Laser three-dimensional fast forming and manufacturing method based on micro arc powder carrying

A technology of laser three-dimensional and manufacturing methods, which is applied in the direction of additive manufacturing, process efficiency improvement, and energy efficiency improvement. It can solve problems that have not yet entered large-scale industrial applications, unsatisfactory manufacturing accuracy, and insufficient research and development of processes and equipment. , to achieve the effect of excellent arc stability and straightness, small thermal deformation, and small amount of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

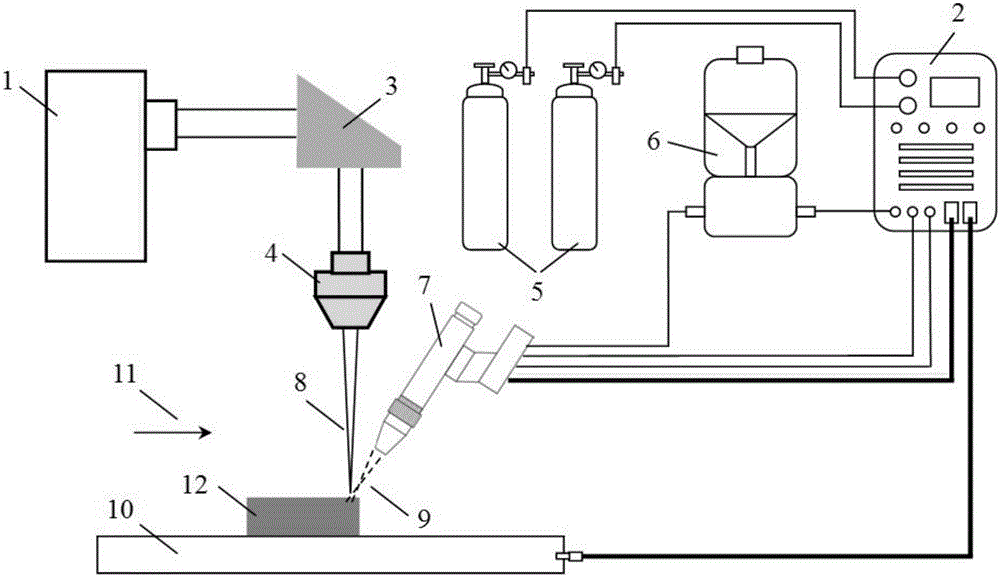

Embodiment 1

[0028] The substrate used in this example is a 304 stainless steel plate with a thickness of 4mm, and the powder material is austenitic stainless steel powder with a particle size of 200-300 mesh. The tungsten pole used is a cerium tungsten electrode, and the electrode connection method is that the cathode of the tungsten pole is connected to the negative pole of the power supply, and the substrate is connected to the positive pole of the power supply by the anode. The main arc current of the micro-beam plasma arc is 35A, the pulse laser peak power is 5.5kW, the pulse width is 5ms, and the defocus is 4mm. Adjust the laser emitting head 4 so that the angle between the laser beam and the vertical plane is 5°, and set the forward speed of the workbench to 12mm / s. The protective gas and working gas used in the micro-beam plasma arc and laser are both pure argon, and the flow rate of the protective gas is 15L / min, and the powder feeding rate of the powder feeder 6 is 20g / min. Cali...

Embodiment 2

[0030] The substrate used in this example is a 6061 aluminum alloy plate with a thickness of 4mm, and the powder material is AlSi-based aluminum alloy powder with a particle size of 200-300 mesh. The tungsten pole used is a cerium tungsten electrode, and the electrode connection method is that the cathode of the tungsten pole is connected to the negative pole of the power supply, and the substrate is connected to the positive pole of the power supply by the anode. The main arc current of the micro-beam plasma arc is 40A, the pulse laser peak power is 5.5kW, the pulse width is 4.5ms, and the defocus is 4.5mm. The angle between the laser beam and the vertical plane is 5°, and the exit direction of the micro-beam plasma arc is at an angle of 25° with the laser beam. Set the table forward speed to 10mm / s. The protective gas and working gas used in the micro-beam plasma arc and laser are all pure argon, and the protective gas flow rate is 20L / min, and the powder feeding rate is 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com