Wire feeding type laser material increase manufacturing method

A laser additive and manufacturing method technology, applied in the direction of manufacturing tools, additive processing, laser welding equipment, etc., can solve the problems of low forming efficiency and high reflectivity of laser energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

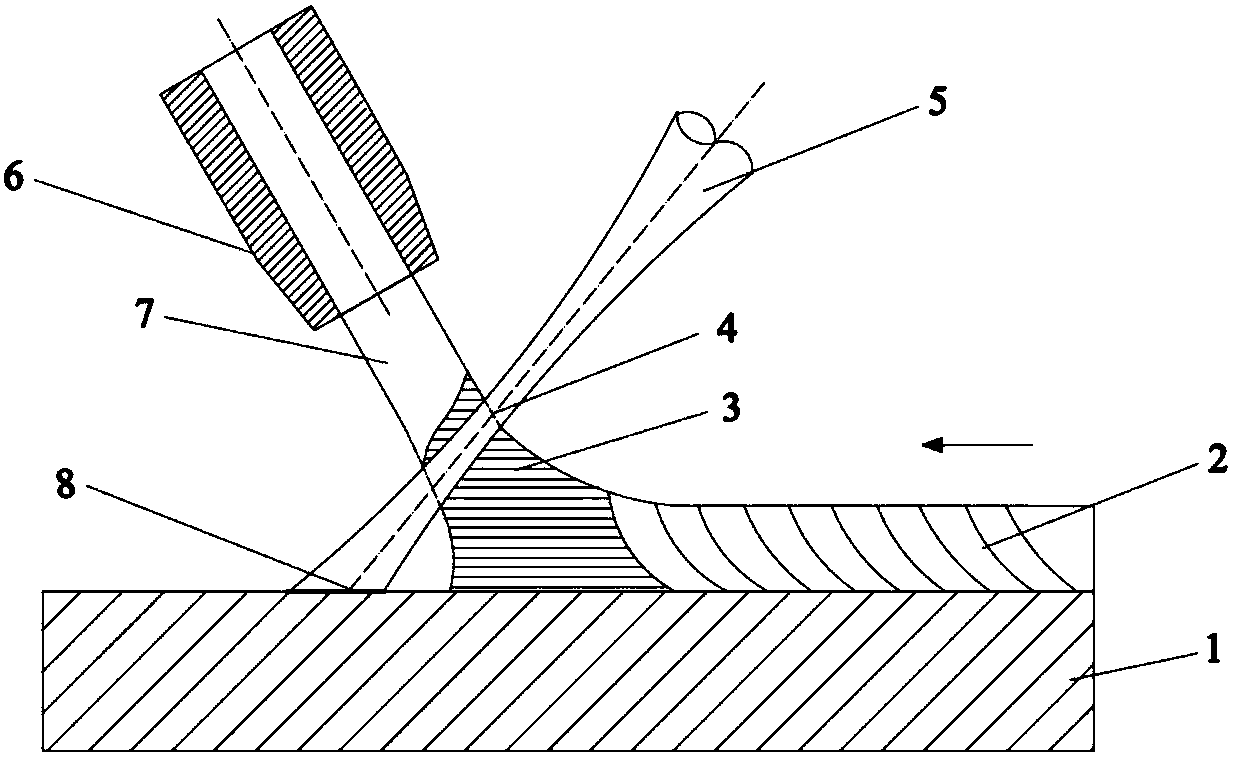

[0043] Embodiment 1: the basic principle of the embodiment of this example sees appendix figure 1, which will not be repeated here. In this example, IPG company YLS-6000 fiber laser is used. The welding wire is made of 316L stainless steel, the diameter of the welding wire is 1.2mm, a 200mm focusing lens is used, and the front wire feeding is adopted. The laser beam and the normal of the workpiece are on the same plane. Adjust the angle between the welding wire and the normal line of the workpiece to be 15°, the angle between the laser beam and the normal line of the workpiece to be 30°, the position of the light spot acting on the welding wire is 2mm away from the surface of the workpiece, the shielding gas is Ar gas, and the gas flow rate is 20L / min. The process parameters are: laser power 3kw, wire feeding speed 3m / min, scanning speed 1.5m / min. Embodiment 1 forming workpiece cross-section OM figure such as attached figure 2 As shown, the forming state of the example of ...

Embodiment 2

[0044] Embodiment 2: the basic principle of the implementation mode of this example sees appendix figure 1 , which will not be repeated here. In this example, IPG company YLS-6000 fiber laser is used. The welding wire is made of 316L stainless steel, the diameter of the welding wire is 1.2mm, a 200mm focusing lens is used, and the front wire feeding is adopted. The laser beam and the normal of the workpiece are on the same plane. Adjust the angle between the welding wire and the normal line of the workpiece to be 30°, the angle between the laser beam and the normal line of the workpiece to be 30°, the position of the light spot acting on the welding wire is 2mm away from the surface of the workpiece, the shielding gas is Ar gas, and the gas flow rate is 20L / min. The process parameters are: laser power 3kw, wire feeding speed 4m / min, scanning speed 1.5m / min. Embodiment 2 forming workpiece cross-section OM figure such as attached image 3 As shown, the forming state of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com