Porcelain white glass and production technique thereof

A technology of porcelain white glass and its production process, which is applied in the field of opalescent glass and its production process to achieve the effects of improving product quality, saving costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

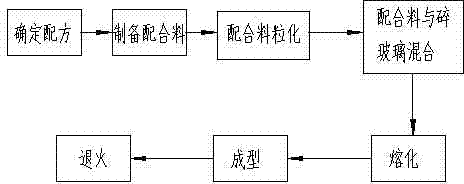

[0030] Such as figure 1 Shown, a kind of porcelain white glass production technique comprises the steps:

[0031] (1) Determine the formula and prepare the batch materials:

[0032] The formula of porcelain white glass includes by weight percentage: 60% batch material, and 40% broken glass. The batch consists of the following components in parts by weight: 58 parts of quartz sand, 14.5 parts of soda ash, 10 parts of aluminum hydroxide, 9.5 parts of sodium fluorosilicate, 6 parts of fluorite, 1 part of Barium sulfate, 1 part of sodium nitrate, 2.4 parts of calcite, 0.6 part of compound clarifying agent.

[0033] The corresponding raw materials are put into the mixing machine according to the corresponding ratio in the porcelain white glass formula to make batch materials, and the batch materials are in powder form. It can control the uniformity of the batch material to ≥95%, and the water content is 4-6%, which is beneficial to enhance the appearance of the final glass produ...

Embodiment 2

[0040] A porcelain white glass production process, the difference from Example 1 is that the batch material is composed of the following components in parts by weight:

[0041] 56 parts of quartz sand, 15 parts of soda ash, 9.5 parts of aluminum hydroxide, 9 parts of sodium fluorosilicate, 7 parts of fluorite, 1 part of sodium nitrate, and 0.6 parts of composite clarifier.

[0042] Example 2

[0043] A porcelain white glass production process, the difference from Example 1 is that the batch material is composed of the following components in parts by weight:

[0044] 55 parts of quartz sand, 15.8 parts of soda ash, 9 parts of aluminum hydroxide, 10 parts of sodium fluorosilicate, 5.5 parts of fluorite, 0.5 parts of sodium nitrate, and 0.5 parts of composite clarifying agent.

[0045] It should be noted that: in the present invention, porcelain white cullet refers to fragments of porcelain white glass, and colorless cullet refers to fragments of colorless glass. In the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com