A method of improving corn sowing efficiency

A corn seeder and corn technology, applied in the direction of spaced quantitative sowing machinery, planter parts, etc., to achieve the effect of increasing circulation speed, avoiding blockage, and improving seeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0032] Such as Figure 1-Figure 5 Shown, a kind of method of improving corn seeding efficiency of the present invention, the method may further comprise the steps:

[0033] S1. Before sowing, the farmland is irrigated. After the irrigation is completed, when the soil in the farmland is in a soft state, the farmland is repaired with a rotary tiller;

[0034] After the farmland renovation in S2 and S1 is completed, the corn is loaded into the corn seeder for sowing;

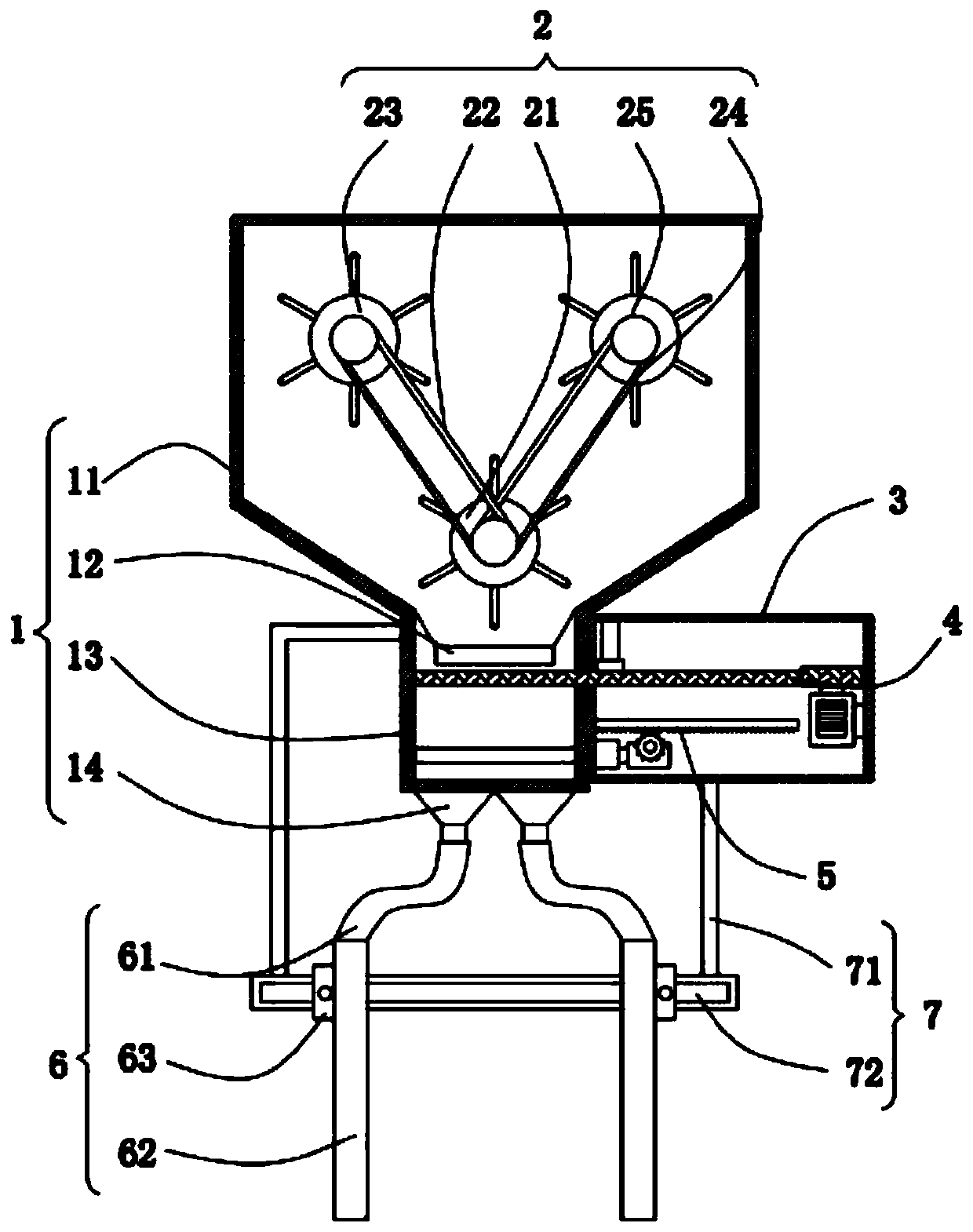

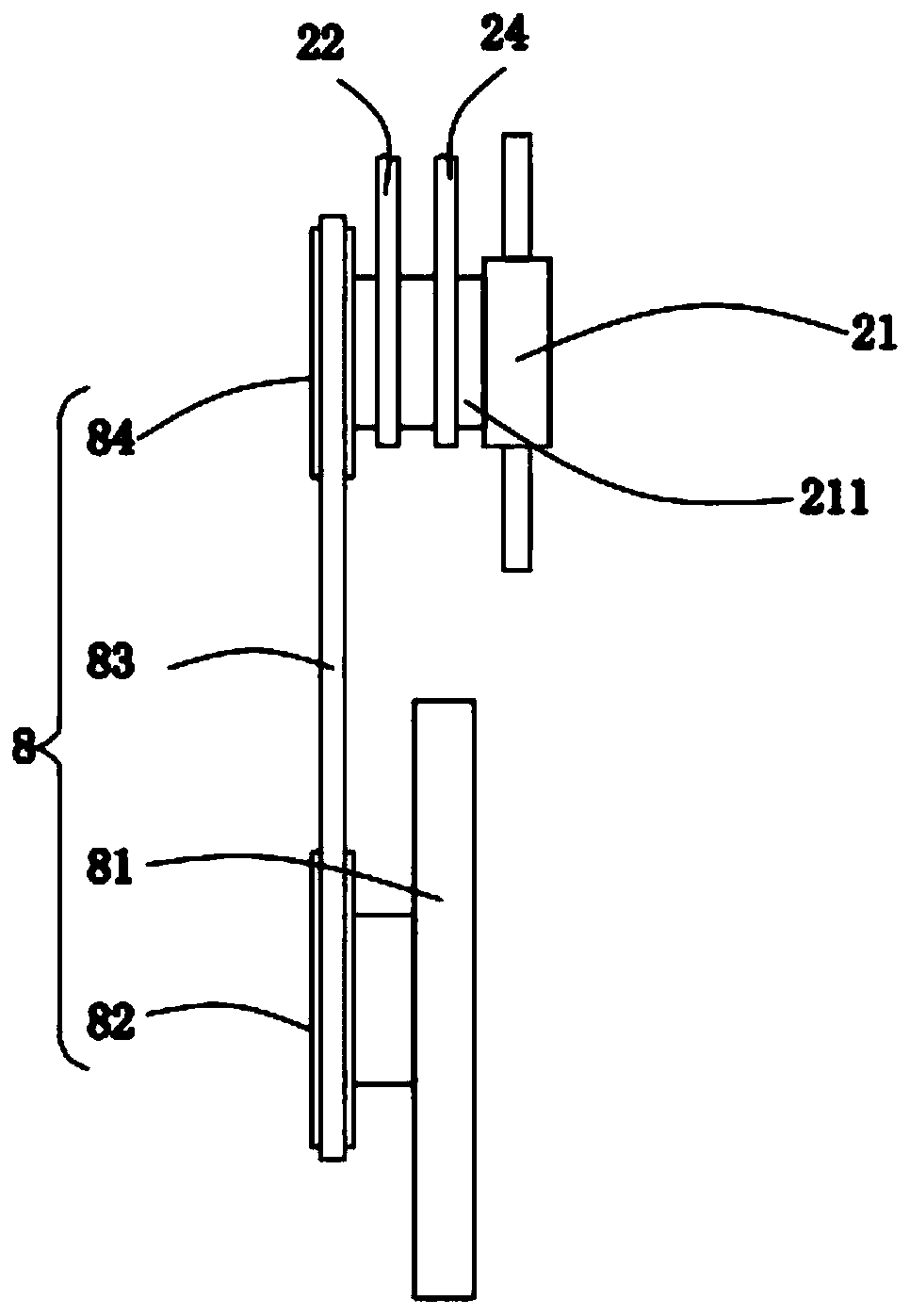

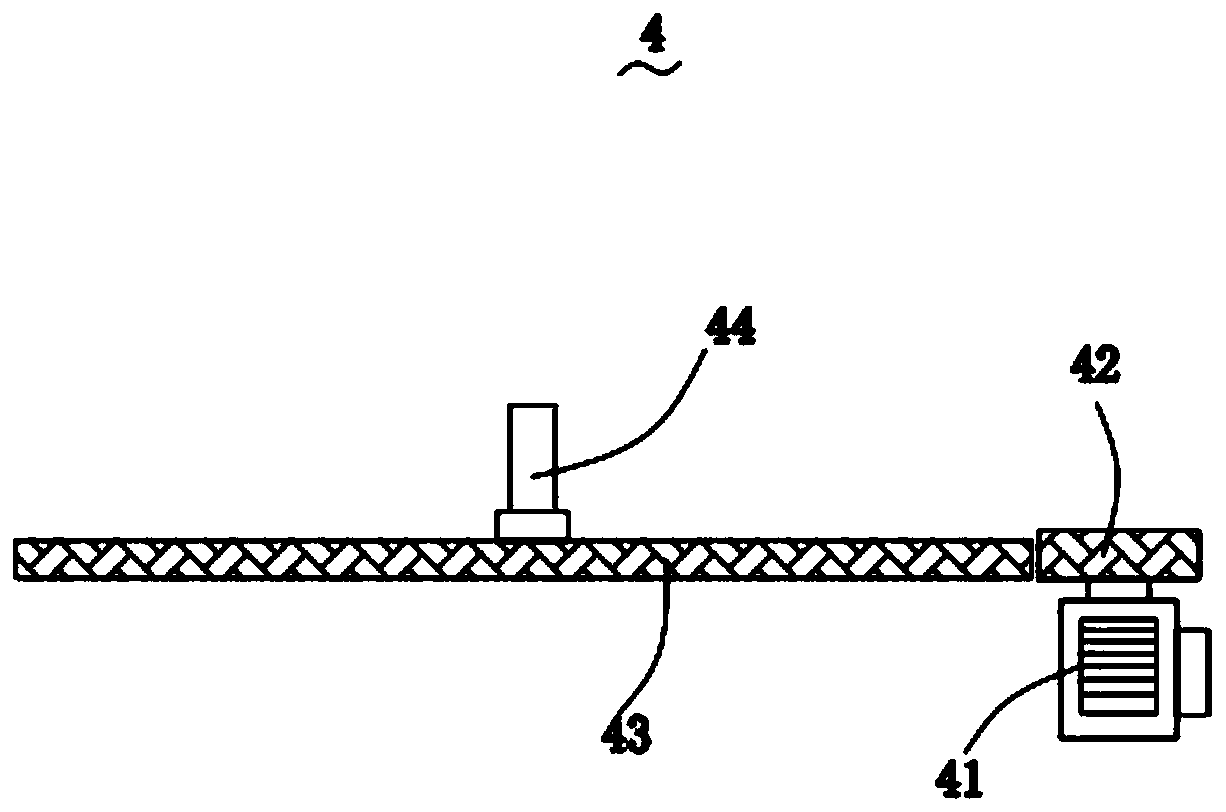

[0035]The corn planter that adopts in this method comprises conveying mechanism 1, stirring mechanism 2, box body 3, blanking control mechanism 4, closing mechanism 5, discharge mechanism 6, moving mechanism 7 and driving mechanism 8; Described conveying mechanism 1 The stirring mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com