Air cap resistance calculation method

A technology of resistance calculation and air cap, applied in the field of boilers, can solve the problems of large resistance coefficient of air distribution plate air cap and large energy consumption of fans, so as to improve the gas-solid two-phase flow field, reduce pollutant emissions, and improve fuel utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

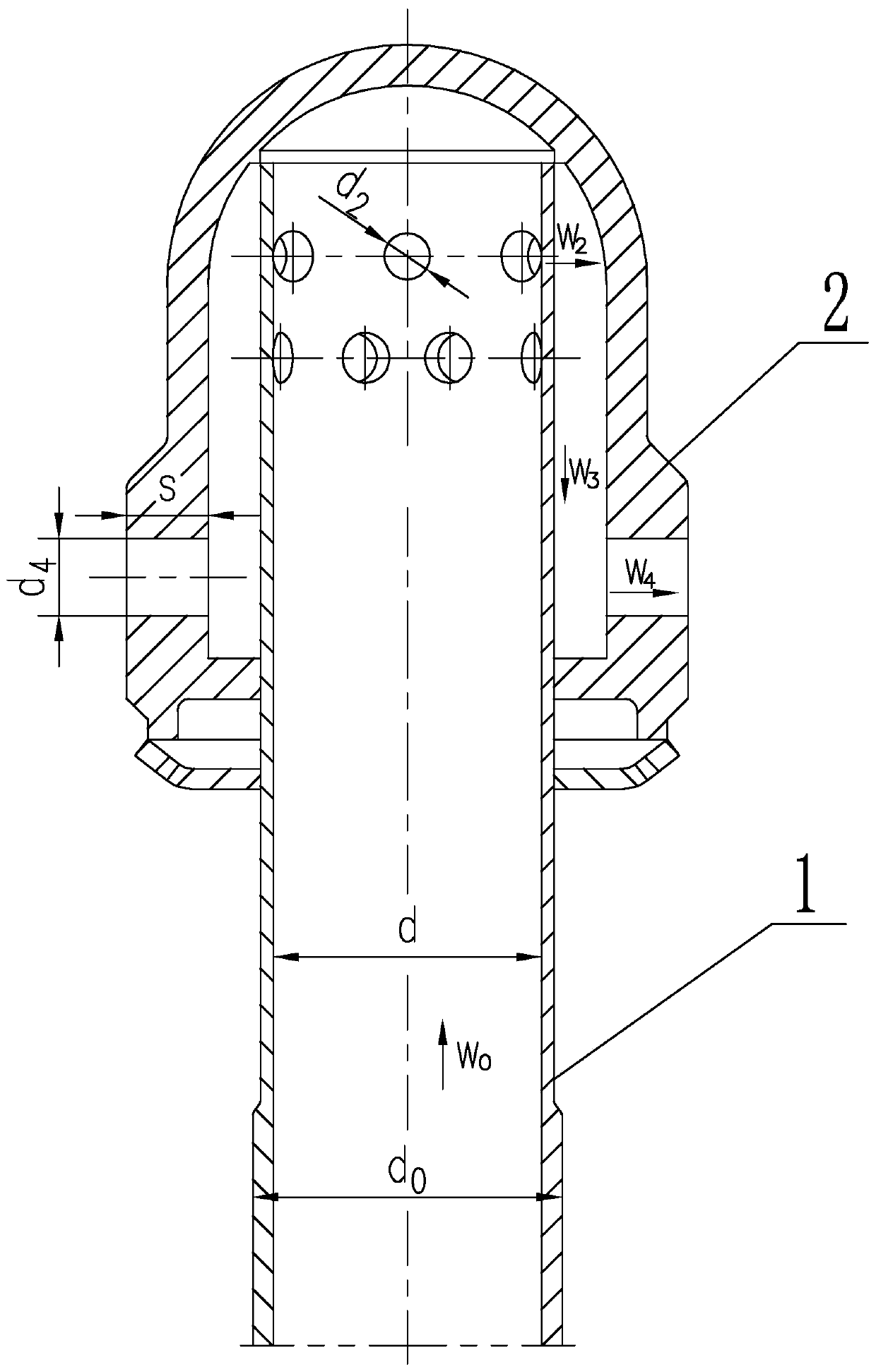

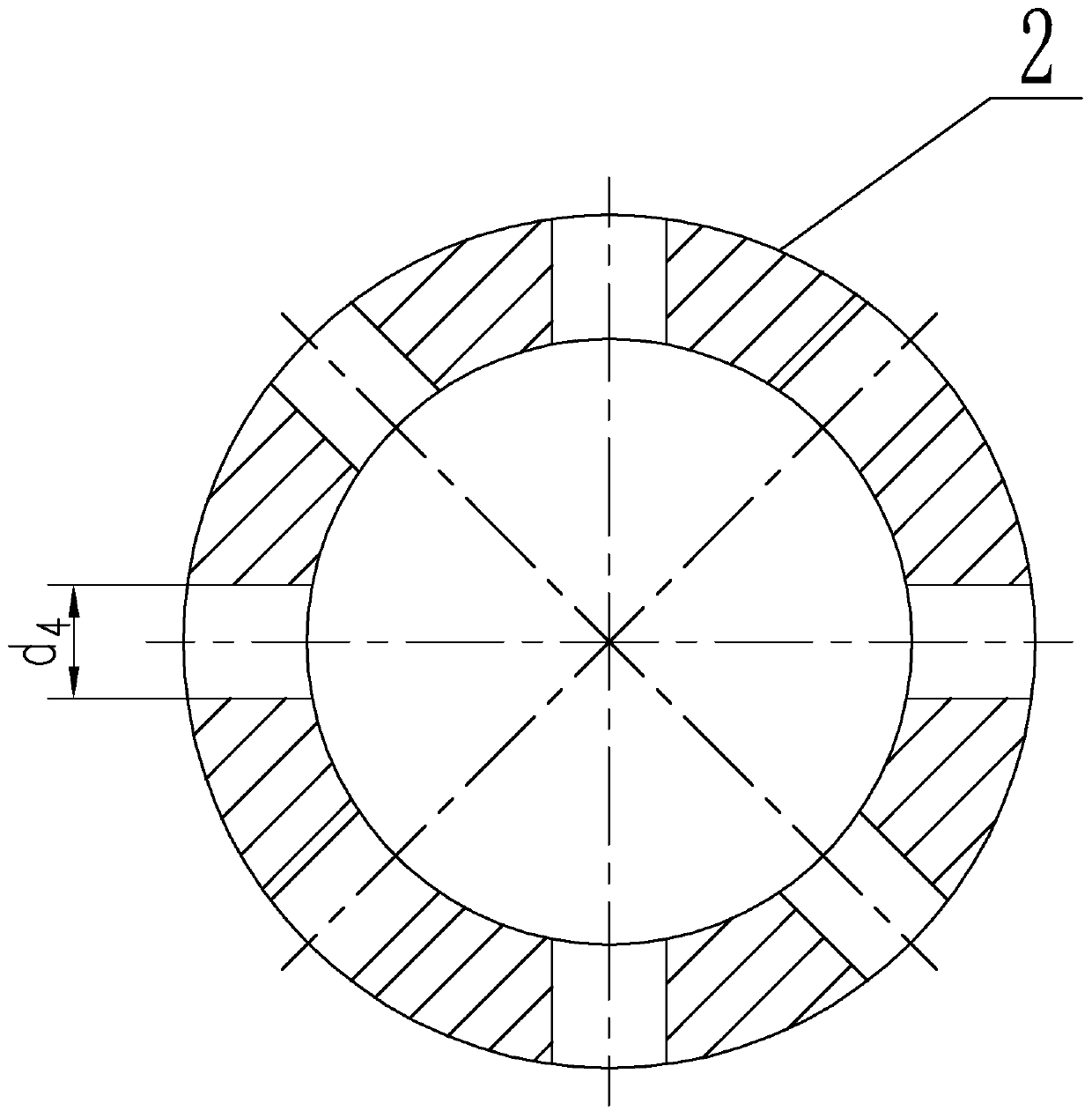

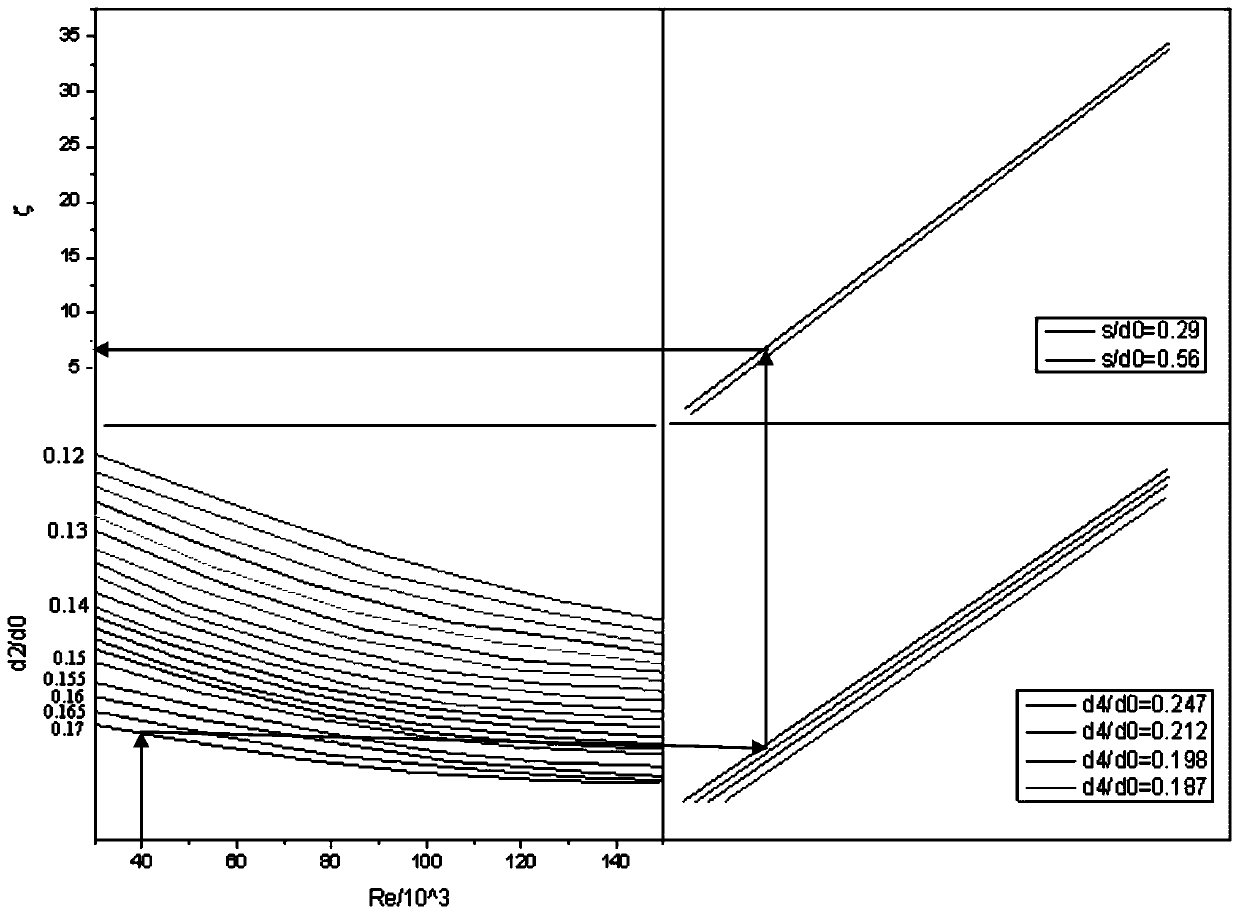

[0019] Specific implementation mode one: combine Figure 1-Figure 3 To illustrate this embodiment, this embodiment includes the following steps:

[0020] 1. The resistance of hot air flowing through a single hood is equivalent to the resistance generated by the hot air in the air inlet pipe 1 on a single hood, and the resistance coefficient of a single hood is equivalent to the resistance coefficient of the flow velocity of the air inlet pipe 1 on a single hood, that is

[0021] ΔP=ζ×ρ×W 2 0 / 2

[0022] Among them, ΔP is the resistance of a single hood, the unit is Pa; ζ is the resistance coefficient of a single hood; ρ is the density of the fluid in the hood, the unit is kg / m 3 ;W 0 is the wind speed in the air inlet pipe 1, the unit is m / s;

[0023] 2. Select the Reynolds number Re first, and select the appropriate Reynolds number according to the viscosity of the fluid, the equivalent diameter of the fluid flow and the flow rate W of the fluid, namely

[0024] Re=W×d / ...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the wind speed W in the air inlet duct 1 of this embodiment 0 It is 35-55m / s.

[0030] The relationship curve between the drag coefficient and the various structural dimensions of the wind cap is suitable for the wind speed W in the air inlet pipe 1 0 The wind speed is between 35-55m / s.

[0031] Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the wind speed W of the air outlet in the air inlet pipe 1 of this embodiment 2 It is 45-60m / s.

[0033] The relationship curve between the drag coefficient and the various structural dimensions of the wind cap is suitable for the wind speed W of the air outlet in the air inlet pipe 1 2 The wind speed is between 45-60m / s.

[0034] Other compositions and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com