PLC circuit board cleaning method and device

A circuit board cleaning technology, which is applied in the field of PLC circuit board cleaning methods and cleaning equipment, can solve the problems of increasing equipment occupation space, inability to flow out, and affecting the cleaning quality of PLC circuit boards, so as to reduce the occupation of height space and reduce the occupation of space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

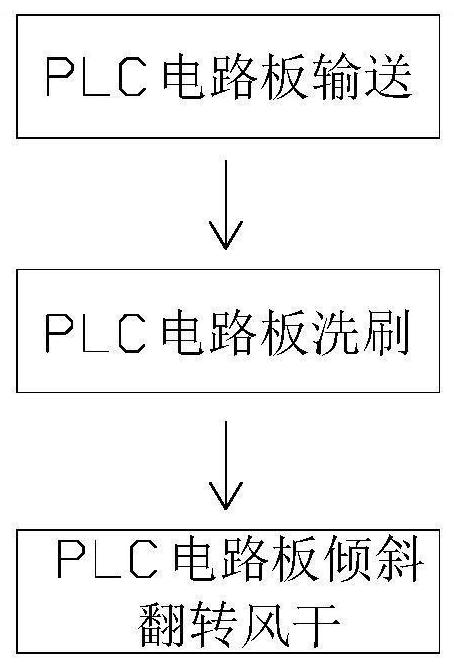

[0035] like figure 1 Shown a kind of PLC circuit board cleaning method, this method comprises the following steps:

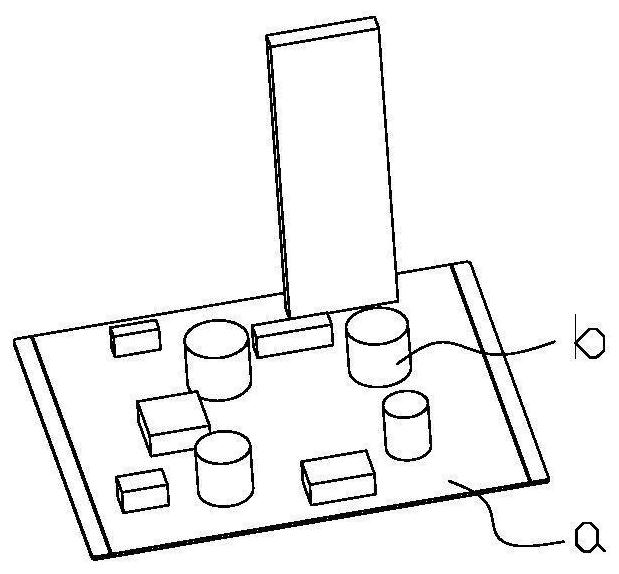

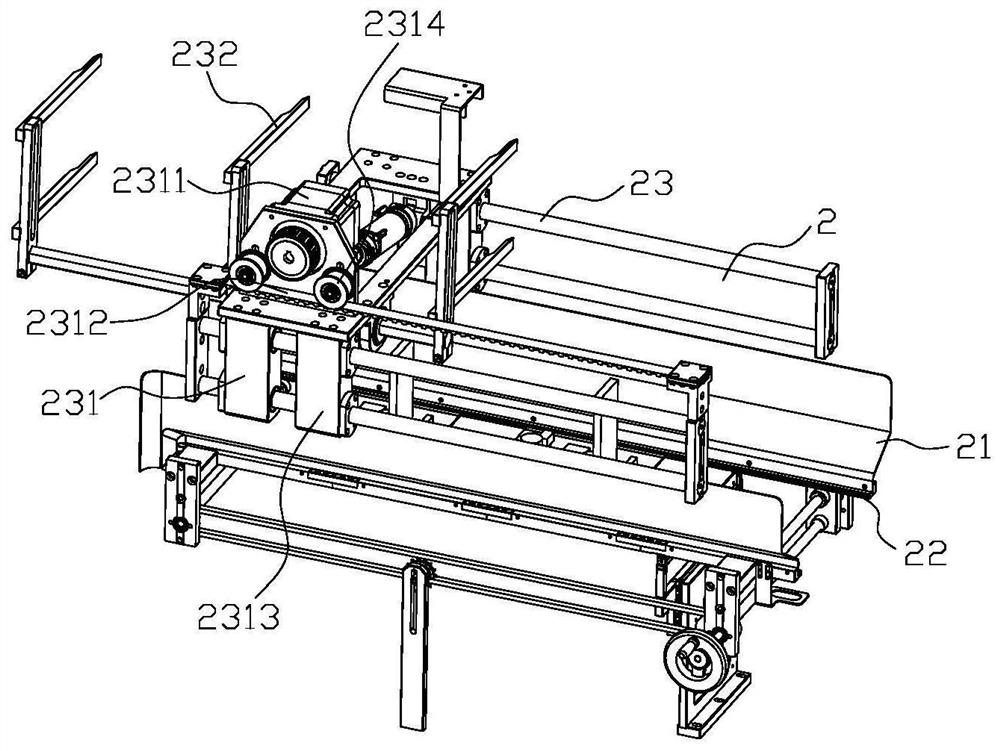

[0036] (1) The PLC circuit board is conveyed by the circuit board conveying device 2: 1) Place the PLC circuit board into the circuit board conveying chute 22, and load the PLC circuit board; 2) The action of the toggle drive motor 2311 drives the toggle flip The component 232 moves to the top of the PLC circuit board, and the toggle lever 2324 is in a horizontal state at this time; 3) The action of the toggle cylinder 2321 sequentially drives the toggle rotation module 2323 and the toggle lever 2324 to move, and the toggle lever 2324 rotates from the horizontal state to Vertical state and in contact with the side of the PLC circuit board; 4) The action of the toggle drive motor 2311 drives the movement of the toggle flip assembly 232, and the movement of the toggle flip assembly 232 drives the PLC circuit board in contact with it to move to the next station; 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com