Preparation method of anti-freezing asphalt material

An asphalt material and anti-icing technology, applied in building insulation materials, building components, buildings, etc., can solve problems such as corrosion of metal materials, industrial salt legacy, damage to aquatic ecosystems and terrestrial vegetation, to prevent road icing, The preparation method is simple and the effect of reducing traffic accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

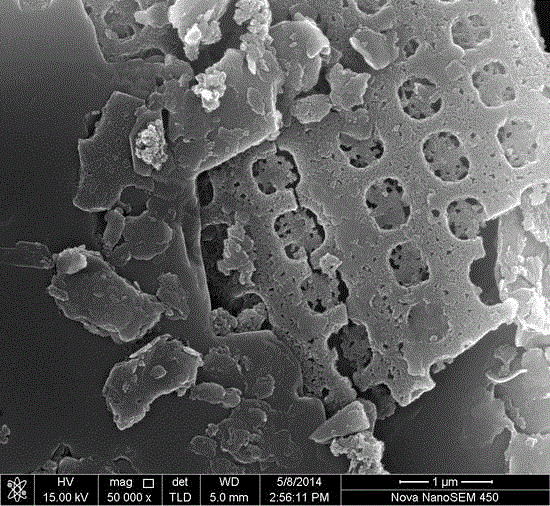

Embodiment 1

[0019] Prepare 500 mL of saturated sodium chloride aqueous solution at 60°C, and then use hydrochloric acid to adjust the pH of the solution to 1. In addition, 4.0 g of emulsifier OP-10 and 9.2 g of diatomite were added to 500 ML of absolute ethanol, stirred vigorously for 30 minutes and then ultrasonically oscillated for 30 minutes to obtain a dispersion of diatomite in absolute ethanol. The above acidic sodium chloride solution was slowly added dropwise to the absolute ethanol dispersion under continuous stirring to produce a large amount of precipitation. The precipitate was vacuum-filtered, dried at 150°C for 12 hours, and cooled to room temperature to obtain a self-made anti-freezing filler, which was stored in a desiccator for later use.

[0020] In a temperature-controlled furnace, 50 parts by weight of the asphalt raw material is heated to a molten state, then 20 parts by weight of anti-icing filler and 30 parts by weight of quartz powder are added to the molten asphal...

Embodiment 2

[0022] Prepare 500 mL of saturated sodium chloride aqueous solution at 80°C, and then use hydrochloric acid to adjust the pH of the solution to 1. In addition, 4.0 g of emulsifier OP-10 and 6.2 g of diatomite were added to 500 ML of absolute ethanol, stirred vigorously for 30 minutes and then ultrasonically oscillated for 30 minutes to obtain a dispersion of diatomite in absolute ethanol. The above acidic sodium chloride solution was slowly added dropwise to the absolute ethanol dispersion under continuous stirring to produce a large amount of precipitation. The precipitate was vacuum-filtered, dried at 150°C for 12 hours, and cooled to room temperature to obtain a self-made anti-freezing filler, which was stored in a desiccator for later use.

[0023] In a temperature-controlled furnace, 50 parts by weight of the asphalt raw material is heated to a molten state, then 30 parts by weight of anti-icing filler and 20 parts by weight of quartz powder are added to the molten asphal...

Embodiment 3

[0025] Prepare 500 mL of saturated sodium chloride aqueous solution at 80°C, and then use hydrochloric acid to adjust the pH of the solution to 1. In addition, 4.0 g of emulsifier OP-10 and 7.3 g of diatomaceous earth were added to 500 ML of absolute ethanol, stirred vigorously for 30 minutes and then ultrasonically oscillated for 30 minutes to obtain a dispersion of diatomite in absolute ethanol. The above acidic sodium chloride solution was slowly added dropwise to the absolute ethanol dispersion under continuous stirring to produce a large amount of precipitation. The precipitate was vacuum-filtered, dried at 150°C for 12 hours, and cooled to room temperature to obtain a self-made anti-freezing filler, which was stored in a desiccator for later use.

[0026] In a temperature-controlled furnace, 50 parts by weight of the asphalt raw material is heated to a molten state, then 40 parts by weight of anti-icing filler and 10 parts by weight of quartz powder are added to the molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com