High-speed submerged-arc welding agent for thin plates

A submerged arc flux, high-speed technology, applied in the direction of arc welding equipment, welding medium, welding equipment, etc., can solve the problems of easy welding penetration, etc., to achieve beautiful weld bead formation, excellent welding process performance and mechanical properties, and good welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

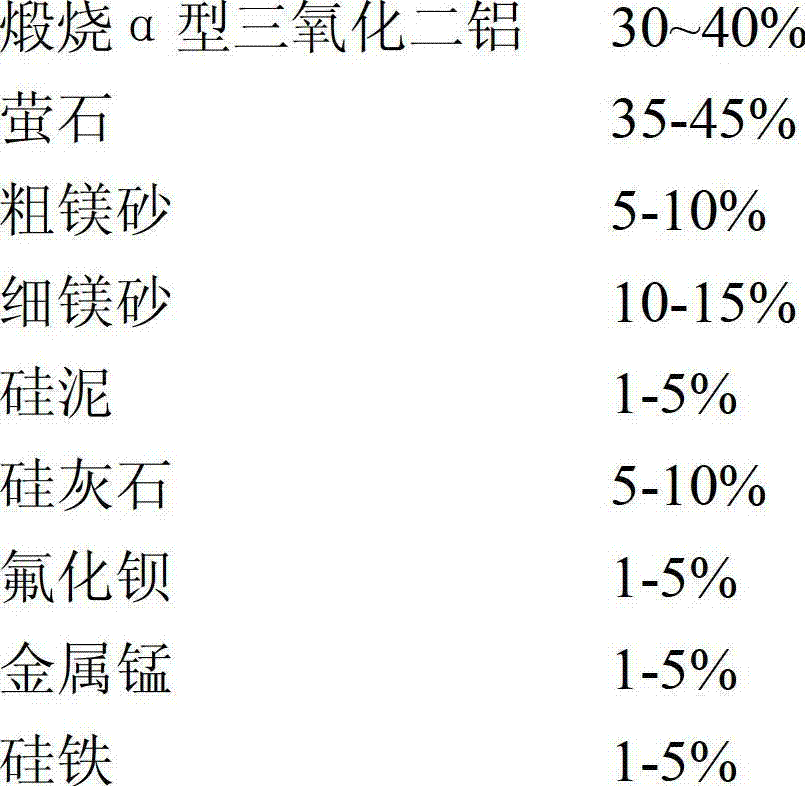

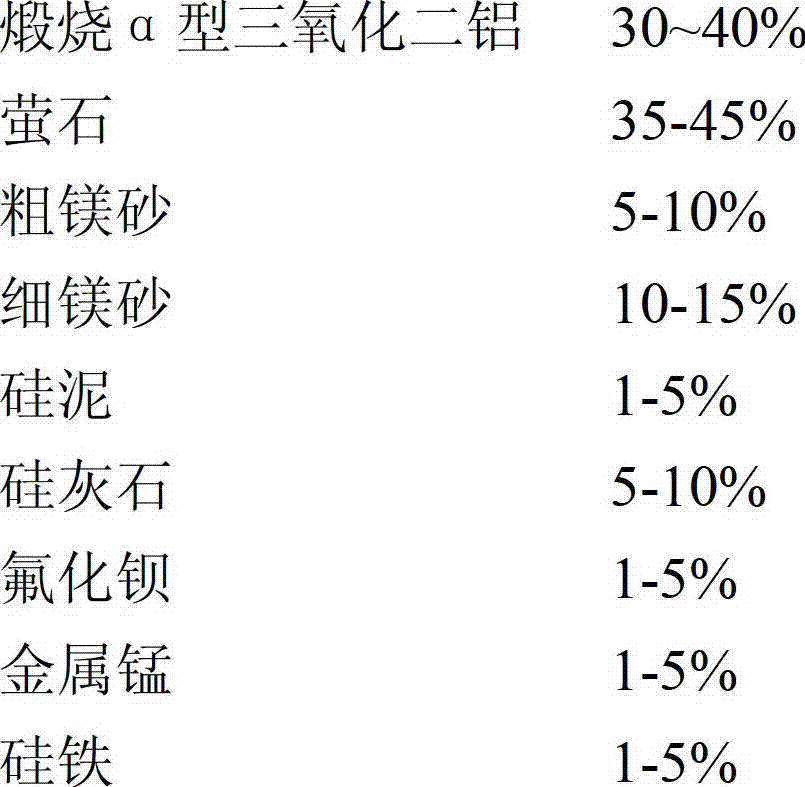

[0028] A high-speed submerged arc welding flux for thin plates, the sintered flux components are composed of calcined α-type aluminum oxide, fluorite, coarse magnesia, fine magnesia, silica mud, wollastonite, barium fluoride, manganese metal and ferrosilicon , the weight percent of its formula components is: calcined α-type aluminum oxide 40%, fluorite 35%, coarse magnesia 5%, fine magnesia 10%, silica mud 1%, wollastonite 5%, fluoride Barium 1%, metal manganese 2%, ferrosilicon 1%, CaF in the fluorite 2 Content ≥ 92%, MgO in the coarse magnesia ≥ 88%, MgO in the fine magnesia ≥ 88%, SiO in the silica mud 2 ≥97%, CaO≥38% and SiO in wollastonite 2 ≥42%, Si≥72% in the ferrosilicon alloy.

Embodiment 2

[0030] A high-speed submerged arc welding flux for thin plates, the sintered flux components are composed of calcined α-type aluminum oxide, fluorite, coarse magnesia, fine magnesia, silica mud, wollastonite, barium fluoride, manganese metal and ferrosilicon , the weight percent of its formula components is: calcined α-type aluminum oxide 30%, fluorite 40%, coarse magnesia 5%, fine magnesia 12%, silica mud 2%, wollastonite 6%, fluoride Barium 1%, metal manganese 3%, ferrosilicon 1%, CaF in the fluorite 2 Content ≥ 92%, MgO in the coarse magnesia ≥ 88%, MgO in the fine magnesia ≥ 88%, SiO in the silica mud 2 ≥97%, CaO≥38% and SiO in wollastonite 2 ≥42%, Si≥72% in the ferrosilicon alloy.

Embodiment 3

[0032] A high-speed submerged arc welding flux for thin plates, the sintered flux components are composed of calcined α-type aluminum oxide, fluorite, coarse magnesia, fine magnesia, silica mud, wollastonite, barium fluoride, manganese metal and ferrosilicon , the weight percent of its formula components is: calcined α-type aluminum oxide 32%, fluorite 37%, coarse magnesia 6%, fine magnesia 11%, silica mud 1%, wollastonite 7%, fluoride Barium 2%, metal manganese 2%, ferrosilicon 2%, CaF in the fluorite 2 Content ≥ 92%, MgO in the coarse magnesia ≥ 88%, MgO in the fine magnesia ≥ 88%, SiO in the silica mud 2 ≥97%, CaO≥38% and SiO in wollastonite 2 ≥42%, Si≥72% in the ferrosilicon alloy.

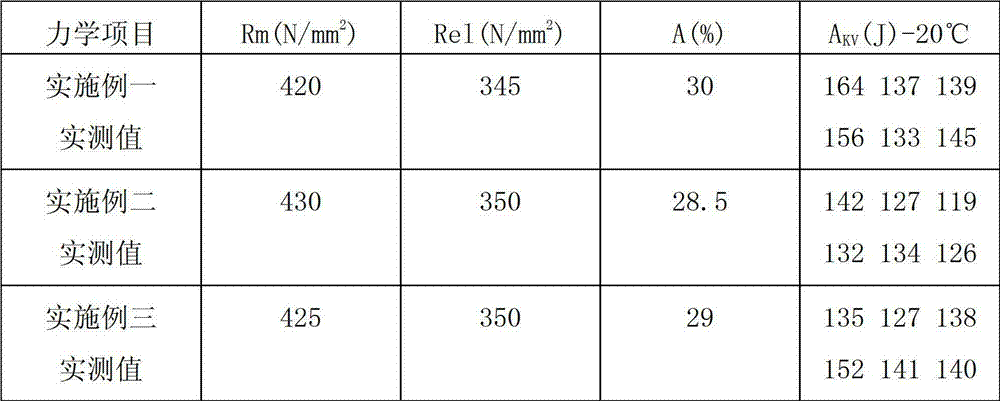

[0033] The flux of the above-mentioned embodiments is welded with H08A welding wire, and the corresponding mechanical properties are shown in the following table:

[0034]

[0035] Through the above test results, verify the mechanical properties:

[0036] The above-mentioned welding tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com