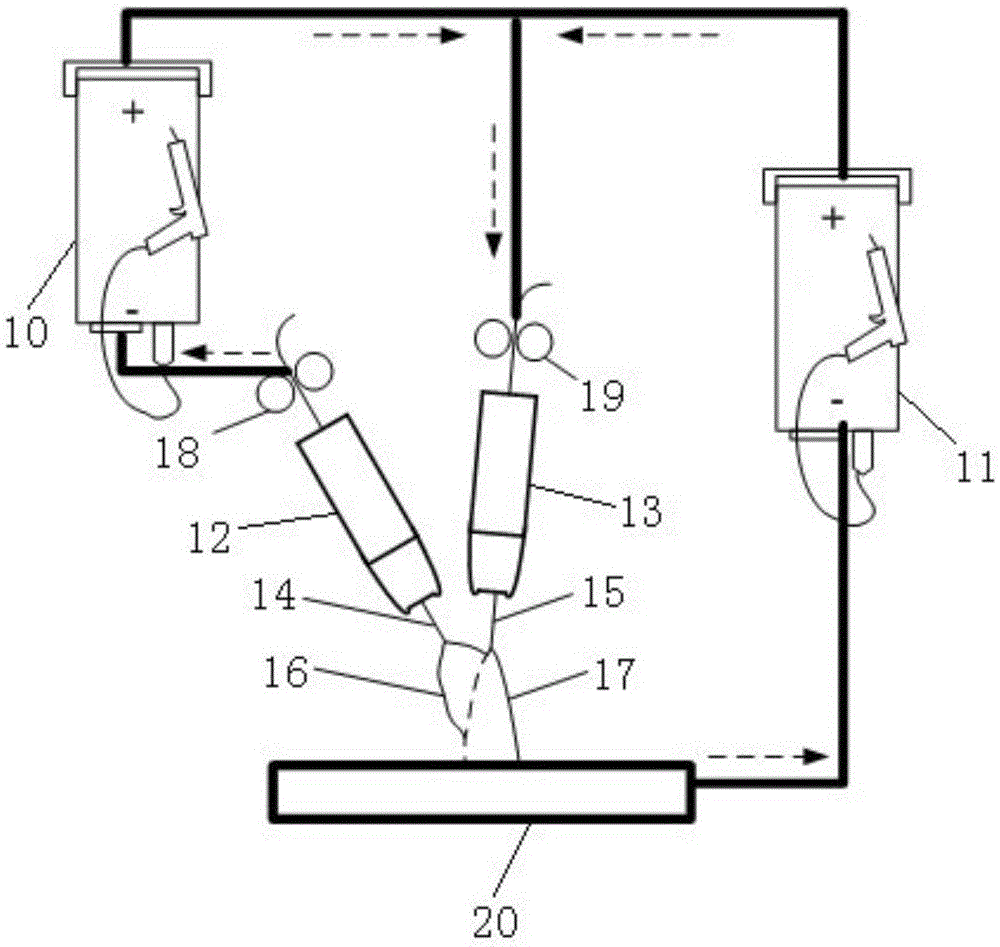

Twin-wire bypass coupled arc efficient metal-inert gas (MIG) welding system

A bypass coupling, welding system technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high cost, reduce welding cost, complex structure, etc., achieve easy control, reduce welding cost, increase change range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

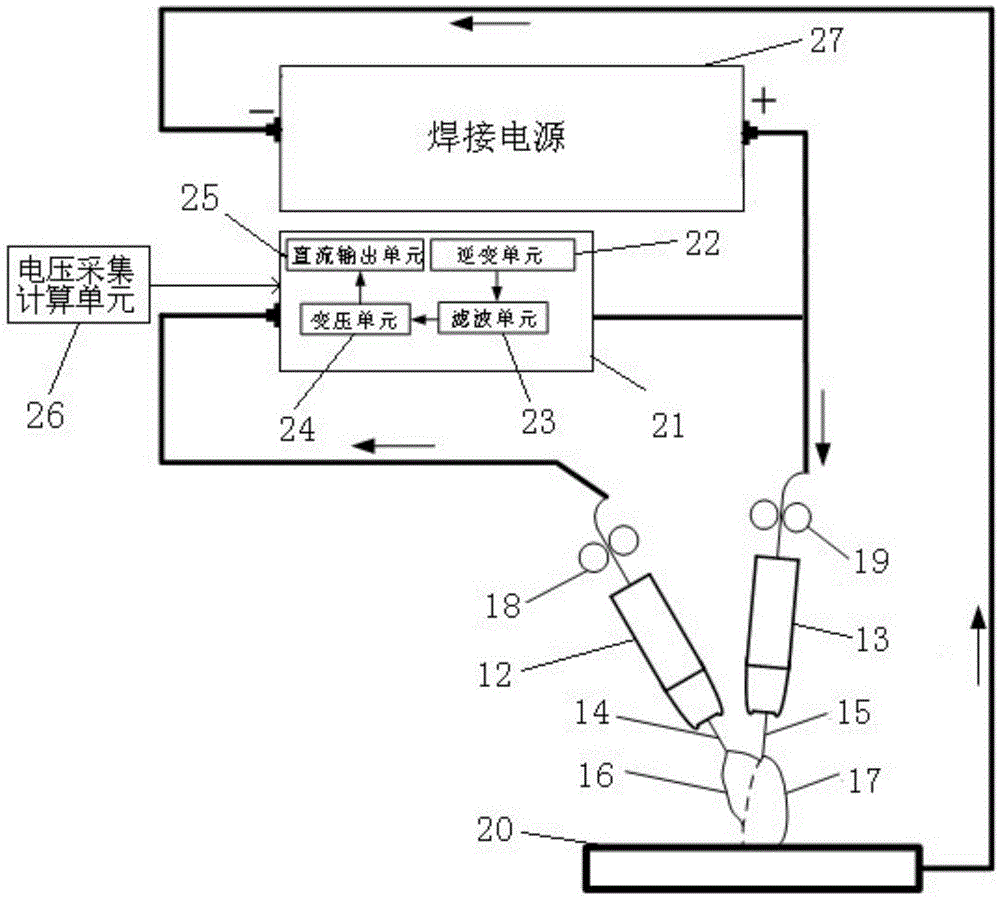

Embodiment

[0023]A Q235 low-carbon steel plate with a length of 60mm, a width of 20mm, and a thickness of 6mm is used as the workpiece 20 to be welded, and is welded by the double-wire bypass coupling arc high-efficiency MIG welding system of the present invention, wherein the inverter unit 22 is a fully-controlled inverter Transformer, the filter unit 23 is an output filter, the transformer unit 24 is a series transformer, the main welding wire 15 and the bypass welding wire 14 both use Φ1.6mm ER415L carbon steel welding wire, and the specific welding steps are as follows:

[0024] (1) before welding, remove the surface oil stain of the workpiece 20 to be welded with acetone, and remove the surface oxide film of the workpiece 20 to be welded with a stainless steel wire;

[0025] (2) Fix the workpiece 20 to be welded on the welding fixture, and adopt the flat plate surfacing welding method;

[0026] (3) The main welding wire 15 is perpendicular to the workpiece 20 to be welded, the bypas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com