Turnout fastener mechanical anti-loosening structure

A technology for fasteners and turnouts, which is applied in the field of mechanical anti-loosening structures of turnout fasteners, can solve the problems of increased production cost, rough appearance, thick rail gaskets, etc., and achieves firm anti-loosening effect, regular and beautiful appearance, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

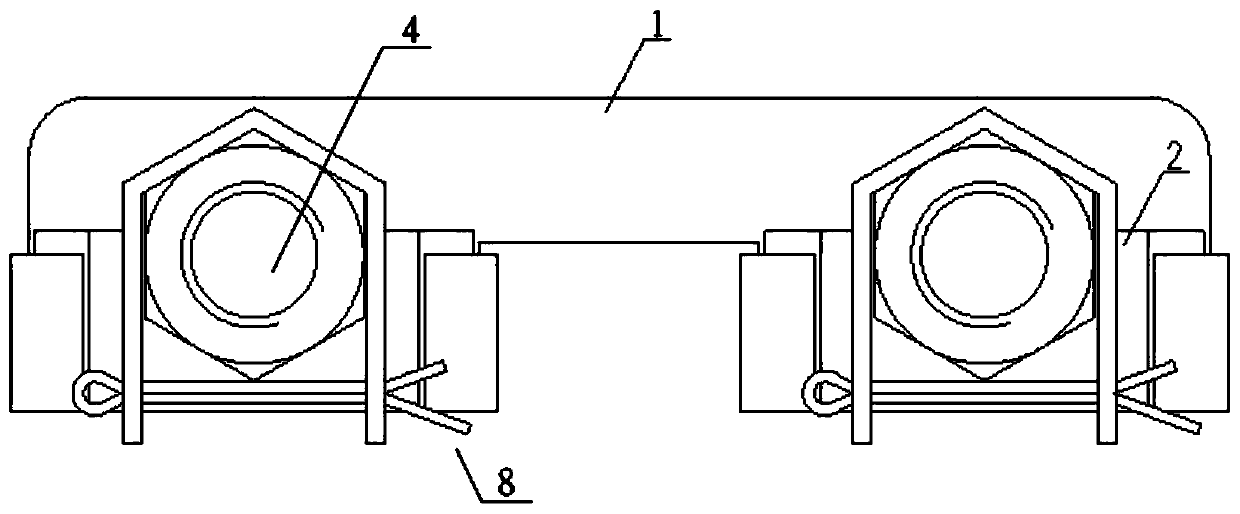

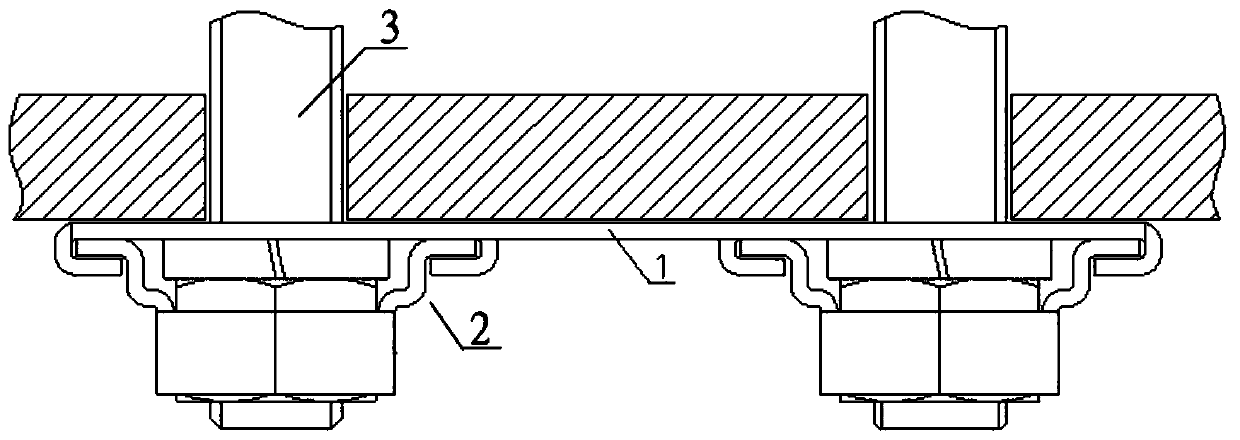

[0020] A mechanical anti-loosening structure for turnout fasteners, such as figure 1 , figure 2 As shown, it includes an anti-rotation support 1 and an anti-loosening piece 2. The anti-rotation support 1 is installed on the opposite rail waist of the turnout component parts, and its two sides are respectively connected with the rail waist of the rail member and the turnout by bolts 3 and nuts 4. Assembly parts fastened together.

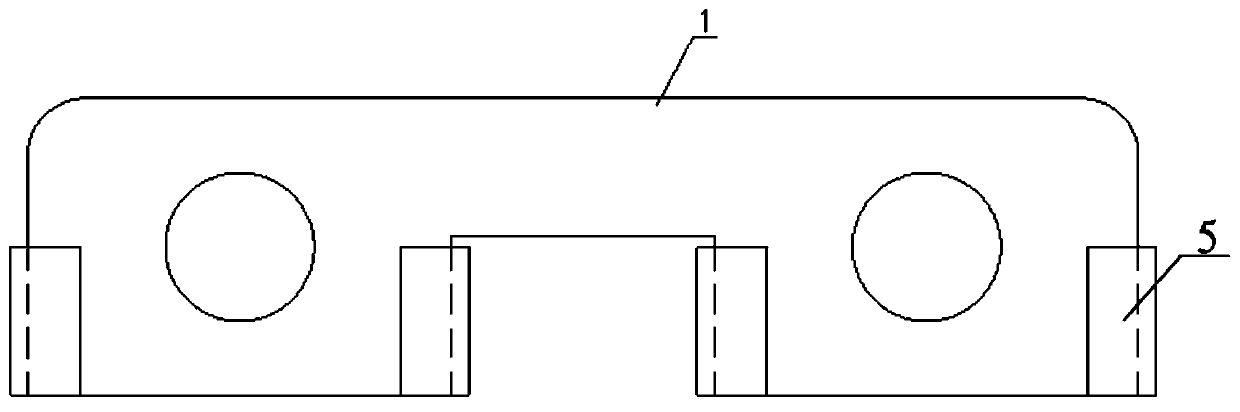

[0021] The anti-rotation support 1 is symmetrically provided with slots 5 on the side facing away from the rail waist, such as image 3 , Figure 4 shown. The anti-loosening piece 2 includes an engaging portion 6 that fits on the outer surface of the nut and has an open bottom, and an inserting portion 7 that cooperates with the slot, and the inserting portion 7 is fixed on the engaging portion 6, Such as Figure 5 , Figure 6 shown.

[0022] When installing the turnout assembly parts, first install the anti-rotation support 1 on the opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com