillation device. The invention provides a medical test tube constant-temperature oscillation device which can perform constant-temperature oscillation on a test tube, can fix the test tube to prevent the test tube from falling off, can cover the test tube to prevent a reactant from spilling out, and can disinfect the test tube to reduce bacteria. A medical test tube constant-temperature oscillation device comprises a first supporting frame, first sliding rails and a roller; wherein the first sliding rails are symmetrically arranged on the two sides of the top of the first supporting frame, the roller is arranged between the two first sliding rails in a sliding mode, a covering mechanism is installed on the roller and matched with the top of the roller in a sliding mode, and feeding mechanisms are symmetrically arranged on the two sides of the top of the roller and are matched with the covering mechanism. By arranging the covering mechanism, the covering mechanism is matched with the feeding mechanism, and constant-temperature oscillation work of the test tubes can be achieved; the fixing mechanism is matched with the roller, so that the test tube can be fixed, and reactants in the test tube can be prevented from flowing out.

Owner:龚玮

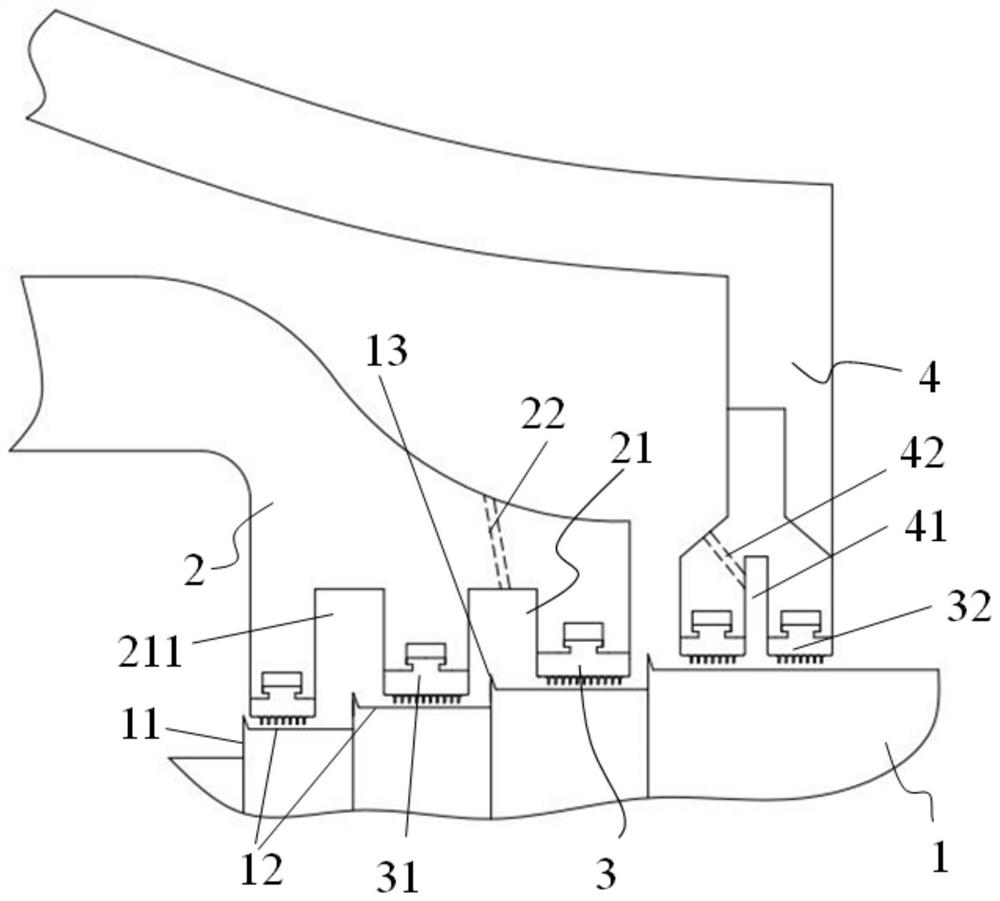

Fabricated thermal insulation concrete wallboard and mounting method thereof

PendingCN114541646AAchieve fixationAvoid outflow situationsWallsInsulation improvementLiquid waterThermal insulation

The invention discloses a fabricated thermal insulation concrete wallboard and a mounting method thereof, the fabricated thermal insulation concrete wallboard comprises a first connecting wallboard and a second connecting wallboard, the side of the first connecting wallboard is connected with the second connecting wallboard, and the first connecting wallboard is filled with a thermal insulation protective layer; the connecting cavity is formed in the side of the heat preservation protective layer; and the first connecting piece is fixedly connected to the left side of the first connecting wallboard. According to the assembly type heat preservation concrete wallboard and the mounting method thereof, liquid water is injected into the connecting cavity, when the external temperature is high, the liquid water absorbs heat, when the external temperature is low, the liquid water releases heat, the heat preservation performance is improved, when the wallboard is grilled by open fire, the first air bag, the second air bag and the third air bag are broken, and the heat preservation performance is improved. And then the extension spring drives the third connecting piece and the second connecting piece to reset to open the circulation channel, so that liquid water in the connecting cavity can be discharged, and a certain flame-retardant effect is achieved.

Owner:牟峰

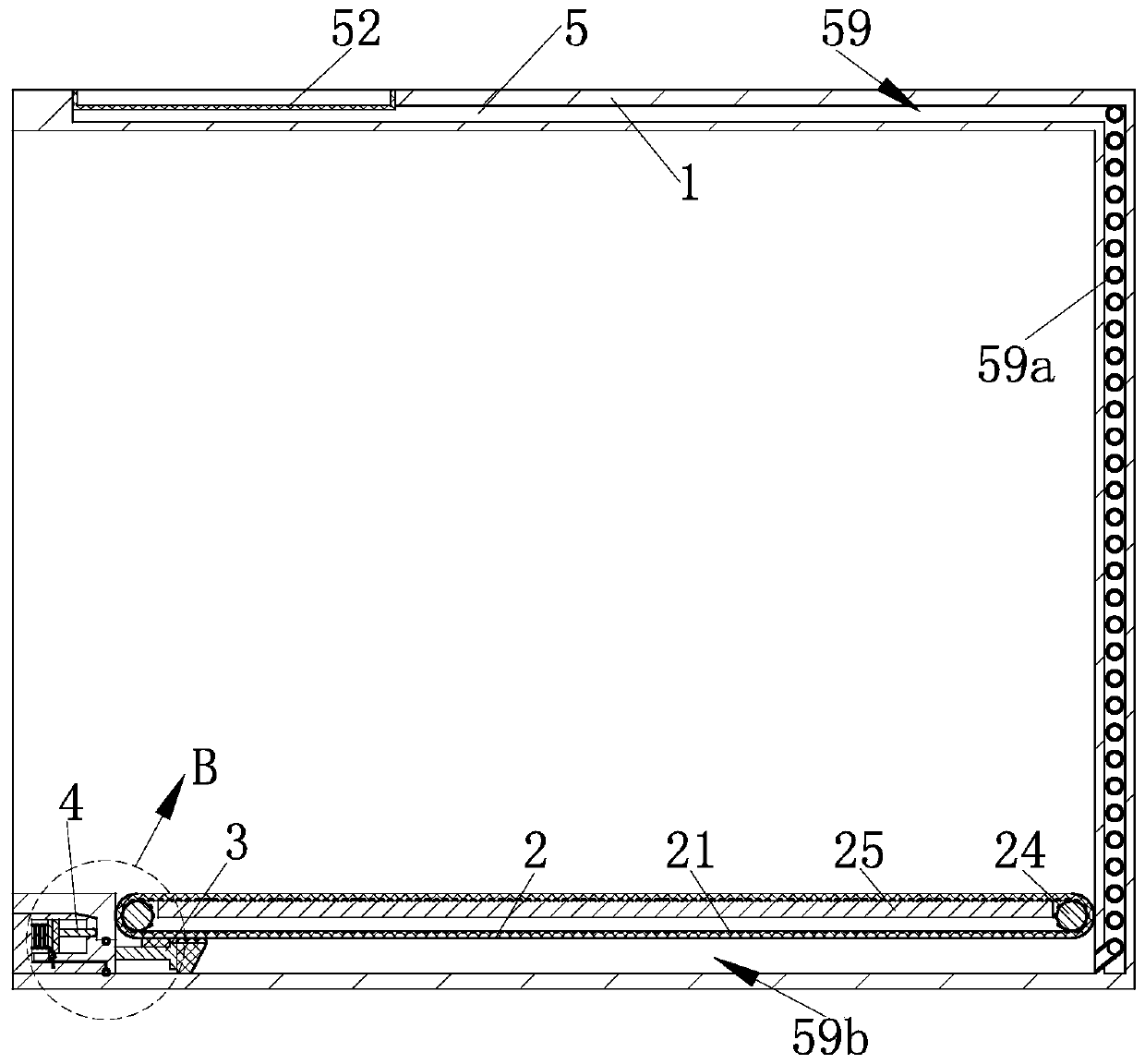

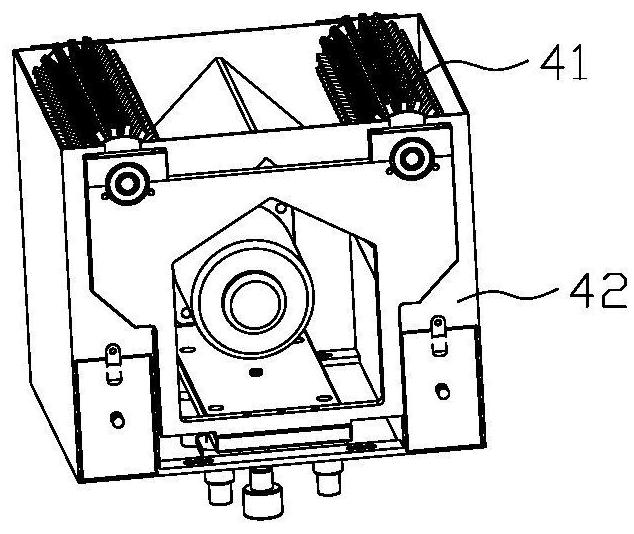

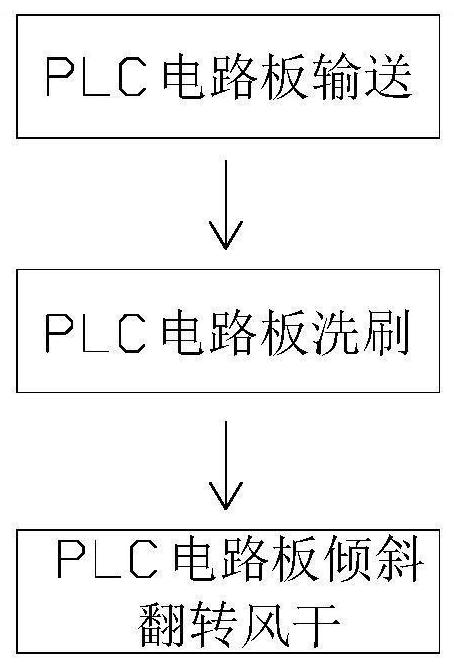

PLC circuit board washing device and washing method

InactiveCN111906064AImprove scrubbing efficiencyHas a guiding roleDirt cleaningDrying chambers/containersBrushControl theory

The invention relates to the field of PLC circuit boards. The invention provides a PLC circuit board washing device. The device comprises a brush movement mechanism and an impurity recovery box. The brush movement mechanism and the impurity recovery box are both fixed to a workbench, the brush movement mechanism is connected with the upper end of the impurity recovery box, and the upper end of thebrush movement mechanism makes contact with a PLC circuit board. The impurity recovery box is used for receiving impurities after the PLC circuit board is cleaned; and the brush movement mechanism isused for cleaning the PLC circuit board. According to the device, by arranging the impurity recovery box, the slow cleaning process of the impurity recovery box is avoided, and the cleaning efficiency of the PLC circuit board is improved.

Owner:张俊

PLC circuit board cleaning method and device

InactiveCN111957630AReduce occupancySmall footprintDrying gas arrangementsDirt cleaningProcess engineeringAir drying

Owner:张俊

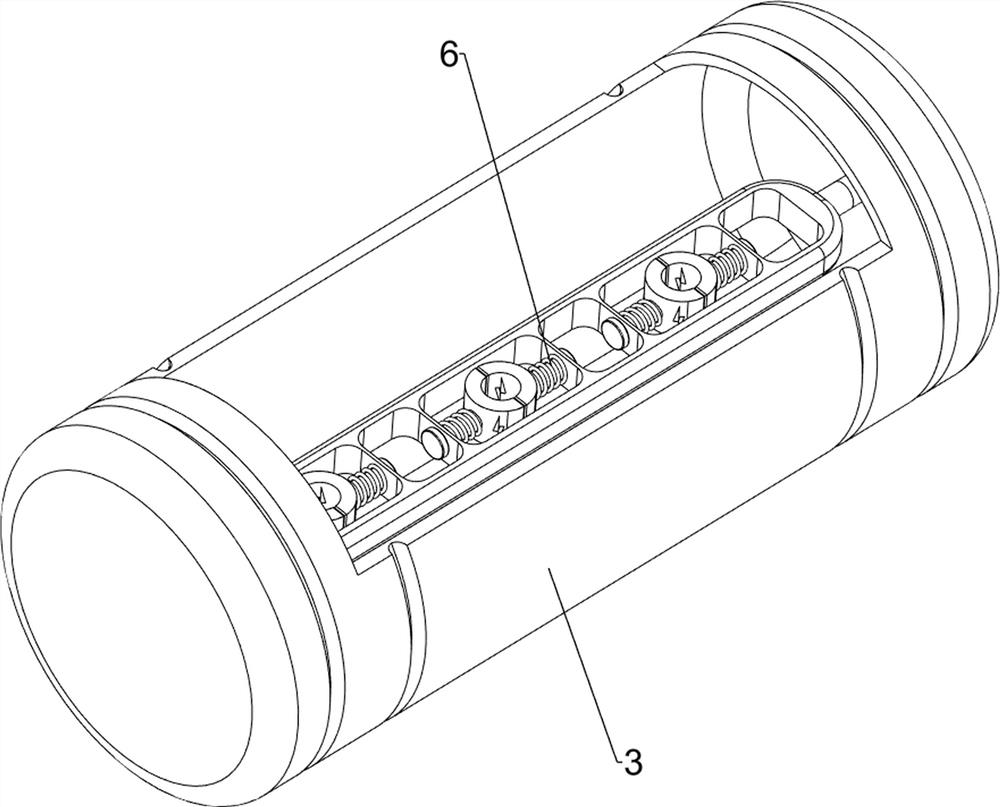

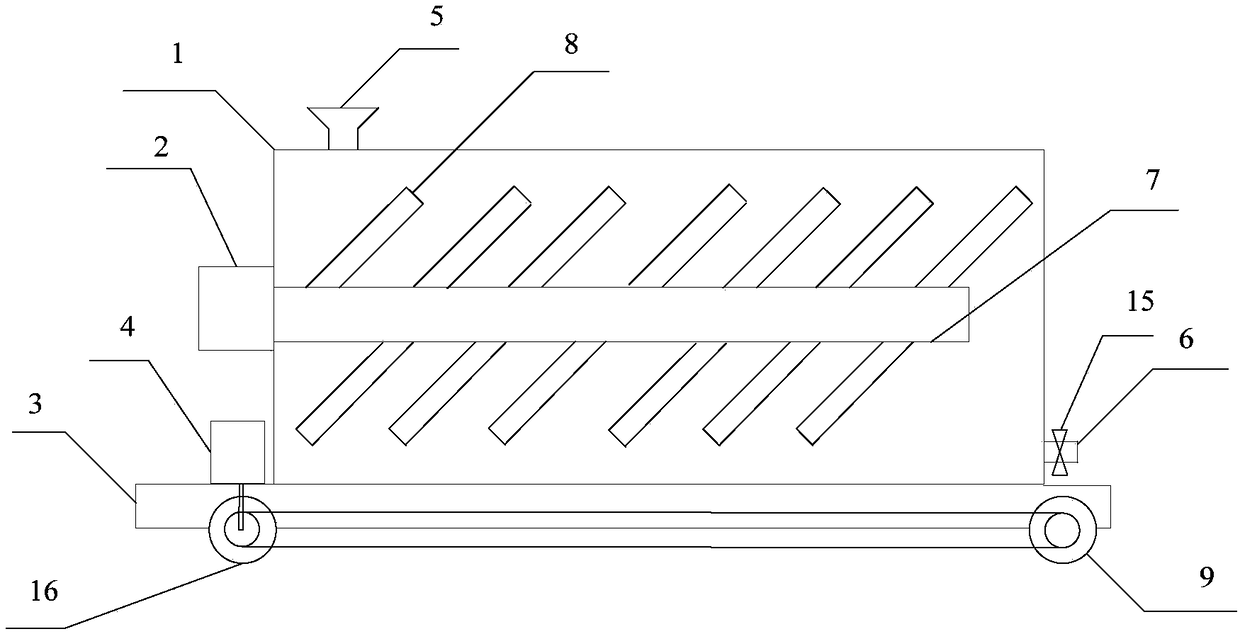

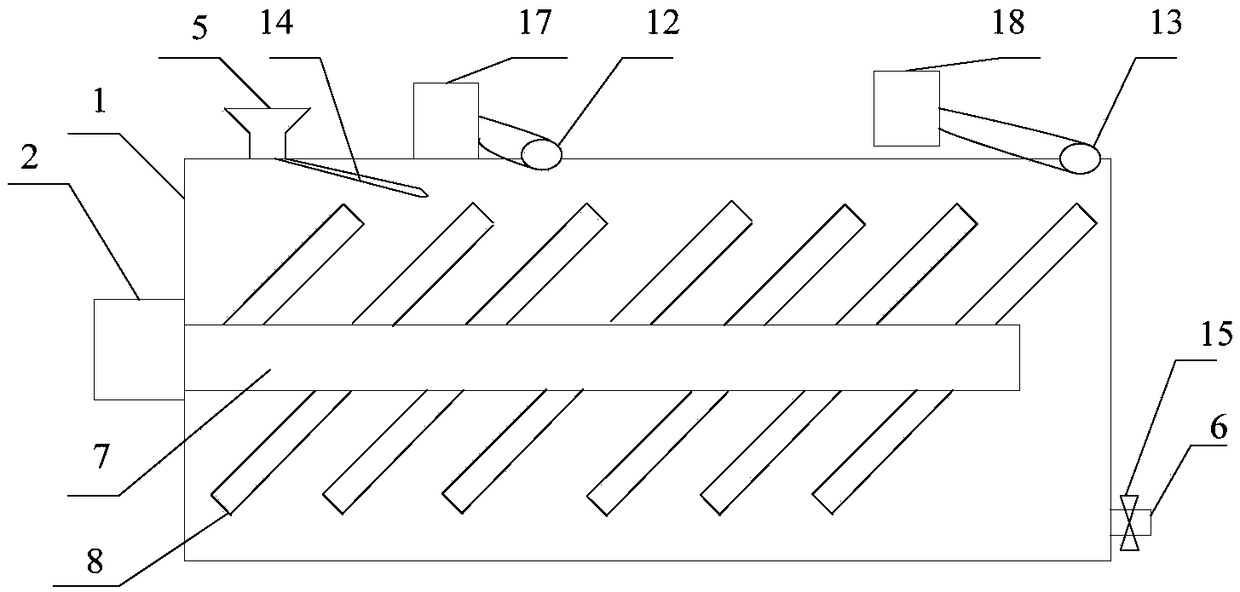

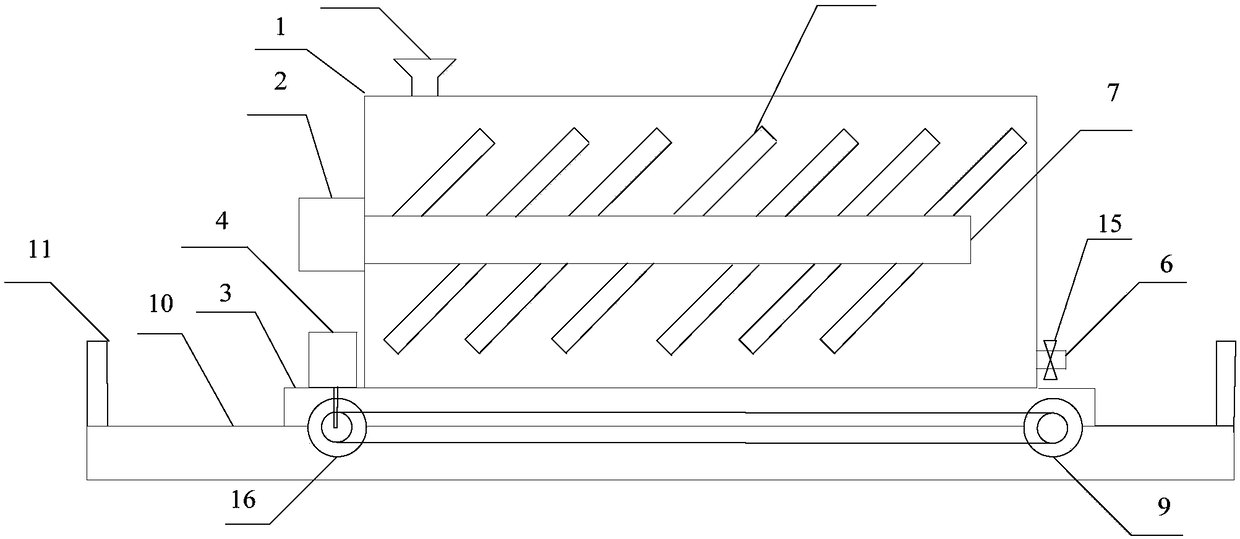

Swing type grinding machine for paint production

InactiveCN108057492AImprove grinding sufficiencyImprove grinding uniformityGrain treatmentsElectric machineryEngineering

The embodiment of the invention provides a swing type grinding machine for paint production. The grinding machine includes a horizontal type grinding tank, a first motor, a grinding tank bottom seat,a second motor and a pulley block. The top of the horizontal type grinding tank is provided with a feeding opening. The bottom of the horizontal type grinding tank is provided with a discharging opening. The side part of the horizontal type grinding tank is provided with the first motor. The interior of the horizontal type grinding tank is provided with a screw rod transversely. The screw rod is provided with multiple inclined grinding blades. The arraying distance between each two adjacent grinding blades is less than the projected length of the grinding blades on the screw rod. The first motor is connected with the screw rod. The bottom seat of the grinding tank is fixedly arranged below the horizontal type grinding tank. The second motor is arranged on the bottom seat of the grinding tank. The bottom of a grinding tank supporting frame is provided with the pulley block. According to the swing type grinding machine for paint production, the horizontal type grinding tank can sway horizontally under the action of the second motor and the pulley block, flowing and mixing of materials in the horizontal type grinding tank are promoted, and the grinding sufficiency and uniformity are improved.

Owner:湖南太子化工涂料有限公司

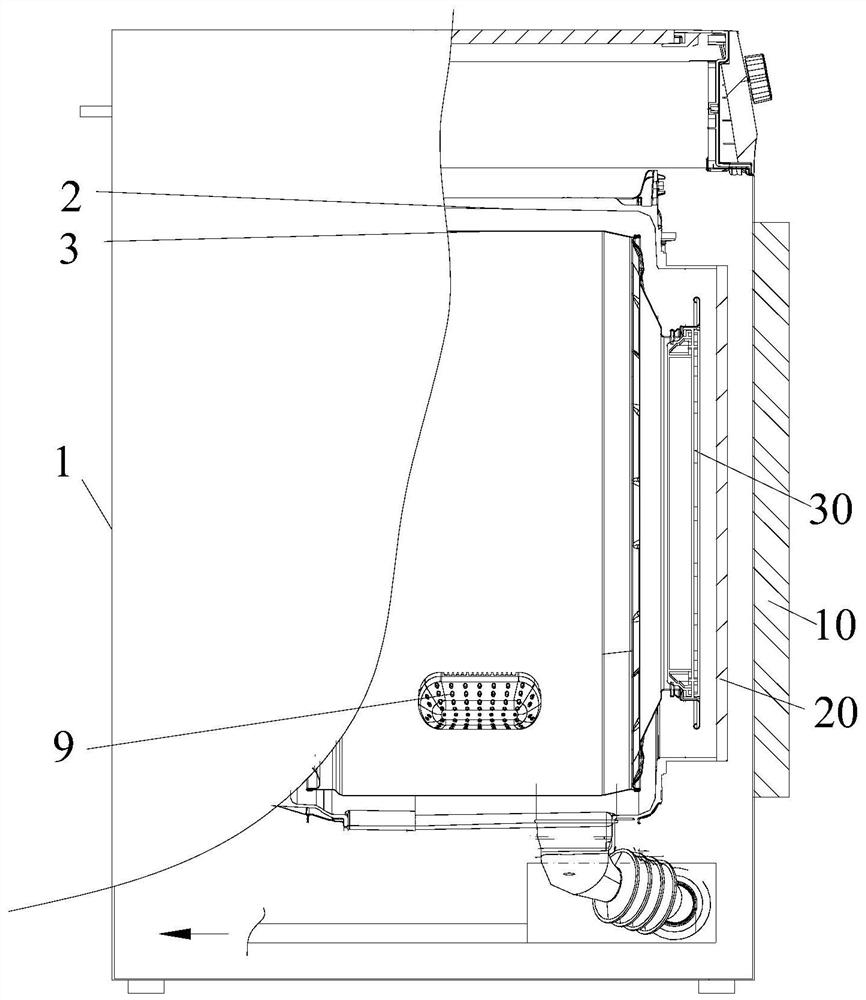

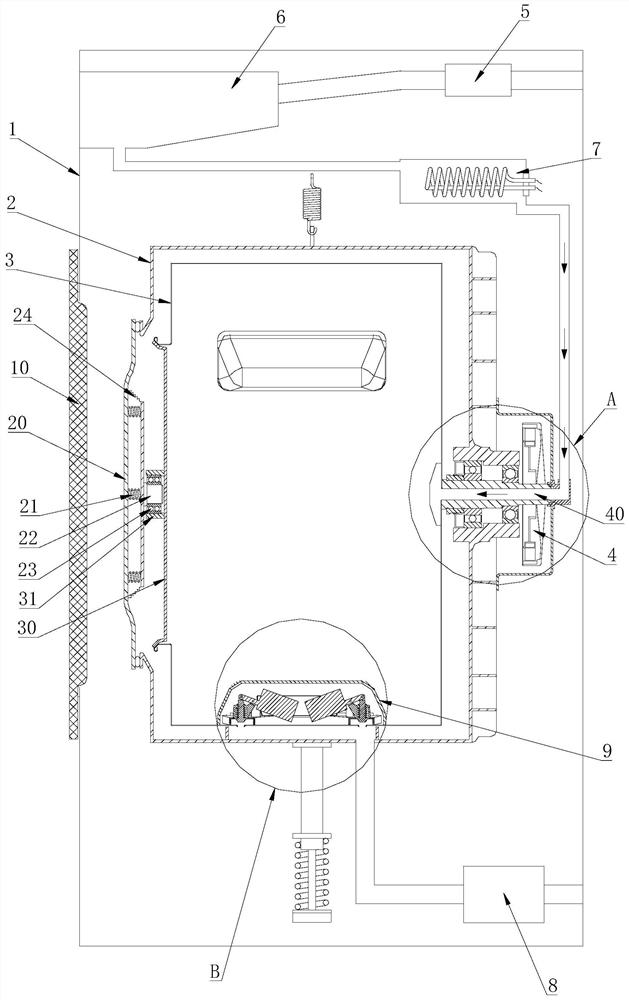

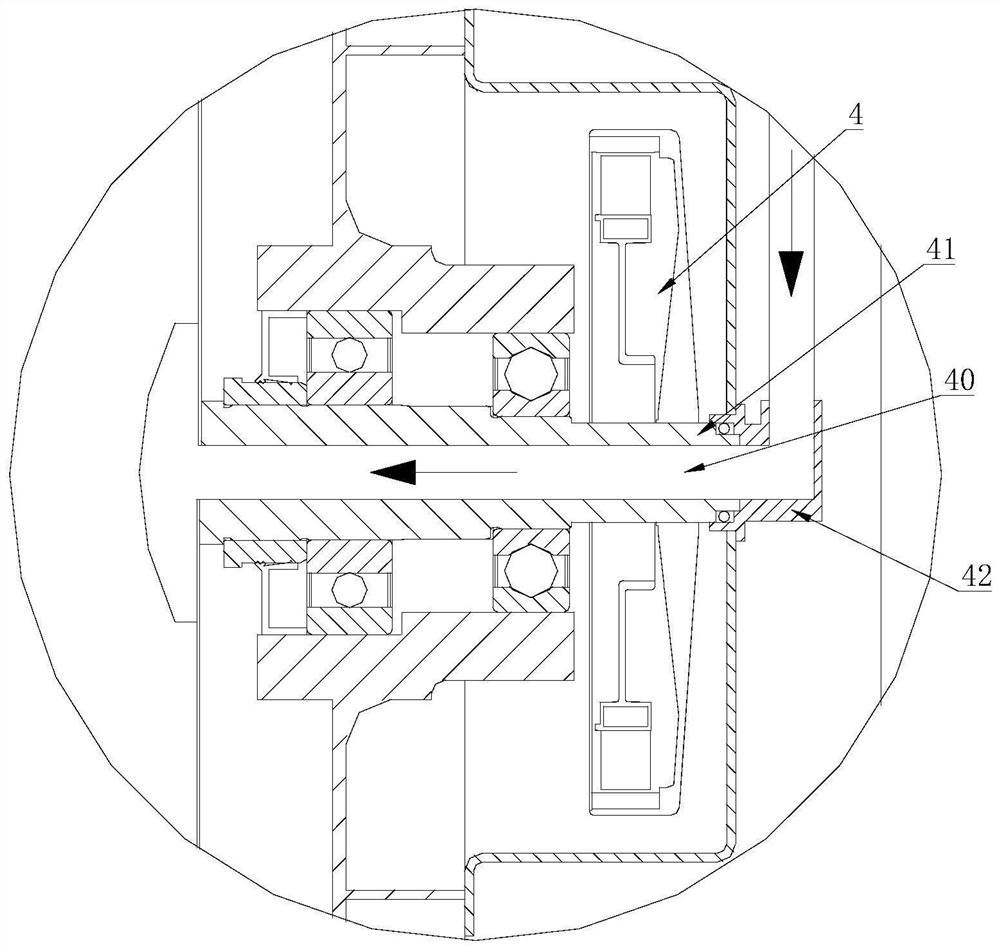

Drum washing machine

ActiveCN112176653AReduce gapAvoid outflow situationsOther washing machinesWashing machine with receptaclesLaundry washing machineWater flow

The invention discloses a drum washing machine. The drum washing machine comprises an outer drum and an inner drum mounted in the outer drum in a sleeved mode, a putting opening is formed in the innerdrum, an opening is formed in the outer drum, and the putting opening and the opening are formed in an overlapped mode in the axial direction of the inner drum; and a first door body for correspondingly sealing the putting opening is mounted on the inner drum, and a second door body for opening and closing the opening is mounted on the outer drum. By arranging the first door body, when the washing machine executes a washing program and the inner drum rotates, clothes always roll in the inner drum, and the clothes are prevented from being clamped in a gap between the putting opening of the inner drum and a washing machine door; and meanwhile, the second door body is arranged at the opening of the outer drum, so that the opening of the outer drum is automatically closed, a sealing window pad is not arranged between a washing machine shell and the opening of the outer drum, and a water flow is prevented from flowing out of the opening of the outer drum.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Supporting structure for building

PendingCN111021721ACleverly structuredReasonable arrangementForms/shuttering/falseworksBuilding material handlingArchitectural engineeringScrew thread

The invention discloses a supporting structure for a building. The supporting structure comprises a first protective plate and a second protective plate. The first protective plate and the second protective plate surround the periphery of the outer side of the column body; fasteners are arranged on the upper side and the lower side of the first protective plate, a threaded rod is connected betweenthe fasteners on the left side and the right side, an auxiliary vibrator is arranged on the right side of the first protective plate, each fastener comprises a clamping plate, a fixing block is arranged on the outer side of the clamping plate, and the threaded rod penetrates through the fixing blocks and the clamping plates. According to the supporting structure for the building, the corner protection device is arranged, the main spiral grains and the auxiliary spiral grains on the fixing rod are mutually meshed, fixing rod is rotated, the fixing rod drives the fixing plate to continuously extrude the included angle position of the first protection plate and the second protection plate, the stability of the included angle is enhanced, the situation that concrete seeps out of the includedangle or the included angle is expanded to cause concrete to flow out is avoided, the fixing angle plate is inserted into the angle groove, the corner protection devices at the upper and lower positions are connected for fixing and thus the stability is further improved.

Owner:安徽省中功立业建设工程有限责任公司

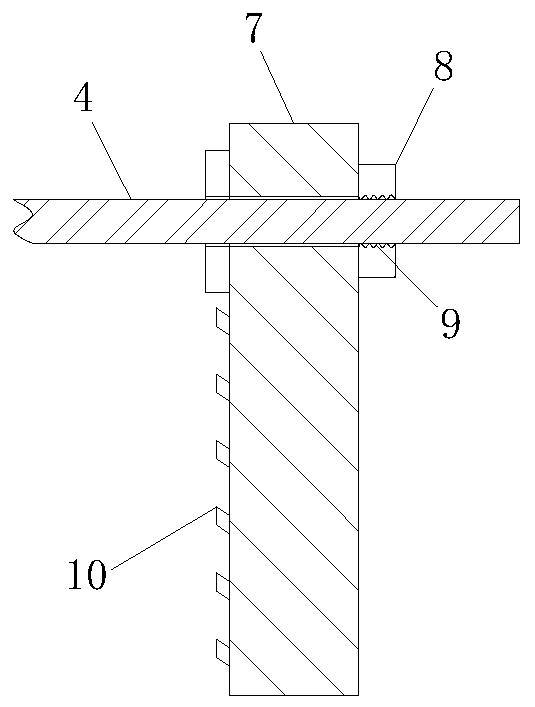

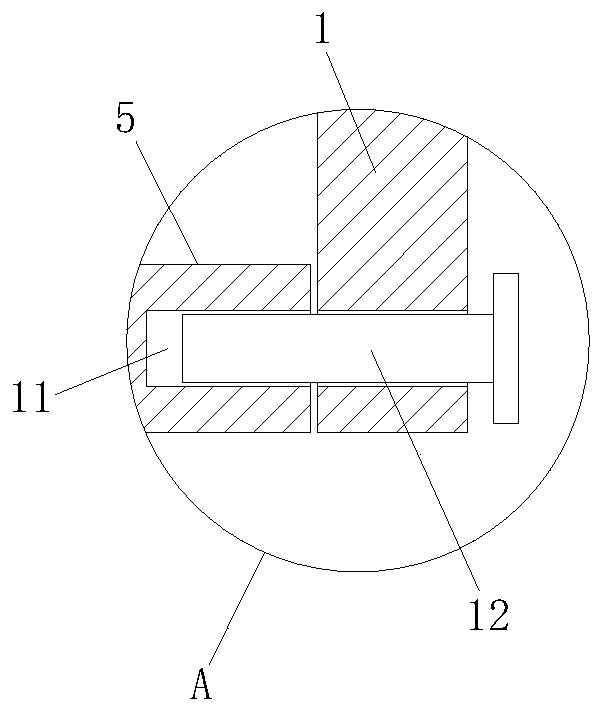

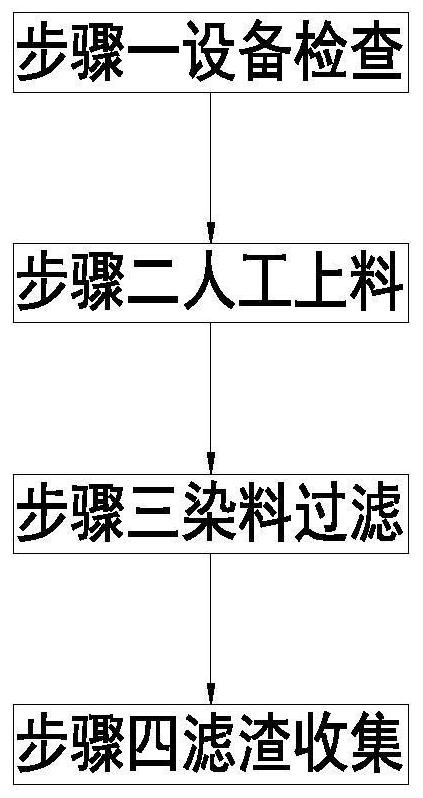

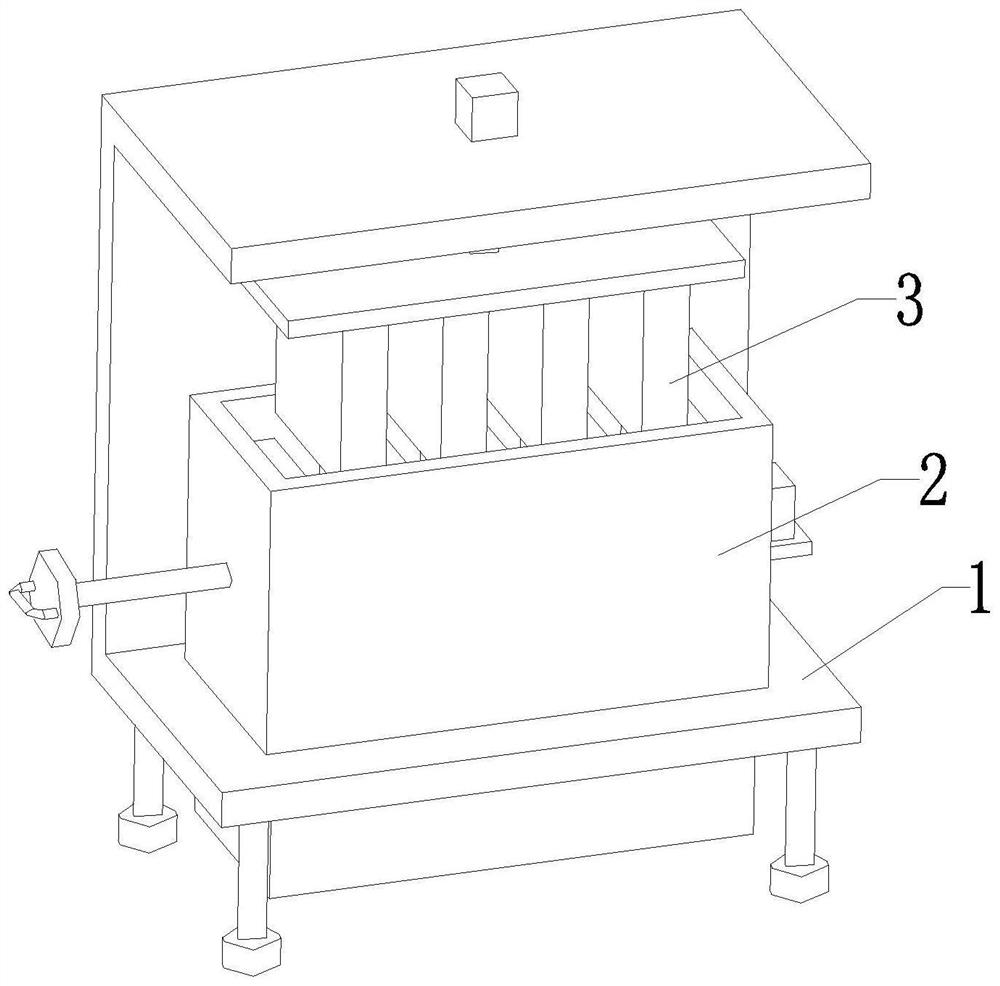

Textile dye filtering and recycling treatment method

InactiveCN112546690AIncrease workloadAvoid wasteful situationsStationary filtering element filtersProcess engineeringIndustrial engineering

The invention relates to a textile dye filtering and recycling treatment method. The method mainly comprises the following steps: equipment inspection, manual feeding, dye filtering and filter residuecollection. Textile dye filtering equipment comprises a mounting frame, a flow guide sleeve part and an ejection sleeve part, wherein the flow guide sleeve part and the ejection sleeve part are sequentially arranged in the mounting frame from bottom to top. The textile dye filtering and recycling treatment method can solve the following problems existing in filtering treatment of textile dyes inthe prior art: a, when the textile dyes are subjected to filtering treatment in the prior art, the textile dyes often pass through a filter screen directly to so as to realize filtering treatment, anddue to the fact that the size of textile-crushed aggregates is small, the situation that the textile-crushed aggregates are discarded is easily caused and cost is wasted; and b, when the textile dyesare subjected to filtering treatment in the prior art, the situation that filtered textile fragments block a filtering grid often occurs, so filtering efficiency is influenced, and the workload of manually cleaning of the filtering net is increased.

Owner:刘岳生

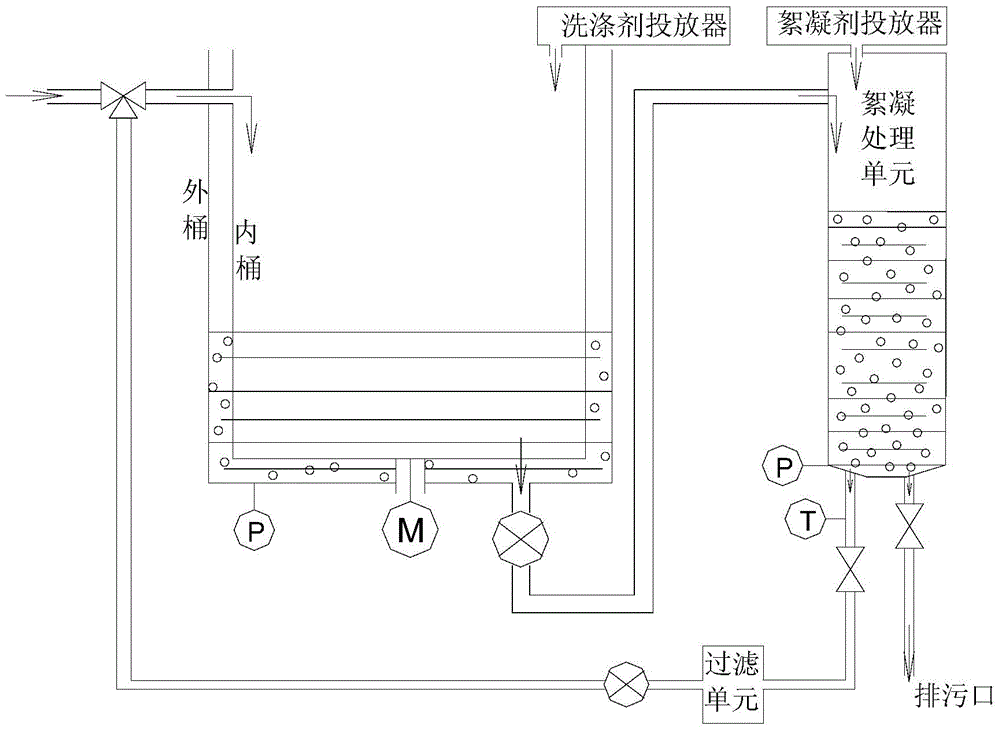

Washing machine and control method

InactiveCN106192293AClean thoroughlyNot easy to rub offHollow article cleaningOther washing machinesFlocculationWater flow

The invention discloses a washing machine. The washing machine comprises a flocculation barrel for performing flocculation treatment on washing water; at least one cleaning fluffy ball is arranged in the flocculation barrel; a stirring mechanism is arranged in the flocculation barrel and stirs the water in the flocculation barrel, so that the at least one cleaning fluffy ball moves along with the water flow at least in the flocculation barrel cleaning process to remove floccules attached to the inside of the flocculation barrel. The invention further discloses a control method of the washing machine. The method comprises steps as follows: water is fed into the flocculation barrel, and the stirring mechanism is started to enable the at least one cleaning fluffy ball to move along with the stirring water flow so as to clean the floccules attached to the inside of the flocculation barrel. With the device and the method, the purpose of removing the floccules retained in the flocculation barrel is achieved. Meanwhile, the washing machine is simple in structure, significant in effect and suitable for popularization and use.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Rotary machine

PendingCN112177969AAvoid outflow situationsStop the leakPump componentsLeakage preventionEngineeringMechanical engineering

The invention discloses a rotary machine. The rotary machine comprises a stator, a first stator and a sealing assembly, the rstator is in a step shape and comprises a plurality of step surfaces and aplurality of peripheral surfaces, the adjacent peripheral surfaces are connected through the corresponding step surfaces, protrusion parts are formed between the peripheral surfaces and the step surfaces, the first stator surrounds the rotator, a gap is formed between the first stator and the rotator, an annular groove is formed in the inner circumferential surface of the first stator, part of themultiple step surfaces are arranged opposite to the annular groove, a first air inlet hole is formed in the first stator and communicates with the annular groove, the sealing assembly comprises a plurality of first sealing parts, the first sealing parts are arranged on the inner circumferential surface of the first stator and are are arranged opposite to the outer circumferential surfaces, and the adjacent first sealing parts are spaced through the annular groove. The rotary machine has the advantages of being good in sealing effect and capable of effectively preventing lubricating oil from leaking.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

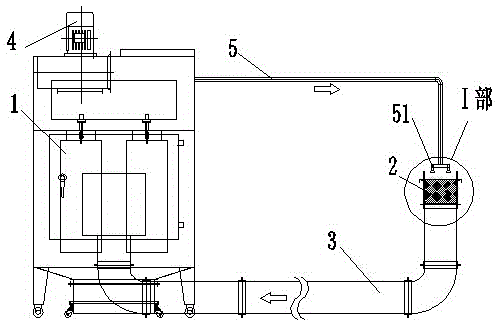

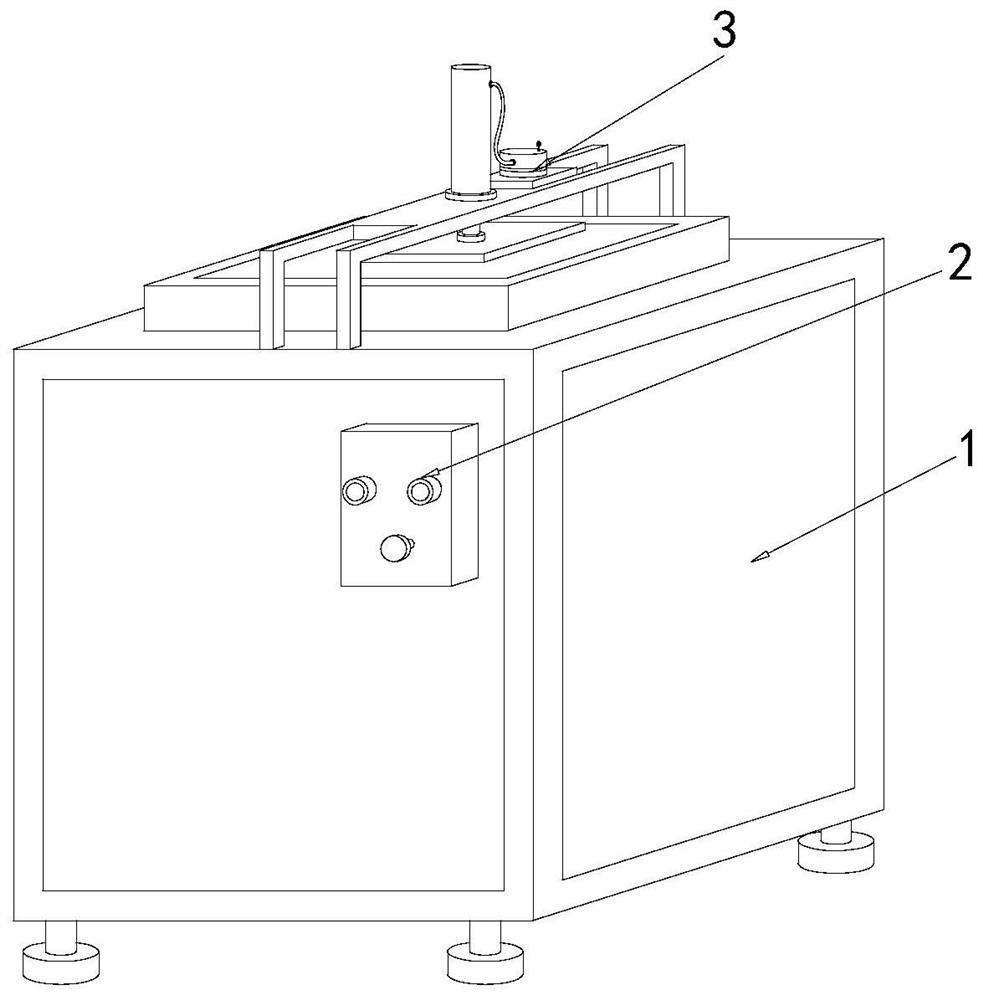

Device for removing powder coating

InactiveCN105107664ARealize mechanized processingEasy to operateSpraying apparatusEngineeringPowder coating

The invention relates to a device for removing powder coating. The device comprises a powder recovery chamber (1) and an accommodation unit (2) arranged outside the powder recovery chamber (1). A suction fan (4) for sucking an accommodation substance, that is, powder, into the powder recovery chamber (1) through a suction tube (3) is arranged at one end of the accommodation unit (2). An air outlet of the suction fan (4) extends to the other end of the accommodation unit (2) through a blowing tube (5). According to the device for removing powder coating, powder is removed through the air flowing principle, and mechanical treatment is achieved; compared with a traditional manual powder removing mode, the device is easy to operate and good in powder removing effect.

Owner:YANGZHOU LEXUD MACHINERY MFG

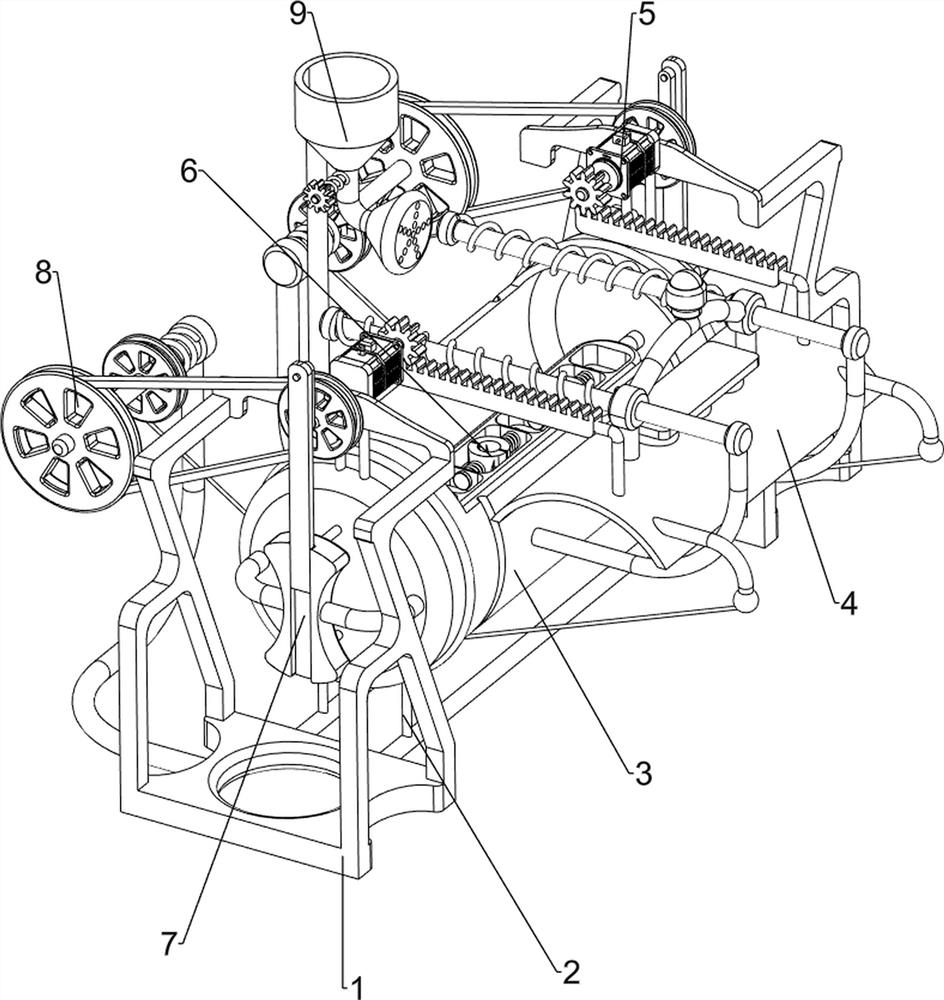

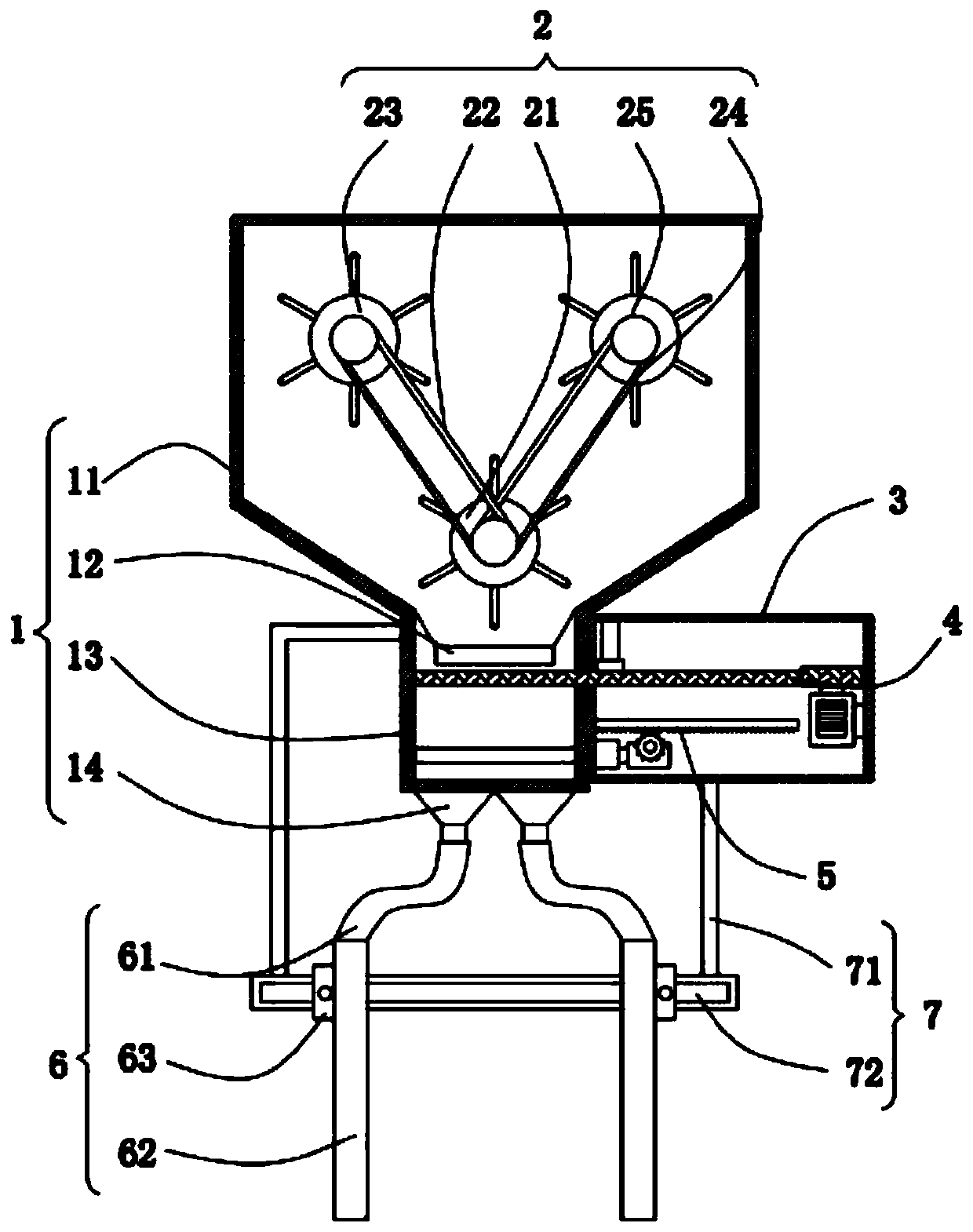

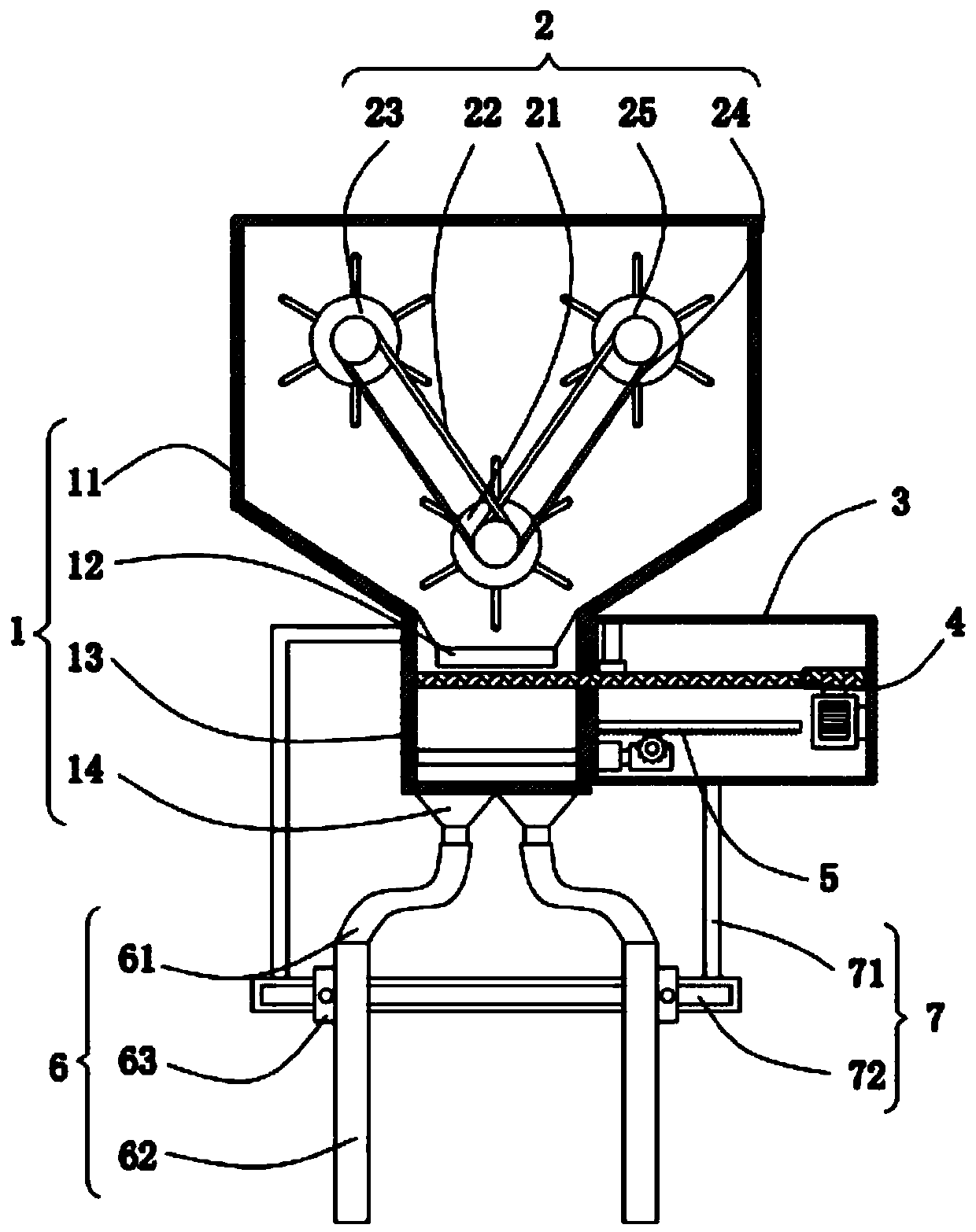

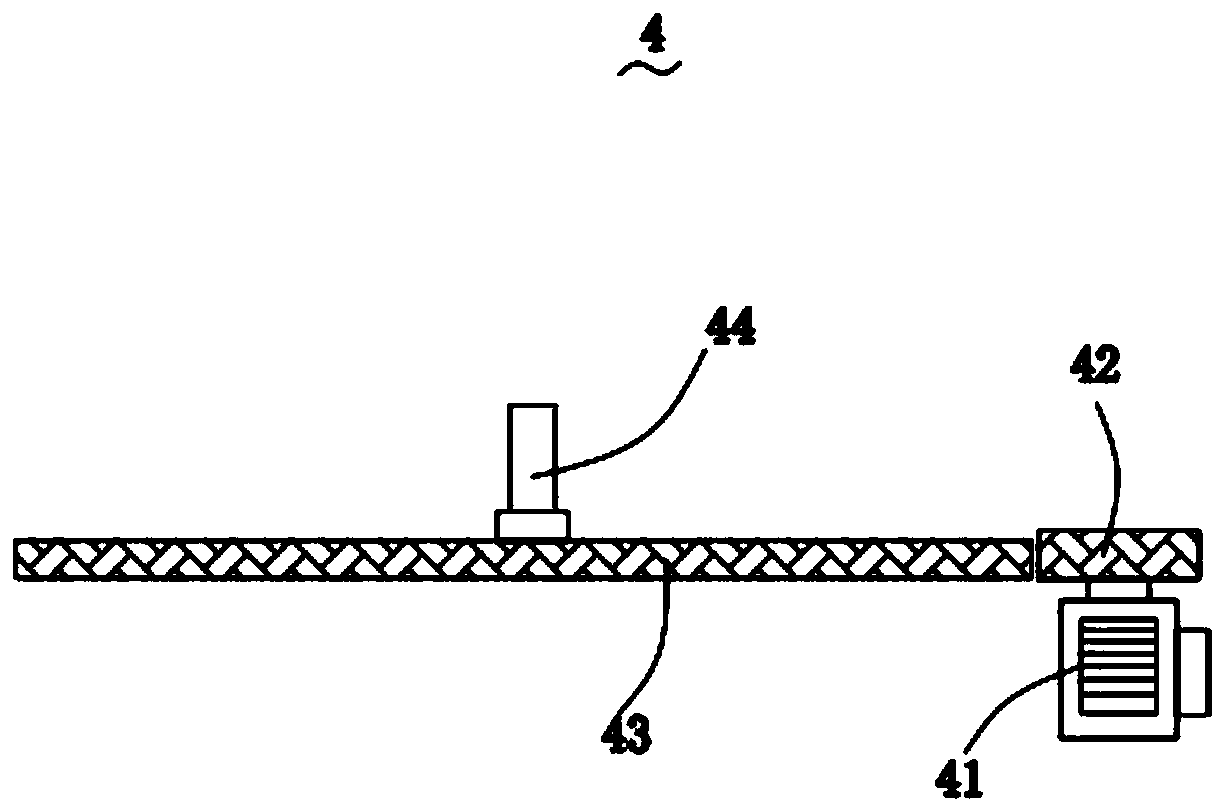

A method of improving corn sowing efficiency

ActiveCN109005795BImprove seeding efficiencySpeed up circulationSeed depositing seeder partsRegular seed deposition machinesSeederAgricultural engineering

The invention relates to the technical field of agriculture equipment, and concretely discloses a method for improving corn seeding efficiency. According to the invention, three stirring wheels arranged in an equilateral triangle are arranged in a storage bin of a corn seeder by the method, when the driving wheels rotate, the three stirring wheels rotate synchronously, the corns on a top layer anda bottom layer of the storage bin are stirred, the corn circulation speed is greatly improved, and the obstruction of the corns in the storage bin can be avoided; a plurality of discharge pipes are used and the spacing of the discharge pipes is adjusted to be the same as the required plant spacing, so that a plurality of seeds are discharged in a single time, and the spacing of the seeds is the same as the plant spacing, so that accurate and efficient seeding is achieved; a sealing plate and a discharge opening can alternately pass through the bottom of a first flow tube, so that the seed arrangement can be stopped after a group of seeds is discharged, the required plant spacing can be set between different groups of seeds, and the seeding effect can be improved.

Owner:海林天龙食品有限公司

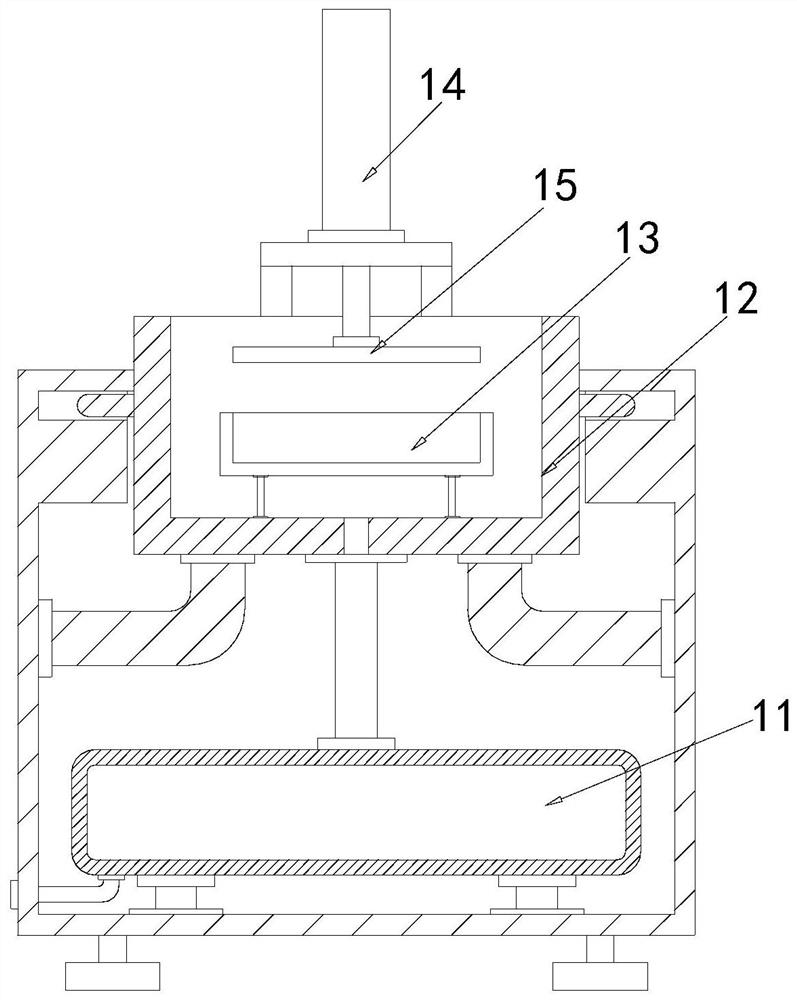

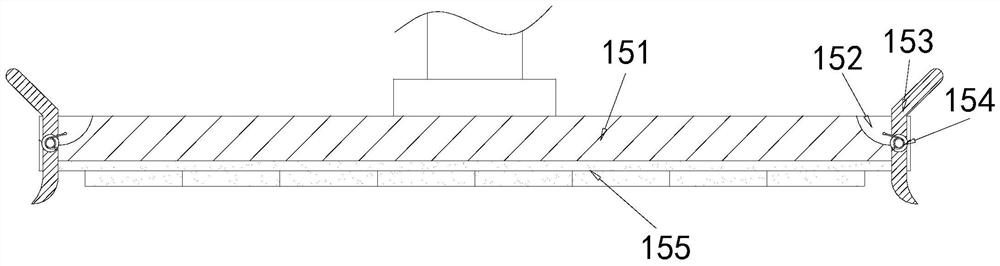

Die pressing device for tray extruding

InactiveCN112248354ASolve low production efficiencyEasy accessDomestic articlesEngineeringMechanical engineering

Owner:WUHU ASIA PACIFIC GENERAL TRAY PACKING CO LTD

Dosing device for water treatment system

InactiveCN114436383AAvoid residueSituations that reduce the effectiveness of the treatmentSpecific water treatment objectivesHollow article cleaningWater treatment systemMedicine

According to the dosing device for the water treatment system, through the push rod, on one hand, due to the fact that the size of a rubber block is the same as that of a square groove, the situation that drug residues occur in the square groove can be avoided, and the dosing efficiency and effect are improved in a disguised mode; on the other hand, some accumulated liquid remaining on the inner wall in the square tank can be cleaned by rotating the cleaning assembly, the situation that when a worker treats different water according to the water treatment system, chemicals need to be replaced, so that new chemicals and remaining chemicals influence each other, and the water treatment effect is reduced is avoided, and the cleaning assembly is fixed through a clamping rod; the effect of fixing a second fixing block is achieved, the effect of fixing the second fixing block is achieved, the effect of limiting and fixing the rotating cleaning assembly is also achieved by fixing a third fixing block and the rotating cleaning assembly in a disguised mode, and when the rotating cleaning assembly works for a long time through a square block, a large amount of medicine accumulated liquid can be attached to the outer portion of cleaning cotton.

Owner:淮安市飞隆环保设备有限公司

Pipeline machine

PendingCN110772116AAvoid outflow situationsAvoid secondary pollutionBeverage vesselsWater storageLine tubing

The invention relates to the technical field of drinking water, and provides a pipeline machine. The pipeline machine comprises a water storage tank, a shell, a base plate and a telescopic device, wherein a through hole is formed in the top of the water storage tank, a water inlet and a water outlet are formed in the bottom of the water storage tank, the shell is provided with air exhaust holes, the base plate is arranged in the water storage tank, the periphery of the base plate is in sealed connection with the inner wall of the water storage tank, the base plate is used for isolating drinking water in the water storage tank from outside air, the telescopic device comprises a shearing fork mechanism and a driving device, the lower end of the shearing fork mechanism is connected with the base plate, under the first work state, the driving device provides power for the shearing fork mechanism, the shearing fork mechanism stretches, under the second work state, the driving device does not provide power for the shearing fork mechanism, and the shearing fork mechanism contracts. For the pipeline machine provided by the invention, the outside air is isolated through the base plate, whena user fetches water, the shearing fork mechanism and the driving device work, the base plate is pushed to fall together with the water level, and thus the problem of secondary pollution of the drinking water is effectively avoided.

Owner:重庆科文净水设备有限公司

Fried bean curd air pressure equipment

InactiveCN112841534AAvoid outflow situationsDoes not affect aestheticsCheese manufactureFood scienceAgricultural engineeringAir pump

The invention discloses fried bean curd air pressure equipment which structurally comprises a main body, a control panel and an air pump; the control panel is mounted at the front end of the main body, the air pump is arranged at the top of the main body, the main body comprises a material collecting box, a downward pressing frame, a material loading box, a telescopic arm and a downward pressing device, and the downward pressing device comprises a downward pressing plate, a rotating groove, a sealing block, a rewinding spring and a pressure reducing device. The sealing block comprises a rotating shaft, a clamping block, a sliding groove, a sealing plate, a water passing hole and a rubber block, and the water passing hole comprises a through hole, a sponge block, a supporting plate, a material passing hole and a material guiding plate. The top of a sealing block is driven to swing outwards through resetting of the rewinding spring, so that the upper end of the sealing block can be clamped to the side end of the material loading box when the pressing device moves downward; the bottom end of the sealing block can abut against the side wall of the material loading box, bean curd is extruded in a sealed mode, the situation that the bean curd flows out of the side end of the lower pressing plate is avoided, the processed bean curd can be square, and the attractiveness of the processed fried bean curd cannot be affected.

Owner:陈桂莲

Multi-axis linkage machining center machine

PendingCN113770795AComplete separationScientific and reasonable structureMaintainance and safety accessoriesElectric machineryScrap

The invention discloses a multi-axis linkage machining center machine which comprises a shell, a collecting mechanism is arranged on one side of an inner cavity of the shell, the collecting mechanism comprises a first motor, a screw rod, a threaded sleeve, a sliding block, a sliding groove and a fan, the sliding groove is formed in the rear end face of the inner cavity of the shell, the fan is fixedly arranged on the front end face of the outer wall of the threaded sleeve, and one end of the outer wall of the fan is slidably connected to the inner wall of a groove plate. According to the multi-axis linkage machining center machine, through cooperation of the first motor, the screw rod, the threaded sleeve, the sliding block, the sliding groove, the fan and a collecting cover, when the multi-axis linkage machining center machine is used, through sliding connection of the fan and the groove plate, the threaded sleeve can drive the fan to stably move left and right, and therefore when the fan moves, cooling liquid and scraps can be completely collected through the collecting cover, which solves the problem that the cooling liquid and the scraps need to be manually cleaned by workers after machining is completed due to the fact that the cooling liquid and the scraps are difficult to thoroughly collect.

Owner:马秀兵

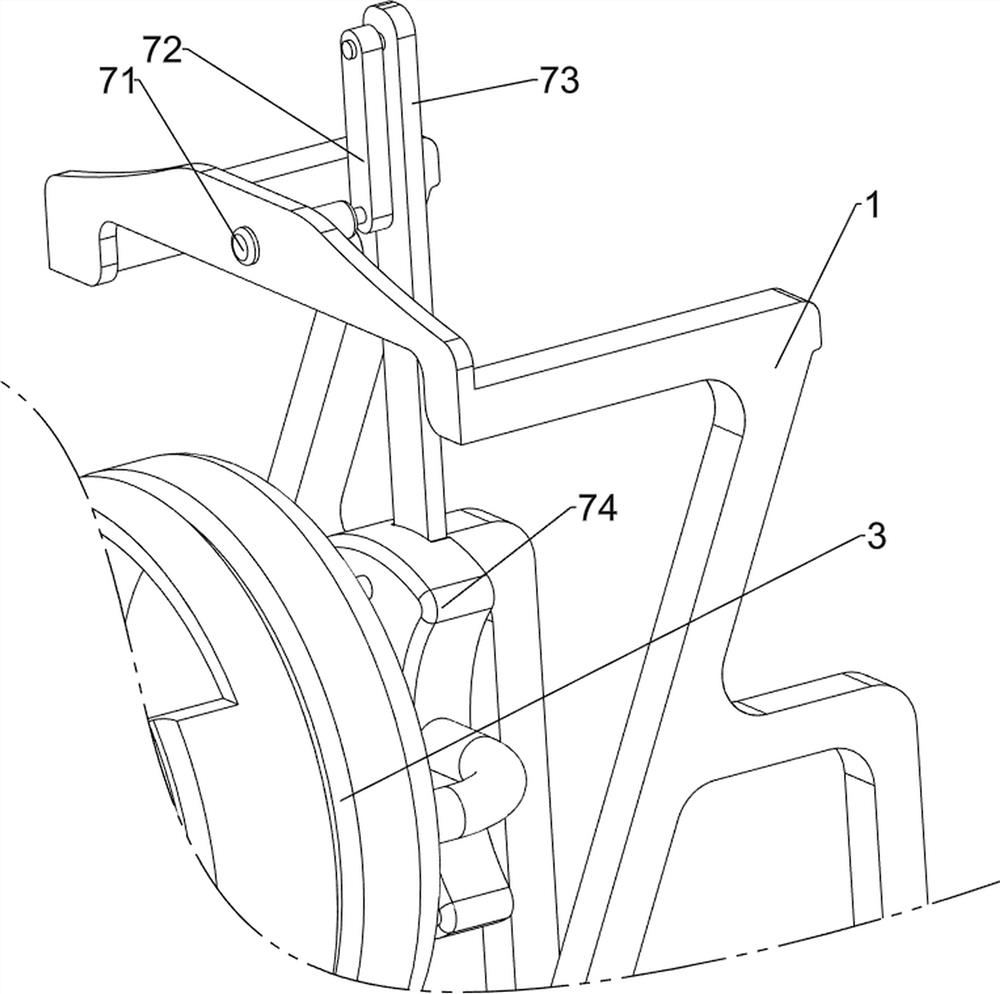

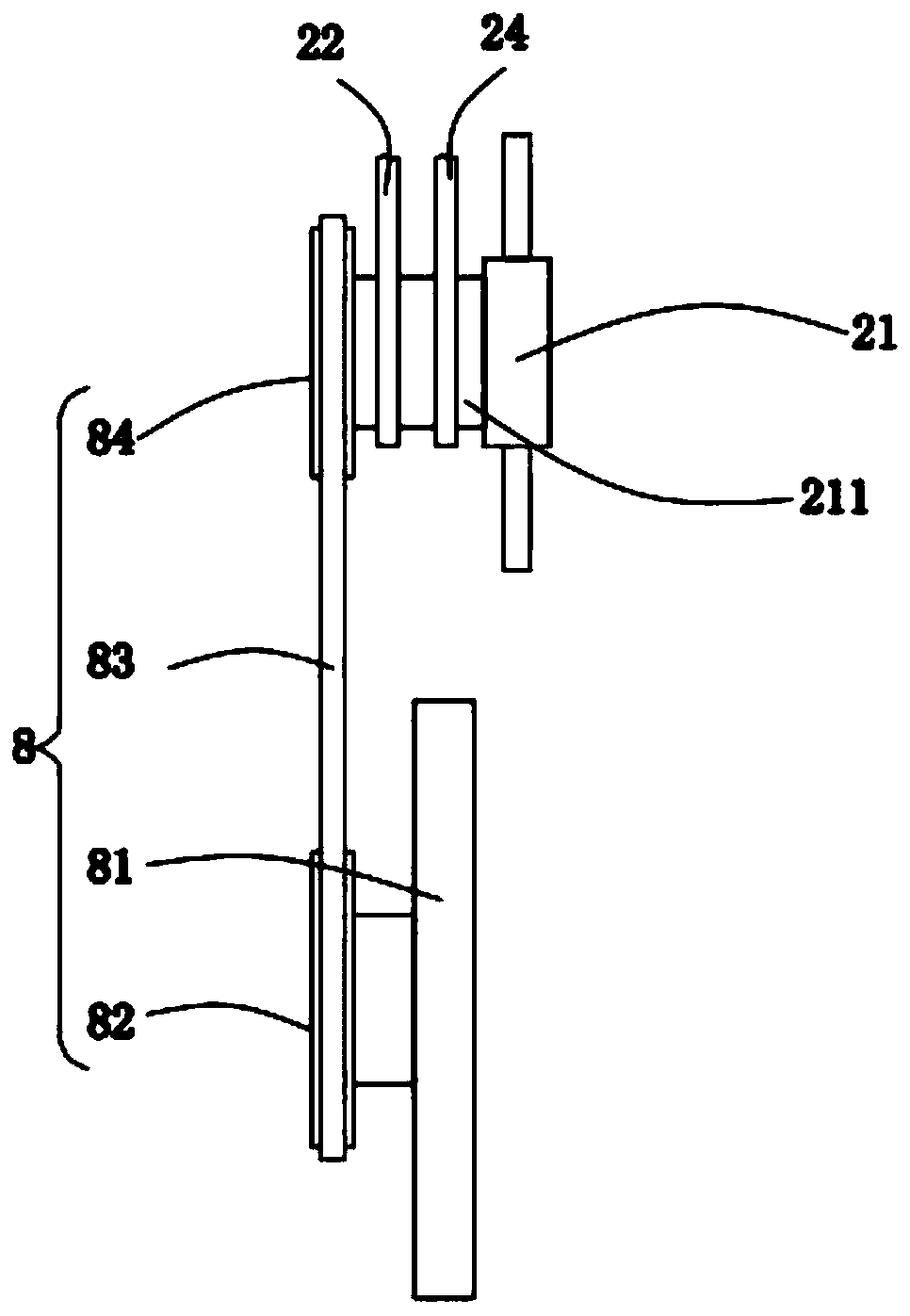

a corn seeder

ActiveCN108990483BAchieving stirringSpeed up circulationSeed depositing seeder partsRegular seed deposition machinesSeederAgricultural science

The invention relates to the technical field of agricultural equipment, in particular to a corn planter. The corn planter comprises a conveying mechanism, a stirring mechanism, a box body, an unloading control mechanism, a closing mechanism, discharging mechanisms, a movement mechanism and a driving mechanism. Three stirring wheels distributed in a triangular shape are mounted in a storage box, when a driving wheel rotates, the three stirring wheels can synchronously rotate, so that corn on the top layer and the bottom layer of the storage box can be stirred, the corn circulation speed is greatly increased, and blockage of the corn in the storage box is avoided. Multiple discharging pipes are adopted, the intervals among the discharging pipes can be adjusted to be identical to the requiredplant distance, so that multiple seeds can be discharged each time, the distance between seeds is identical to the plant distance, and accurate and efficient planting is realized; a blocking plate and a discharging port can alternately pass by the bottom of a first circulating pipe, thus, seed discharging can be stopped after one group of seeds are discharged, the required plant distance can be reserved for different groups of seeds, and the planting effect is improved.

Owner:许美凤

An industrial waste water discharge purification recycling device

ActiveCN111888832BImprove purification efficiencyGuaranteed purification efficiencyTreatment involving filtrationFiltration circuitsIndustrial waste waterProcess engineering

Owner:YIYANG SHENGLI CHEM IND

Device for protecting sealing clamp of suspended section of reversed loader

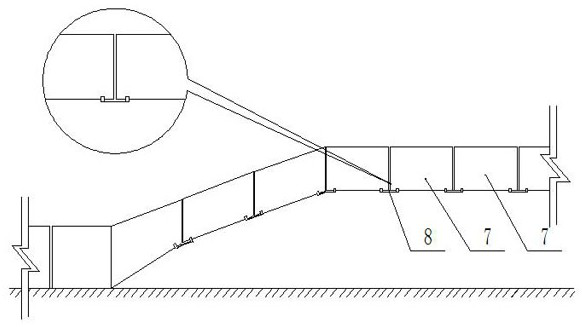

ActiveCN112660688AAvoid outflow situationsAvoid storage loss problemsEngine sealsConveyor partsEngineeringWater leak

The invention provides a device for protecting a sealing clamp of a suspended section of a reversed loader and belongs to the technical field of downhole reversed loaders and aims to solve the problem that a crack of an abutted groove of the suspended section of the current reversed loader leaks water. The technical scheme is as follows: the device comprises a sealing gasket and a fixed plate, wherein the left and right ends of the fixed plate are hinged to the reversed loader separately, a limiting bump is arranged in a direction, close to the reversed loader, of the fixed plate, the sealing gasket is arranged between the fixed plate and the abutted groove, the fixed plate comprises a left fixed plate and a right fixed plate, the two fixed plates are provided with telescopic structures along the width direction of the reversed loader, and a rubber blanket is arranged between the two telescopic structures which are connected by a bolt, and the sealing gasket is a waste belt. The technical effect is as follows: the device is simple in structure and convenient and rapid to mount, avoids manual mine cleaning, and ensures smooth and safe forward movement smoothly.

Owner:YUWU COAL CO LTD OF SHANXI LUAN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com